© ASTRALPOOL 2016 ALL RIGHTS RESERVED. PROPRIETARY DOCUMENT.

1. INTRODUCTION TO MODBUS AND PRODUCT

Thank you very much for purchasing the Compact electric heater with MODBUS-RTU features. This

manual is intended for professional installer, if you are not, please consult to your official distributor.

MODBUS is an open field bus successfully used through the world to connect field devices to a main

controller. This is the reason why MODBUS has been our choice to offer to our customers and partners

an automated solution easy to integrate not only with our brand products but also with a vast

collection of third party components and controllers.

MODBUS, MODBUS-RTU and other related names are registered trademarks of MODBUS Organization.

Further information and documentation can be found at http://www.MODBUS.org/

1.1. PRINCIPLE OF OPERATION

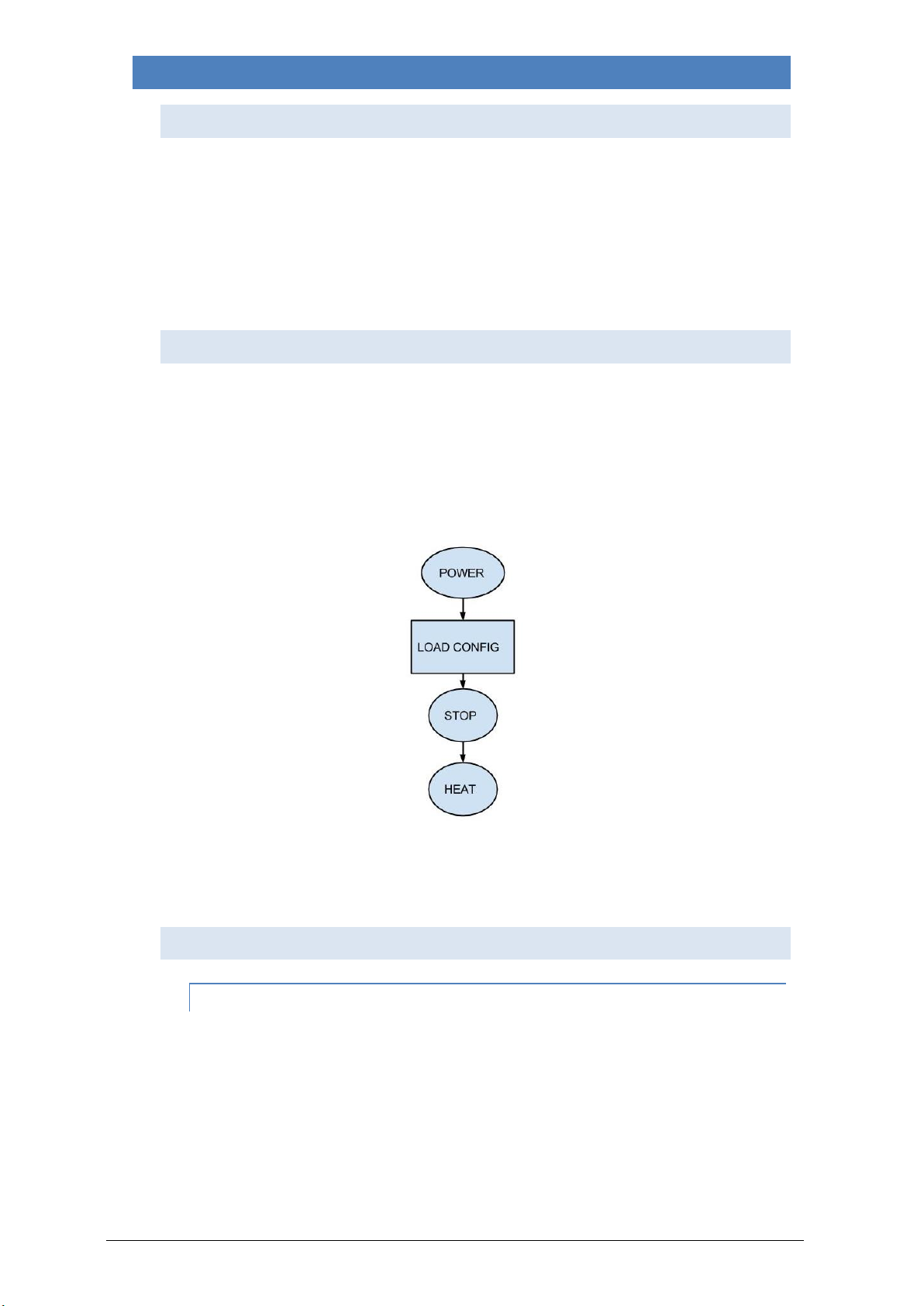

The Compact Heater implements MODBUS-RTU as a control-communications feature that allows its

operation and supervision tasks from a MODBUS automation environment. Preventive maintenance

and fault analysis is also possible thanks to the implementation of internal registers in the Compact

Heater with the more relevant operational and error events.

Whenever the Compact Heater is installed, you are not forced to connect it to a MODBUS system, as

far as you do not aim to control or supervise it externally. The Compact Heater can run in local mode,

as traditionally done, without using the MODBUS layer.

However, we expect that the implementation of MODBUS-RTU in the Compact Heater will open to our

advanced customers and partners a wide range of new opportunities and implementation scenarios

thanks to the simplicity and flexibility of the MODBUS-RTU layer.

Using a MODBUS-RTU message, the Compact Heater can report errors, historical data and so on, giving

to the user/installer a wide range of new features based in the automation of an already existing and

proved Compact Electric Heater.

1.2. BASIC CHARACTERISTICS

The MODBUS communication system provides a Master/Slave implementation among devices sharing

a physical connection. For the Compact Heater, the physical connection is a RS485 half-duplex serial

layer, which has been chosen among other options due to its wide implementation and roughness.

For the Compact Heater, a RS-485 half duplex wired connection has been implemented and the

Compact Electric Heater is designed to run in a single-master system. In this implementation, Master

and Slave figures has a clear role that is crucial to clear understand for a proper system

implementation.

Master Device: Device that controls the data exchange in the bus and, if necessary, implements co-

ordination tasks among different slaves (i.e. PLC Programmable Logic Controller, SCADA, etc.).

Slave Device: Devices connected to the bus that attends to the requests from the master, either

reporting information or executing tasks as per Master request.