Type:WM70

Service manual

Contents

Updates...................................................................................................................................................................... 4

Introduction ............................................................................................................................................................. 5

Troubleshooting strategy.................................................................................................................................. 6

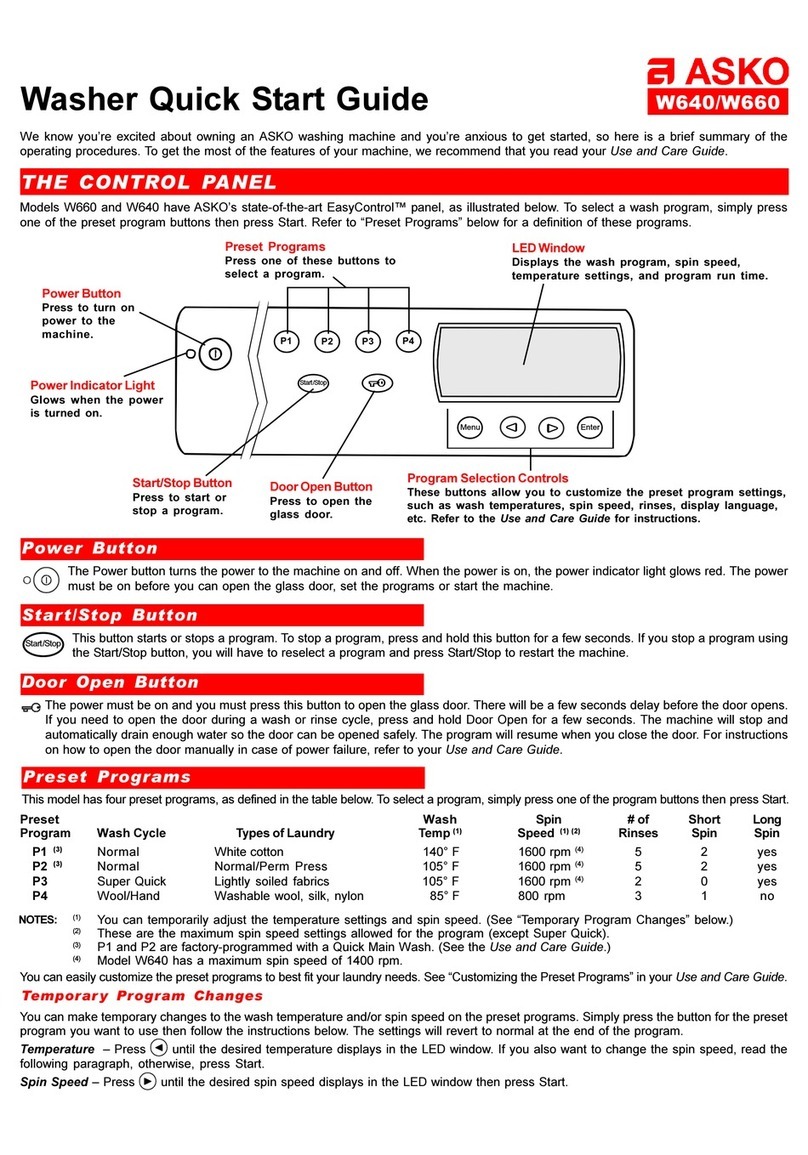

WM70.1 Overview Panel............................................................................................................................ 7

Service menu ................................................................................................................................ 8

Fault indications..........................................................................................................................10

Wiring diagram WM70.1 CIM ...........................................................................................12

Wiring diagram WM70.1 UM ............................................................................................14

WM70.2 Overview Panel..........................................................................................................................16

Service menu...............................................................................................................................17

Fault indications..........................................................................................................................18

Wiring diagram WM70.2 .....................................................................................................20

WM70.3 Overview Panel..........................................................................................................................22

Service menu...............................................................................................................................23

Shop program .............................................................................................................................28

Fault indications..........................................................................................................................29

Wiring diagram WM70.3 ......................................................................................................32

Components and measurement values WM70................................................................................34

Thermistor measurement values WM70..............................................................................................35

Technical data WM70.......................................................................................................................................35

Tools...........................................................................................................................................................................36

Rehanging the door...........................................................................................................................................37

Replacing panels, control unit and detergent compartment.....................................................40

Replacing front panel, door, cover plate and the hinges...............................................................43

Emergency opener for door lock..............................................................................................................44

Wash agitator removal....................................................................................................................................45