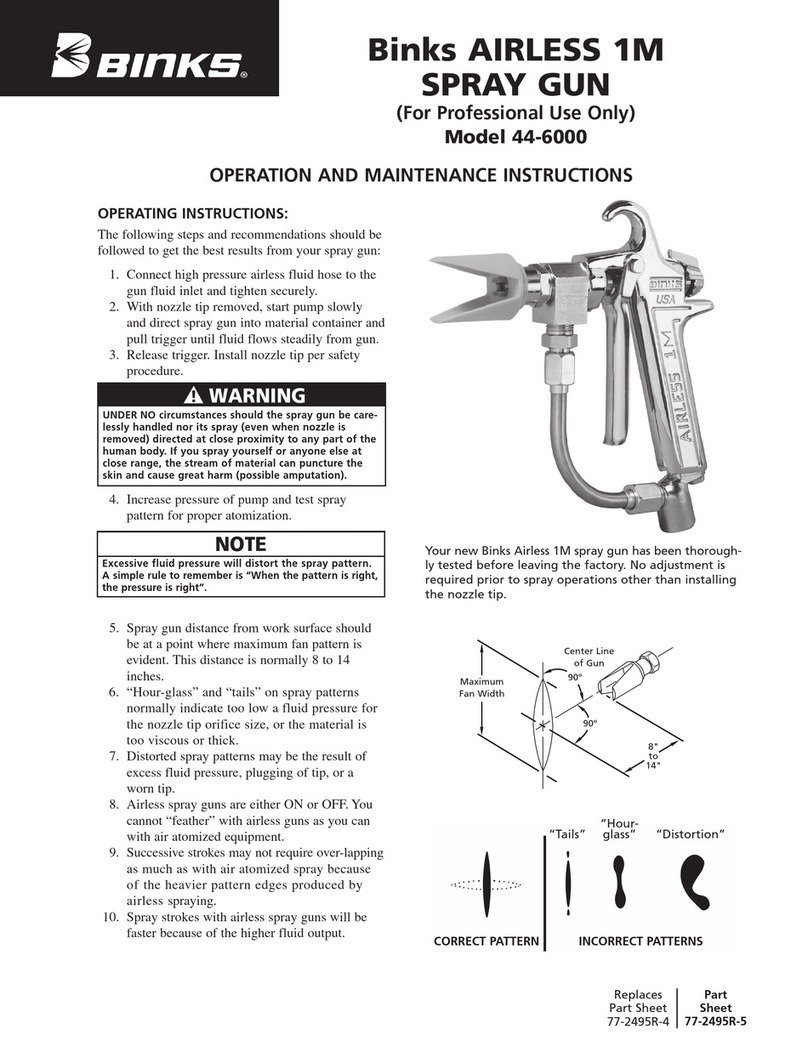

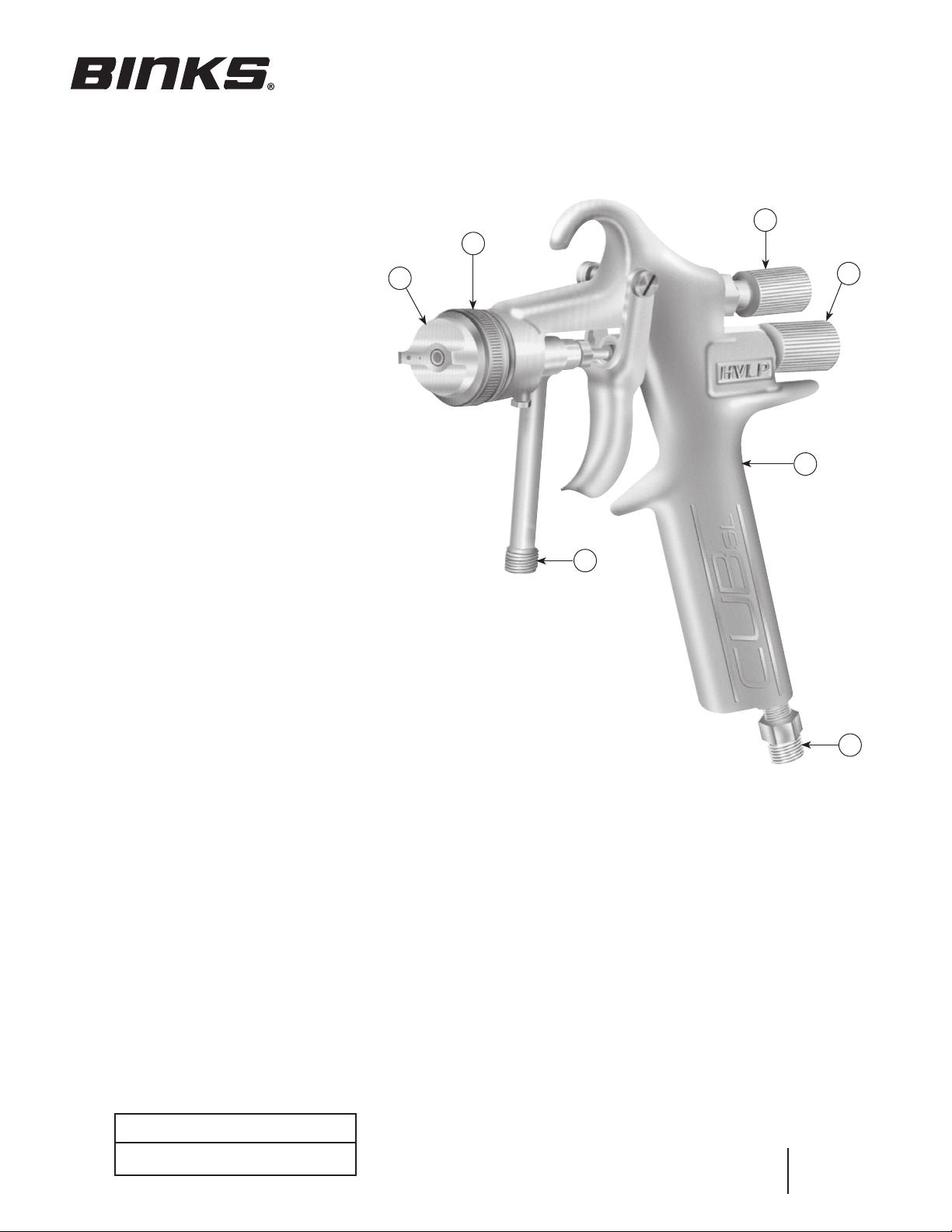

Your new Binks Mach 1 Cub SL HVLP

gun is exceptionally rugged in con-

struction and is built to stand up under

hard, continuous use. However, like any

other precision instrument. its most

efficient operation depends on a knowl-

edge of its construction, operation and

maintenance. Properly handled and

cared for, it will produce beautiful,

uniform finishes long after other spray

guns are worn out.

The Mach 1 Cub SL gun can be used in

three modes: siphon feed, pressure

assist, or pressure feed tank hook-ups.

In siphon mode, lowered air pressure in

the gun draws fluid from the cup into

the gun. The pressure assist function

works when air flows through the cup’s

check valve assembly, pressurizing the

liquid in the cup and and forcing it up

into the gun. Pressure feed modes for

tanks rely on systems that separately

regulate fluid and air flow. Instructions

for assembling the gun with either the

siphon cup or pressure assist cup are

included here and also with the cup

assemblies. Below are brief descrip-

tions and illustrations of the siphon

feed, the pressure assist, and the

pressure feed tank hook-ups.

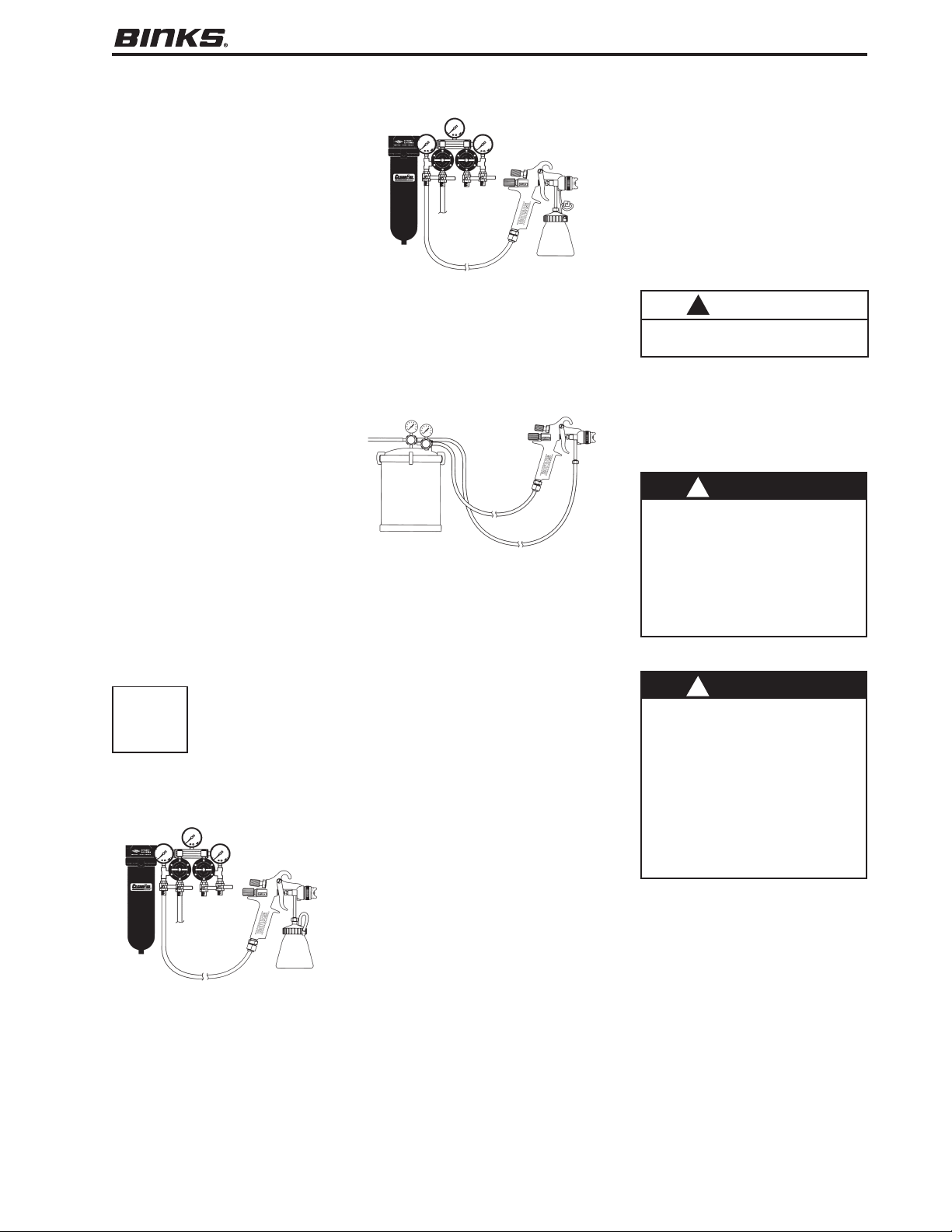

SIPHON FEED CUP HOOK-UP

Air pressure for atomization is regulat-

ed at extractor. The amount of fluid is

adjusted by fluid control knob on gun,

viscosity of paint, and air pressure.

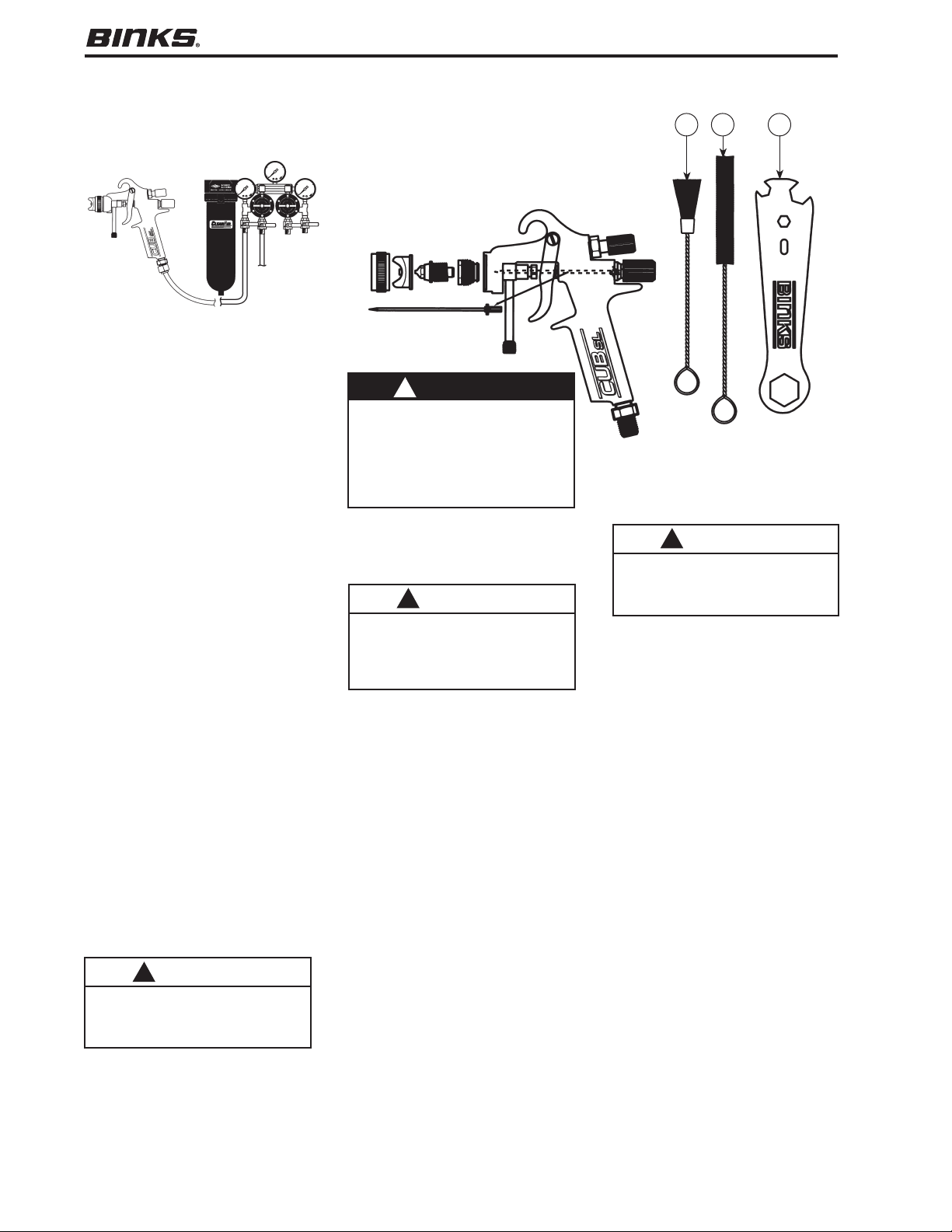

PRESSURE ASSIST CUP HOOK-UP

Air pressure for atomization is regulated

at the extractor. The fluid pressure is

from the front of the gun, through check

valve to cup.

PRESSURE FEED TANK

HOOK-UPS

For portable painting operations, use

a double regulator pressure feed tank

hook-up. Air pressure for atomization

and for fluid supply is regulated by two

separate air regulators on tank. The Mach

1 Cub SL comes standard with a 40T

fluid nozzle to be used in siphon feed

operations, see note on page 7 regarding

nozzle options and materials use.

HOW TO SET UP YOUR GUN

FOR SIPHON APPLICATIONS

(See Cup Part Sheet for Parts

Identification)

1. Attach one end of vent tube to

connector on cup lid.

2. Push the other end of vent tube down

through loop on side of cup lip.

3. Insert the threaded fluid inlet into

the swivel nut, taking care to

position the vent tube away from

the gun trigger.

4. Rotate the swivel nut until tight to

attach the cup to the fluid inlet.

HOW TO SET UP YOUR GUN

FOR PRESSURE ASSIST

OPERATIONS

1. Screw the swivel nut onto the

threaded end of the fluid inlet.

2. Remove the 1/4" plug and gasket

from the gun.

3. Replace the plug and gasket with

the connector supplied with the cup

assembly.

4. Slip the longer end of the check

valve assembly over the gun connec-

tor and attach the shorter end to the

connector on the cup lid.

CONNECTING TO AIR HOSE

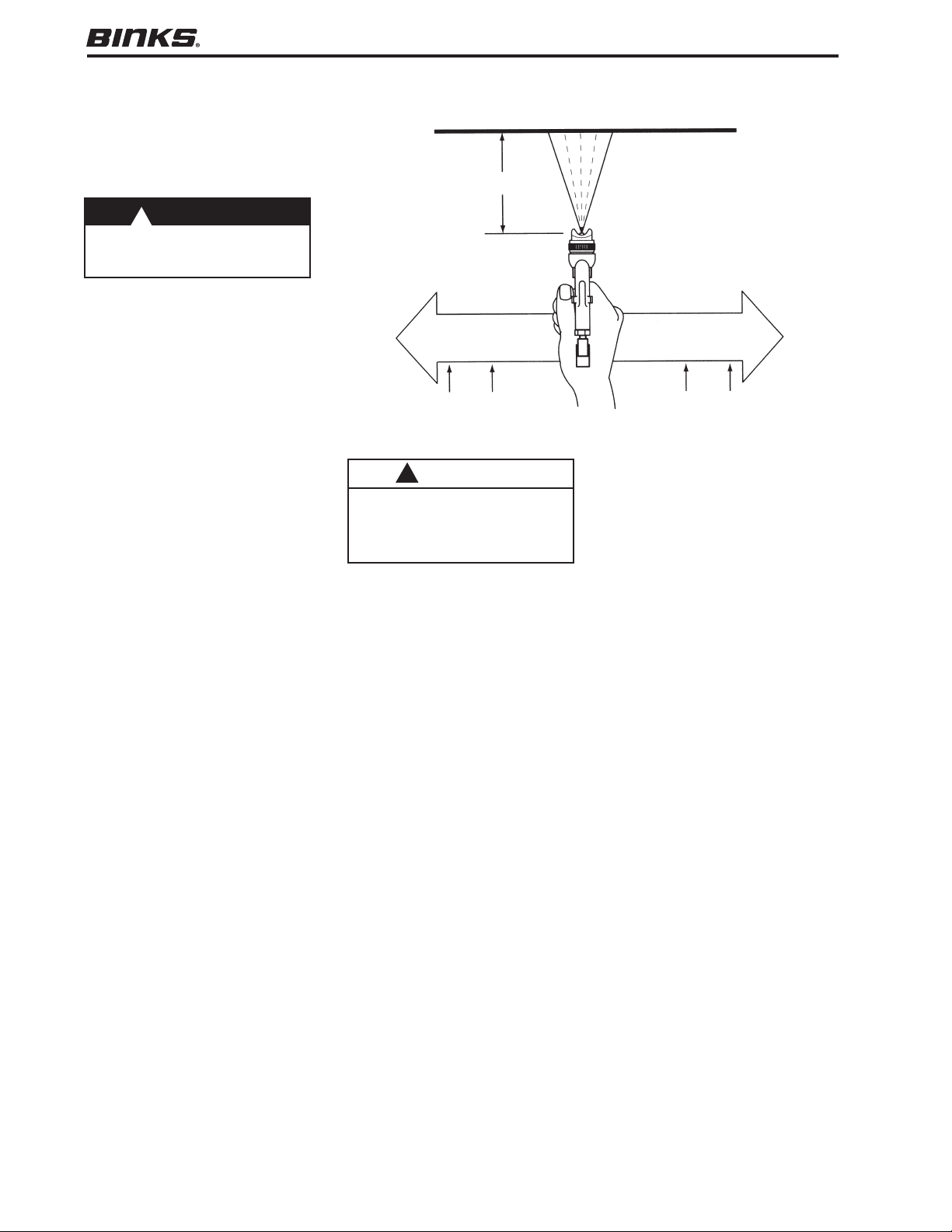

CONTROLLING FLUID FLOW

Air pressure for atomization is regulat-

ed at the extractor (see illustration pg.

4). The flow of fluid is adjusted by the

fluid control knob on the gun, and by

paint viscosity, air pressure, and nozzle

size. Nozzles with larger apertures give

higher flow rates. You can adjust fluid

flow by turning the fluid control knob.

Turn clockwise to restrict the needle

opening, counterclockwise to enlarge it.

3

HOW TO SET UP and OPERATE YOUR Binks Cub SL HVLP SPRAY GUN

CAUTION

Over-tightening connector will dam-

age its delicate threading.

!

WARNING

REGARDING AIR PRESSURE SAFETY

Shut off air pressure before connect-

ing or disconnecting air hose or

removing any components from the

gun. Air should be supplied by a suit-

able length of 1/4" diameter air hose

fitted with a 1/4" NPS(f) connector at

the gun end. For hose lengths over

25', use 5/16" diameter hose.

!

WARNING

REGARDING PAINTS, SOLVENTS AND

OTHER COATINGS SAFETY

Do not use open containers for stor-

age or disposal of paint, other coat-

ings, cloth, or paper used in

preparation and application. Many

paints and coatings contain volatile

chemicals that are a cause of pollu-

tion and are a health and fire hazard.

Always wear appropriate clothing,

including gloves, and eye protection,

and a respirator when using the gun.

!

CA PROP

65

PROP 65 WARNING

WARNING: This product

contains chemicals known

to the State of California to

cause cancer and birth

defects or other

reproductive harm.