® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 2 -

Contents

1.0 INTRODUCTION ................................................................................................................... - 3 -

1.1 General Information ........................................................................................................... - 3 -

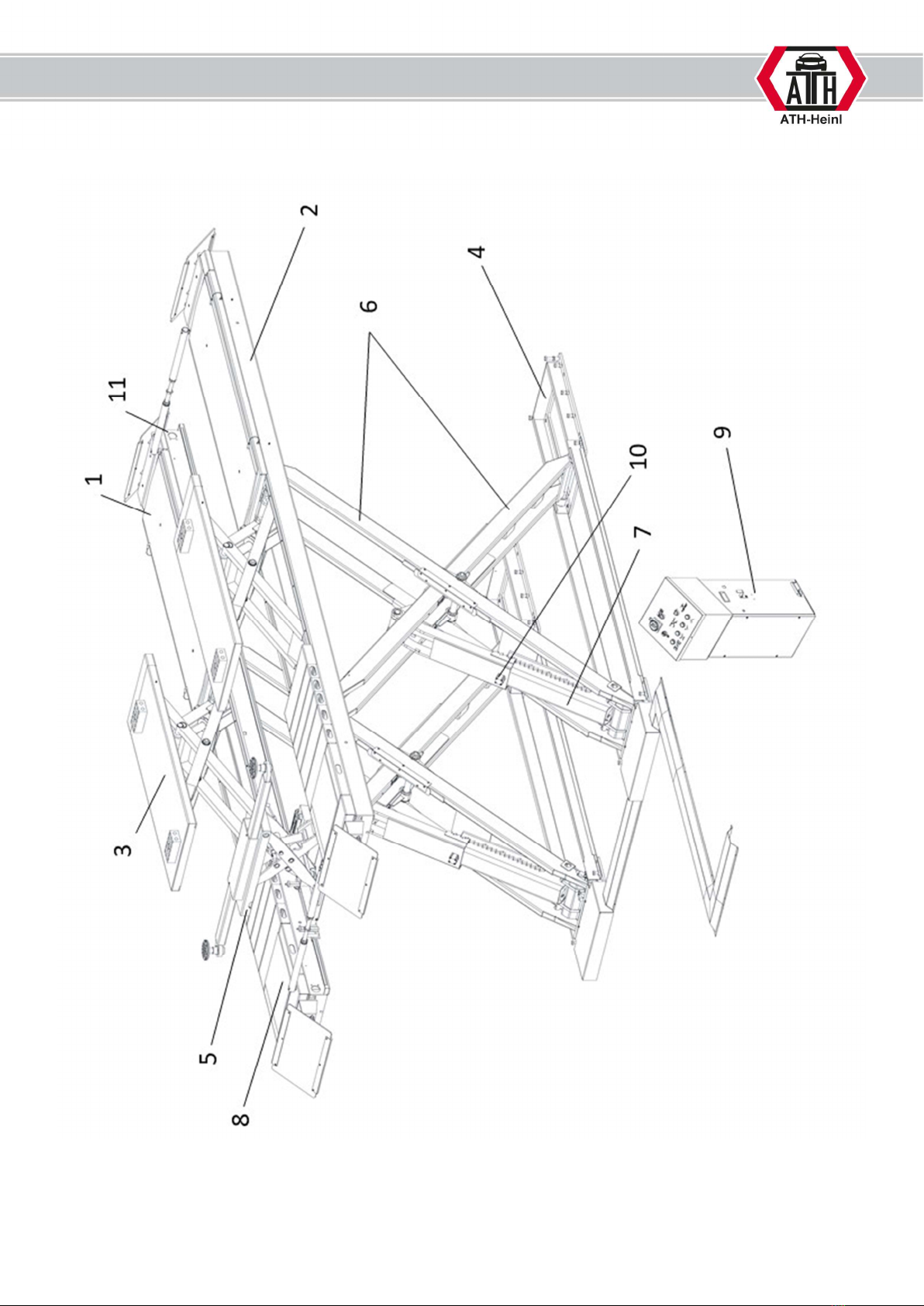

1.2 Description ........................................................................................................................ - 4 -

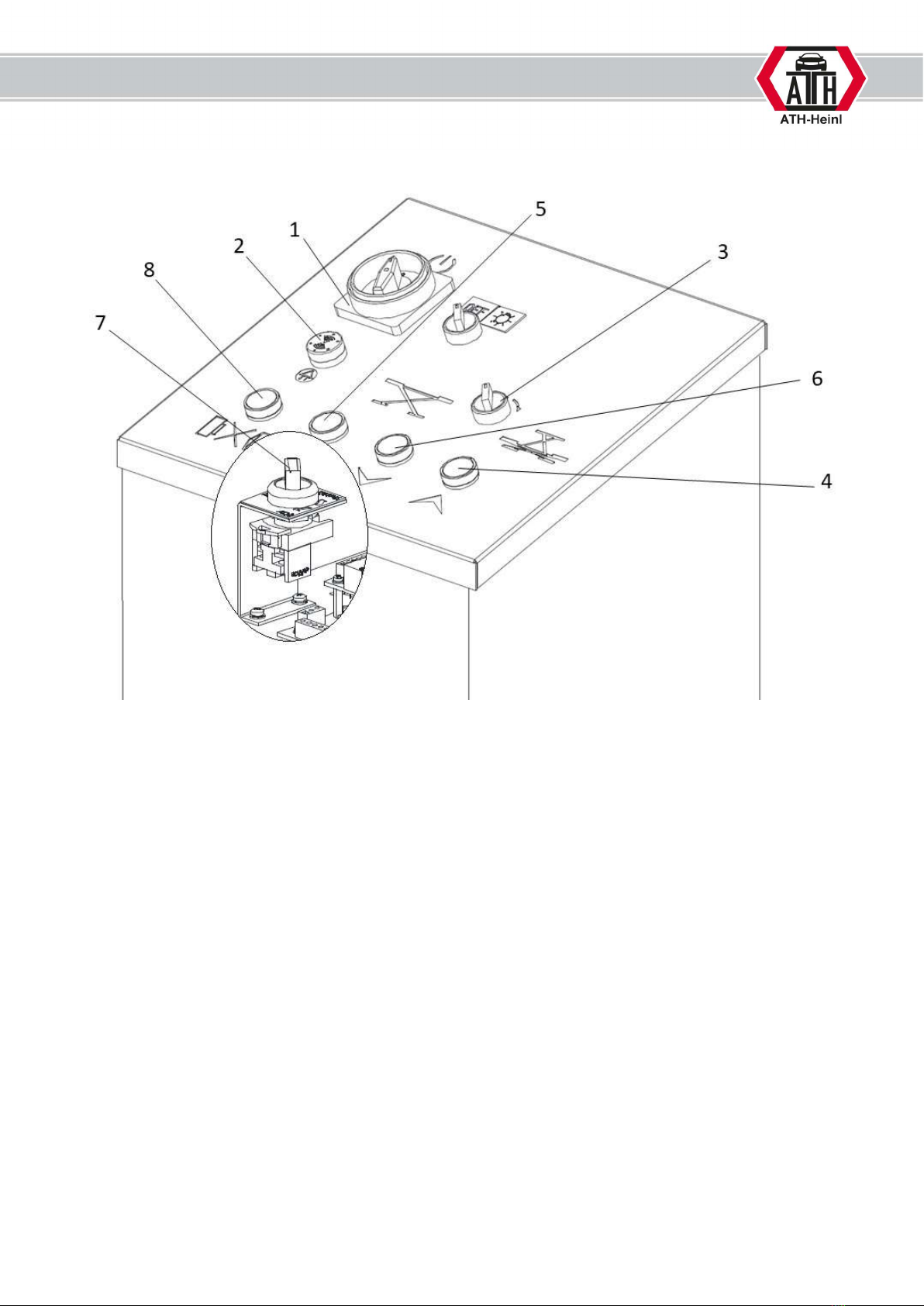

1.3 Operation.......................................................................................................................... - 6 -

1.4 Technical Data .................................................................................................................. - 9 -

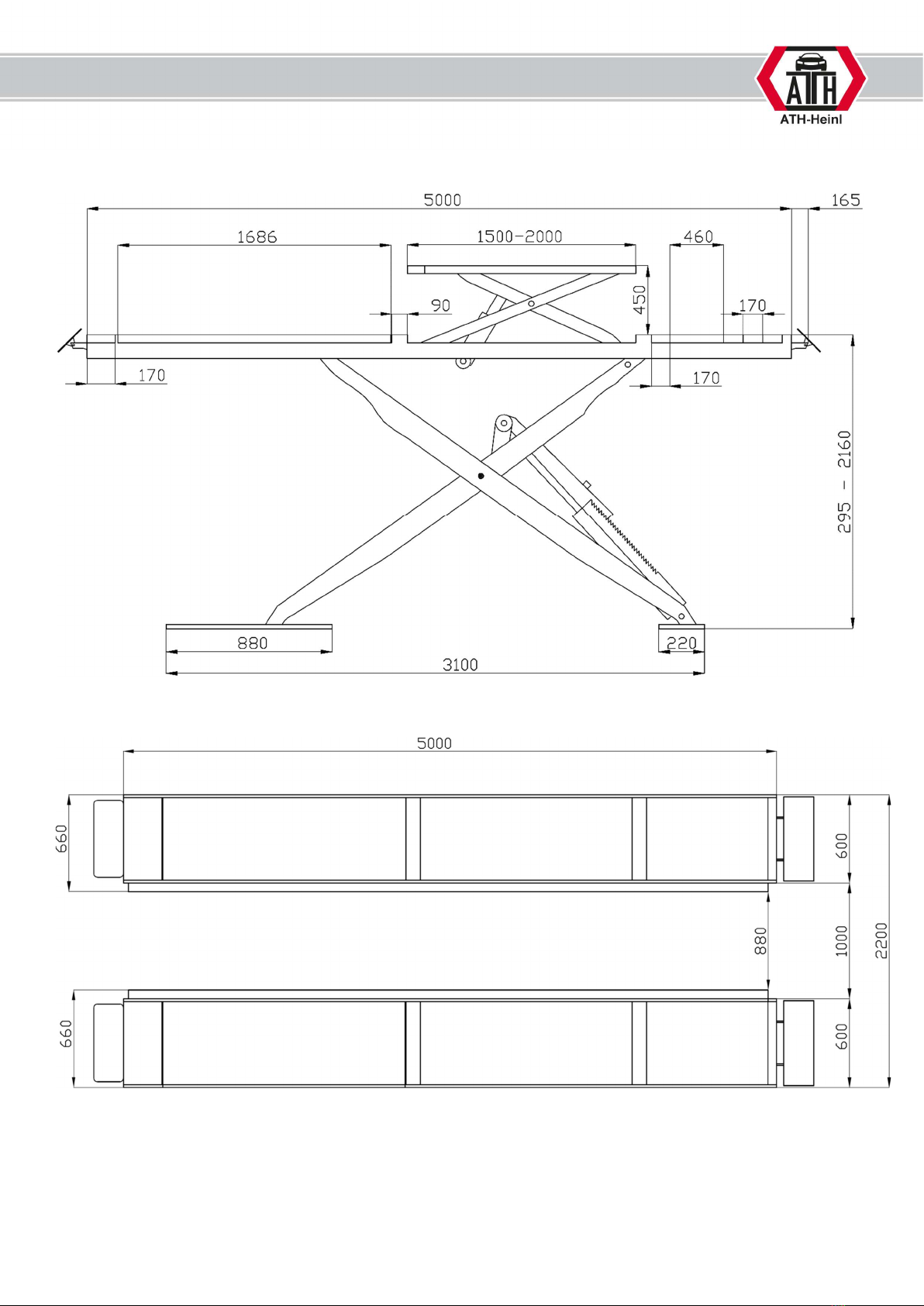

1.5 Scale Drawing ................................................................................................................. - 10 -

2.0 INSTALLATION ................................................................................................................... - 14 -

2.1 Transport & Storage Conditions ........................................................................................ - 14 -

2.2 Unpacking the machine .................................................................................................... - 14 -

2.3 Delivery Contents ............................................................................................................ - 15 -

2.4 Location .......................................................................................................................... - 17 -

2.5 Fixing ............................................................................................................................. - 18 -

2.6 Electrical Connection ........................................................................................................ - 18 -

2.7 Pneumatic Connection ...................................................................................................... - 19 -

2.8 Hydraulic Connection ....................................................................................................... - 19 -

2.9 Assembly ........................................................................................................................ - 19 -

2.10 Completion of Work ...................................................................................................... - 31 -

3.0 OPERATION ....................................................................................................................... - 32 -

3.1 Operating Instructions ..................................................................................................... - 32 -

3.2 Basic Information ............................................................................................................ - 33 -

4.0 MAINTENANCE ................................................................................................................... - 34 -

4.1 Consumables for installation, maintenance and servicing..................................................... - 34 -

4.2 Safety Regulations for Oil ................................................................................................. - 35 -

4.3 Notes ............................................................................................................................. - 36 -

4.4 Maintenance or Service Plan ............................................................................................. - 36 -

4.5 Troubleshooting / Error Display and Solutions .................................................................... - 37 -

4.6 Maintenance and Service Instructions ................................................................................ - 39 -

4.7 Disposal .......................................................................................................................... - 40 -

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG / EC-/EU-DECLARATION OF CONFORMITY...................... - 41 -

6.0 APPENDIX .......................................................................................................................... - 42 -

6.1 Pneumatic circuit diagram ................................................................................................ - 42 -

6.2 Electric circuit diagram ..................................................................................................... - 43 -

6.3 Hydraulic circuit diagram .................................................................................................. - 44 -

7.0 WARRANTY CARD ............................................................................................................... - 45 -

7.1 Scope of the Product Warranty ......................................................................................... - 46 -

8.0 INSPECTION LOG ............................................................................................................... - 47 -

8.1 Installation and Handover Log .......................................................................................... - 48 -

8.2 Inspection Plan ................................................................................................................ - 49 -

8.3 Visual inspection (authorised expert) ................................................................................. - 50 -

9.0 SPARE PART BOOK ............................................................................................................. - 54 -

10.0 NOTES ............................................................................................................................... - 87 -