JCI 24/7 Parts Number 888-474-0115

© 2006 JCI

crushing chamber for service work. Never rely on hydraulic pressure to keep the upper frame raised.

You could be crushed and killed if the upper frame lowers unexpectedly.

• Always stop the crusher immediately if any gauges show abnormal readings, or if there is a sudden

obvious change in operation. Be alert for noises that might indicate trouble.

• Inspect, lubricate, maintain and repair the crusher in accordance with the instructions contained in

this manual and any additional manuals or documentation provided with the crusher.

• Inspect all warning signs and caution decals. If they become torn or not readable contact your local

dealer or Johnson Crushers International for replacement.

• On portable plants be sure that the trailer is properly blocked and level. All blocking must be suit-

able to support the trailer dead load weight plus the crusher impact live loading.

• Before starting the crusher visually check the tramp iron and clamp cylinder pressure gauges on the

hydraulic manifold. Both pressures should range from 2700 psi to 3000 psi. Occasionally check the

system pressure gauge with the hydraulic pump motor running. This pressure shall not exceed 3000

psi.

• Avoid stopping the crusher with material inside the crushing chamber. In the event that the crushing

chamber is full of rock use the hydraulic clearing feature. Always inspect the crushing chamber and

U-seat after a clear for loose or jammed rock.

• Do not adjust the close side setting smaller than the recommended minimum setting for your mantle

and bowl liner combination.

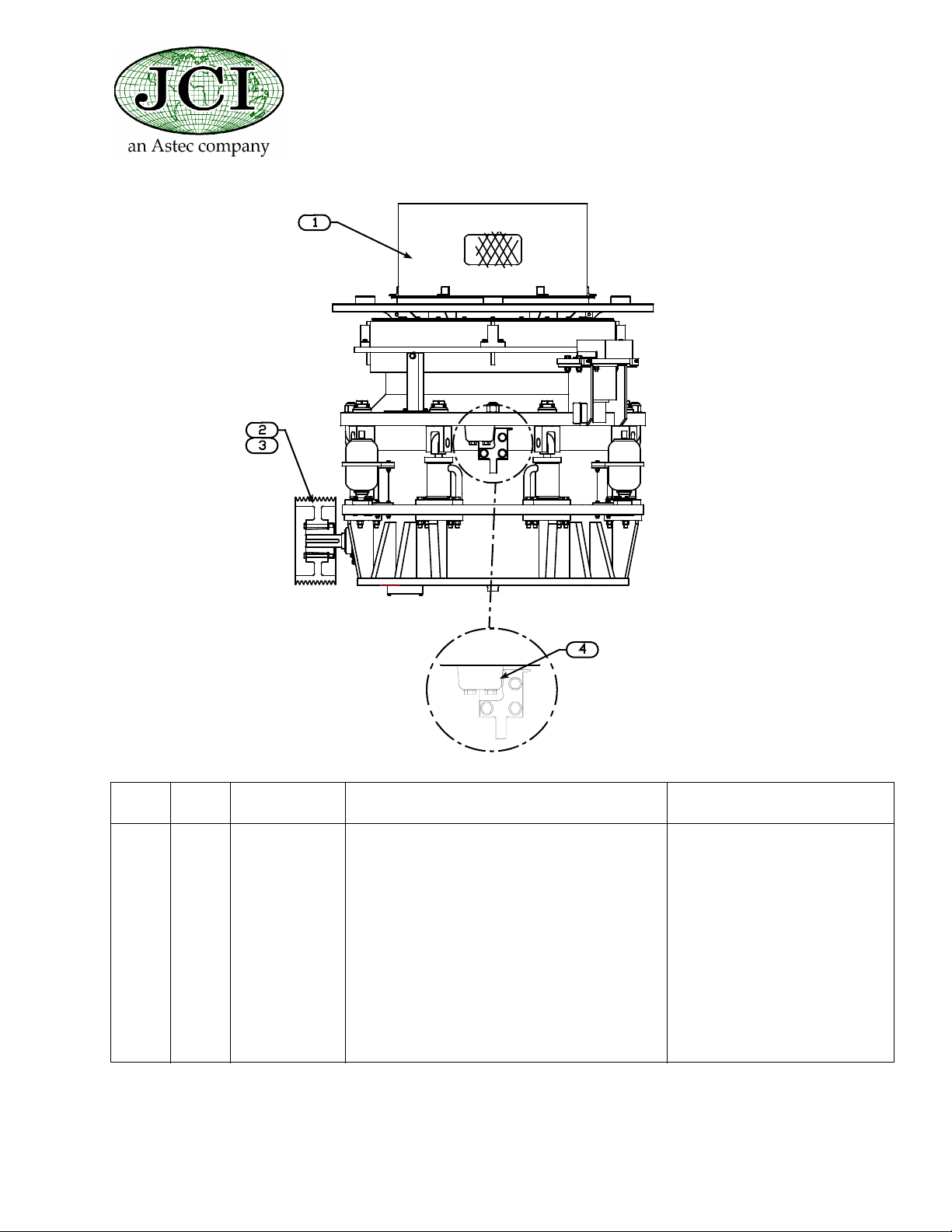

• An oil flow meter has been provided as a safety device to protect the crusher components in the

event of a lubrication system failure. Should the flow meter detect a flow of oil less than its preset

value, the electrical panel will activate the warning horn alerting crusher operators that the machine

needs to be shut down immediately to prevent permanent damage to crusher components. In addi-

tion, it is strongly suggested that the control circuit be wired such that, when the warning system is

activated, the feed device feeding the crusher is shut down. The crusher should be shut down imme-

diately after the rock has cleared the crushing chamber (less than 10 seconds).Wear your hard hat at

all times.

• Stop the crusher, lock out power, and tag controls:

1.Before performing any lubrication, maintenance, adjustments, or repairs.

2.Before removing any spilled materials.

3.Before clearing jams or working on the crusher.

4.Whenever any unusual noises or sudden changes in operation are noticed .

• Refer to the JCI Operation Manual for screen safety information. If your copy of the manual is miss-

ing, please contact your local JCI dealer or the JCI Parts Department for a replacement copy.Read

your Operation Manual for your screen. Be sure that you fully understand all phases of screen opera-

tion. A careful and well-trained operator is the best insurance against an accident.