temperature unit: °C

pressure unit: hPa

correction for altitude: 0 hPa(absolute pressure)

preset computed value: dew point temperature

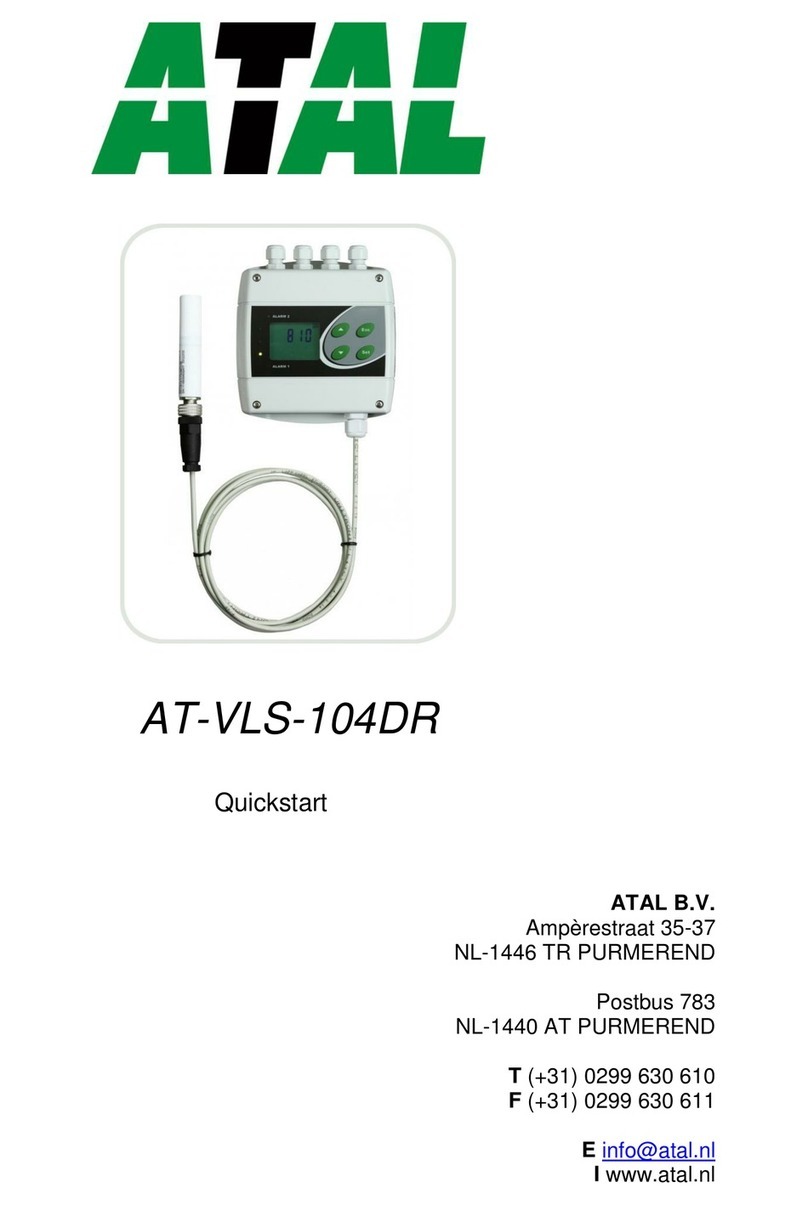

Device installation

Devices are designed for indoor applications. It is recommended to mount them on universal

wiring box (common installation box KU68) with using two enclosed mounting screws. For correct

function there is necessary to find proper device place. It shouldn’t be placed at places where it can

be affected by sunshine, near radiators, heating elements and other heat sources, air handlers,

windows, doors, into racks and shelves and similar places. For buildings with less thermal

insulation there is not suitable to place them on external walls of building. If there are

communication conductors placed into conduit, there is strongly recommended make it caulk, to

restrict air flow around device.

Connect cables to terminals with respecting the signal polarity (see figure). Terminals are

self-clamping and can be opened by a suitable screwdriver. For the opening, insert the screwdriver

to upper terminal hole and lever by him.

There are two ways, how to power devices with RS232 interface. They can be powered

either from master device or from external power source. For powering from master device RS232

interface there is necessary to interconnect DTR and RTS signals with the device. For powering

from external power source, there is necessary to connect positive power terminal to DTR into

device terminal only and then do NOT interconnect DTR and RTS with master device.

Devices with RS232 interface:

Termina

l

Connect to

GND Shielding, power source ground

Tx Output data for master device, transmit

Rx Input data from master device, receive

RTS Connect with RTS signal to master device, eventually o not connect

DTR Connect with DTR signal to master device or connect positive power terminal from

external power source

Devices with RS485 interface contain “doubled” connection terminals to provide continuous

connection of next RS485 devices. Terminals description:

Terminal Connect to

A+, B- RS485 communication line

Shielding of communication line

+U, GND Power source positive terminal, power source ground

For devices with RS485 interface here is recommended to use shielded twisted copper cable

(e.g. SYKFY), maximal length 1200m. The cable must be located at indoor rooms.

Nominal cable impedance should be 100 Ω, loop resistance max. 240 Ω, cable capacity

max. 65 pF/m. Suitable cable is e.g. SYKFY 2x2x0.5 mm2, where one wire pair serves for the

device powering and the other pair for communication link.

The cable should be led in one line, i.e. NOT to „tree“ or „star“. Termination resistor should

be located at the end. For short distance other topology is allowed. Terminate the network by a

termination resistor. The value of the resistor is recommended about 120 Ω. For short distance

termination resistor can be left out. The cable should not be led in parallel along power cabling.

Safety distance is up to 0.5 m, otherwise undesirable induction of interference signals can appear.

3