Manual, Control Module, PROFINET, DL10

Document #9620-20-C-DL10-04

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com

C-2

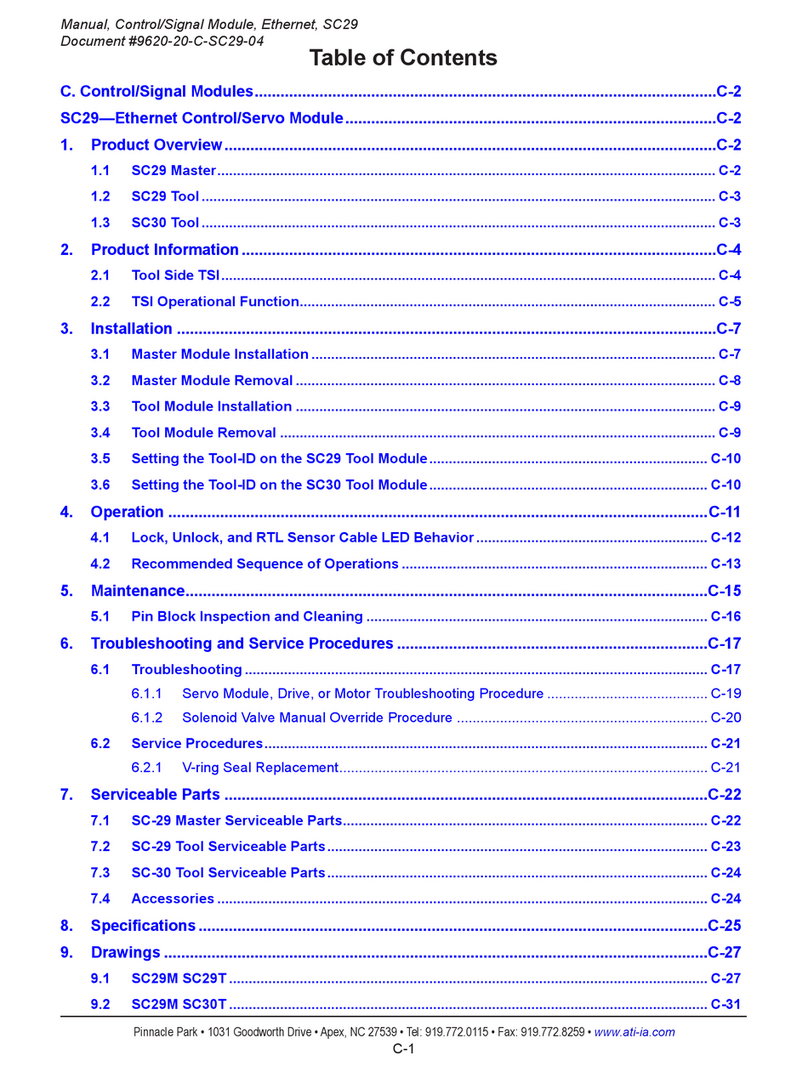

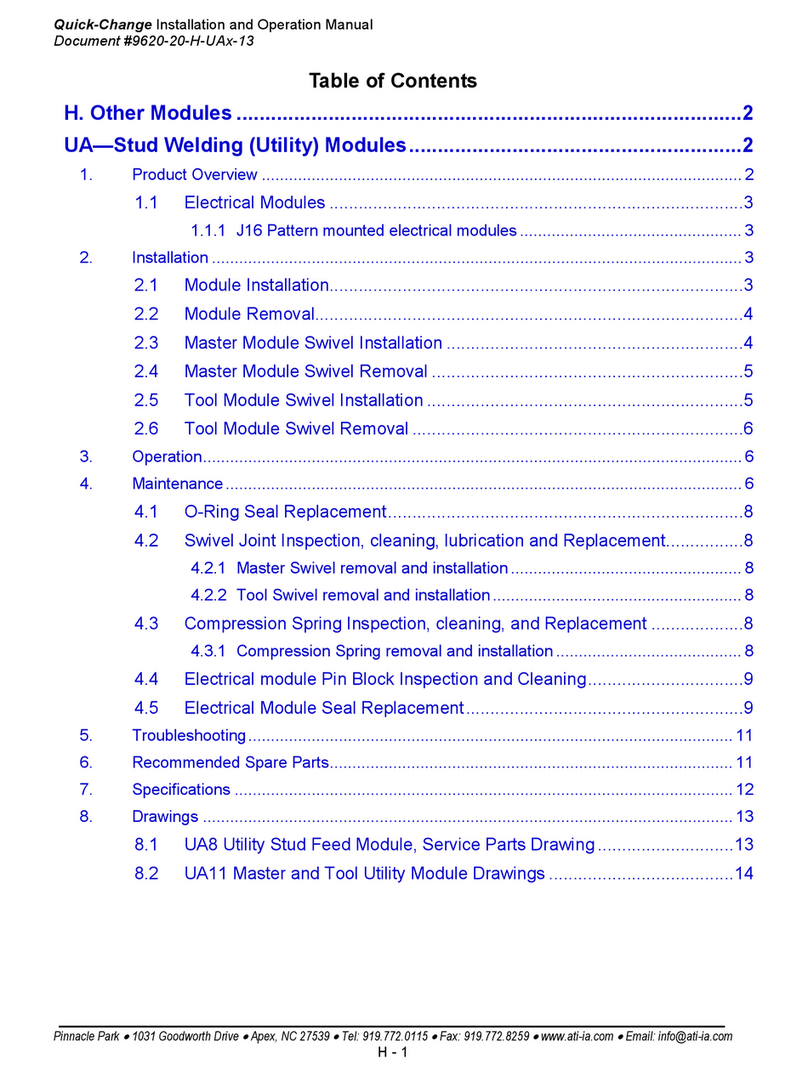

3. Installation ...........................................................................................................................C-23

3.1 Master Control/Signal Module Installation............................................................................ C-23

3.2 Master Control/Signal Module Removal................................................................................ C-24

3.3 Tool Control/Signal Module Installation................................................................................ C-24

3.4 Tool Control/Signal Module Removal.................................................................................... C-25

3.5 Setting the Tool-ID................................................................................................................... C-26

3.6 PROFINET Interface................................................................................................................ C-26

3.7 Utility Schematic ..................................................................................................................... C-26

3.8 Electrical Connections............................................................................................................ C-26

4. Operation .............................................................................................................................C-27

4.1 Lock, Unlock, and RTL Sensor Cable LED Behavior........................................................... C-28

4.2 Inputs........................................................................................................................................ C-29

4.2.1 Locked.......................................................................................................................... C-29

4.2.2 Unlocked ...................................................................................................................... C-29

4.2.3 Input/Logic Power Good............................................................................................... C-29

4.2.4 Output Power Available................................................................................................ C-29

4.2.5 RTL1 and RTL2............................................................................................................ C-29

4.2.6 Tool Present ................................................................................................................. C-29

4.2.7 Tool Power Is On.......................................................................................................... C-29

4.2.8 Unlatch Enabled........................................................................................................... C-29

4.2.9 TSIV ............................................................................................................................. C-29

4.2.10 TSRV............................................................................................................................ C-29

4.2.11 RTLV1 and RTLV2........................................................................................................ C-29

4.3 Error Conditions...................................................................................................................... C-30

4.3.1 ERROR ON LATCH...................................................................................................... C-30

4.3.2 ERROR ON UNLATCH ................................................................................................ C-30

4.3.3 UNSAFE UNLATCH..................................................................................................... C-30

4.3.4 RTL/RTLV Mismatch .................................................................................................... C-30

4.3.5 TSIV/TSRV Mismatch................................................................................................... C-30

4.3.6 Lock/Unlock Sensor Fault ............................................................................................ C-30

4.3.7 COMM Error................................................................................................................. C-30

4.4 Recommended Sequence of Operation................................................................................ C-32

5. Maintenance.........................................................................................................................C-39

5.1 Pin Block Inspection and Cleaning ....................................................................................... C-40