6

Any revisions must first be approved by the product designer. Version: 201909 Revision by: JST

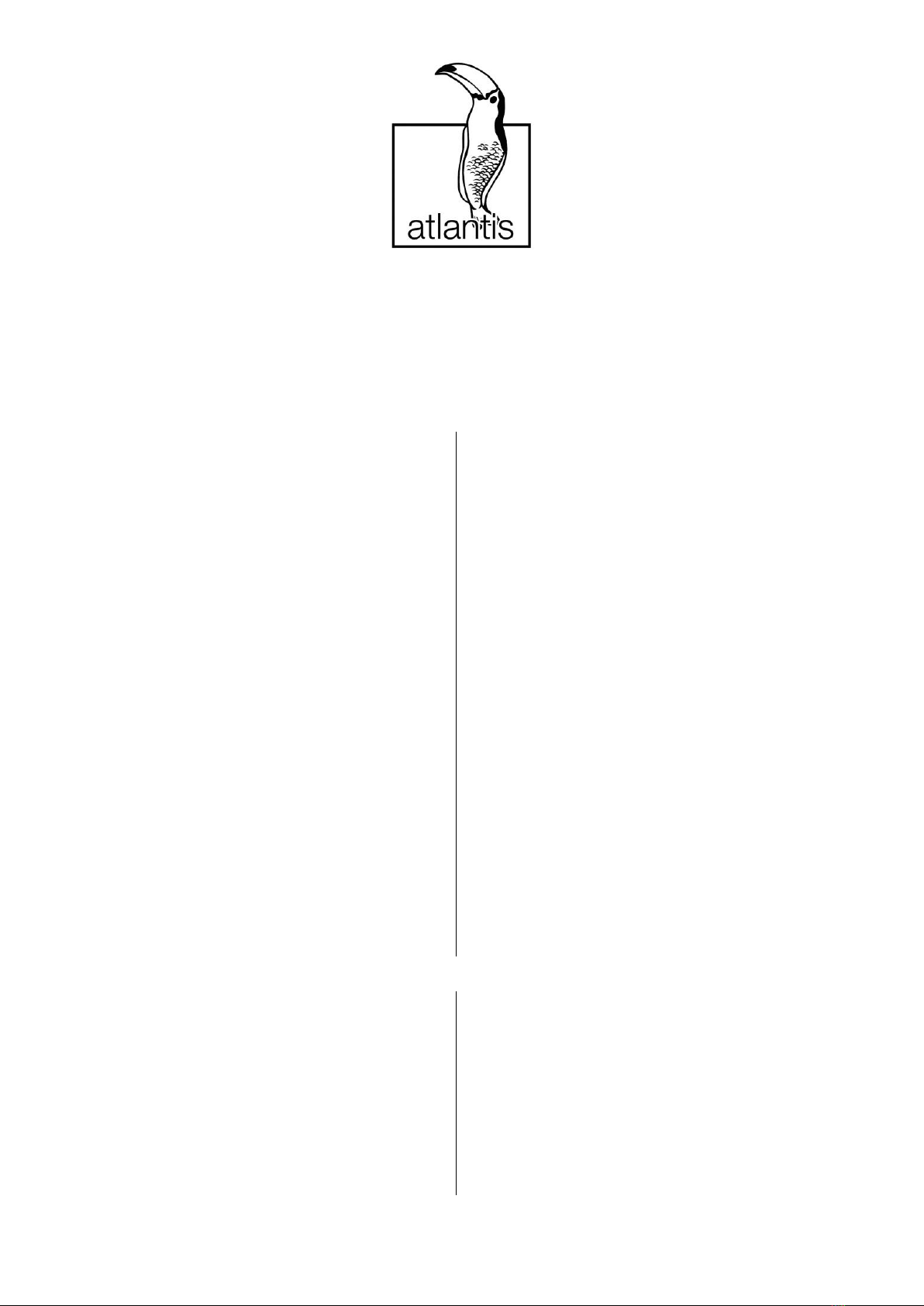

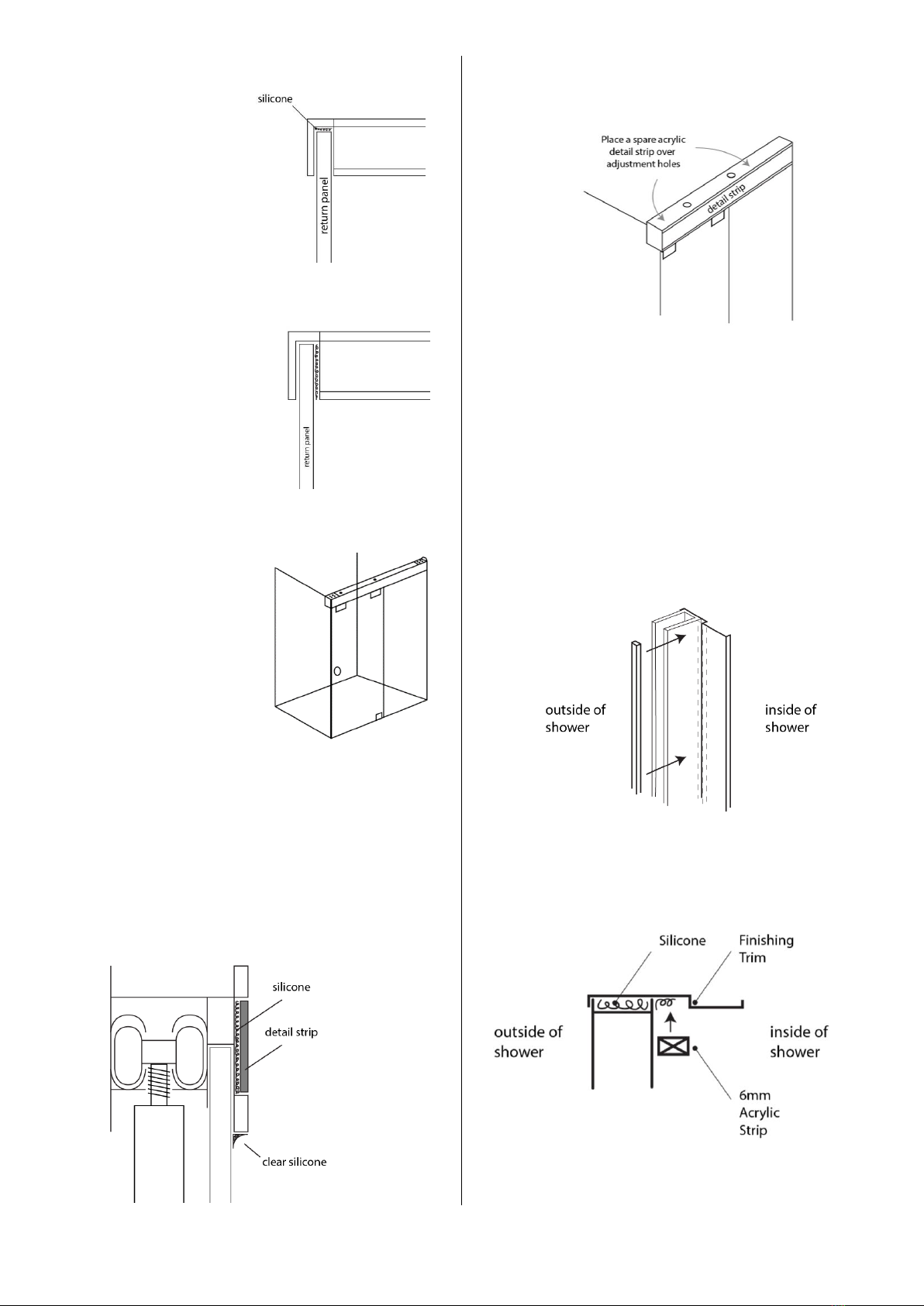

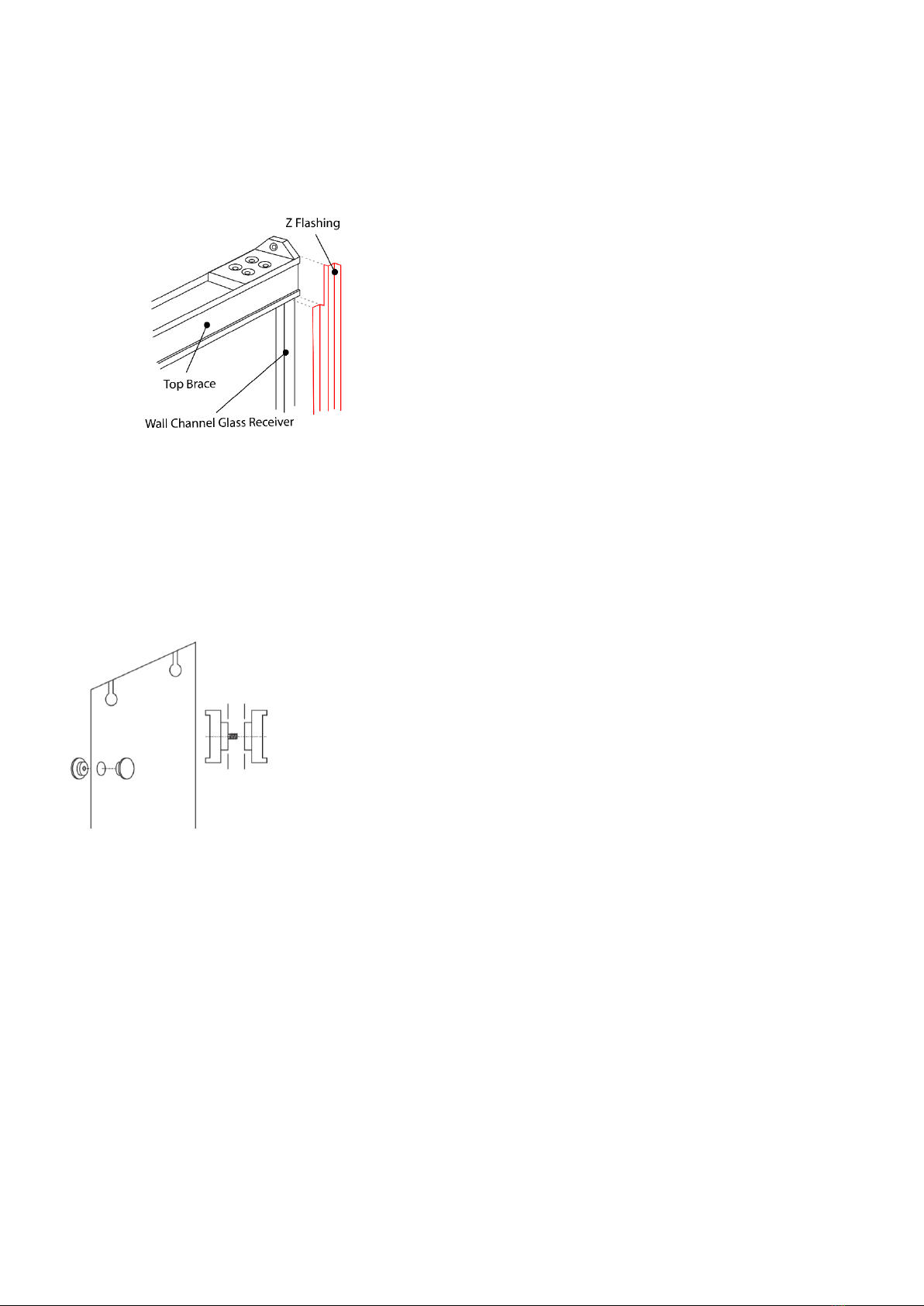

18. DOOR ALIGNMENT

Adjustment holes have been predrilled in the

top track. Door alignment can be achieved by

using 4mm hex key through the top track into

the top of the door hangers. Turn the key

anticlockwise to lift the door.

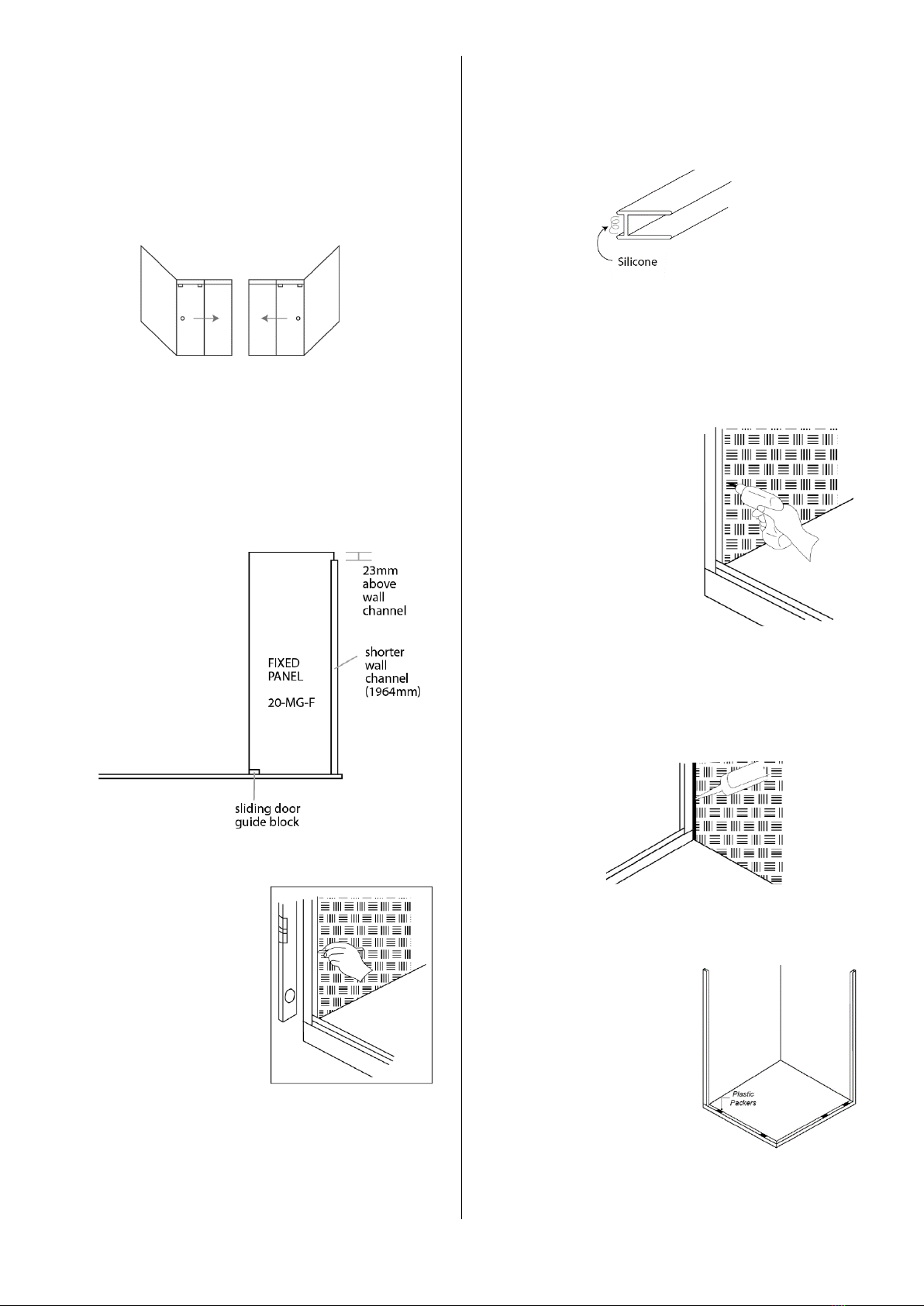

19. HANDLE INSTALLATION

Assemble the handles as shown. Clear gaskets

are supplied with

the handle.

Position one on

each side

between the

glass and handle.

* The stainless steel handle assembly is optional

20. SILL INFILL

Trim the sill infill to fit between the fixed panel

and the return panel. Apply a continuous bead

of clear silicon to each inside face of the base

channel and at

each end. Ensure

the ends of the

sill infill are

completely filled

and place the

infill into the

base channel in

the location as shown.

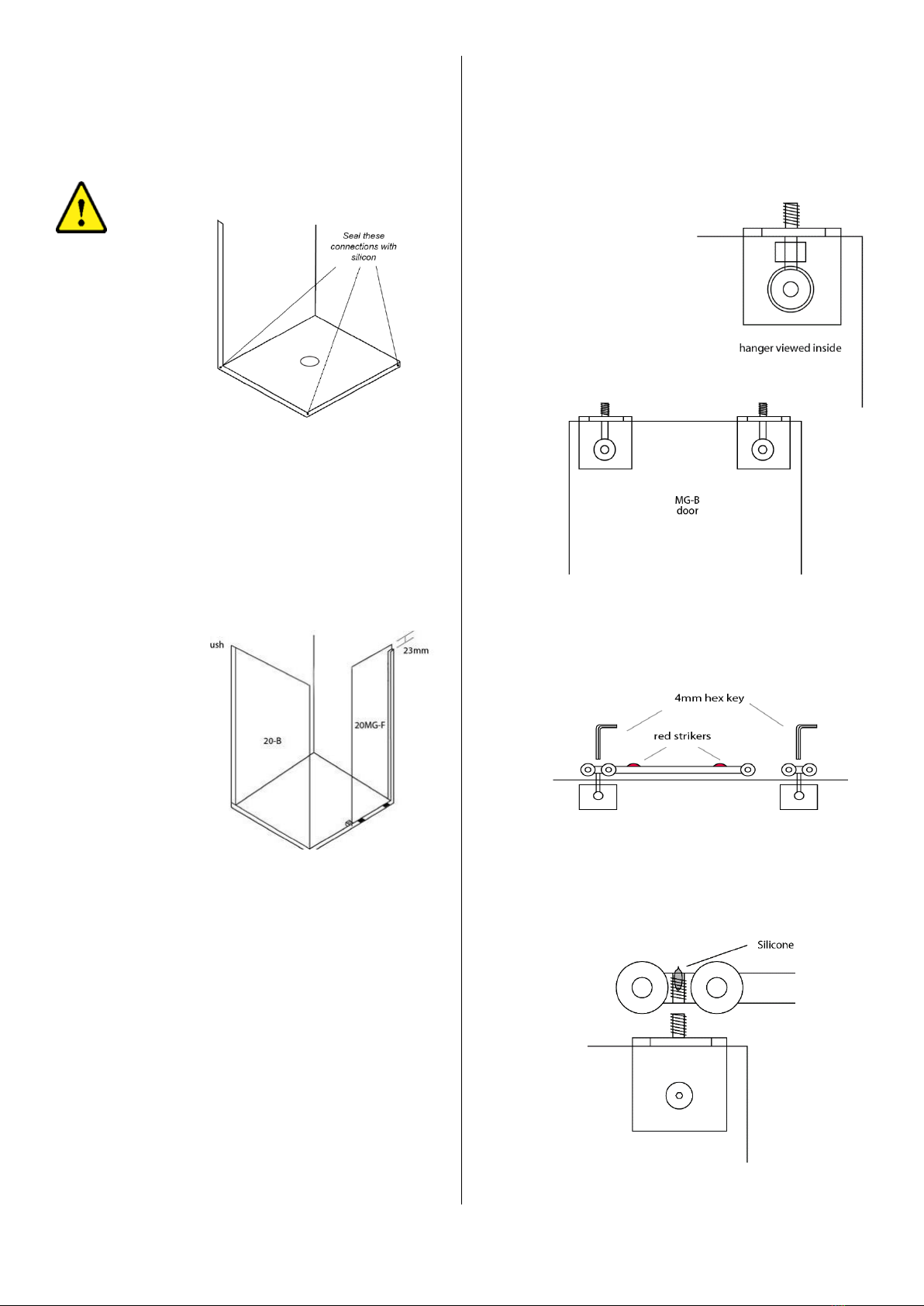

21. SLIDING DOOR GUIDE BLOCK

Ensure the guide block isn’t too tight (must

allow the glass to slide through it). Slide the

door as far back in an open position as possible.

Slip the sliding guide block under the door and

locate it in line with the end of the fixed panel

on the opening side.

Apply a small bead of silicon to the bottom and

side of the block and then place into position –

firmly to the inside of the glazing channel. Use

adequate clear packers on the outside of the

glass to firmly press the glass against the guide

block. Tape glass and block into place to ensure

they do not move while silicon cures.

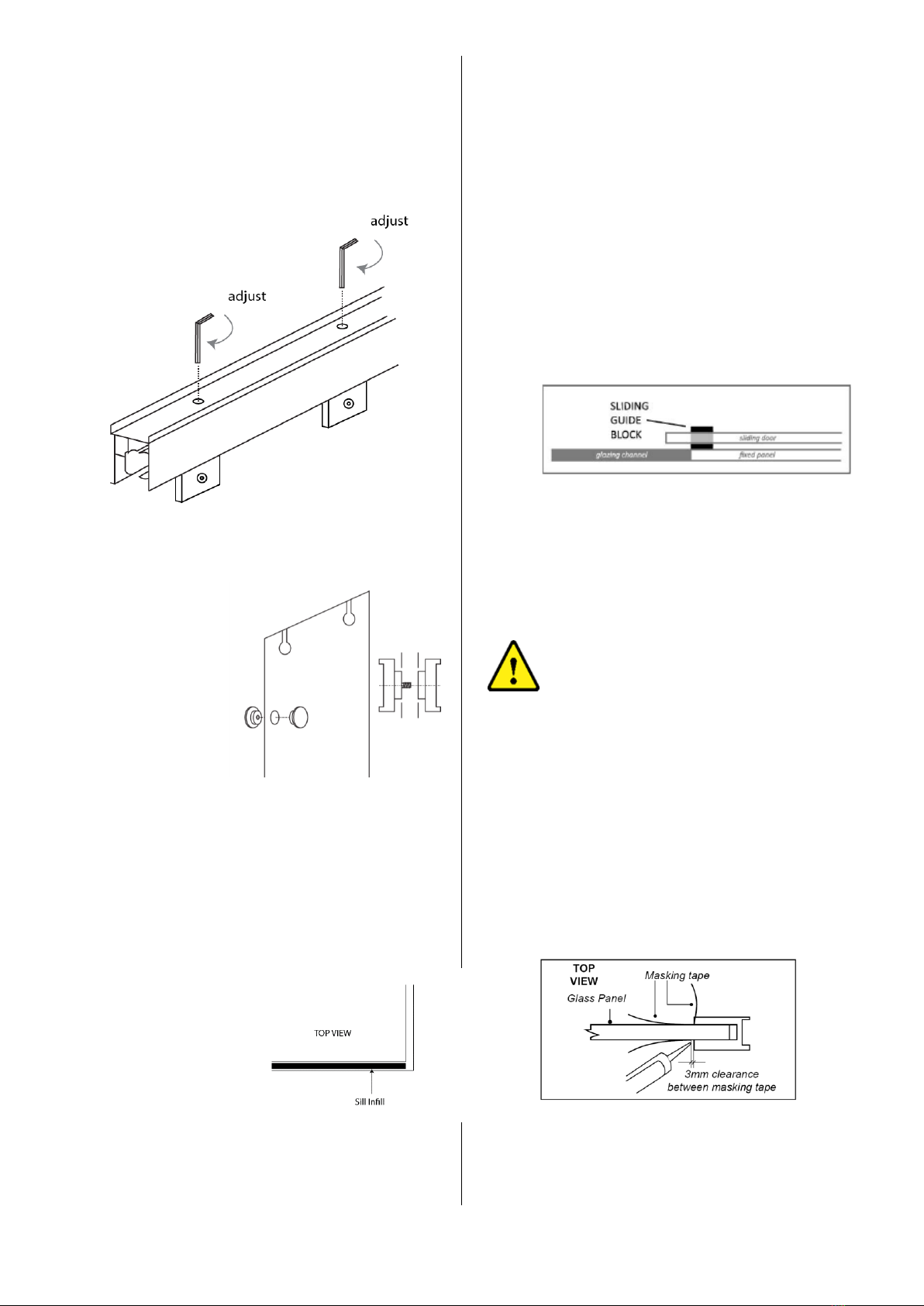

23. CLEAR FLEXIBLE WEDGE

2x lengths of clear flexible wedge have been

supplied. Wedge can be inserted into wall

channel, outside of glass panel. This will hold

panel in position, prior to final silicone seal.

These are to be used at installer discretion.

Wedge is not to be used in base channel.

Base channel is to be siliconed as per below.

24. SILICON APPLICATION

Using the blue tape supplied, mask the glazing

channels and glass at the intersections as

previously shown. Apply clear silicon to the

inside and outside of the base and wall receiver

channels. Use a spatula to remove the excess

silicon. Remove the masking tape immediately

after application.