2

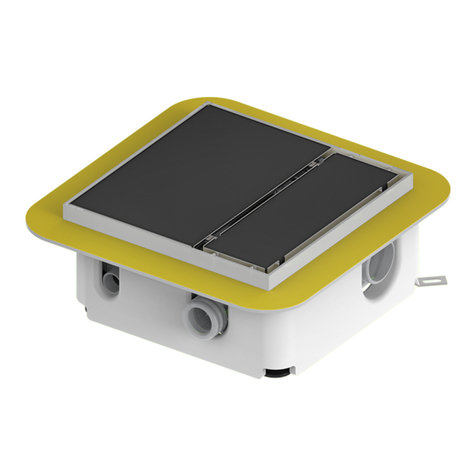

AVID LP R2

InstallatIon and operatIng InstructIons

3.0 FIELD WIRING

ATTENTION

Before installing the conduit entry gland, please

ensure that it is the correct size and thread form.

An incorrect gland may affect the enclosure

ingress protection rating.

3.1 The terminal strip base has been

designed to offer easy access for wire

termination.

3.1a It is not necessary to remove the terminal

strip to connect the field wiring, but if

required, first remove the terminal strip

retaining screw and keep safe as this will

be required to secure the terminal strip

when complete.

3.1b Lift the terminal strip evenly off of the

two base pins and terminate the wiring

in accordance with the wiring diagram

which is located on the of the cover.

NOTE

For special builds of the AVID LP product it may be

necessary to have an additional A4 wiring diagram

placed in the packing box.

3.1c Position the terminal strip over the

two base pins and press evenly in the

direction of the pins.

3.1d Secure with the retaining screw removed

in step 3.1a.

4.0 EASIFIX CAM SETTING

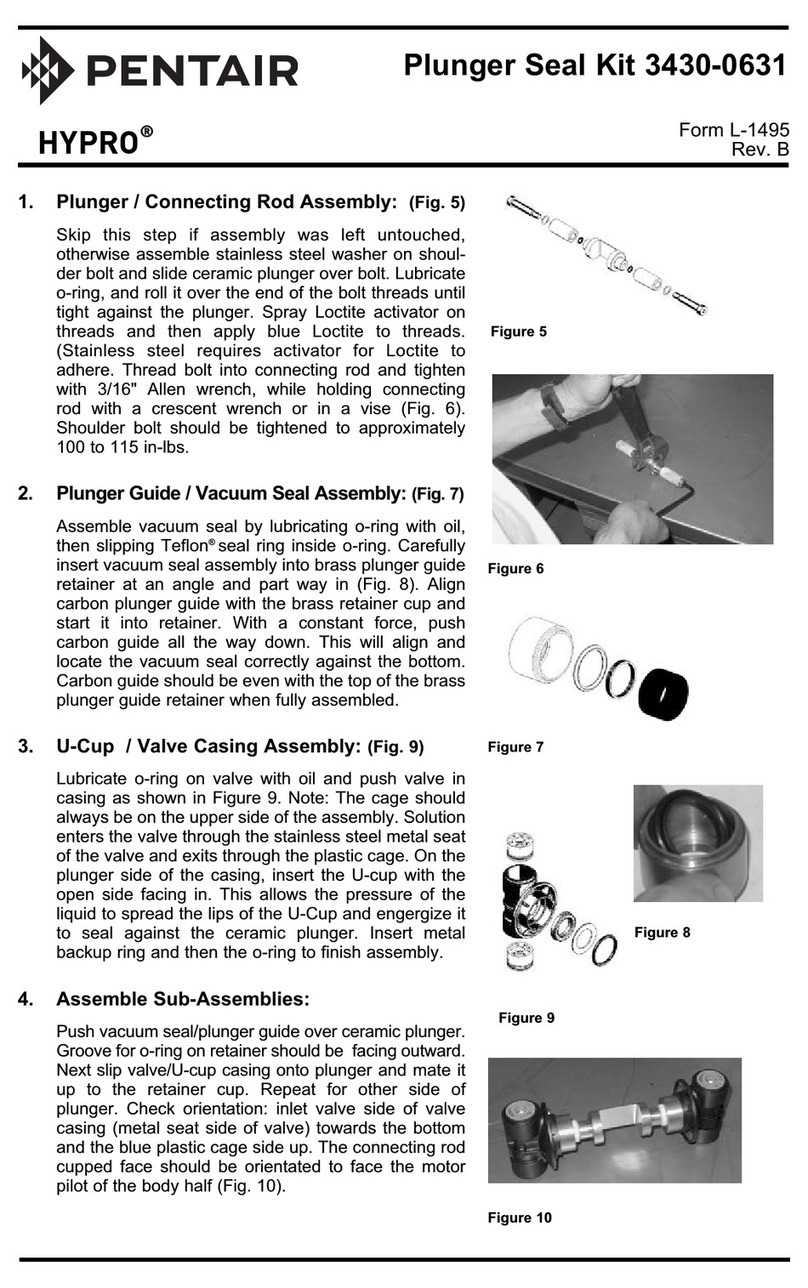

4.1 To set the switch or sensor cam (Fig.3),

lift the bottom cam and turn until

switch / sensor is activated and then

release. The spring will push the cam

back onto the splined shaft.

4.2 Operate the actuator to the opposite

extreme, push down on the top cam

andturn until the upper switch / sensor

isactivated.

4.3 Operate the actuator from one extreme

to the other several times to ensure that

theswitches / sensors activate correctly.

5.0 COVER ASSEMBLY

5.1 Before assembling the cover assembly to

the AVID LP housing, check the cover seal

detail to ensure that it is not damaged

and free of debris.

5.1 Engage the shaft into the beacon bore

and rotate the cover assembly so that the

shaft drive flats fully engage.

5.2 Approximately align the cover with the

housing flange and secure using either

a 8 mm A/F spanner / socket drive or an

appropriately sized flat blade screwdriver.

5.3 Tighten the screws to a torque value of

18to 22 Lb/Ins.

6.0 READY FOR USE

6.1 The AVID LP switchbox is now ready

foruse.

6.2 If there are any un-used conduit entries,

please ensure that they are plugged using

correctly rated IP blanking plugs.

7.0 TECHNICAL DATA

Area classification - non hazardous.

Ingress protection - IP66 / 67

Switch / sensor options

Mechanical Switch – SPDT Form C,

Electricalrating -

24, 48, 110 & 240 VAC / 15Amps,

24 VDC / 15 Amps

48 VDC / 2.5 Amps

Alternative inductive proximity sensors;

P&F - NJ2-V3-N, NBB3-V3-Z4, NBB2-V3-E2

IFM - IS5026, IS5001, IS0003, IS5003, NS5002

Turck - Bi2-Q10S-AP6X, Bi2-Q10S-YOX

Telemecanique - XS7-H10PA340

Terminal strip –

Weco 302 HDS, 8 points or Klippon MK3,

6points.

Conduit options –

Up to 2 x M20 x 1.5p or ½”-14 NPT

Ambient Temperature Range –

Minus 20°C to +80°C

Figure 3

Top Cam (OPEN)

Push down, turn

and release.

Bottom Cam

(CLOSED). Lift, turn

and release.