02

Flex Head Reversible HD Cut Off Tool408

INTENDED USE OF THE TOOL

The 408 cut off tool is designed to be used with standard 3" cut-off wheels that are meant for

16,000rpm or above to cut sheet metals and other thin metal materials. Do not use this tool outside of

the designed intent. Never modify the tool for any other purpose or use.

BEFORE USE

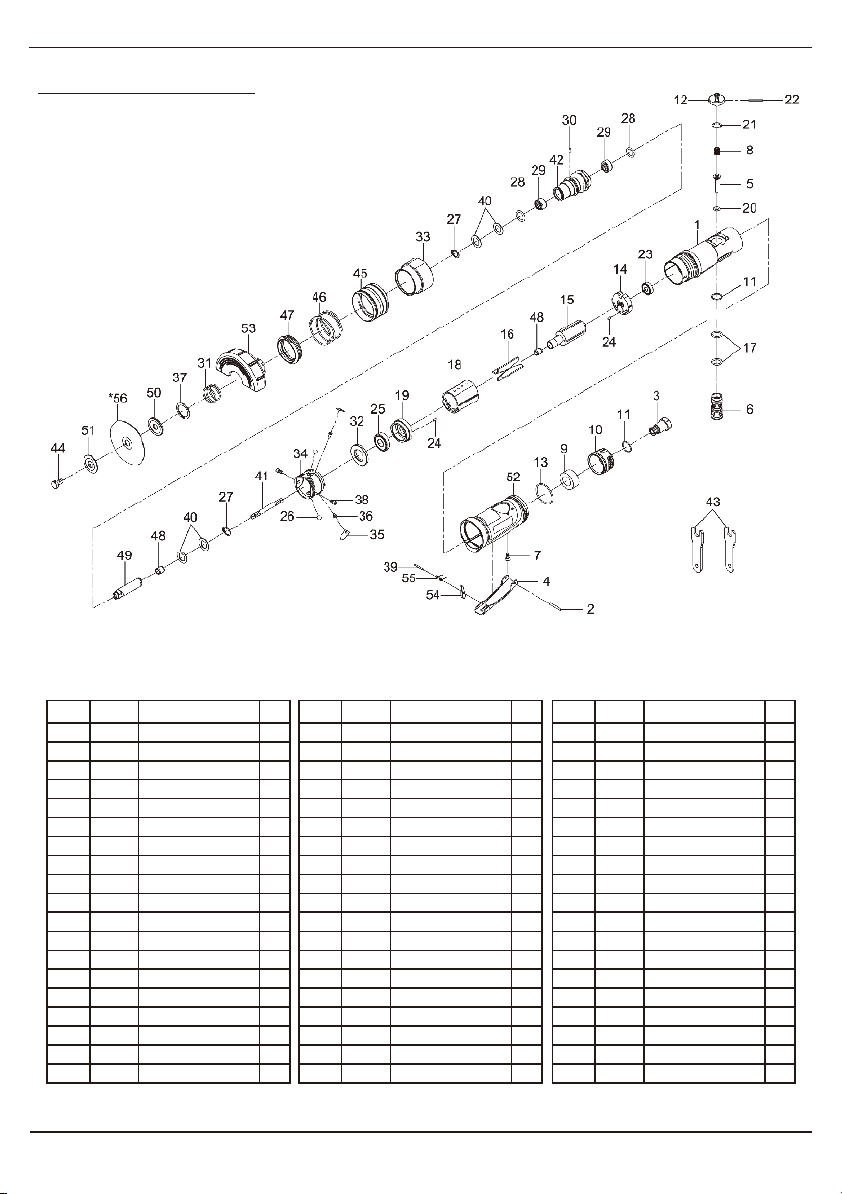

Before use, check the parts diagram and part number listing on page 6 to make sure all parts are

included. If any parts are missing or damaged, please call your distributor.

SPECIFICATIONS:

PRODUCT INFORMATION

• Flex-head design allows for setting the

tool 25° forward or backward for

clearance

• Forward and reverse dial, you choose

where the sparks are thrown

• 0.8 horsepower motor, designed for full

throttle heavy-duty applications

CAUTION: TO HELP PREVENT PERSONAL INJURY.

• Use of this product can expose you to chemicals including ethylene glycol, gasoline vapors and

engine exhaust, which are known to the State of California to cause cancer, birth defects, or

reproductive harm. For more information, visit www.P65Warnings.ca.gov. Always wear ANSI

approved safety equipment, safety glasses and clothing when using this product.

Study, understand, and follow all instructions provided with this product. Failure to read and follow

all warnings and operating instructions may result in damages and serious injury or death.

• Always wear ANSI approved goggles when using this product. (Users and Bystanders).

• Never use this tool for any application other than for which it was designed.

• Only use accessories designed for this tool.

• Never alter or modify this tool in any way.

• Improper operation and/or maintenance of the tool, modification of the tool, or use of the tool with

accessories not designed for it could result in serious injury or death.

• Always select the correct accessories of the correct size and design for the job that you are

attempting to perform.

• Always work in a clean, safe, well-lit, organized and adequately equipped area.

• Do not begin repairs without assurance that vehicle is in secure position, and will not move during repair.

• Users of this tool should review the chemical composition of the work surface and any products used

in conjunction with this tool for any such chemicals prior to engaging in any activity that creates dust

and/or microscopic particles.

• Users should obtain the Material Safety Data Sheets for all identified chemicals, either from the

manufacturer or their employer, and proceed to study, understand, and follow all instructions and

warnings for exposure to such chemicals.

• Some examples of these chemicals are: lead from lead based paints; crystalline silica from bricks,

cement and other masonry products; and arsenic and chromium from chemically treated lumber. A

listing of the chemicals can be obtained at www.oehha.ca.gov under Propoisition 65.

• In order to reduce their exposure to such chemicals, users should always:

- work in well-ventilated areas.

WARNING

- wear appropriate safety equipment and clothes that are

specifically designed to filter out microscopic particles.

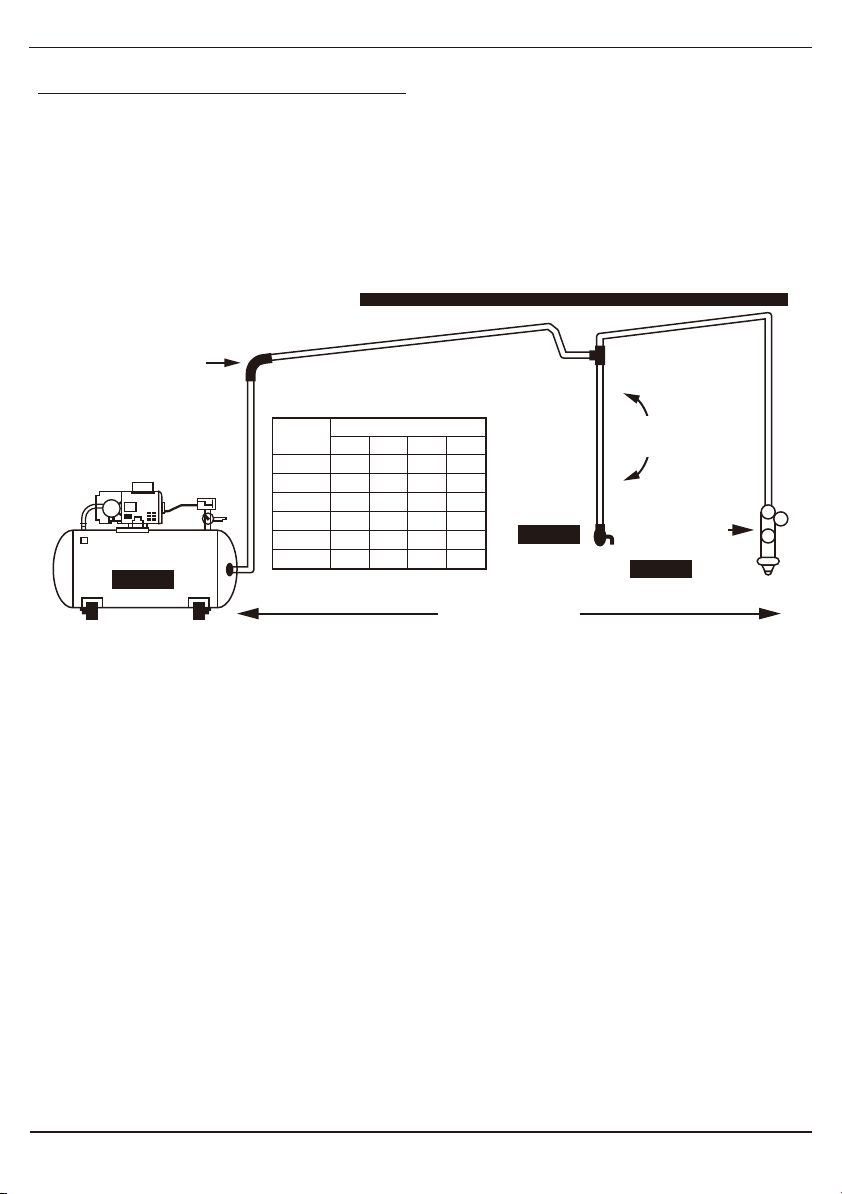

Wheel Size: 3" (75mm)

Free Speed: 16,000 RPM

Overall Length: 9.6" (243.84 mm)

Net Weight: 2.9 lbs. (1.315 kgs)

Air Consumption: 5.3 CFM

Power: 0.8 HP

Air Inlet Thread NPT: 1/4"

Air Pressure: 90 PSI (6.2 Bar)