O

A CB D

2

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

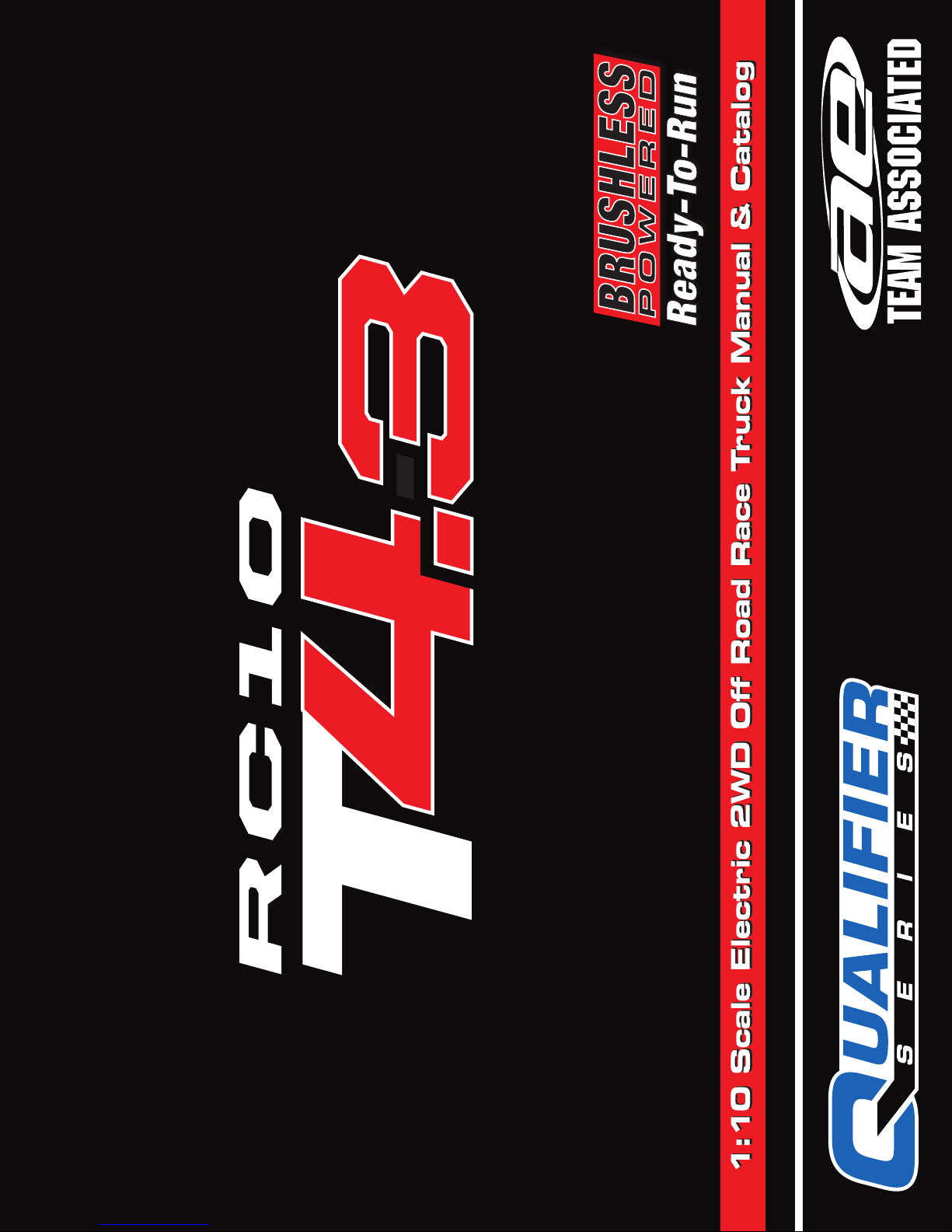

:: Introduction

:: KIT Features

:: Additional

:: Other Helpful Items

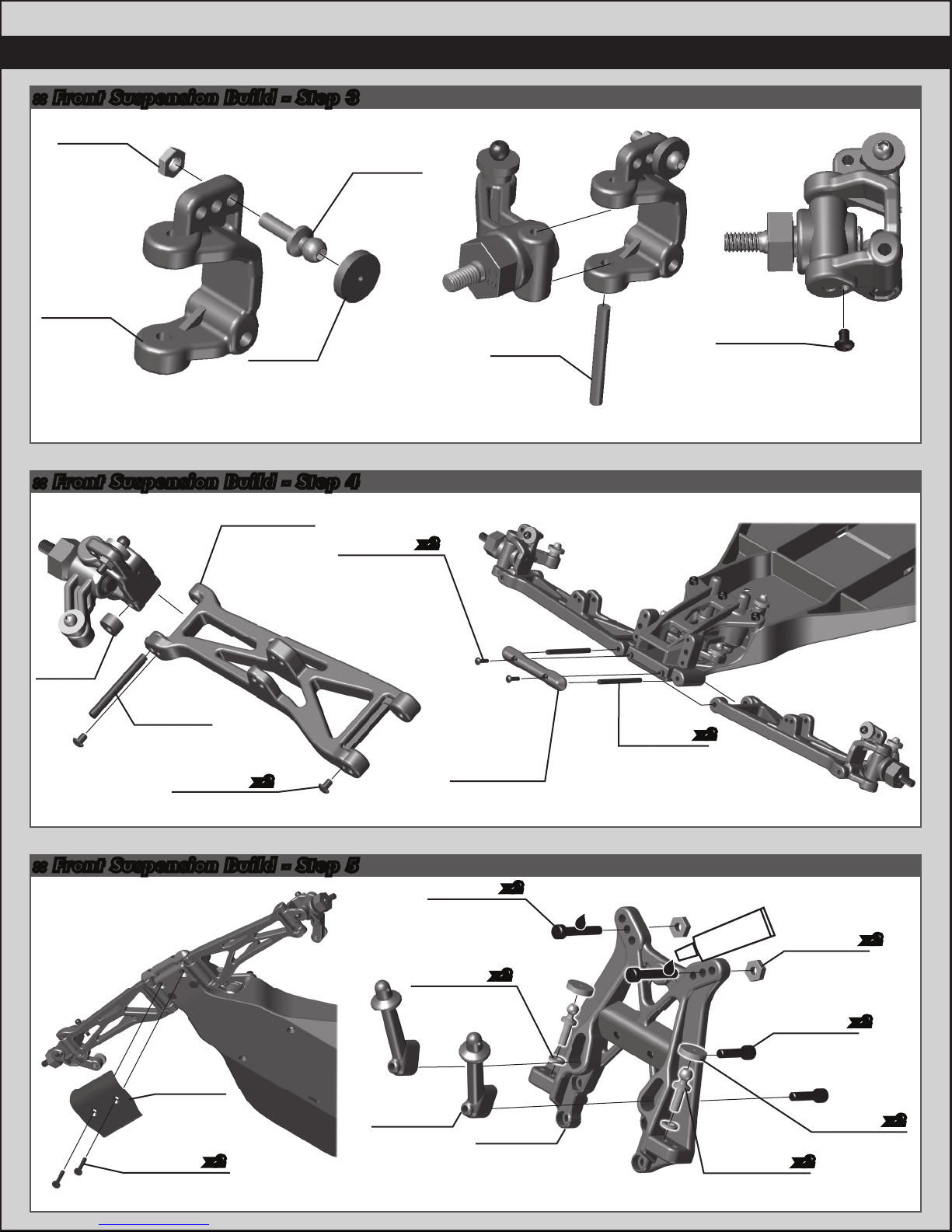

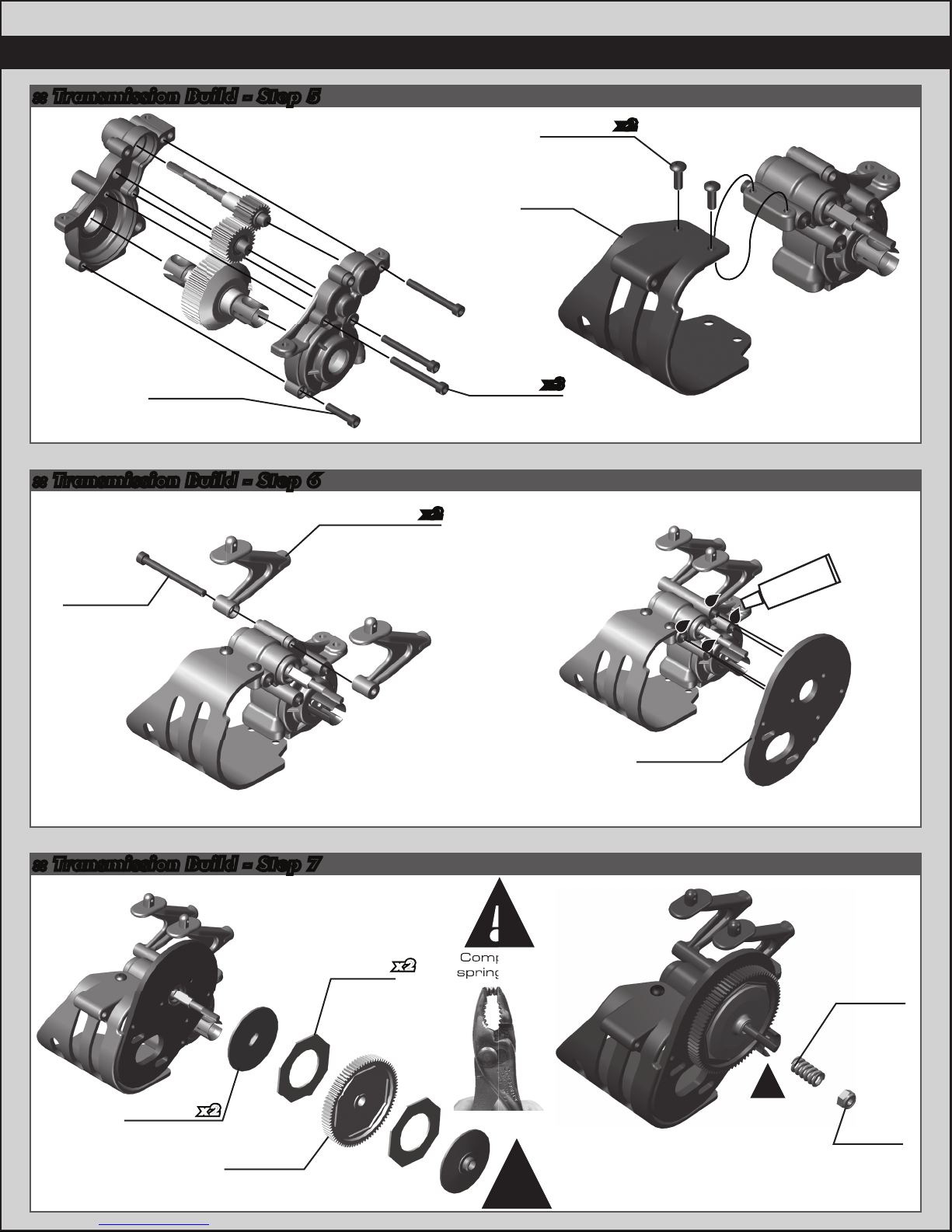

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and

maintaining your new RC10 T4.3. Please take a moment to read through this manual to help familiarize yourself with these steps.

We are continually changing and improving our designs; therefore, actual parts may appear slightly different than in the

illustrations. New parts will be noted on supplementary sheets located in the appropriate parts bags. Check each bag for these

sheets before you start to build.

Features in the T4.3 RTR:

• Fully assembled 2WD truck based on the 8-time R.O.A.R. National Champion platform

• Brushless Electronic Speed Control

• Powerful Reedy brushless motor

• 2.4 GHz 2-channel radio system with digital metal gear servo

• Water-resistant enclosed receiver box

• Blue anodized aluminum V2 coil-over shock absorbers

• Heavy-duty sealed gear differential with adjustable slipper clutch

• Factory finished Interceptor 2.0 polycarbonate body

• High traction tires pre-mounted on white hex drive wheels

• Molded composite chassis and battery strap that fits NiMH or LiPo battery packs

• Rugged steel turnbuckles for adjustable camber and front toe-in

• Vertical ball ends for roll center adjustments, front & rear

Your new T4.3 RTR comes factory assembled including radio

gear, motor, and ESC. However, there are some items you will

need to complete your kit (refer to catalog for suggestions):

• AA-size batteries for transmitter (x4)

• 6 cell NiMH battery pack or 2 cell LiPo battery pack

• Battery charger (we recommend a peak detection charger)

Tools included:

• Allen wrenches #6950 (.050”, 1/16”, 3/32”, 5/64”)

• 1.5mm allen wrench • Molded tools #6956

• Camber gauge #1719 • Shock building tool #6429

• Silicone Shock Fluid (Refer to catalog for complete listings)

• Body Scissors (AE Part # 1737) • Reamer / Hole Punch • Wire Cutters • Hobby Knife

• FT Hex Wrenches (AE Part # 1655) • Needle Nose Pliers • Multi Tool (AE Part #7494)

• Soldering Iron • Calipers or a Precision Ruler • Green Slime shock lube (AE Part # 1105)