2

Inhoud

Notice, installation and troubleshooting.................................................................................................1

Introduction......................................................................................................................................................4

General safety rules .....................................................................................................................................4

Device description and important notices...................................................................................................5

Getting started .................................................................................................................................................6

What is needed for operation......................................................................................................................6

Mounting the device....................................................................................................................................6

Device settings .............................................................................................................................................8

Checking functions.......................................................................................................................................9

Device setup ...................................................................................................................................................10

Setup using web interface..........................................................................................................................10

General ......................................................................................................................................... 11

Network ........................................................................................................................................ 11

Alarm limits................................................................................................................................... 12

Channels ....................................................................................................................................... 13

SOAP protocol............................................................................................................................... 13

Email ............................................................................................................................................. 14

Modbus a Syslog protocols........................................................................................................... 15

SNMP ............................................................................................................................................ 15

Time .............................................................................................................................................. 15

WWW and security....................................................................................................................... 16

Setup using TSensor software....................................................................................................................16

Factory defaults .........................................................................................................................................17

Communication protocols..............................................................................................................................19

Website ......................................................................................................................................................19

SMTP –sending e-mails .............................................................................................................................19

SNMP 19

Modbus TCP ...............................................................................................................................................20

SOAP 22

Syslog 24

SNTP 24

Troubleshooting .............................................................................................................................................25

I forgot the device IP address ....................................................................................................................25

I cannot connect to the device...................................................................................................................25

In search window is only IP and MAC address displayed ............................................................. 25

Device IP address is not displayed in window Find device........................................................... 25

The device is not found even after manually setting MAC address......................................... 25

Error or n/a is displayed instead the measured value...............................................................................25

Error2 is displayed on all channels instead the measured value...............................................................26

I forgot the password for setup .................................................................................................................26

Factory defaults .........................................................................................................................................26

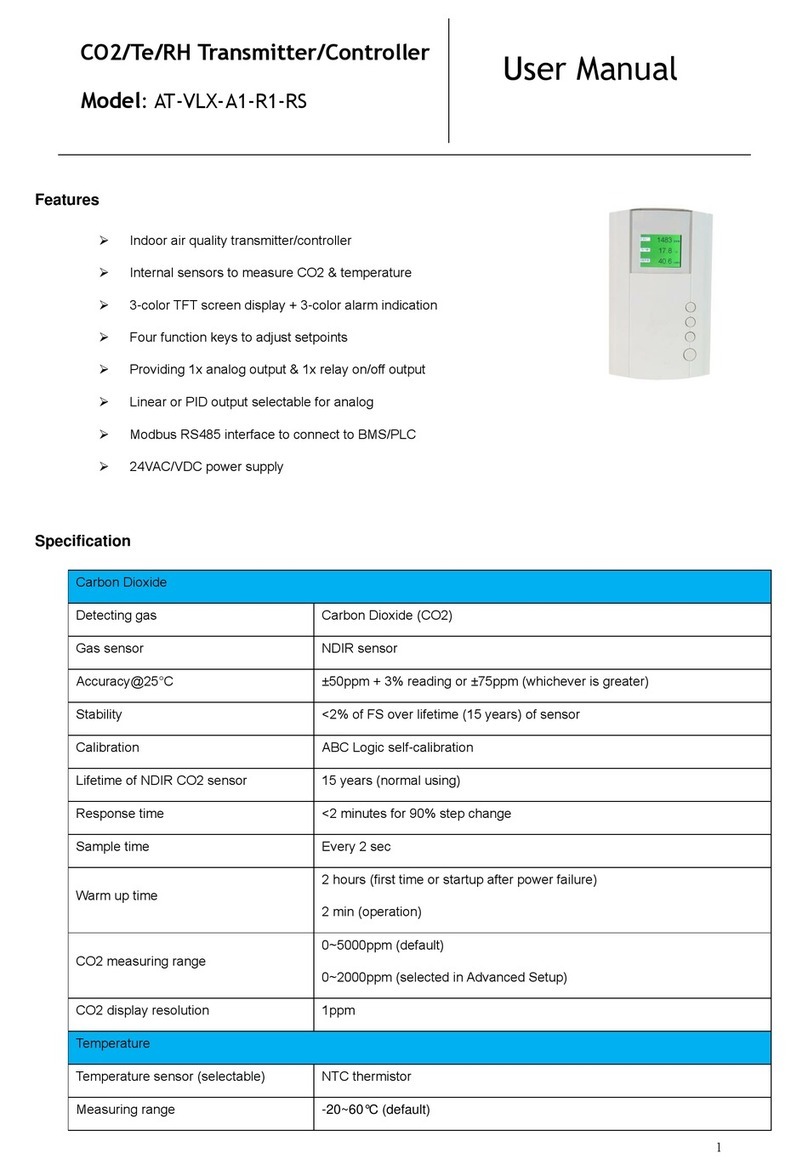

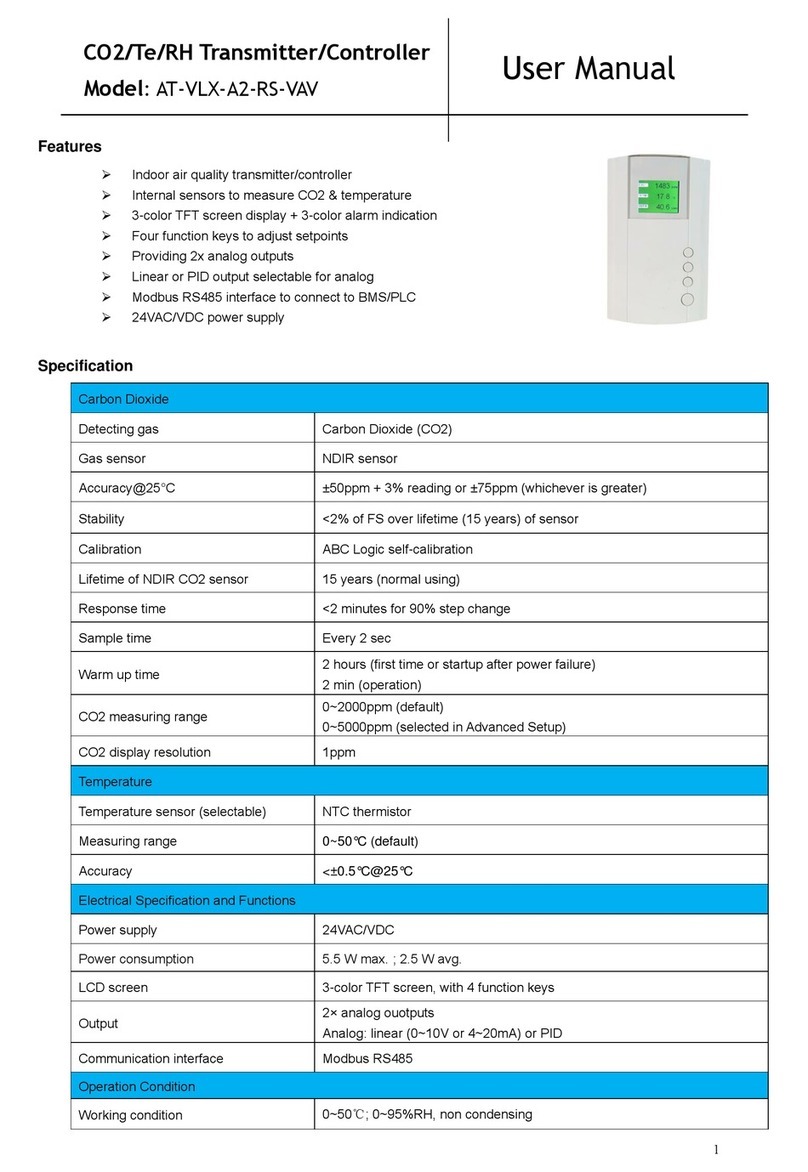

Technical specifications..................................................................................................................................27

Dimensions.................................................................................................................................................27

Basic parameters........................................................................................................................................28

Operating terms.........................................................................................................................................30

End of operation ........................................................................................................................................30

Technical support and service....................................................................................................................30

Preventive maintenance ............................................................................................................................31