Asko TD30 User manual

Other Asko Dryer manuals

Asko

Asko Classic T208H Guide

Asko

Asko 7703 - User manual

Asko

Asko T794C FI User manual

Asko

Asko 7003 Operating instructions

Asko

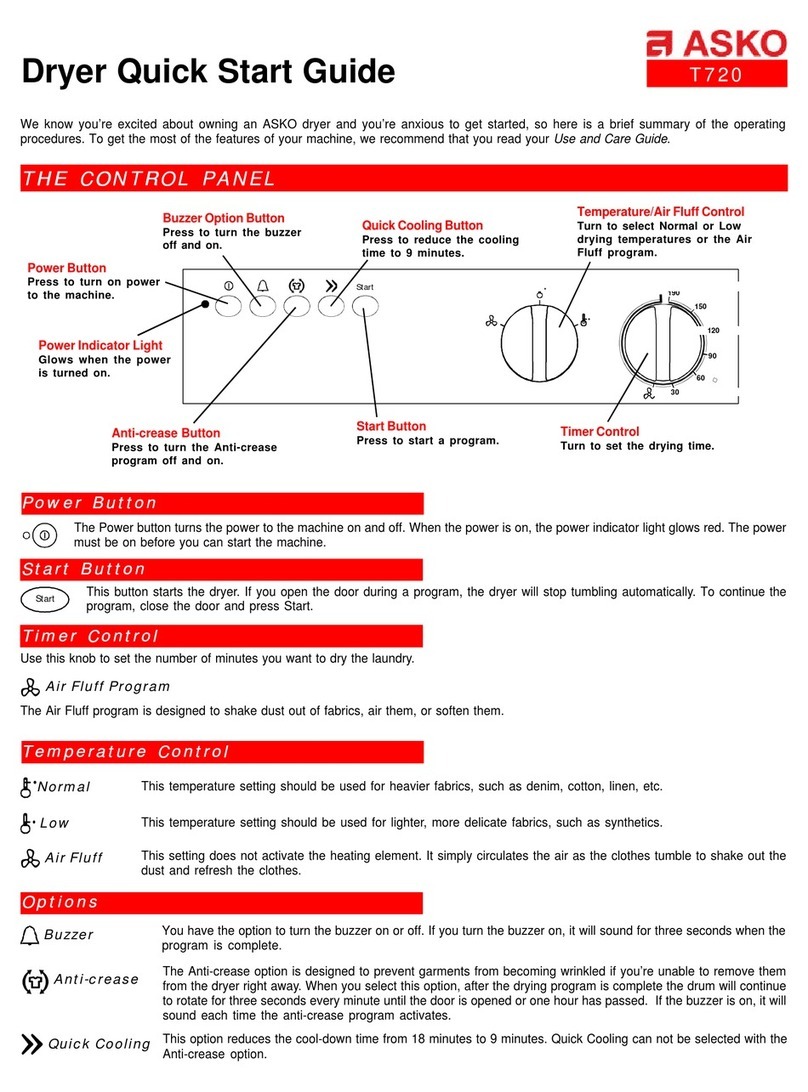

Asko T720 User manual

Asko

Asko PROFESSIONAL TDC112HPS User manual

Asko

Asko T783C Assembly instructions

Asko

Asko T754 Assembly instructions

Asko

Asko T793C User manual

Asko

Asko TLS752GXXL Instruction Manual

Popular Dryer manuals by other brands

Bosch

Bosch WTA79200GB Installation and operating instructions

Amana

Amana W10233410A Use and care guide

Bosch

Bosch Logixx 10 WTB76556GB Instruction manual and installation instructions

Electrolux

Electrolux EW2H328R2 user manual

Beko

Beko DS8433RX1M user manual

Dawlance

Dawlance Spinner DS 6000 C owner's manual

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual

Samsung

Samsung DV431AEPXAC user manual

Speed Queen

Speed Queen ADE3TRW5431AW01 Specifications