1

CONTENTS

1. Precautions for Use···································································································2

2. Refractive Index and Brix(%)·····················································································7

(1)What is refractometer?················································································································ 7

(2)What is the Refractive Index? ····································································································· 7

(3)Brix(%) scale ······························································································································· 7

(4)Temperature correction··············································································································· 7

3. Unpacking and Installation························································································8

(1) Unpacking··································································································································· 8

(2)Installation···································································································································· 8

4. Names and Functions of Components······································································9

(1)Detection Section (Fig. 4-1 and Fig. 4-2)···················································································· 9

(2)Display Section·························································································································· 10

5. Mounting the Detection Section ··············································································12

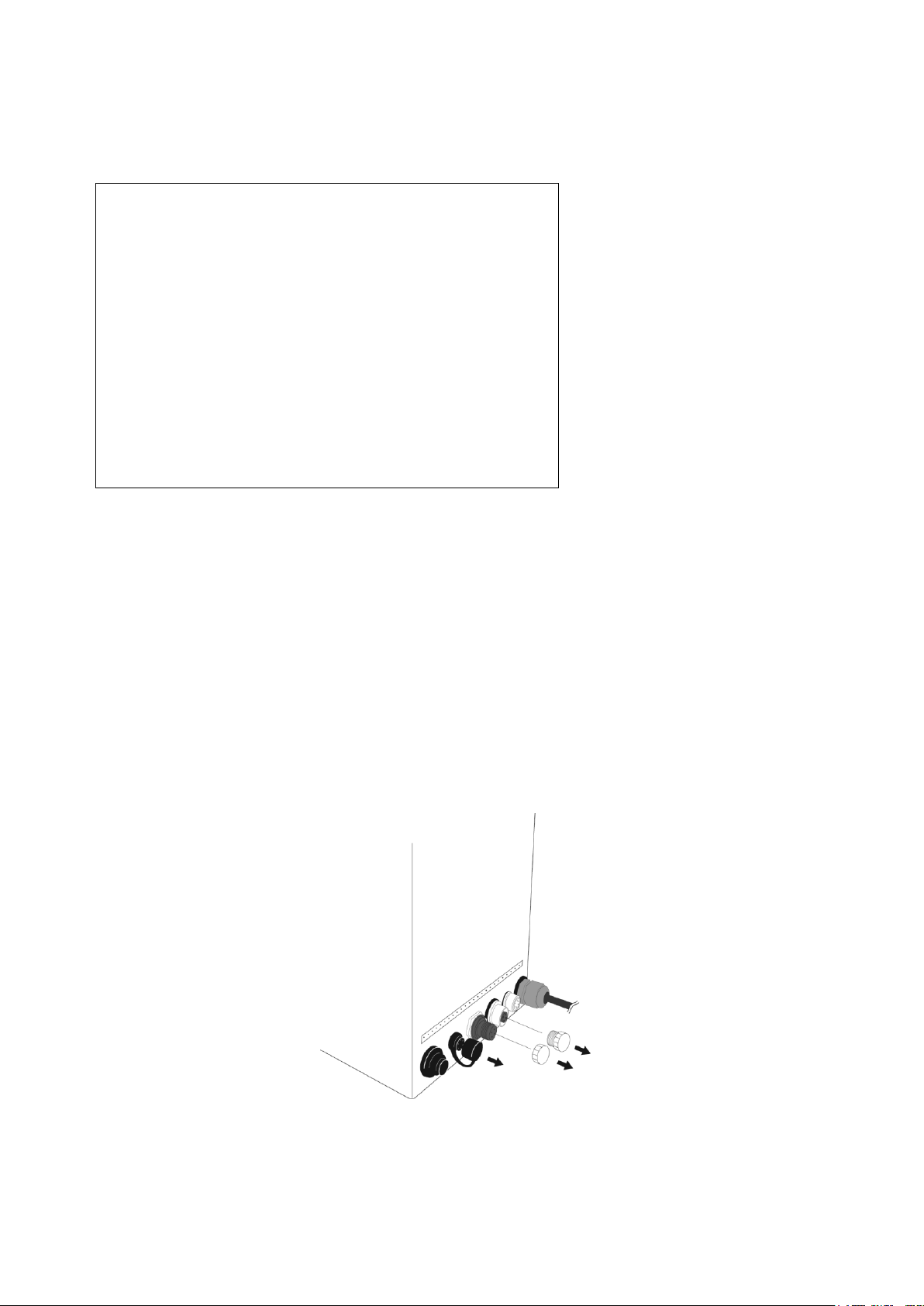

(1)Types of Sample Inlet Unit (Fig. 5-1) ························································································ 12

(2)Mounting the Sample Inlet Unit (Fig. 5-2)················································································· 13

(3) Mounting on the Piping (main) (in the case of L type)····························································· 14

(4) Mounting on the Piping (main) (in the case of straight type)··················································· 14

(5) Position of the thermo sensor ·································································································· 14

6. Mounting the Display Section··················································································15

7. Connecting the Detection Section to the Display Section·······································17

8. External Output ·······································································································19

(1)Recorder Output (Fig. 8-2 and Fig. 8-3) ··················································································· 19

(2)RS-232C Output························································································································ 20

(3) Alarm Output (high- and low-limiter output)············································································· 21

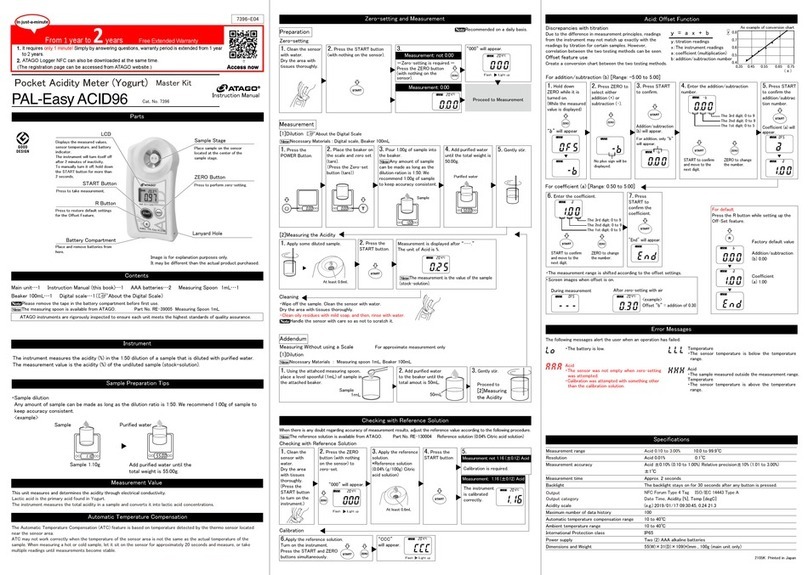

9. Turning On the Power·····························································································22

10. Setting Measurement Value Display Modes····························································23

(1) Common Operation·················································································································· 23

(2) Change from nD Mode to Brix ·································································································23

(3) Change from Brix Mode to nD ·································································································24

(4) Change from Brix Mode to Conc ····························································································· 24

(5) Confirmation of Measurement Values at Each Mode ····························································· 25

11. Setting Measurement SET UP Mode······································································26

(1) Calibration Procedure··············································································································· 26

(2) Setting alarms··························································································································· 28

(3) Setting recorder output············································································································· 29

(4) Setting Conc (User Scale)········································································································ 30

(5) Setting Decimal Place ·············································································································· 44

(6) Scale ON/OFF Set-Up ············································································································· 45

12. Measurement Procedure·························································································47

13. Cleaning the Prism··································································································48

14. Definitions of Error Messages·················································································49

15. Availability of Parts··································································································50

16. Specifications ··········································································································51

17. Dimensions··············································································································52

18. Repair Service and Warranty Period·······································································53

19. ATAGO CO.,LTD. Service Centers··········································································54