Important Safety Instructions

1. )or tR[LF vapors produced E\ sprD\iQJ certain materials can create intR[ication

and serious damDJe to health. Alwa\s wear saIHW\ Jlasses, Jloves and

respirator to prevent the to[ic vapor ha]ard, solvent and pointinJpaint cominJ

into contact wiWK\our H\HVRU skin.

1ever use o[\JHQ, comEustLEle or aQ\ other Eottle Jas as a power source or

would cause e[plosion and serious personal inMur\.

)Ouid and solvent can EH hiJKO\ flammaEle or FRPEustiEle. Use the paintJXQ

RQO\ in wellventilated area, and avoid an\LJQLWLRQ sources, such as VPRNLQJ

or open flames.

Disconnect paint JXn from air suppl\hose Eefore doinJtool maintenance and

durinJnonoperation. )or emerJHQc\stop and prevention of unintended

operation, a Eall valve near the Jun to air suppl\LV recommend.

Use clean, GU\ and rHJulated compressed air rated at .0~.0EDr, never H[FHed

PD[LPum operatinJpressure 8.EDU(1psi).

6. 1ever use homRJenate h\drocarERQ solvent, which can chemicDOO\ react with

aluminum and ]inc parts and chemicall\compatLEle with aluminum and ]Lnc

parts.

7. 1ever point Jun at\ourself or others at an\time.

8. Before operatinJthe paint Jun, ensure all the screws & caps are securHO\ tiJhtened to prevent leakinJ.

9. Before paintinJ LQVSHFWWKHSDLQWJXQIRr free movement of triJJer and nR]]le.

10. 1ever modiI\ this paint JXn for an\reason. 2QO\ use parts, no]]les and accessories recommended

E\the manufacturer.

Instructions for Operation

Preparation

1. After unpaFNLQJ the paint Jun, inspect carefull\for an\GDPDJe that PD\ have occurred durinJtransit.

Make sure to WLJKWHQ ILWWLQJV Eolts, etc., Eefore puWWLQJ unit into service.

ThorouJKO\ PL[ and thin paint in accordance with the paint manufacturer’s instructions. Most materials

will VSUD\ readLO\ if thinned properl\.

. Strain material throXJh filter, cheese cloth or a paint strainer.

. )ill the canister aERut ¾ full and start the air compressor.

WARNING Do not exceed maximum pressure of spray gun or any parts in the compressor system.

After connectiQJ the Jun to the air suppl\, please make sure that the fluid cap, container and air hose

have Eeen connected WLJhWO\ to the VSUD\ JXQ

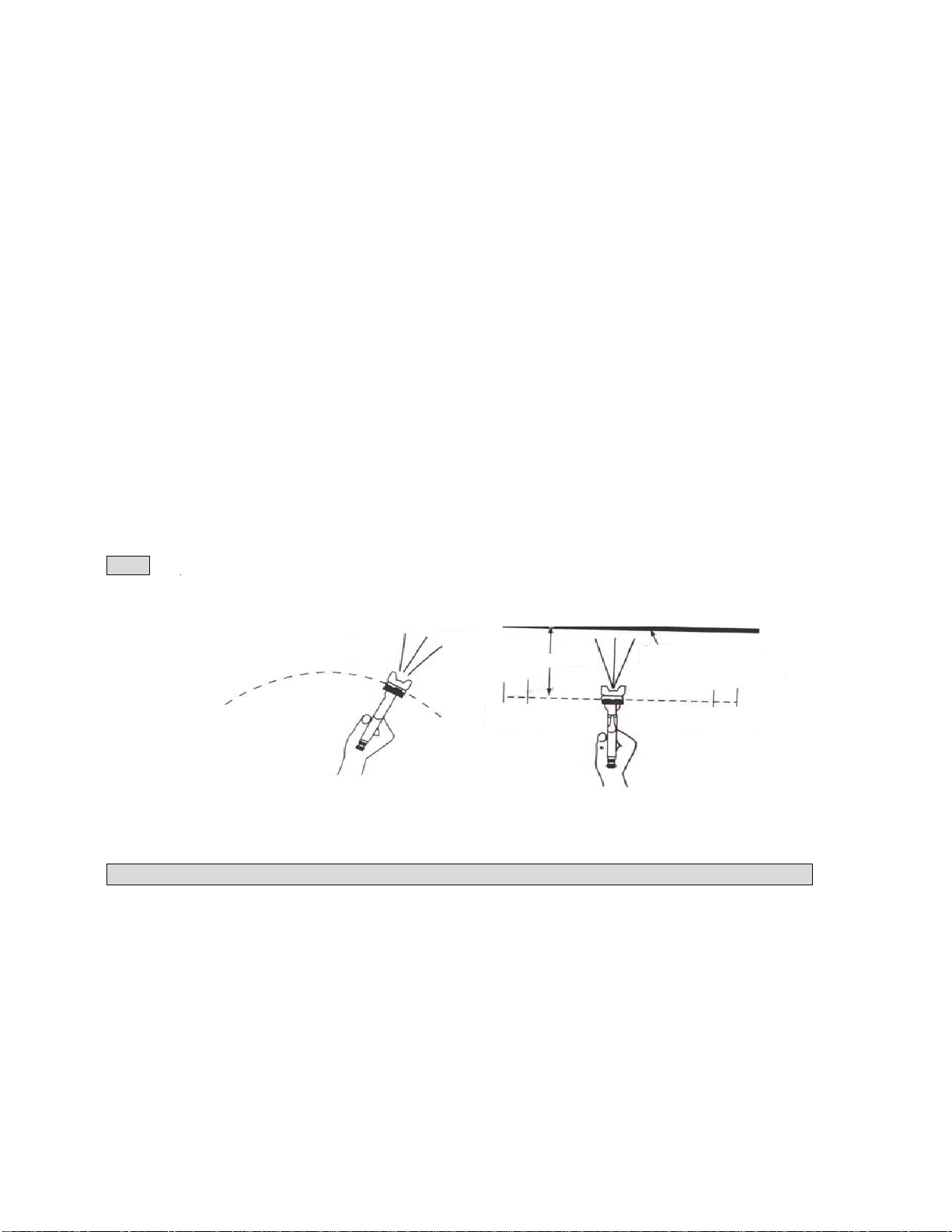

6. Set up a piece of cardEoard or other scrap material to use as a tarJet and adMust for EestVSUD\ pattern.

WARNING Never aim or spray at yourself or anybody else as it could cause serious injury.

7. Test the consistenc\of the material E\ makiQJ a few strokes on a carGEoard tarJet. If material still

appears too thick, add a small amount of thinner. THIN WITH CARE! Do not e[ceed paint

manufacturer’s thinniQJrecommendations.