I. Table of contents

1Device description .......................................................................................................................................... 4

2Operating notes.............................................................................................................................................. 5

2.1 Installation ................................................................................................................................................ 5

2.2 Connections .............................................................................................................................................. 6

2.3 Signal-LED.................................................................................................................................................. 9

2.4 Maintenance and Cleaning ....................................................................................................................... 9

3Fieldbus interface (Option)........................................................................................................................... 10

4Parameterization .......................................................................................................................................... 11

4.1 Command input and VLMTool ................................................................................................................ 11

4.2 Parameter ............................................................................................................................................... 12

4.3 Additional commands ............................................................................................................................. 20

5Technical data............................................................................................................................................... 26

6Error messages ............................................................................................................................................. 27

7Dimensional and installation drawings......................................................................................................... 28

8Declaration of conformity ............................................................................................................................ 29

II. List of figures

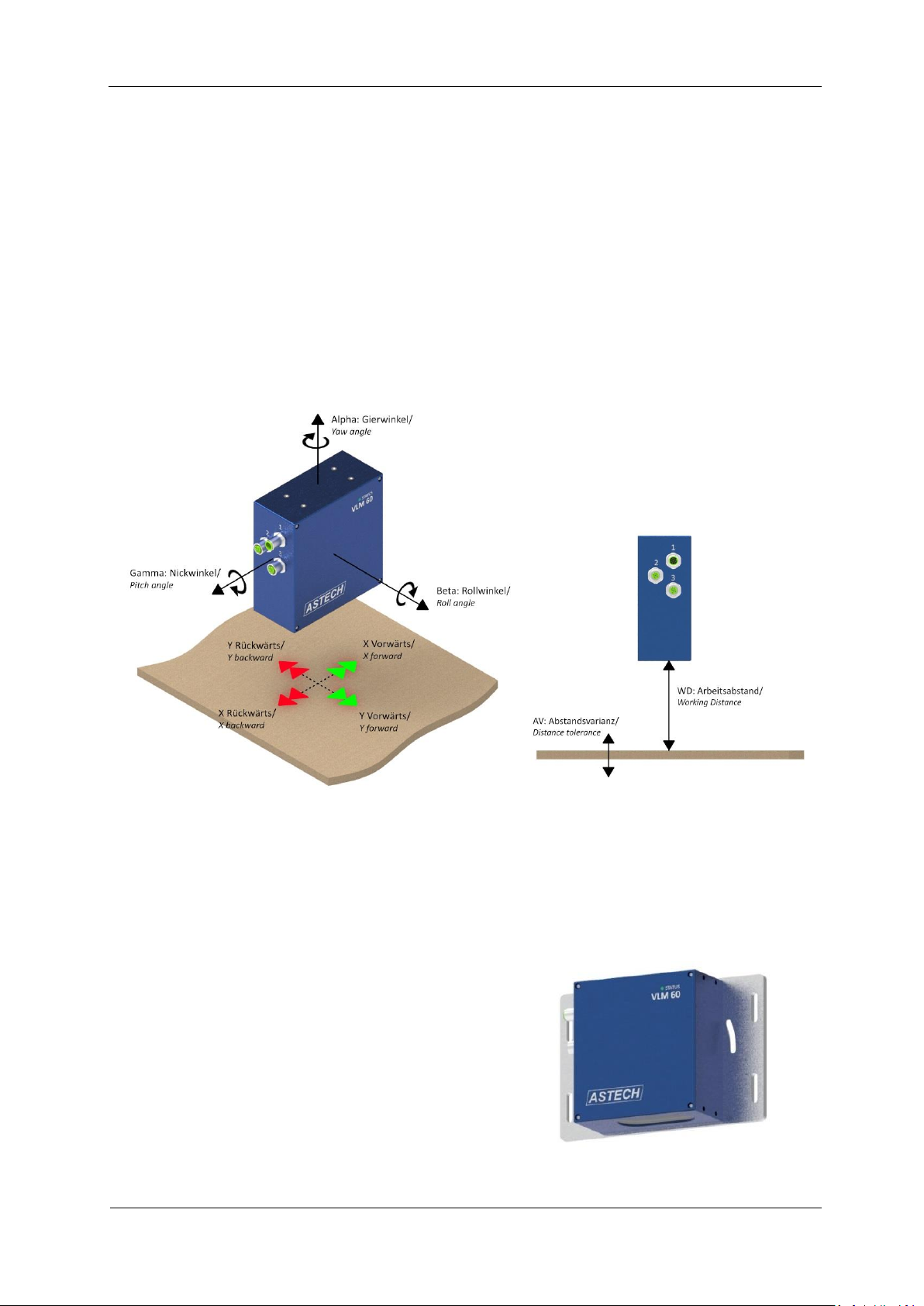

Figure 1: Structure of a VLM60 ............................................................................................................................... 4

Figure 2: Mounting orientation of the VLM60 ........................................................................................................ 5

Figure 3: Working distance of the VLM60............................................................................................................... 5

Figure 4: VLM60 with mounting plate..................................................................................................................... 5

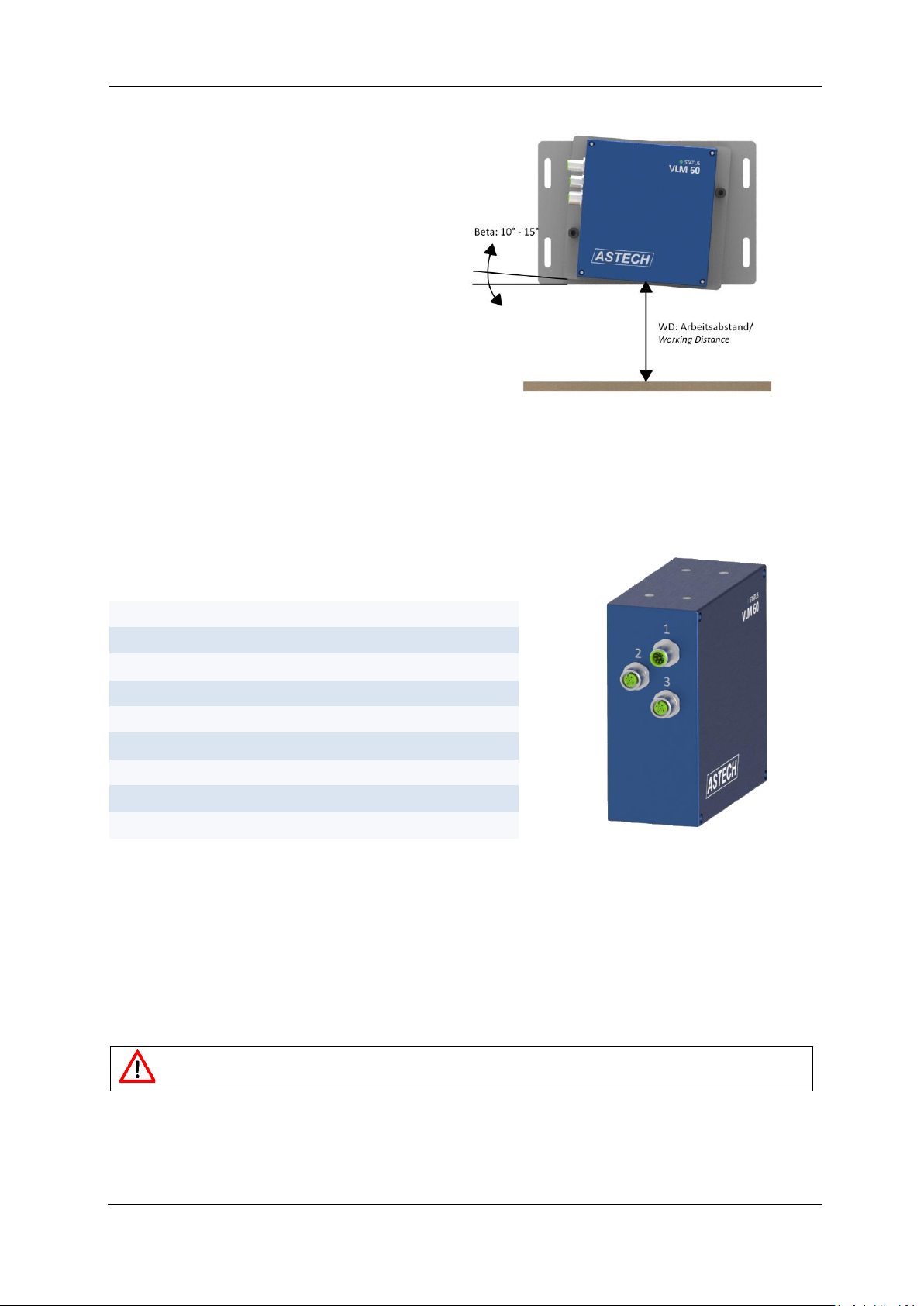

Figure 5: VLM60 with rotating plate ....................................................................................................................... 6

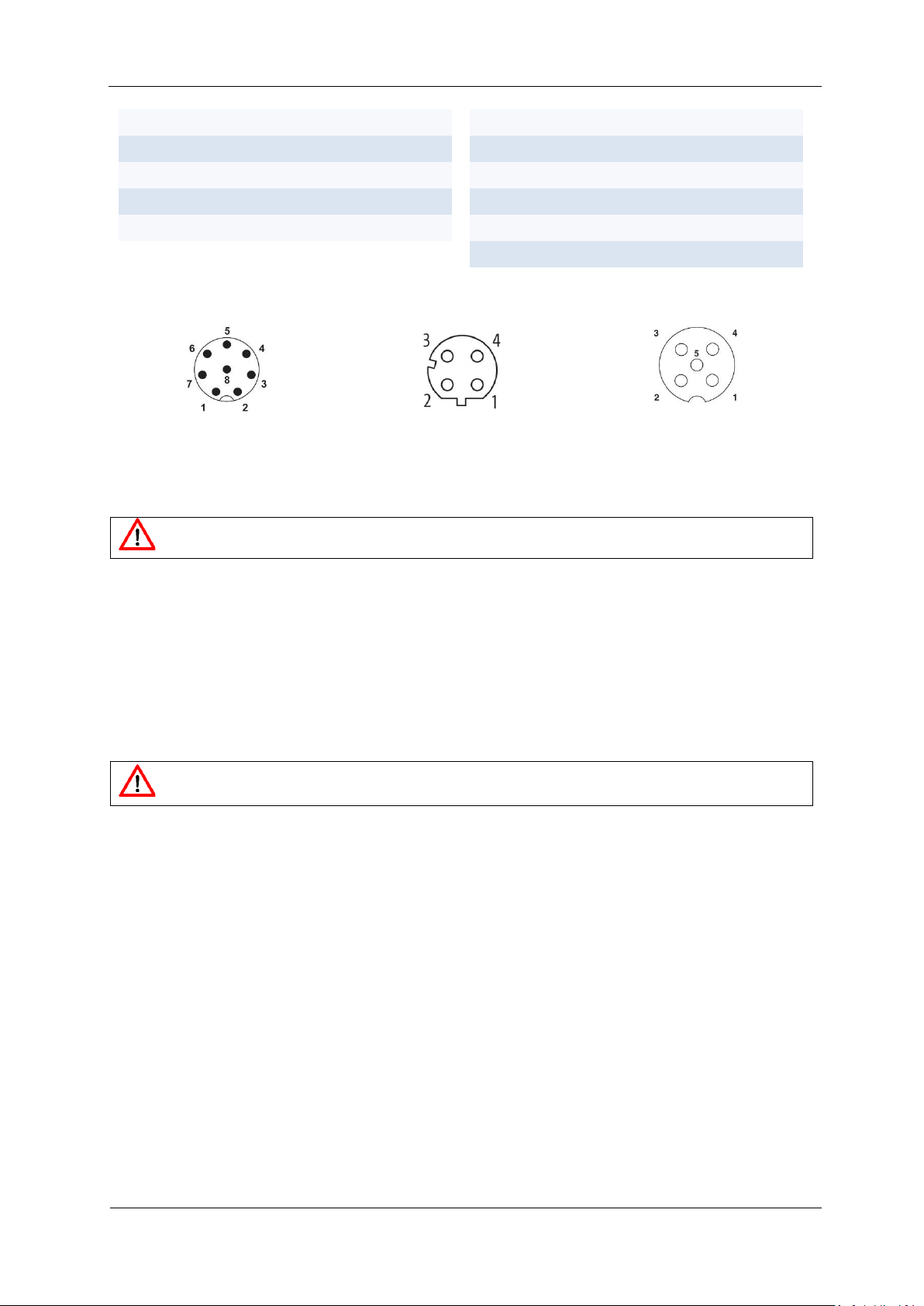

Figure 6: Connections.............................................................................................................................................. 6

Figure 7: Pin arrangement of the connections, seen from device side................................................................... 7

Figure 8: Pulse sequence of the encoder interface................................................................................................. 8

Figure 9: VLMTool ................................................................................................................................................. 11

Figure 10: Housing dimensions ............................................................................................................................. 28

Figure 11: Mounting dimensions .......................................................................................................................... 28

III. List of tables

Table 1: Configuration of connection 1................................................................................................................... 6

Table 2: Configuration of connection 2................................................................................................................... 7

Table 3: Configuration of connection 3................................................................................................................... 7

Table 4: Light conditions of the signal LED.............................................................................................................. 9