Page10

The 1805FI can only be installed with a custom door

panel that extends from the toe kick to the counter top.

The unit comes with everything needed to make

installing the door panel easy. The door is predrilled for

the panel’s mounting screws.

The custom panel should be at least 1/4” thick.

ITEMS PRITEMS PR

ITEMS PRITEMS PR

ITEMS PROO

OO

OVIDEDVIDED

VIDEDVIDED

VIDED WITHWITH

WITHWITH

WITH THE UNITTHE UNIT

THE UNITTHE UNIT

THE UNIT

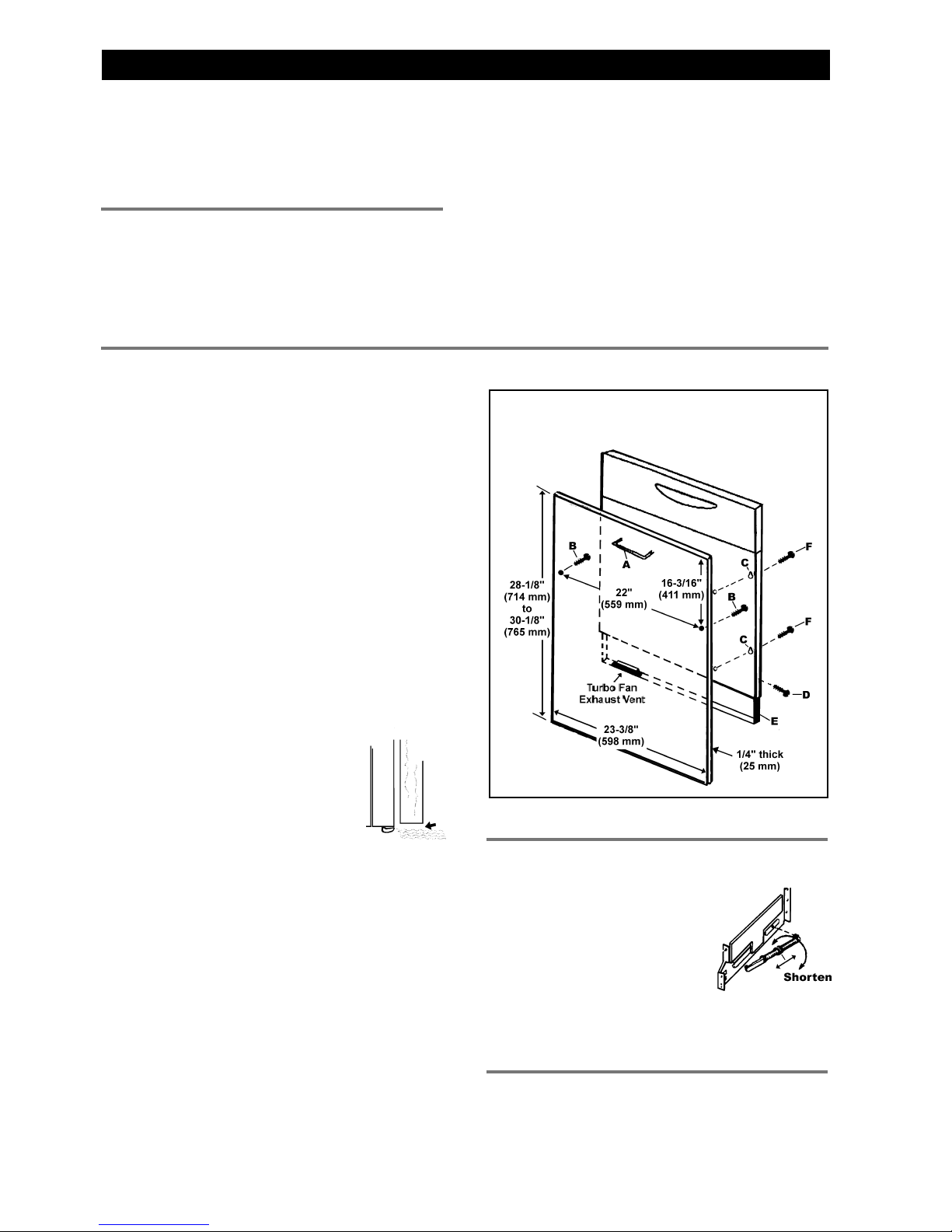

♦Two 3/8” screws (B)

♦One protective tape (C)

♦Four adhesive-backed plastic spacer washers (D)

♦Four 1-3/4” screws (G)

ADJUSTING THE DOOR SPRINGSADJUSTING THE DOOR SPRINGS

ADJUSTING THE DOOR SPRINGSADJUSTING THE DOOR SPRINGS

ADJUSTING THE DOOR SPRINGS

Afteryou install the custompanel,

make sure the door can be

opened at any angle. If it tends to

fall down, pull out the machine

and tension the door springs on

the sides of the machine by

moving them one hole farther

back or by twisting the spring to

make it shorter. If that doesn’t resolve the problem, you

mayneed to purchase theheavy-duty door springs (Part

Number 8071323-77).

FASTENING THE DISHWASHERFASTENING THE DISHWASHER

FASTENING THE DISHWASHERFASTENING THE DISHWASHER

FASTENING THE DISHWASHER

TO THE CABINETTO THE CABINET

TO THE CABINETTO THE CABINET

TO THE CABINET

Refer to page 8.

Installing the 1805FI Custom Panel

WARNING!

The custom panel must not

obstruct the turbo fan exhaust.

See step 4 above for instructions

on how to adjust the fan exhaust.

CUSTCUST

CUSTCUST

CUSTOM POM P

OM POM P

OM PANEL DIMENSIONSANEL DIMENSIONS

ANEL DIMENSIONSANEL DIMENSIONS

ANEL DIMENSIONS

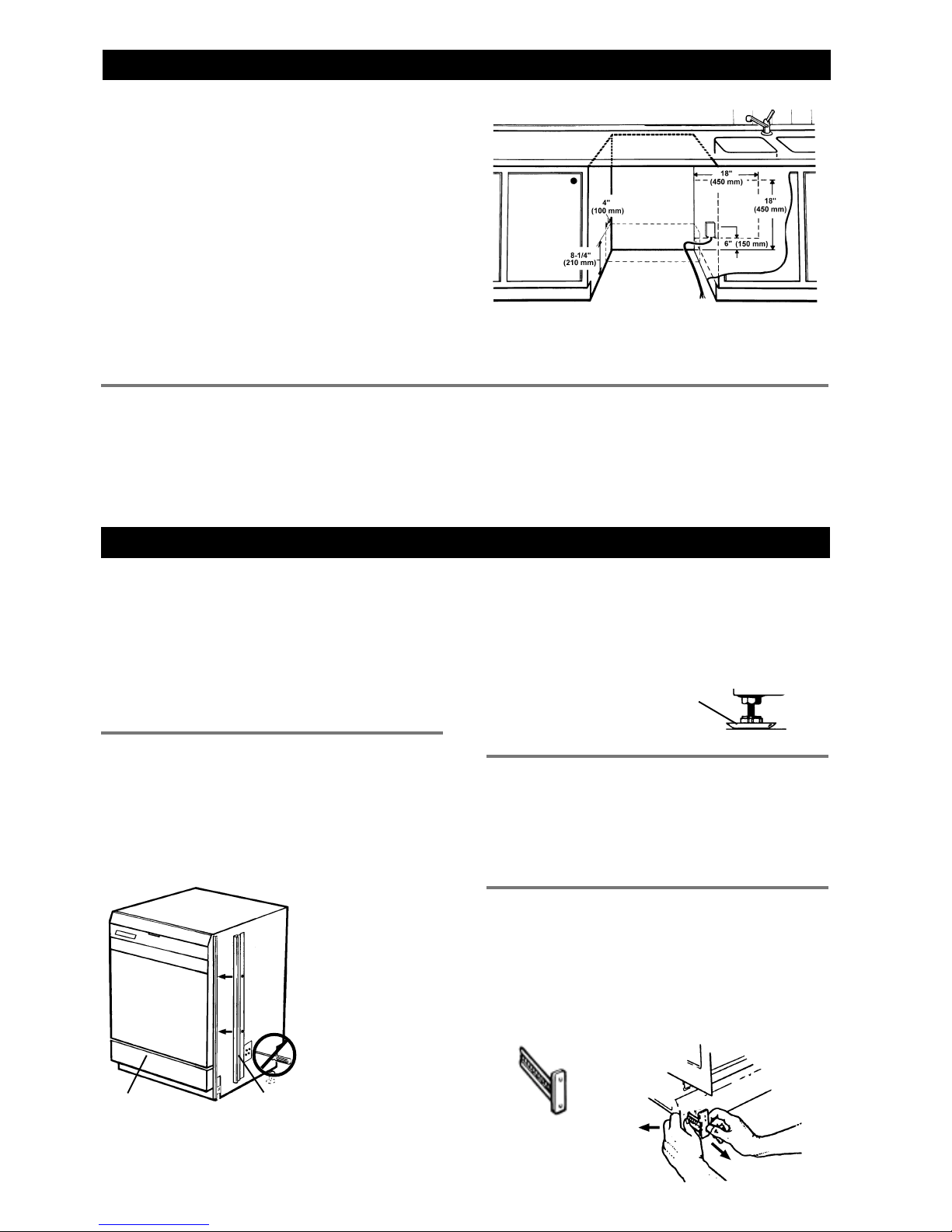

Width: 23-3/8” (597 mm)

Height: 28-1/8”–30-1/8” (714 mm–765 mm)

(Measured from the top of the panel to

the lower edge of the kitchen cabinet.)

Thickness: 1/4” (25 mm)

Weight: Up to 22 lb.

NOTE:

Specifications subject to change without

notice.

NOTE:

Heavy-duty door springs can be purchased for

wooden door panels weighing over twelve

pounds. (P/N 8071323-77).

INSTINST

INSTINST

INSTALLINGALLING

ALLINGALLING

ALLING THE CUSTTHE CUST

THE CUSTTHE CUST

THE CUSTOM POM P

OM POM P

OM PANELANEL

ANELANEL

ANEL

Before fitting the custom panel, the dishwasher must

be installed underneath the cabinet. After you’ve made

the required measurements, pull the machine out again

to install the panel.

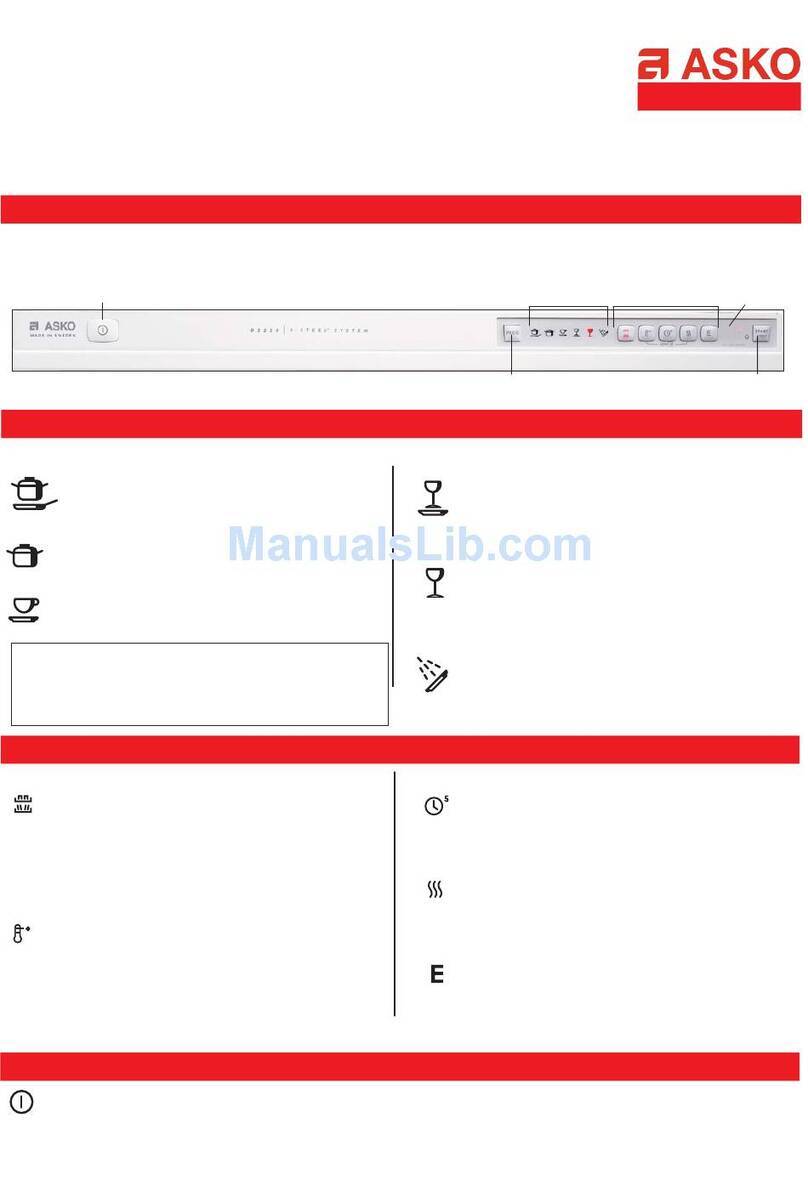

Refer to the illustration at right for instruction references.

1. Fit the handle (A) onto the panel according to the

manufacturer’s instructions. (

NOTE:

A handle

should be used rather than a knob, because a knob

does not provide enough grip.)

2. Peel the adhesive backing off the washers and place

them in line with the four keyholes (C) on the metal

front of the dishwasher door.

3. Loosen the screws (D) on the outer edges of the

dishwasher door.

4. Pull the turbo fan exhaust frame (E) down until the

loweredge aligns with the lower edge of the cabinets

and tighten the screws. Next, snap the plastic duct

into the turbo fan exhaust vent.

5. The two short screws (B) go into the back of the

panel, 16-3/16” from the upper edge of the panel

and 5/8” from the outer edges. Insert the short

screws into the panel, leaving 1/8” of space between

the screw head and the panel.

6. Hook the panel screws (F) into the keyholes (C) on

the dishwasher door.

7. Push the panel upwards until the lower edge aligns

with the lower edge of the cabinets.

NOTE:

The custom panel should not extend more

than 2-15/16” below the bottom of the dishwasher

door. Otherwise, it will strike the toe kick and

damage the machine and/or the panel.

8. Open the door and tighten the screws (F) inside.

9. Remove the backing from the protective tape and

apply it on the bottom edge of the panel, in front of

the exhaust vent.

FITTINGFITTING

FITTINGFITTING

FITTING THETHE

THETHE

THE 1805FI1805FI

1805FI1805FI

1805FI CUSTCUST

CUSTCUST

CUSTOM DOOR POM DOOR P

OM DOOR POM DOOR P

OM DOOR PANELANEL

ANELANEL

ANEL