3

T700 AND T760 – VENTED DRYERST700 AND T760 – VENTED DRYERS

T700 AND T760 – VENTED DRYERST700 AND T760 – VENTED DRYERS

T700 AND T760 – VENTED DRYERS

These models are vented dryers; therefore, they

requiredoutsideventingforaproperinstallation.

Room temperature air is heated by the heating

elementanddrawnintothedrum,whereitextracts

thedampness fromtheclothes.Thepaddles inthe

drumpreventtheclothesfromstickingtoeachother.

Air passes through the lint filter in the front door,

throughtheexhaustsystemandouttheexhaustvent.

On Model T700, on the way through the air

extractionsystem,theairpassesoverthethermostats.

Thethermostatsmeasurestheexhausttemperature

as it leaves the dryer. When using the automatic

program,thethermostatsindicatewhentheclothes

aredry.

On Model T760, on the way through the air

extractionsystem,theairpassesahumiditysensor.

The sensor measures the amount of humidity in

theclothes.Ifyouareusinganautomaticprogram,

thesensorindicateswhentheclothesaredry.

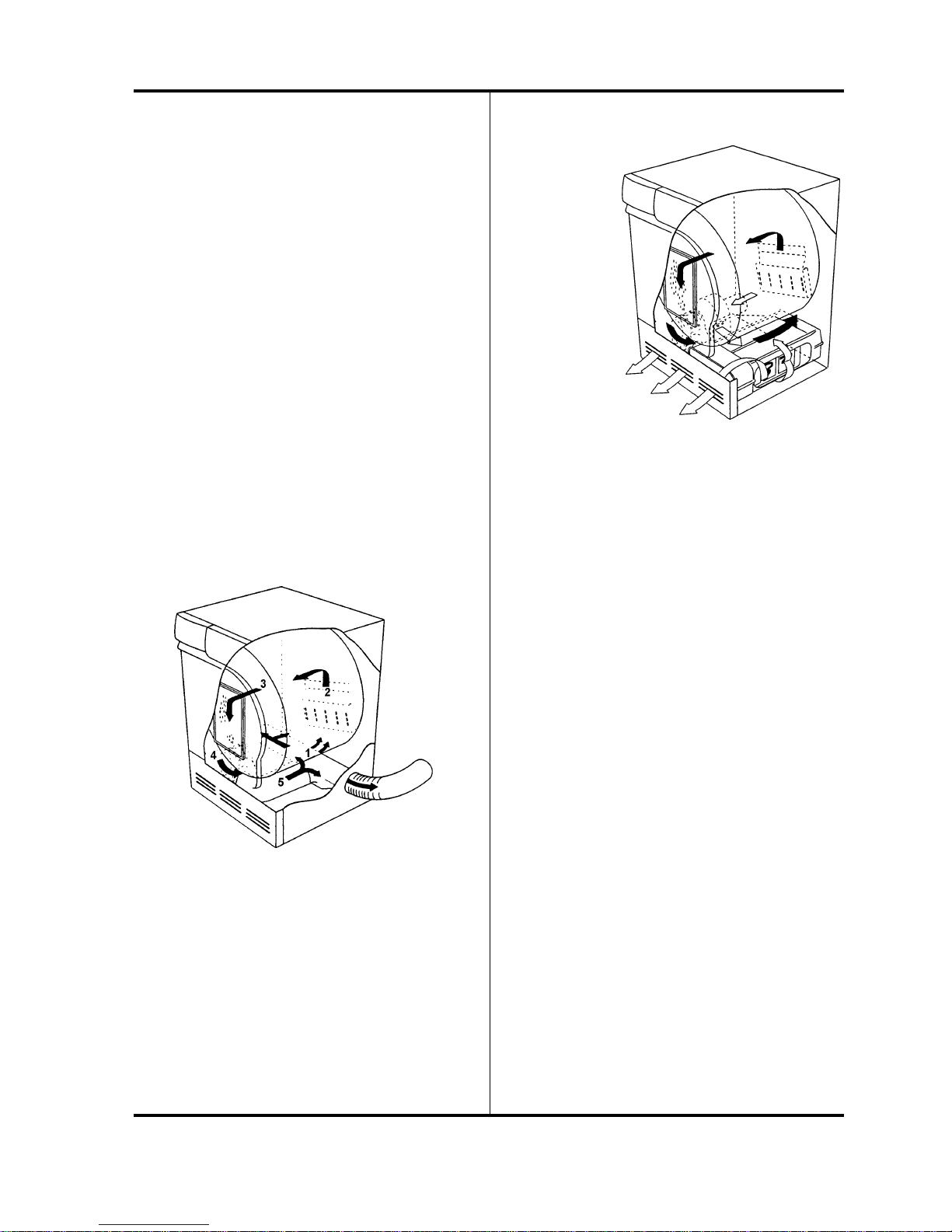

THE DRYING PROCESS

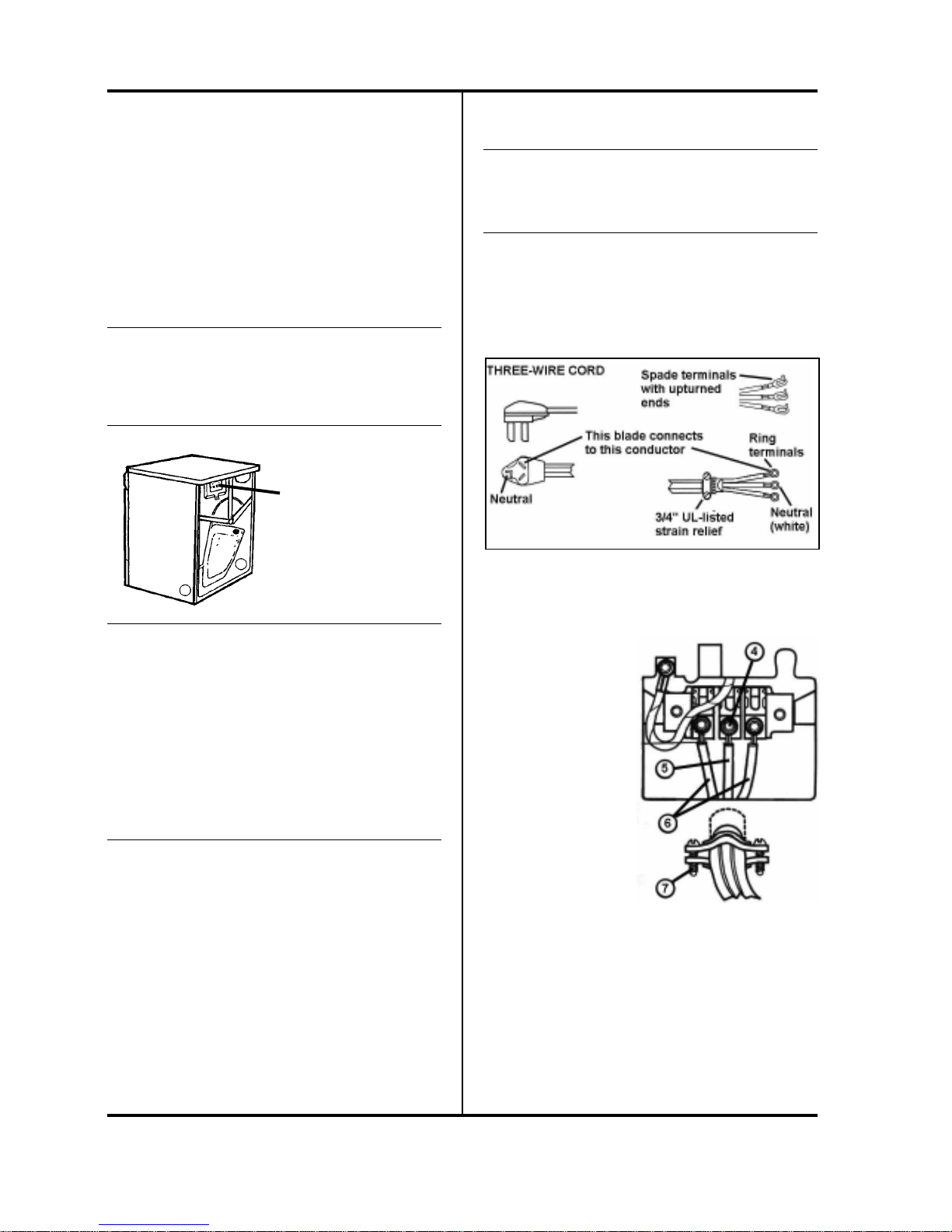

T720 AND T780 – CONDENSING DRYERST720 AND T780 – CONDENSING DRYERS

T720 AND T780 – CONDENSING DRYERST720 AND T780 – CONDENSING DRYERS

T720 AND T780 – CONDENSING DRYERS

These models are non-vented, condensing dryers

thatareusedinareaswhereventingisnotpossible.

Condenserdryershavetwocirculationsystems:one

for drying air and one for cooling air. In the

following illustration, the black arrows show the

warm drying air, and the white arrows the cooling

airatroomtemperature.

1. Room temperature air

2. Air that has been heated.

3. Maist air going through the lint filter

4. Air passing the thermostats

5. Air going out the exhaust

Model T720 is a timed dryer only. The user sets

the amount of time for the dryer to run.

Thedrumpaddlespreventtheclothesfromsticking

toeachother.Onthewaythroughtheairextraction

system,theairpassesahumiditysensor.

Model T780hasasensorthatmeasurestheamount

of humidity in the clothes. If you are using an

automatic program, the sensor indicates when the

clothesaredry.

DRYING AIRDRYING AIR

DRYING AIRDRYING AIR

DRYING AIR

Room temperature air is heated by the heating

element and passes through the drum, where it

blowsthroughtheclothesandextractsthedampness

from them.

Theairisfilteredthroughthelintfilterinthefront

door, goes down to the fan and onwards to the

condenserunit.

Onitswaythroughthecondenserthesaturatedair

releasesitswater content.The extractedwater falls

intoaholder,fromwhichitiseitherpumpedupto

awater tankortakenoutviaadrainhose toafloor

drainorsimilar.

COOLING AIRCOOLING AIR

COOLING AIRCOOLING AIR

COOLING AIR

Thecondenseriscooledbyairatroomtemperature,

drawninthroughtherearofthemachine.Theairis

blownthroughthecondenserandexhauststhrough

a grill in the bottom hatch. If the machine is built

into a cabinet, the air is drawn through the gap

between the floor and the bottom of the machine.

T700 and T760 Air Circulation

T720 and T780 Air Circulation

The black arrows

show the warm

drying air. The

white arrows

show the cooling

air at room

temperature.