2 | Auto Wash 365 Manual | v1.1

© ATL Agricultural Technology Limited: June 2019

Innovation In and Out of Parlour

Index

Manual Version........................................................................................................... 4

About the Auto Wash 365................................................................................................ 5

Installing the Auto Wash 365,.......................................................................................... 7

Good Practice During the Installation............................................................................... 8

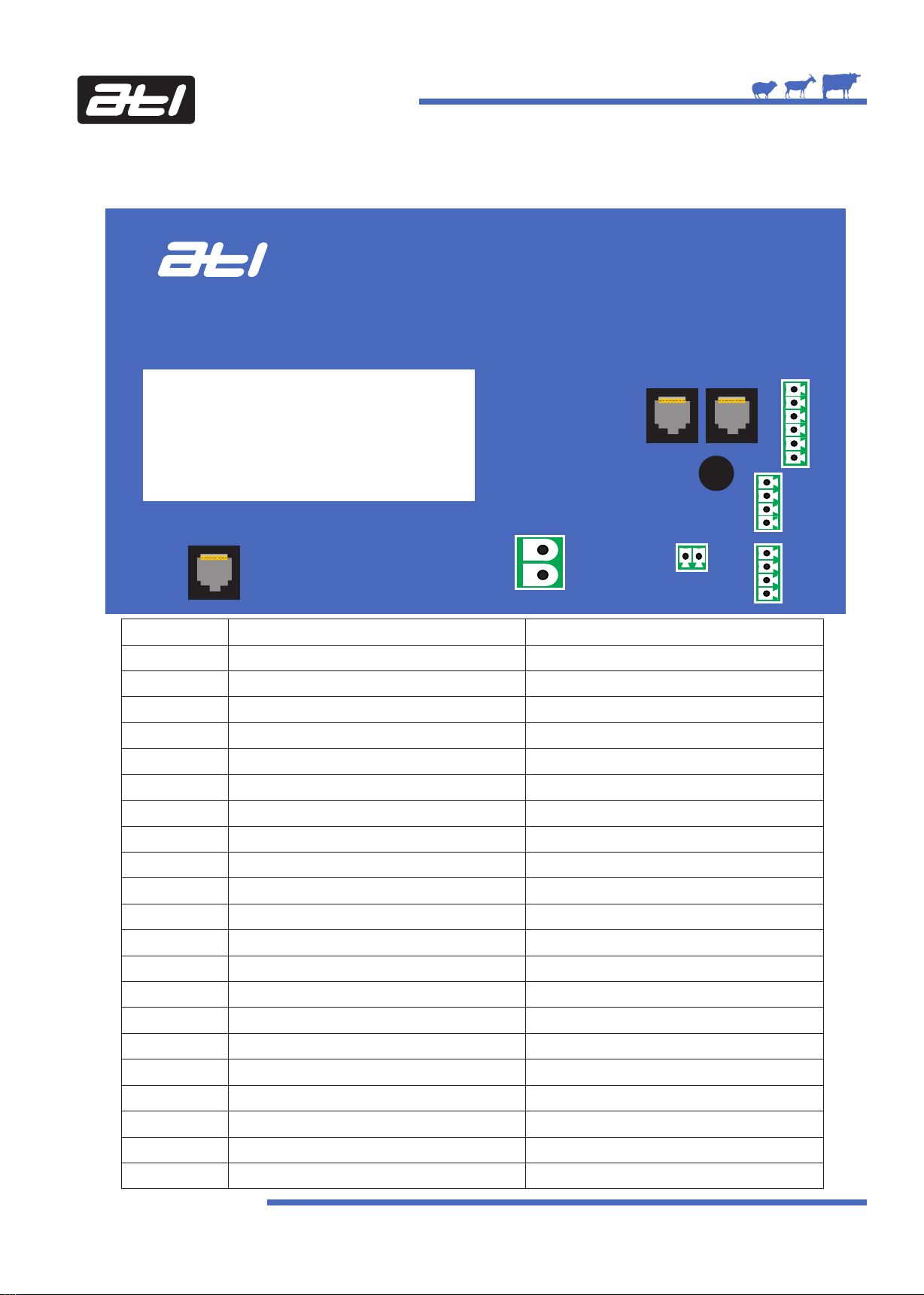

Auto Wash 365 Control PCB Wiring Connections................................................................. 9

Auto Wash 365 Input/Output PCB Wiring Connections......................................................... 10

Auto Wash Pump Box 800 Connections - Internal Hot and Cold Water Valves.......................... 12

Auto Wash 365 Layout Diagram.................................................................................... 13

Connecting the Auto Wash 365 to Vacuum Pumps.............................................................. 14

Connecting the Auto Wash 365 to the optional milk line lockout proximity sensor...................... 16

Setting Up the Auto Wash 365....................................................................................... 17

The Keypad............................................................................................................... 17

The Display................................................................................................................ 17

Entering Setup............................................................................................................ 18

The Key Buzzer Setting................................................................................................. 18

Setting the Time.......................................................................................................... 18

Setting the Date.......................................................................................................... 19

Editing Programs - See Page 31....................................................................................... 21

Editing Tasks - See Page 34............................................................................................ 21

Setting the Wash Trough Lock Out................................................................................... 21

Setting the Milk Tank Lock Out........................................................................................ 22

Setting the Vacuum Pump Type...................................................................................... 22

Calibration the Peristaltic Pumps - See Page 36................................................................... 22

Test Displays Diagnostic................................................................................................ 23

Test Keyboard Diagnostic.............................................................................................. 24

Input/Output (I/O) Printed Circuit Board (PCB) Diagnostics................................................. 25

Input/Output (I/O) Printed Circuit Board (PCB) Test Routines............................................... 27

Control Printed Circuit Board (PCB) Serial Number.............................................................. 29

Control Printed Circuit Board (PCB) Software Version.......................................................... 29

Restore Factory Settings............................................................................................... 30

Exit Setup.................................................................................................................. 31

Editing Programs......................................................................................................... 32