atecpool AQUA METER User manual

AQUA METER

USER MANUAL

Contents

1

1Contents

1Contents 1

Table of Figures 2

2Introduction 3

Explanation of Safety Warnings 3

User Competence 4

3Safety and Responsibility 5

General Safety Warnings 5

Hazards arising from non-compliance to

safety instructions 6

Safe operation 6

Personal protective equipment 6

Personnel competence 6

4Appropriate and Desired Use 7

Notes about product warranty 7

Product Software 7

Principles 7

Foreseeable wrong use 7

4.4.1 Wrong assembly 7

4.4.2 Wrong installation 7

Wrong electrical wiring 7

5Product Description 8

Product Data 8

General Specifications 8

Electrical Features 8

Scope of Delivery 8

6Technical Data 9

7Dimensions 10

8Mechanical Installation 11

Wall Assembly 11

Panel Assembly 11

Sensor Assembly for each model 12

8.3.1 For CON Models 12

8.3.2 For ORP Models 12

8.3.3 For pH Models 12

9Electrical Installation 13

Plug Electrical Connection 13

Fixed Electrical Connection 13

Device Schema 14

Electrode Selection 15

9.4.1 Heat Sensor 15

9.4.2 Analogue Output 15

9.4.3 Digital Inputs 15

10 Operation 16

General Operation 16

Adjusting Device Output Control Mode 16

Parameters 17

10.3.1 Changing Parameter Value 17

Parameter List 18

Calibration 20

10.5.1 Calibration of pH and ORP Devices 20

Output Control Modes 22

Analogue Output Modes 23

Password Use 23

11 Maintenance / Malfunction Cases 24

Maintenance 24

Malfunction Cases 24

11.2.1 Electrical Malfunctions 24

12 Warranty / Standards 25

Warranty 25

Standards 25

Contents

2

Table of Figures

Figure 1 Front Side Device Size ......................... 10

Figure 2 Device Side Size .................................. 10

Figure 3 Device Rear Size.................................. 10

Figure 4 Wall Assembly ..................................... 11

Figure 5 Panel Assembly ................................... 11

Figure 6 For Con Models.................................... 12

Figure 7 For ORP Models ................................... 12

Figure 8 For pH Models...................................... 12

Figure 9 Plug Electrical Connection.................... 13

Figure 10 Fixed Electrical Connection ................ 13

Figure 11 Mainboard ......................................... 14

Figure 12 Mainboard AC input ........................... 14

Figure 13 Mainboard DC input ........................... 14

Figure 14 Heat Sensor ....................................... 15

Figure 15 NTC connection.................................. 15

Figure 16 pt100 connection............................... 15

Figure 17 Analogue Output ................................ 15

Figure 18 Jumper settings ................................. 15

Figure 19 Digital Inputs...................................... 15

Figure 20 Panel Tag........................................... 16

Figure 21 Adjusting Device Output Control Mode 16

Figure 22 Changing Paramater Value................. 17

Figure 23 Access to the calibration menu .......... 20

Figure 24 Single Point Calibration ...................... 20

Figure 25 Double Point Calibration ..................... 21

Figure 26 Calibration of Conductivity Device ...... 21

Introduction

3

2Introduction

Please read following information carefully and

completely. This information shall ensure that you

benefit from operating instructions at optimum

level.

These instructions define the functions of

technical data.

Explanation of Safety Warnings

These operating instructions give information

about the technical data and functions of the

product. And provide detailed safety information.

Safety warnings and notes are categorized as

below. Pictographs are used here as adapted for

different circumstances. These pictographs are only

for example.

DANGER!

Type and source of danger

Result: Death or severe injury.

Measures to be taken to prevent such danger.

Defines the danger that creates the threat

directly. Causes death or severe injury unless

prevented.

WARNING!

Type and source of danger

Possible Result: Death or severe injury.

Measures to be taken to prevent such danger.

Defines a possible dangerous situation. Causes

death or severe injury unless prevented.

CAUTION!

Type and source of danger

Possible Result: Light or insignificant

injuries. Material damage.

Measures to be taken to prevent such danger.

Defines a possible dangerous situation. Causes

light or insignificant injury unless prevented. Can

also be used for material damage warning.

NOTE!

Type and source of danger

Result: Causing damage to the product or

individuals.

Measures to be taken to prevent such danger.

Defines a possible damaging action. Causes

damage to the product or individuals unless

prevented.

INFORMATION!

Operational tips and additional information

Source of information. Additional measures.

Defines operational tips and other useful

information. Not given for a dangerous or

harmful situation.

Introduction

4

User Competence

WARNING!

Danger of injury in case of personnel incompetence!

Operator of device/facility is responsible for complying with competencies.

Incompetent personnel working with the device or keeping the device in danger zone might cause severe

injuries or material losses.

- All operations should be handled by competent personnel

- Keep away incompetent personnel from danger zones

Training

Description

Informed Person

Defines a person that has been informed about possible hazards in

case of unruly behaviors contrary to duties assigned, and informed

about relevant situations and informed about necessary protection

equipment and measures.

Trained User

Defines a person that meets the standards of an informed person and

plus trained by the manufacturer or another authorized sales partner

Trained Expert

Defines a person that can recognize possible hazards and evaluate the

duties assigned thanks to his/her knowledge of rules in addition to the

training, information and experience in that field. The activities based

on years of experience in that field can be taken into consideration

while assessing someone as an expert.

Electricity Expert

Defines a person that can work in electrical facilities, and recognize

and prevent possible dangers thanks to his/her knowledge of

regulations and standards in place in addition to the training,

information and experience.

Electricity experts should have received training on the field of work

and have knowledge on important standards and regulations.

Electricity expert should fulfill the provisions of legal regulations for

preventing accidents.

Customer Services

The service technicians that are trained and authorized for operations

in the facility by the manufacturer are described as customer services.

Safety and Responsibility

5

3Safety and Responsibility

General Safety Warnings

Following warnings are given for assisting you to

eliminate possible dangers that might arise while

using the product. Risk prevention measures are

always valid independent of any special action.

Safety instructions that give warning against certain

activities or situations are given in relevant sub-

sections.

DANGER

Life-threatening danger due to electric shock

Falsely wired, exposed or damaged cables might

injure you.

Replace damaged cables immediately.

Do not use extension cables.

Do not bury cables.

Fix cables to prevent damage to other

equipment.

DANGER

Do not use the product in explosive

environments.

WARNING

Causing damage to the product or individuals.

There is no on/off switch on the device

Device starts operating when powered after

connection to mains voltage.

Make sure that all screws are tightened and

sealed properly.

WARNING

Usage Error!

Possible Result: Death or severe injury.

Make sure that device is used only by

sufficiently qualified and competent personnel.

Operator is responsible for the competence

of personnel.

WARNING

Electronic Malfunctions!

Possible Result: Material damage that might

cause device to be damaged.

Device's electricity mains line shouldn't be set

up on installation with damaged data line.

Operator is responsible for taking appropriate

malfunction elimination measures.

CAUTION

Increased accident risk due to lack of

qualification on personnel side!

Product and accessories can only be mounted,

operated and maintained by staff with sufficient

qualifications.

Make sure that all actions are taken by personnel

with sufficient and appropriate qualifications.

Prevent access to system by unauthorized

persons.

CAUTION

Purpose Oriented Usage

Causing damage to the product or individuals.

Device has been designed to measure and

check liquids fluids.

This device can only be used in line with this

operating manual and technical data in operating

manuals and specifications of individual

components (such as Sensors, Dosing Pumps,

Calibration Tools, etc.)

CAUTION

Hassle-free Sensor Operation

Causing damage to the product or individuals.

Accurate measurement or dosing is only

possible with perfect sensors.

Pay attention to operating manuals of sensors.

Check and calibrate sensors regularly.

Safety and Responsibility

6

Hazards arising from non-

compliance to safety instructions

Non-compliance with safety instructions will bring

risks not only for the staff but also for environment

and the unit.

Here are some specific consequences:

Failure of vital functions in product and system.

Failure of necessary maintenance and repair

methods.

Safe operation

There are more safety rules in addition to the safety

instructions stated in this operating manual and

they should be followed:

Accident prevention regulations safety and

operating provisions

Safety measures for using dangerous items

Environmental protection provisions,

Applicable standards and legislation.

Personal protective equipment

You should use relevant protective equipment

depending on the type of work and degree of risk.

As minimum, following protective equipment is

provided:

Protective Protective Protective

Clothing Gloves Goggles

The operator should use protective equipment

during these tasks:

Assigning,

When device is working,

Demounting, maintenance works, disposal.

Personnel competence

Any staff member working on the device should

have specific knowledge and skills.

Anyone working on the device should meet

following conditions:

- Participation in all training courses,

- Personal fitness to the specific task,

- Personal competence for the specific task,

- Training for the use of device,

- Safety equipment data and mode of operation

- This Operating Manual and especially the safety

instructions relevant to this work with sub-sections,

- Knowledge on basic arrangements relevant to

health, safety and accident-prevention.

All persons should have following qualifications as

minimum:

-Receive training as expert to work on the product

independently,

-Receive sufficient training to work on the product

under the guidance and surveillance of a trained

expert,

This Operating Manual differentiates user groups:

(see 2.2 User Competence Page 4)

Appropriate and Desired Use

7

4Appropriate and Desired Use

Notes about product warranty

Undefined use of the product in any way might risk

the function or desired protection of the product.

This shall invalidate warranty claims!

Please remember that responsibility lies with the

user in following cases:

•Use of the product in an inconsistent way with

the section titled "appropriate and desired

use" especially with regards to safety

•Unauthorized changes on the device by the user

Product Software

Aquameter v3 R4

Principles

•Information on usage and environment (see 6

Technical Data Page 9).

•Product is not designed for outdoors unless

appropriate protective measures are taken.

•Avoid liquid and dust leakage into product and

also direct sunlight exposure.

•Do not operate the product in a potentially

explosive environment unless there is EC

Certificate of Conformity for potentially

explosive atmospheres.

Foreseeable wrong use

You can find below information about unaccepted

product practices or relevant equipment practices.

This section has been designed to detect and

prevent possible wrong uses beforehand.

Foreseeable wrong use will affect product life:

4.4.1Wrong assembly

Wrong or loose screwing.

4.4.2Wrong installation

Wrong connection of sensors due to wrong material

or improper connections.

Damage in cable lines due to twisting or excessive

tightening.

Use of damaged parts,

Wrong electrical wiring

Unsafe mains or mains voltage that do not comply

to standards.

Wrong connection cables for mains voltage.

Installation where it is not possible to cut off power

supply immediately or easily.

Product Description

8

5 Product Description

Product Data

AQUA METER is a Measurement Conversion

and Control device that has been developed to

measure three various values as pH, ORP and

Conductivity and to convert them into and control

various output units.

Described as AQUA METER pH, AQUA METER

ORP or AQUA METER CON, each of these devices is

related to only one unit. pH and CON devices also

fulfill heat compensation of units by measuring

heat at the same time.

General Specifications

This operating manual is applicable to Aquameter

Control device. Installation, operation and service of

all these control devices are different from each

other (certain differences in technical data,

malfunctions and repair).

Standard Hardware

•measurement, control and conversion

device for pH, ORP, conductivity.

•pH, ORP measurement with standard

combined electrodes; conductivity

measurement with standard

conductivity probe.

•Heat compensation in measurements

with heat measurement feature.

•Fully digital adjustment and automatic

calibration without adjustment bar,

screw driver, etc. thanks to buffer

liquids.

•Chemical Level Tracking

•Storage Level / Flow Tracking

•Ratio Control per Signal Input

•High operational reliability, electrical

isolation, full insulation against

humidity, acid and chlorine steam.

•Easy and flexible installation.

•Micro controller technology.

•Analogue control output (0-5V, 0-10V,

1-5V, 0-10mA, 0-20mA, 4-20mA, )

•Programmable alarm output.

•User Password

•Heat Sensor

Electrical Features

Device fulfills control duty by respecting user

settings.

Device complies with electrical devices regulations.

Device complies with following standards:

TS EN 61010-1

TS EN 61326-1

Scope of Delivery

Control device

User's Manual

Assembly Set

Calibration Liquid

CAUTION

Calibration liquid varies based on the model type

of your device.

Technical Data

9

6 Technical Data

Model

pH

ORP

Conductivity

Measurement Range

pH 0,00 –14,00

0 –50ºC NTC

-25 –+125ºC Pt100

0 –1250mV

0,01 –20,00mS

0 –50ºC NTC

-25 –+125º Pt100

Solubility

0,01 pH, 0,1 ºC

1 mV

0,01 mS 0,1 ºC

Heat Compensation

NTC - Pt100

NTC - Pt100

Relay

Control Output

NO; 220VAC 5A, NC; 250VAC 2A

NO; 28VDC 5A, NC; 28VDC 1A

Relay

Alarm Output

Analogue Output

0-5V, 0-10V, 1-5V, 0-10mA, 0-20mA, 4-20mA

Chemical Level Input

NO-NC

Storage Level / Flow Input

NO-NC

Signal Input

0Hz –1KHz

Feeding

230VAC 50-60 Hz, 6W 12-28VDC (for DC model), 6W

Fuse

AC model : 63mA Fast 20x5mm glass fuse

DC model : 1A Fast 20x5mm glass fuse

Operating Temperature

0 .. 50 ºC

Body

IP56

Packaged Weight

1,17 Kg

Product Weight

0,7 Kg

Packaging Dimensions

210 x 240 x 180 mm

Product Dimensions

143 x 80 x 183 mm

Dimensions

10

7 Dimensions

Please find dimensions and assembly hole sizes of

the device below. All dimensions are given in mm.

Mark the surface on which the product is to be

installed in accordance with the template before

starting assembly.

Make sure that the surface is dry and clean.

Figure 1 Front Side Device Size

Figure 2 Device Side Size

Figure 3 Device Rear Size

Mechanical Installation

11

8 Mechanical Installation

Mechanical Assembly:See

User Competence page 4

CAUTION

Assembly Site and Conditions

▪Device meets IP65 protection and sealing if

all seals and screws are placed correctly.

▪Electrical assembly should be performed

after mechanical assembly.

▪Please choose a site that will lend easy

access to control panel.

▪Do not permit direct sunlight on the device.

▪Operating environmental temperature: -

20/+60°C and 90% relative humidity (non-

condensing)

▪Allowed working temperatures of other

sensors and actors should be considered.

▪This device has been designed only for

indoor use. Place it inside a panel to protect

from external factors for outdoor use.

CAUTION

Reading and Commanding Position

Install the device in a space with normal room

temperature that is well ventilated and place it at

eye level in order to read and manage it properly.

CAUTION

Assembly Position

Device has been designed to be used with wall-

type mount as a standard.

Assemble the device with the cable inlet facing

downwards all the time.

Allocate sufficient space for cables and hoses.

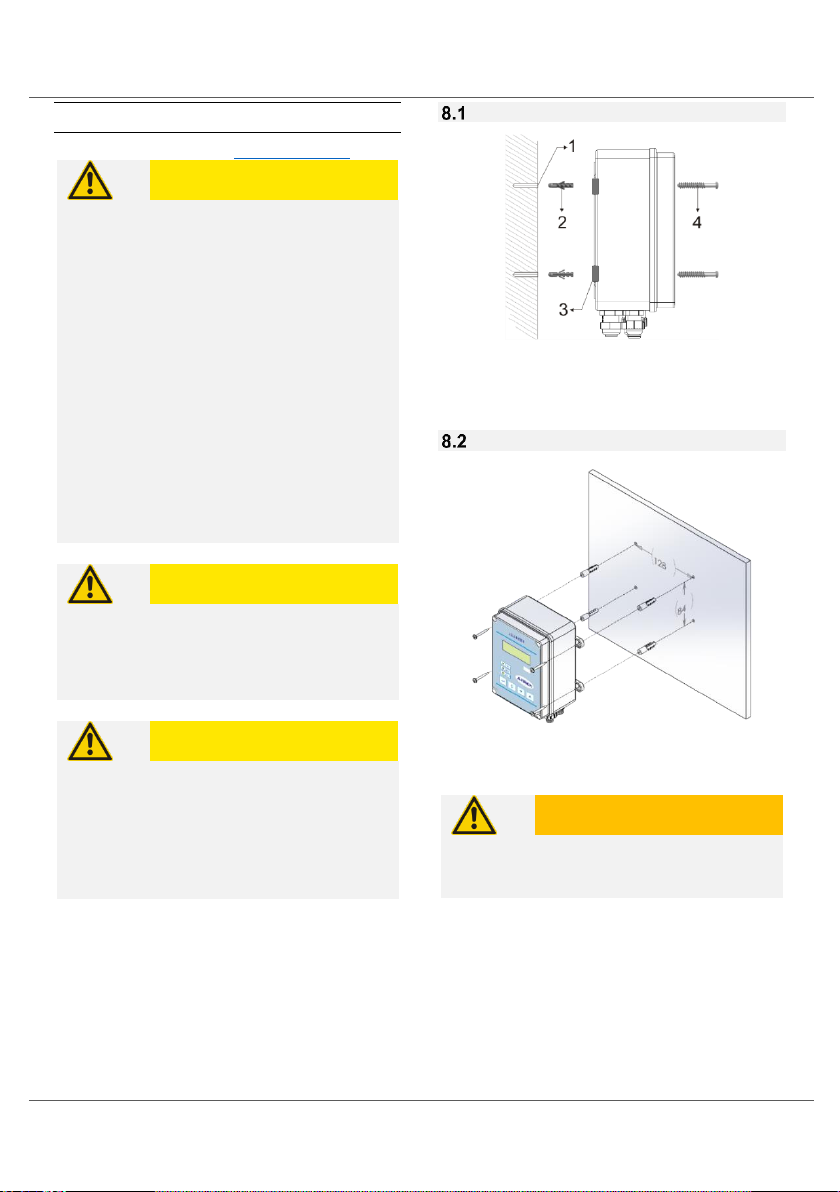

Wall Assembly

1) Ø 8x50mm 2) 8mm Anchor

3) Hanging Bracket 4) 4.2x50 YSB Screw

Panel Assembly

A: 128 mm B: 84 mm C: Ø 4,5 mm

WARNING

Place the control device by leaving 110 mm

space from four sides as minimum for the proper

position.

1. Mark the hole dimensions on the surface of

assembly.

2. Drill hole (1).

3. Place the anchor shown as (2) into the hole.

4. Align the hanging brackets (3) on the device to

the holes.

5. Screw and fix the device (4).

Figure 4 Wall Assembly

Figure 5 Panel Assembly

Mechanical Installation

12

Sensor Assembly for each model

8.3.1For CON Models

8.3.2For ORP Models

8.3.3For pH Models

Figure 6 For Con Models

Figure 7 For ORP Models

Figure 8 For pH Models

CONDUCTIVITY SENSOR INPUT

LEVEL SENSOR INPUT 1

LEVEL SENSOR INPUT 2

ORP SENSOR INPUT

LEVEL SENSOR INPUT 1

LEVEL SENSOR INPUT 2

TEMPERATURE SENSOR INPUT

pH SENSOR INPUT

LEVEL SENSOR INPUT 1

LEVEL SENSOR INPUT 2

Electrical Installation

13

9 Electrical Installation

Electrical Assembly: See

User Competence

page 4

WARNING

Parts Under Electric Voltage!

Possible Result: Death or severe injury.

Unplug from mains before opening the body.

Unplug damaged or broken devices from mains

to make them off-circuit.

WARNING

Humidity on Contact Sites

Protect electrical wire, cable and connection

socket from humidity using appropriate design

and technical measures. Humidity in contact

areas might cause damage

WARNING

Cable Duct

Cables should be driven inside a cable duct to

reduce tension.

Based on the model, device power supply can be

AC or DC. AC connection is shown next to here and

electrical properties are described in the technical

specifications. For DC connection, see 9.3 Device

Schema Page 14.

There are two relay outputs (for Control and

Alarm). Names of terminal connections inside the

device are given as abbreviations in front of the

connectors.

Electronic circuit is protected with fuse. Please use

appropriate fuse based on the model. See 6

Technical Data Page 9

Plug Electrical Connection

Fixed Electrical Connection

L: Phase N: Neutral E: Earthing (functional)*

•A switch or circuit breaker should be

integrated.

•Switch or circuit breaker should be placed

appropriately and easily accessible.

•Switch or circuit breaker should be marked

as separating element.

* WARNING

Functional earthing connection is used for

external devices. It is not a circuit protector.

Figure 9 Plug Electrical Connection

Figure 10 Fixed Electrical Connection

DEVICE

DEVICE

Circuit

Breaker

Switch

Electrical Installation

14

Device Schema

Jumper settings

Figure 11 Mainboard

Figure 13 Mainboard AC input

Figure 12 Mainboard DC input

Electrical Installation

15

Electrode Selection

Electrodes used by the device are shown on

the table. Connections are made with BNC

connector. It is stated on the device which

electrode to be connected where.

Device Type

Electrode Type

pH

Standard Combined pH Electrode

ORP

Standard Combined ORP

Electrode

Con

Conductivity Electrode

9.4.1 Heat Sensor

AQUA METER pH and

Con devices support

two types of heat

sensors as NTC and

Pt100. heat sensors

are capable of

connecting to connection point on the device

directly.

Detailed image of NTC

Connection point is

given on the left.

Pt100

Heat Sensor

Connection

9.4.2 Analogue Output

Device can give 6 different analogue

outputs in total. You can select one

of those outputs using the jumpers

on the device.

Analogue Output

Connection and Jumper

Settings

9.4.3Digital Inputs

There are 3 digital inputs as two level sensors and

one counter input while connections can be made

as seen on top.

Figure 19 Digital Inputs

Figure 14 Heat Sensor

Figure 15 NTC connection

Figure 16 pt100 connection

Figure 17 Analogue Output

Figure 18 Jumper settings

Operation

16

10 Operation

General Operation

Control panel consists of 4 function buttons and 3

status LEDs. You can access and control

parameters using these 4 function buttons.

Below you can find example of Set parameter.

Adjusting Device Output Control

Mode

Device output control mode is shown on right

upper corner of screen.

There are three different statuses.

OFF : Device output is constantly off.

AUTO : Device output starts automatically

based on the adjusted value.

ON : Device output is constantly on.

These can be changed using up button.

Figure 20 Panel Tag

Figure 21 Adjusting Device Output Control Mode

Operation

17

Parameters

10.3.1 Changing Parameter Value

Figure 22 Changing Paramater Value

Access parameters by pressing enter button.

See the screen on the left.

Use Up[ ] and down[ ] buttons to find Set parameter.

Screen on the Left

Enter the section to change parameter value by pressing enter button.

See the screen on the left.

Change the value as you desire using up and down buttons.

Exit after setting the value with enter button and return to previous menu.

[C] button will enable you to return to previous menu without setting the

value.

Use [C] button to return to main screen.

Operation

18

Parameter List

Parameter

Description

Value

Default

pH

ORP

Con

01

_Device

Settings from

Factory

Shows Device

Type

0: pH

1: ORP

3: Conductivity

0

1

2

02

_Temp.Sens.

Settings from

Factory

Shows

Temperature

Sensor Type

0: Pt100

1: NTC 10K

1

03

Mode

Device Operating

Mode

0: Off

1: Auto

2: On

0

04

Cont Mode

Device Control

Mode

0: Relay Control

1: Ratio Control

2: Signal Ratio Control

0

05

Output Mode

Output Mode

0: Increase Control

1: Decrease Control

2: Decrease / Increase Control

1

0

1

06

Cont. Run

Continuously

Operating

When device is On

mode

0: Return to Auto Mode in 1 minute

1: Continuous Output

0

07

Analogue

Type

0: Ratio Control Output

1: Full Scale Output

0

08

Temp Comp.

Temperature

Compensation

0: Passive

1: Active

0

0

1

09

Log Interv.

Data Sending

Period

0-30 min.

3

10

Pass Enable

Password

Protection

0: Passive

1: Active

0

11

Cal Type

Calibration Type

0: Single Point

1: Double Point

1

0

0

12

LR

Output on Lower

Limit Value

Exceed

0: Passive

1: Active

0

13

HR

Output on Higher

Limit Value

Exceed

0: Passive

1: Active

0

14

Filter Delay

Filter Delay

0-99 sec.

0

15

Level1 C

Type

Level 1 Input

Contact Type

0: NO

1: NC

0

16

LV2/FL Type

Level 2 Input /

Flow Switch

Contact Type

0: NO

1: NC

0

Operation

19

17

Pulse Count

Signal Ratio

Control Pulse

Count

0 –250 pulse

10 pulse

18

RelayOnTime

Signal Ratio

Control Relay On

Time

0,0-25,0 min.

1,0 min.

pH

ORP

Con

19

Set

Set point

0,00-

14,00pH

0-

1250mV

0,00-

20,00mS

7,00pH

650mV

5,00mS

20

Set Ofset

Offset level

0,00-

1,00pH

0-

100mV

0,00-

1,00mS

0,05pH

5mV

0,05mS

21

Ratio Diff.

Difference of

analogue output

100% point from

Set Value

0,00-

14,00pH

0-

1250mV

0,00-

20,00mS

1,00pH

100mV

1,00mS

22

Low Alarm

Value low alarm

0,00-

14,00pH

0-

1250mV

0,00-

20,00mS

6,00pH

550mV

4,00mS

23

High Alarm

Value high alarm

0,00-

14,00pH

0-

1250mV

0,00-

20,00mS

8,00pH

750mV

6,00mS

24

Buf Sol 1

Buffer 1 Liquid (in

pH and ORP

devices)

0,00-

14,00pH

0-

1250mV

0,00-

20,00mS

4,00pH

225mV

1,41mS

25

Buf Sol 2

Buffer 2 Liquid (in

pH and ORP

devices)

0,00-

14,00pH

0-

1250mV

0,00-

20,00mS

7,00pH

475mV

2,77mS

26

Password

Password Set

0000 –9999

0000

** Varies depending on device type. Values are as follows.

pH=14,00 ORP=1250 Con=20,00

Table of contents

Popular Measuring Instrument manuals by other brands

Young

Young 86004 instructions

TSI Instruments

TSI Instruments ALNOR MicroManometer AXD 550 owner's manual

Wohler

Wohler BC 600 operating manual

Flomotion Systems

Flomotion Systems LT260 Operation and maintenance manual

REED

REED R6010 instruction manual

WATERS CORPORATION

WATERS CORPORATION TA Instruments DSC 2010 Operator's manual