3

SENTIR mat 14

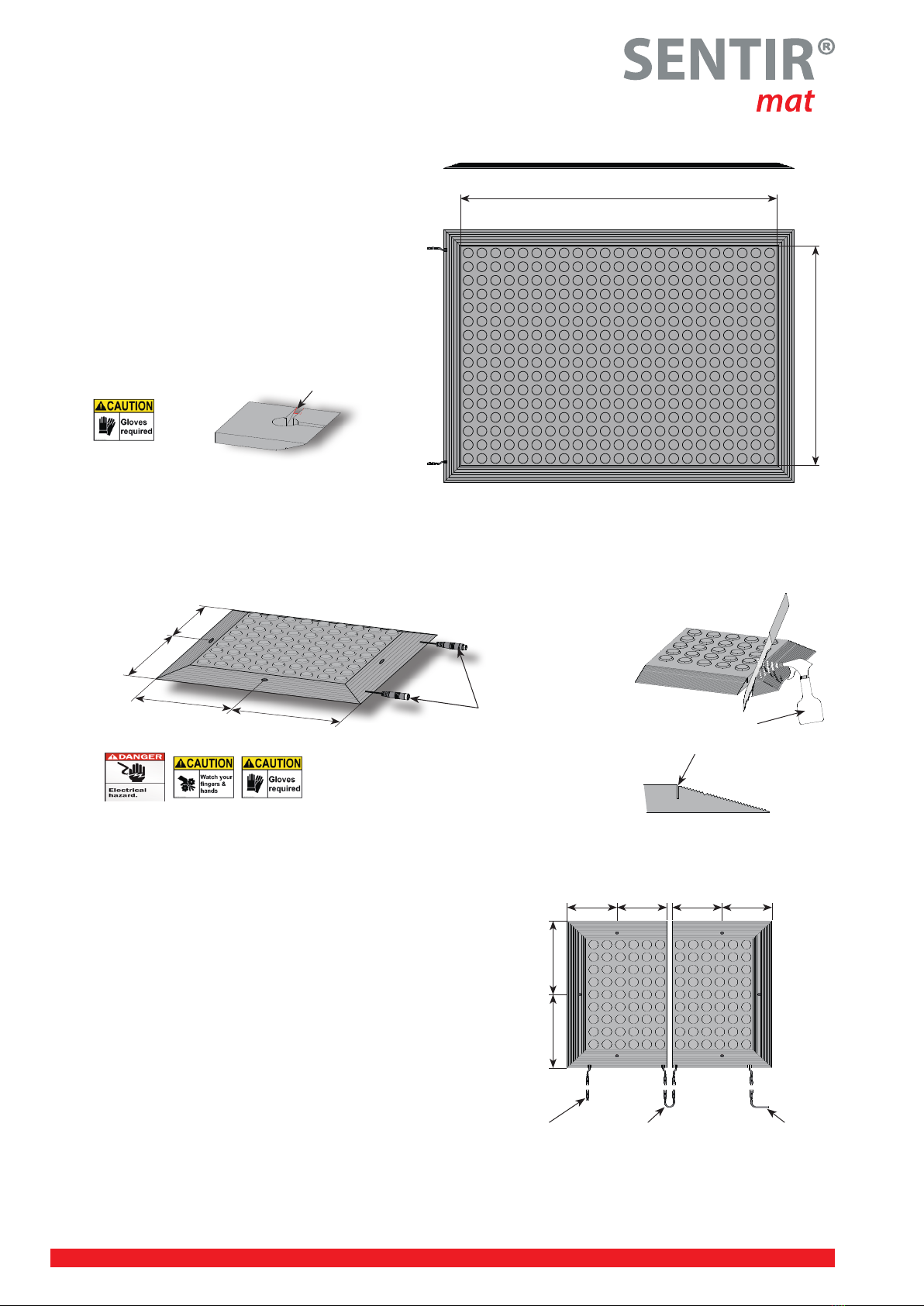

SENTIR mat 14 ARB (SENTIR mat 14 TBV)

3

3

,5

(1,3

2

")

6

(0

,2

4")

5

(0

,2

0

")

6

7

(2

,6

4")

17,8 (0,70")

7

,5

(0

,3

0

")

5

(0

,2

0

")

40 (1,57")

17,8

(0

,70")

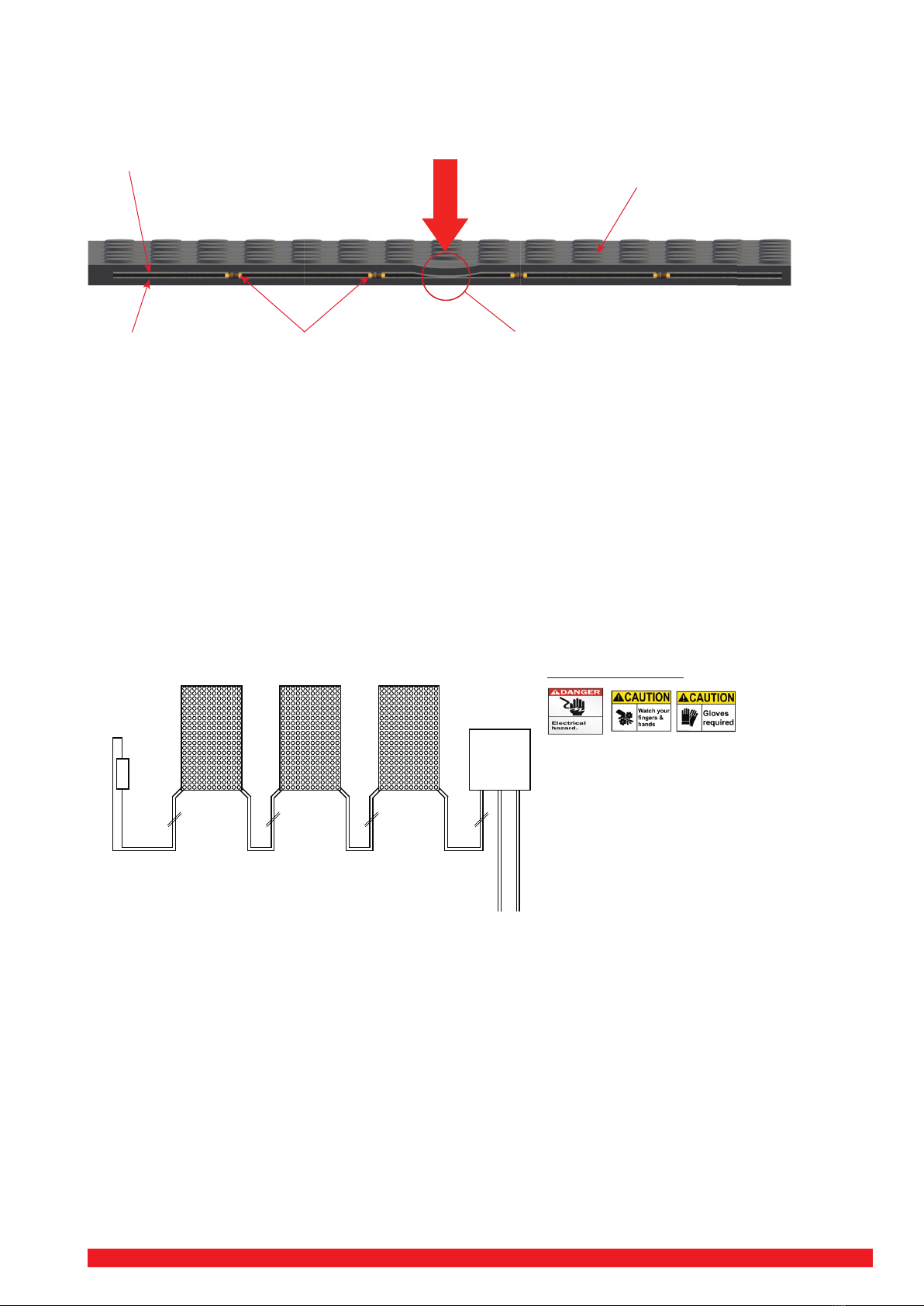

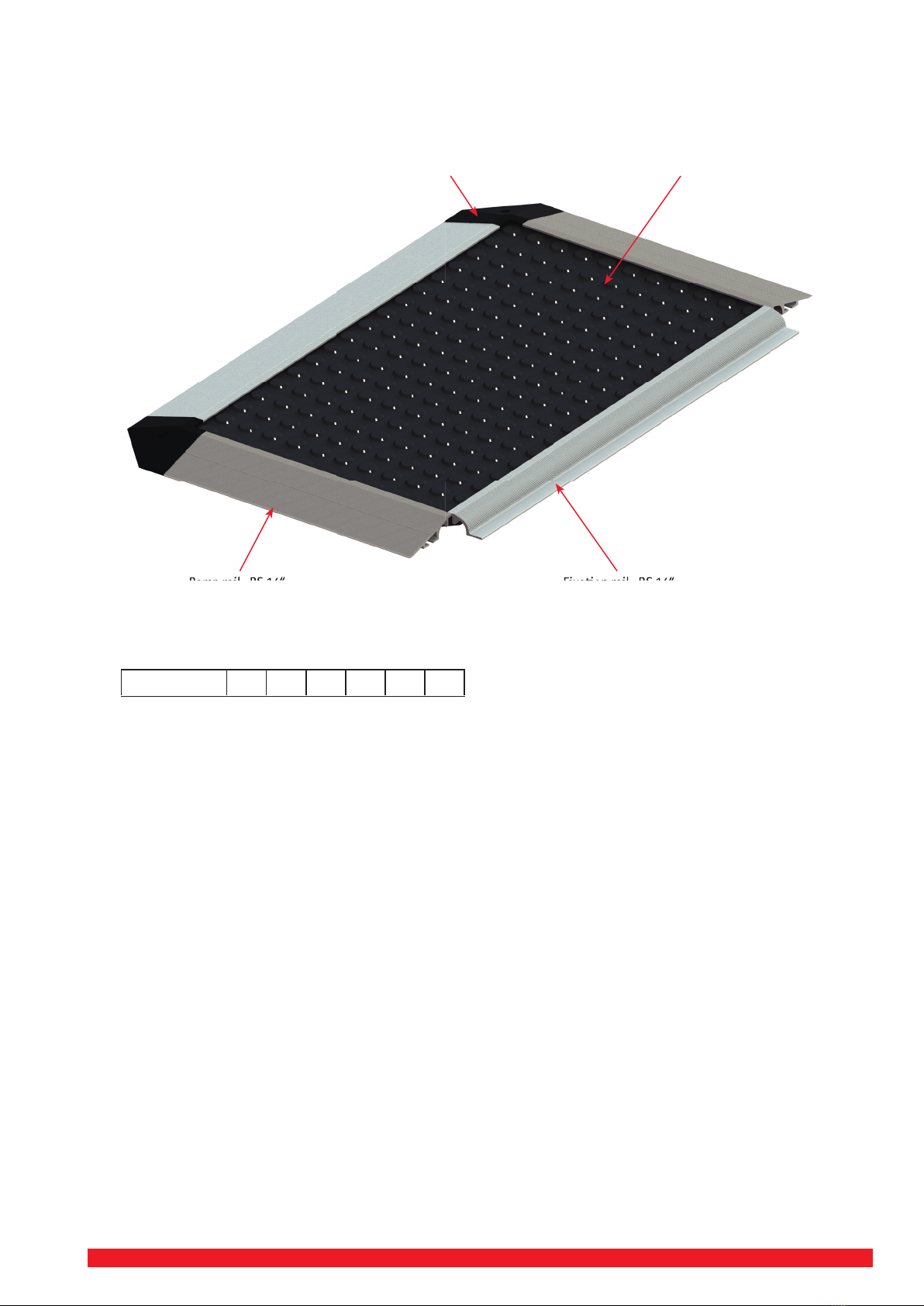

Ramp rail RS 14

Marking groove Fixation rail BS 14

Cable duct Connection cable Fastening grommet (available on request)

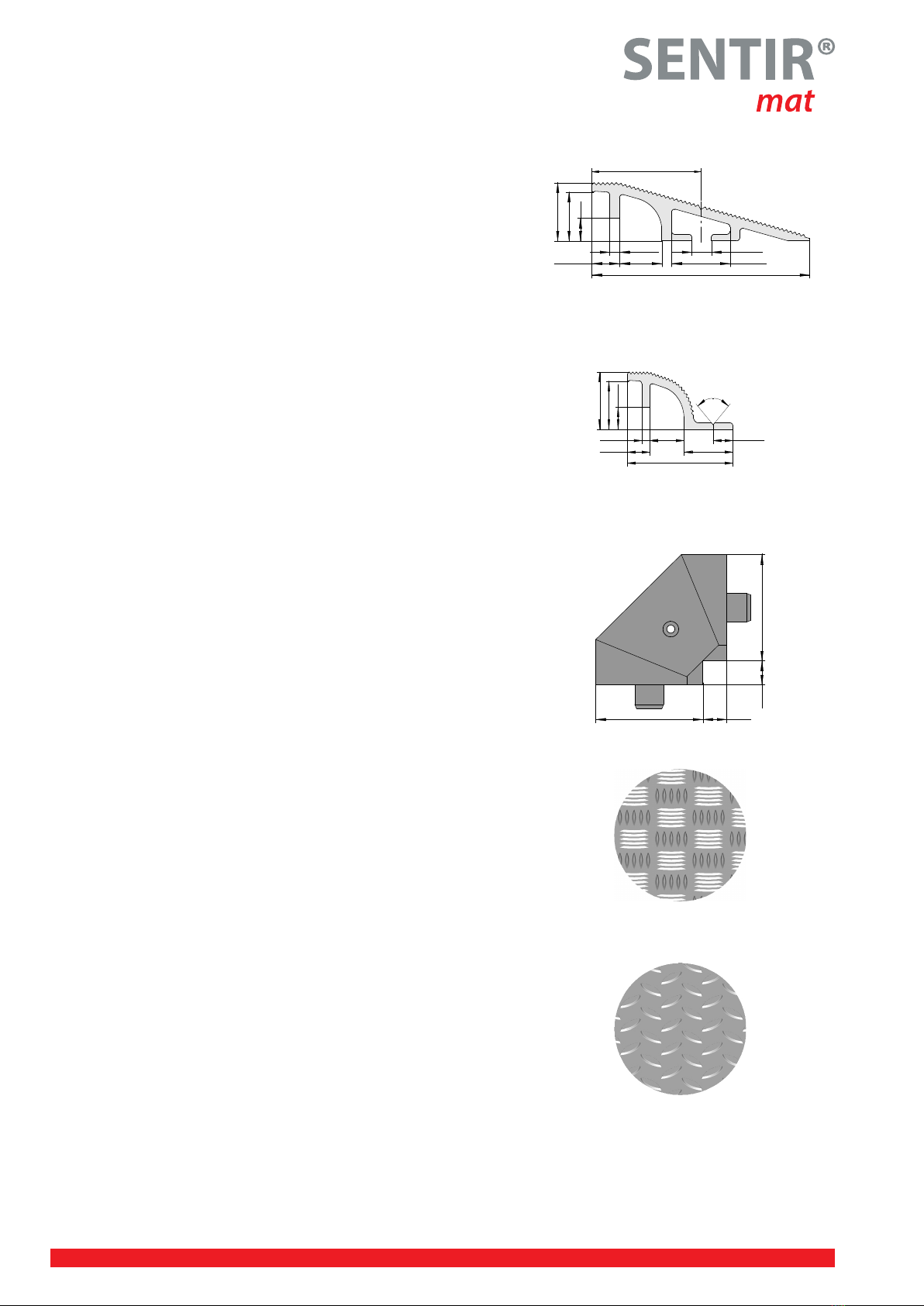

33,5 (1,32")

6 (0,24")

5 (0,20")

67 (2,64")

17,8 (0,70")

7,5 (0,30")

5 (0,20")

40 (1,57")

17,8 (0,70")

14,5 (0,57")

Ramp rail RS 14

Marking groove Fixation rail BS 14

Cable duct Connection cable

Steel plate

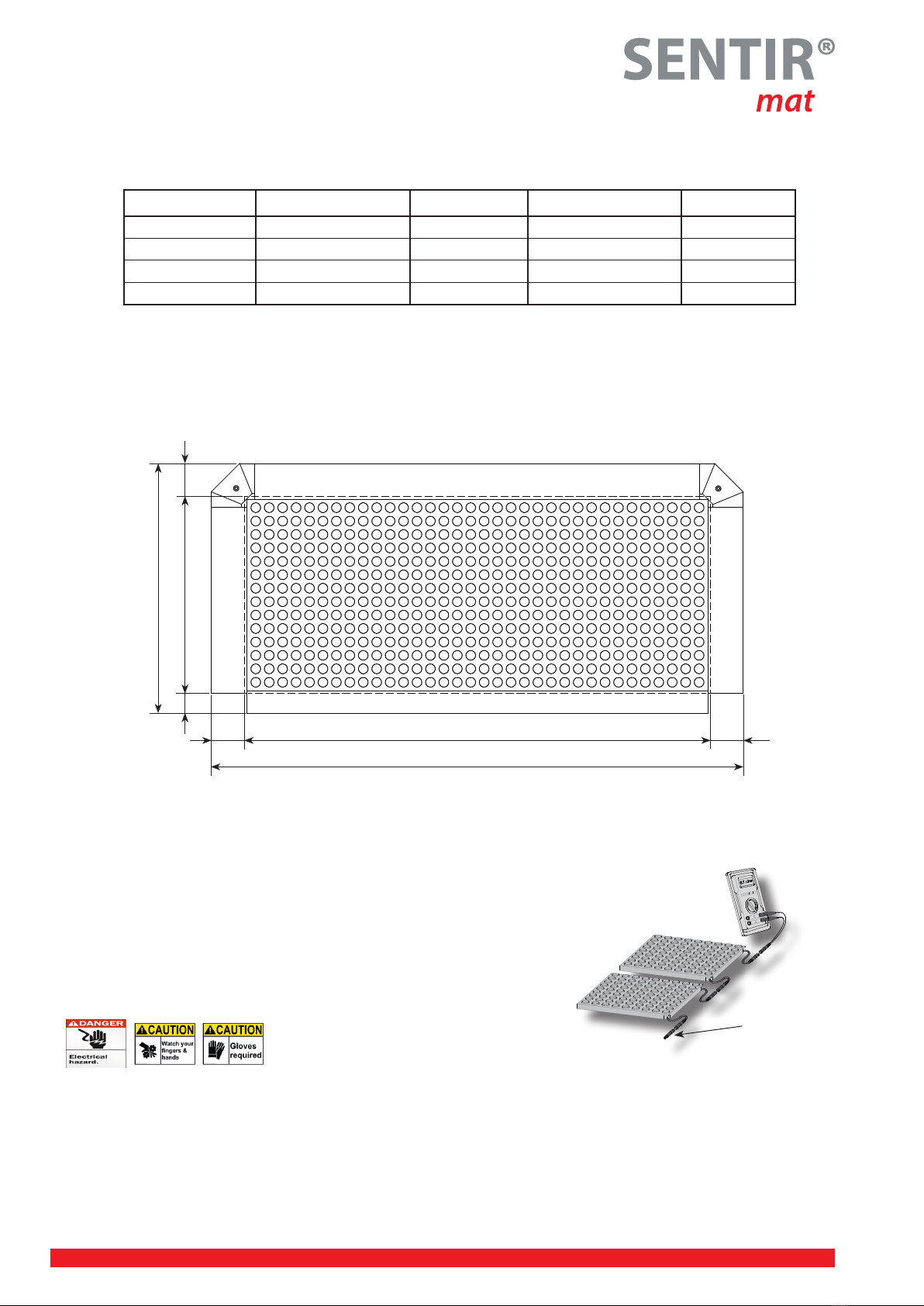

Technical specication for Safety contact mats

SENTIR mat 14 U/ SENTIR mat 14 T SENTIR mat 14 ARB

Max. dimensions 2000 mm x 1250 mm (78,74“x49,21“) 2000 mm x 1250 mm (78,74“x49,21“)

Standard dimensions

available from stock

only SENTIR mat 14 U / T

1000 mm x 750 mm (39,37“ x 29,53“)

1000 mm x 1000 mm (39,37“ x 39,37“)

1000 mm x 1500 mm (39,37“ x 59,06“)

Height 14 mm (0,55“) with covering 14 mm (0,55“) with covering

Surface Euro dot checkered

Weight U 24,9 Kg/m2(54,9lb/10,76ft2);

T 26 Kg/m2(57,32lb/10,76ft2)

approx. 31,5 kg/m² (69,45lb/10,76ft2)

Inactive edge 16 mm(0,63“) 30/40 mm (1,18“/1,57“)

Switching pressure Test piece Ø 80 mm (3,15“) = approx. 150 N Test piece Ø 80 mm (3,15“) = approx. 150 N

Static load max. 2000 N over Ø 80 mm (3,15“) * max. 2000 N over Ø 80 mm (3,15“) *

Response time < 25 ms* < 25 ms*

Switching cycles min. 1 million* min. 1 million*

Electrical capacity 24 V 100 mA 24 V 100 mA

Material PUR black, 78 +/- 5 Shore A

(optional PUR yellow, 78 +/- 5 Shore A)

PUR black, 78 +/- 5 Shore A

(optional PUR yellow, 78 +/- 5 Shore A)

Protection class IP 65 (IP 67) IP 65 (IP 67)

Temperature range -10°C (+14°F) to +55°C (+131°F) -20°C (-4°F) to +55°C (+131°F)

Chem. resistance:

Oil

Petrol

Solvent

Diluted Acid

Diluted lye

good

resistant

sufcient

resistant

resistant

Aluminium

good

good

good

good

good

Connection cable Standard: 2 pcs. - 2 x 0,34 PVC / PU cover black Ø 3,5 mm with

M8 male/female plug 120 mm (4,72”)

Alternative: 1 pc. 4 x 0,25 PVC / PU cover black Ø 4,4 mm with open wires

(BN: 1, BU: 3 || WH: 2, BK: 4)

Fire and shock evaluation UL 508 and CSA C22.2 no. 14 (no evaluation of protective safety function)

* tested according to DIN EN ISO 13856-1