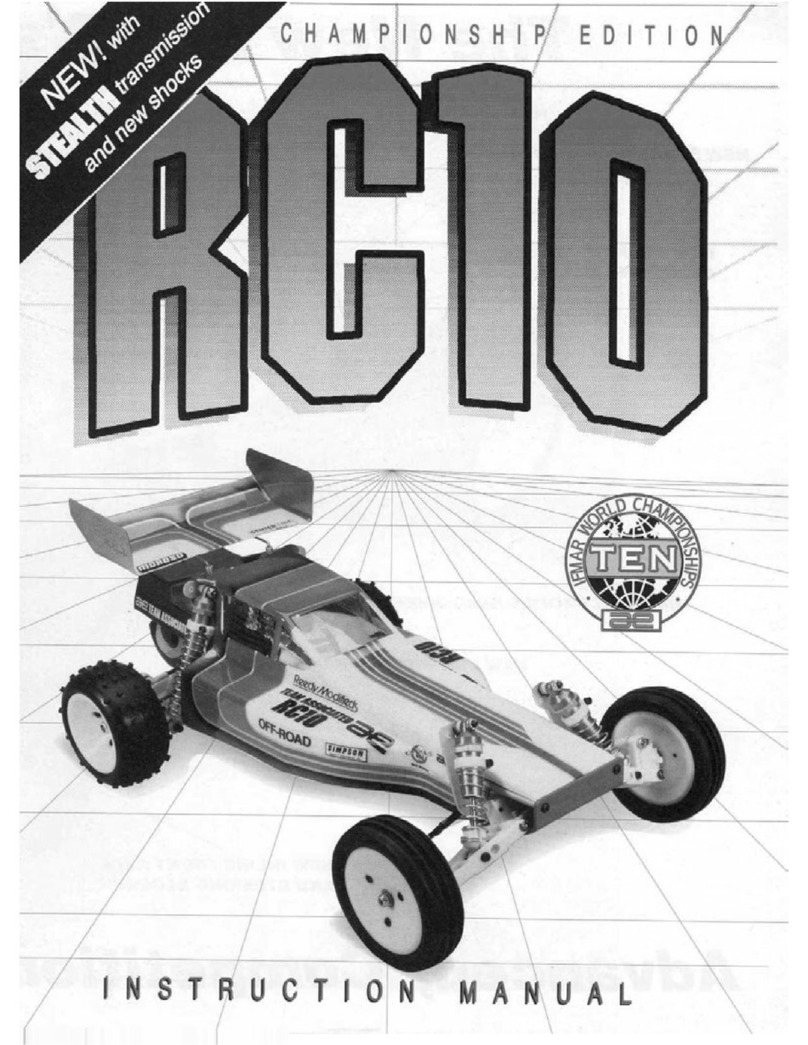

shoulder down

8405, qty 2

upper suspension

arm

8407, qty 2

10° upper sus-

pension arm

mount 8417, qty 4

pivot ball

8415, qty 2

upper suspension

arm turnbuckle

8411, qty 2

upper suspension

arm eyelet

s t e p 1

ASSEMBLE UPPER

SUSPENSION ARM

Assemble parts #8405, 8415,

and 8411.

ATTACH UPPER ARM MOUNT TO LOWER ARM

Attach #8407 10° mount to the #8419 lower

suspension arm using two #8409 screws. WARNING!

Screws are difficult to screw in. Turn carefully so you

do not strip out the head.

INSTALLING UPPER AND LOWER PIVOT BALLS

Before popping in the pivot balls, make sure there are

no burrs inside the pivot ball holes.

Pop the #8417 pivot balls into the suspension arms as

shown. Make sure that the shoulders of the pivot balls

in the lower suspension arms are facing upward and

the pivot balls in the upper arm are facing downward

as shown. Orient ball to the rounded side of the upper

arm as shown.

Now assemble the right side.

L E F T S I D E

B A G A

REMOVE THESE

PARTS FOR:

4015: step 1

1:1

1:1

B E F O R E B U I L D I N G

OPEN THE BAGS IN ORDER

The assembly is arranged so that you will open and finish that

bag before you go on to the next bag. Sometimes you will

have parts remaining at the end of a bag. These will

become part of the next bag. Some bags may have a large

amount of small parts. To make it easier to find the parts, we

recommend using a partitioned paper plate for spreading out

the parts so they will be easier to find.

MANUAL FORMAT

The following explains the format of these instructions.

The beginning of each section indicates:

1Which bag to open ("BAG A").

2Which parts you will use for those steps. Remove only the

parts shown. "1:1" indicates an actual size drawing; place

your part on top and compare it so it does not get confused

with a similar part.

3Which tools you should have handy for that section.

4In some drawings, the word "REAR" with an arrow indicates

which direction is the rear of the car to help keep you oriented.

5 The instructions in each step are ordered in the order you

complete them, so read the words AND follow the pictures. The

numbers in circles are also in the drawing to help you locate

them faster.

6When we refer to left and right sides of the car, we are

referring to the driver's point of view inside the car.

SUPPLEMENTAL SHEETS

We are constantly developing new parts to improve our kits.

These changes, if any, will be noted in supplementary sheets

located in a parts bag or inside the kit box. Check the kit box

before you start and each bag as it is opened. When a

supplement is found, attach it to the appropriate section of the

manual.

Now clear off your workbench, line up some partitioned

plates, grab your hot dog, root beer, bag o'chips, hang up your

DO NOT DISTURB sign, and let's go!

R E A C H I N G U S

ASSOCIATED ELECTRICS, INC.

3585 Cadillac Ave.

Costa Mesa, CA 92626

USA

CUSTOMER SUPPORT

(714) 850-9342

FAX (714) 850-1744

web site: http://www.rc10.com

©1998 Associated Electrics, Inc.

3

T O O L S U S E D

Match this number

to the text to find

your way faster

8411

8415

8405

8407 8419

8409 (blue)

8409

(blue)

8417

8417

8409, qty 4

4-40 x 1/2"

shoulder screw,

blue aluminum

1:1

1:1

8419, qty 2

lower suspension

arm

shoulder up

left side

right side

the side with

the rounded corner

should face up

1/16"

3

5

F

R

O

N

T