Contents

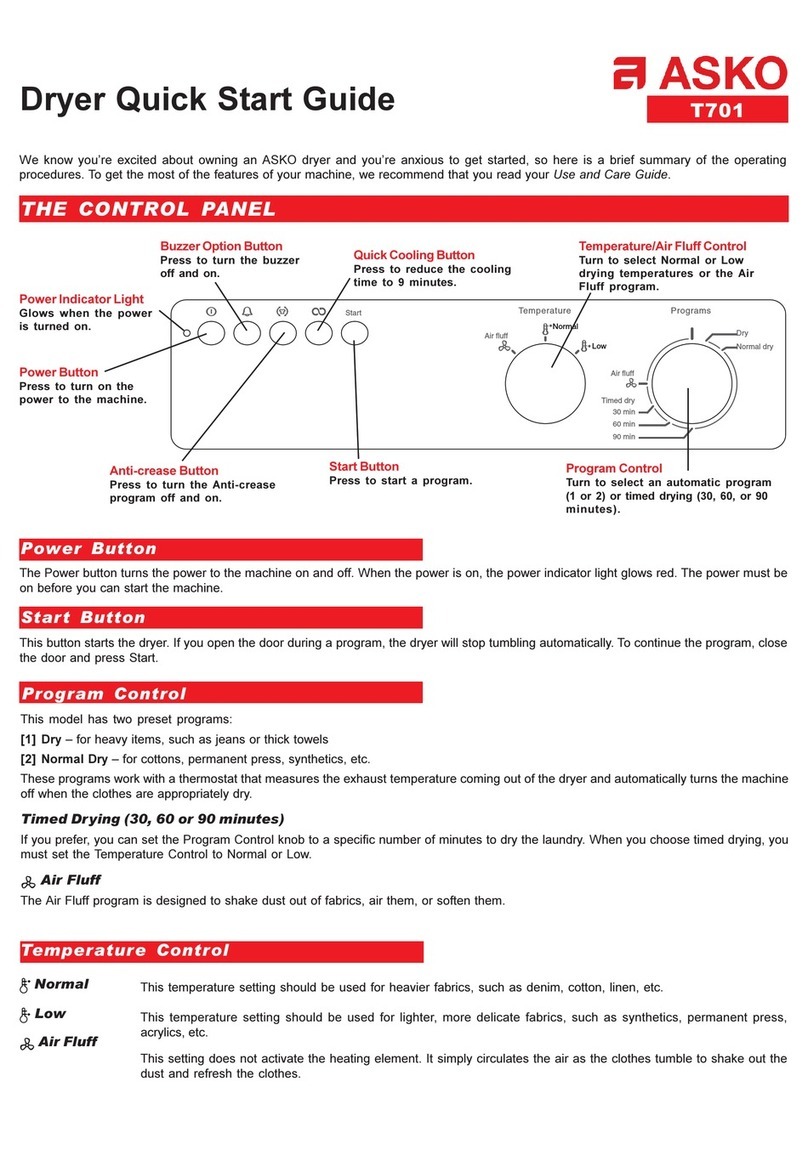

❏ Tumble Dryer Basics...............................................................................................2

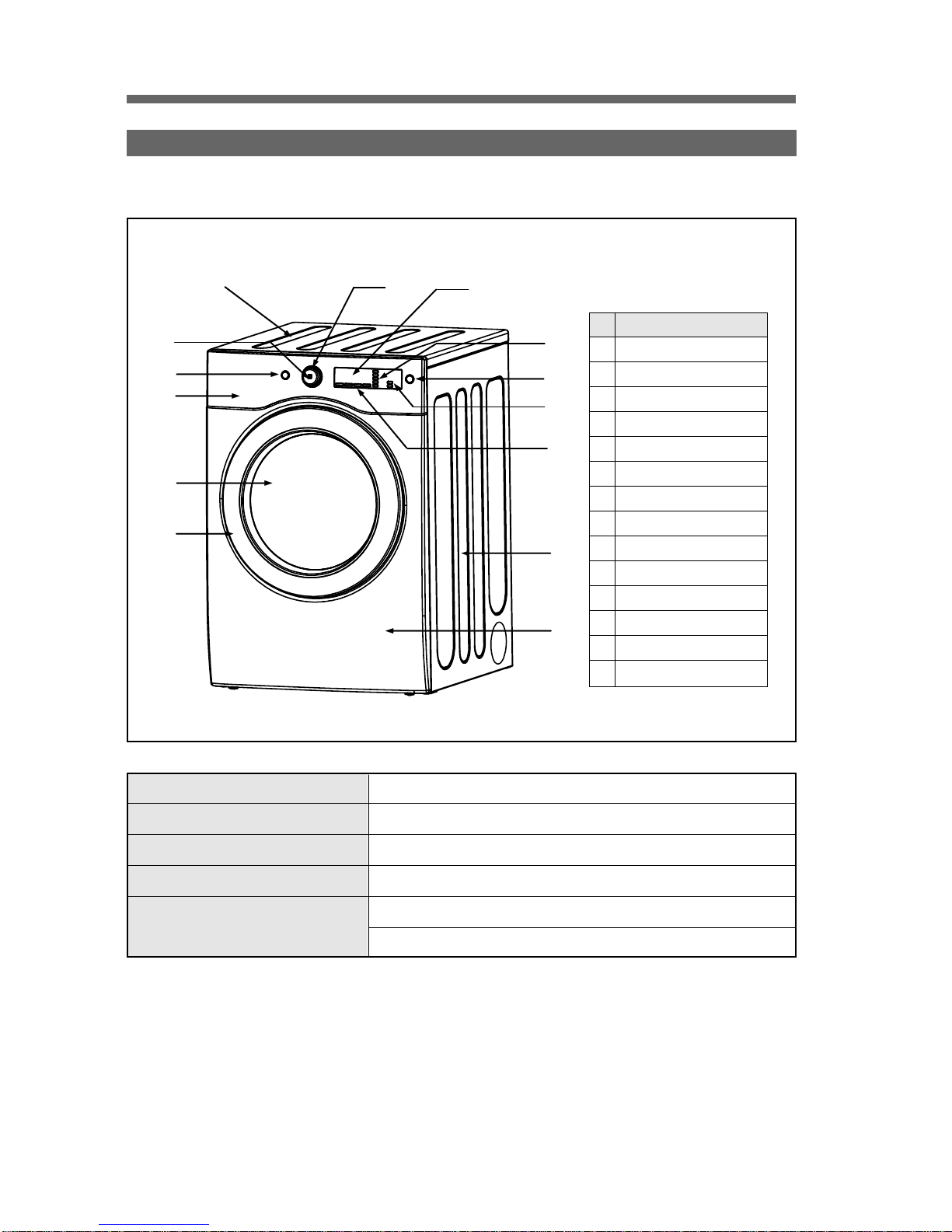

❏ Dryer Specification..................................................................................................4

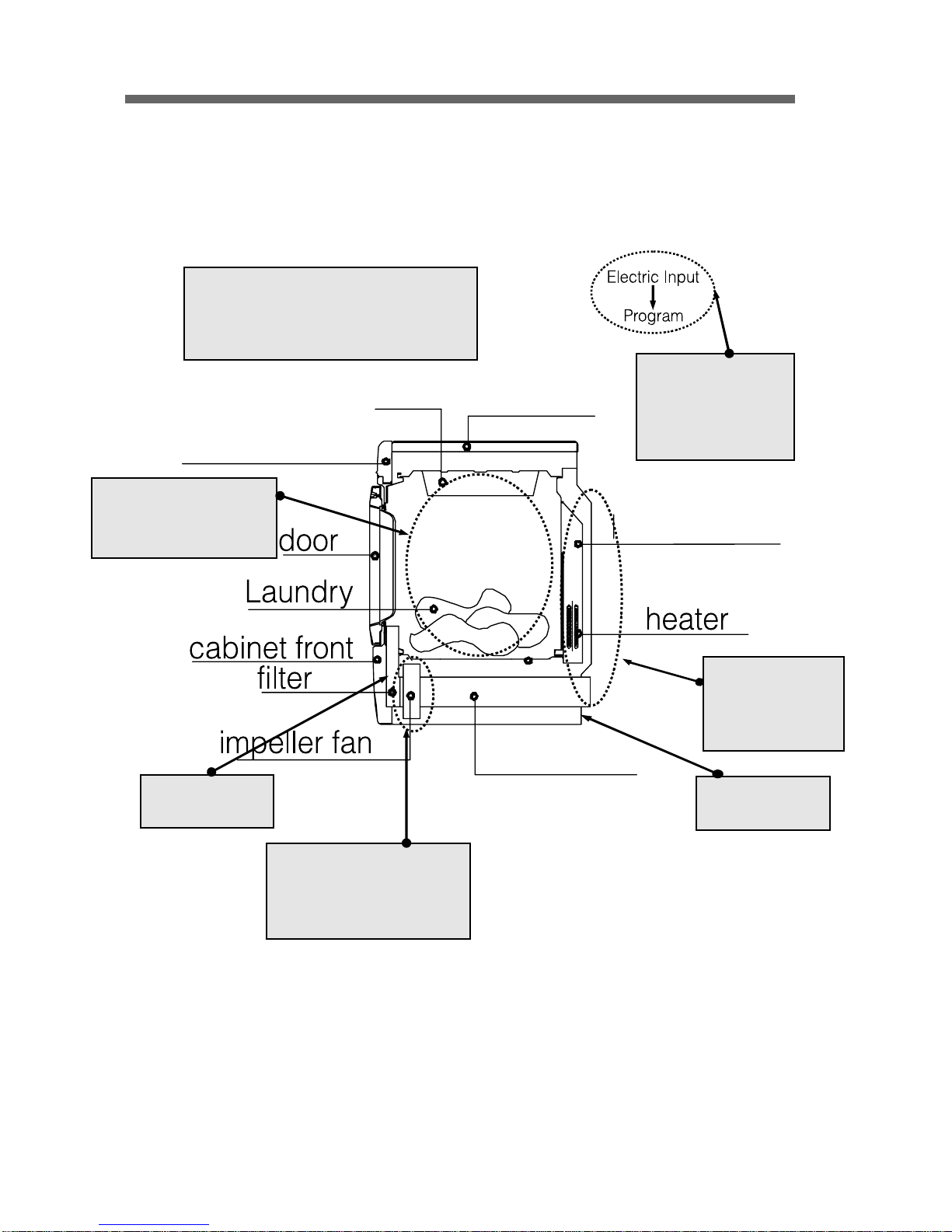

❏ Operating Mechanism Diagram (Electric Type)....................................................5

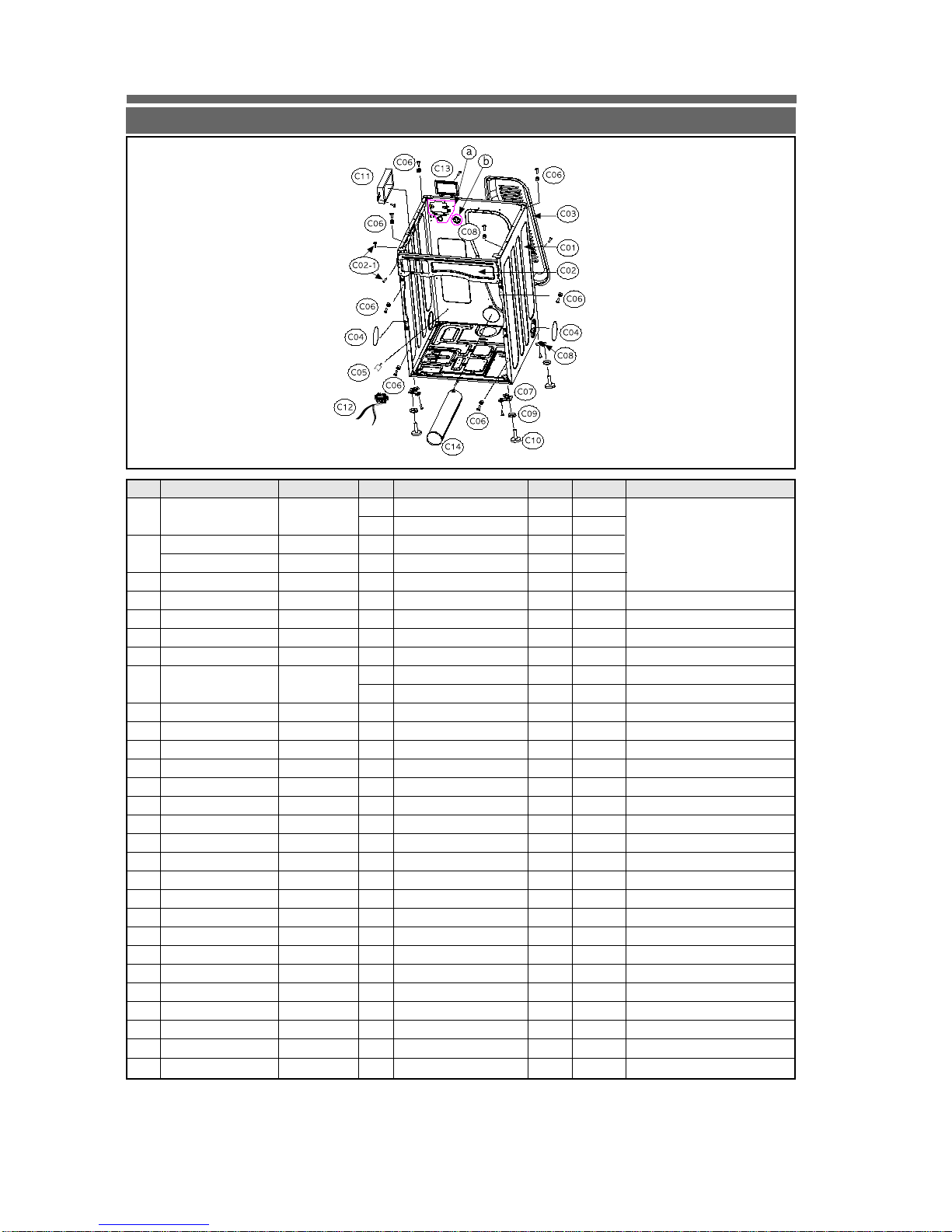

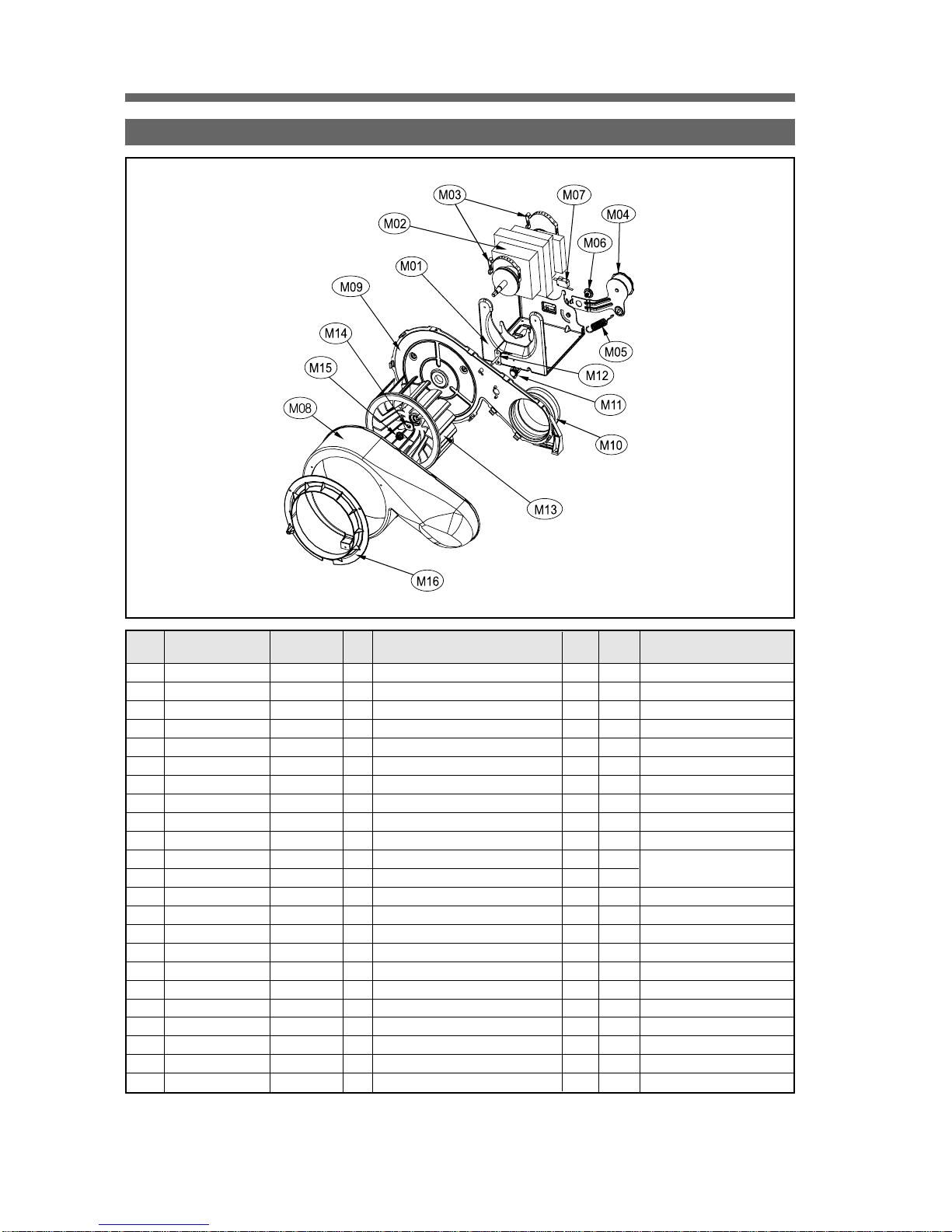

❏ Parts List by Ass’y...................................................................................................6

❏ PCB Function Specification .................................................................................16

❏ Drum Dryer Troubleshooter.................................................................................29

❏ Dryer Installation...................................................................................................31

❏ Dryer Service Notices ..........................................................................................35

❏ Dryer electronic devices

Electric Parts List - Electric Clothes Dryer...........................................................36

Fan Thermostat ....................................................................................................37

Thermostat Cut-Out .............................................................................................38

Thermostat Control...............................................................................................39

Lamp Assembly ...................................................................................................40

Door Switch ..........................................................................................................41

Heater Assembly..................................................................................................42

Belt Switch (Microswitch)....................................................................................43

Fan Thermistor ....................................................................................................45

Dryer Motor ..........................................................................................................46