9

Operating

hAvoid working in extremely hard materials e.g. granite and reinforcing iron

(reinforcement bar) which would cause substantial vibrations and excessive wear

on the pick hammer.

hCheck regularly that the machine is well lubricated. The chuck and insertion tool

shank must always be covered by a film of oil.

Maintenance

Regular maintenance is a prerequisite for machine safety. Replace damaged and

worn components in good time.

Check the machine and insertion tool for wear and damage at regular intervals. Do

not use a very worn or damaged insertion tool.

When cleaning mechanical parts with a solvent, make sure that you comply with

current health and safety regulations and ensure that there is sufficient ventilation.

Daily maintenance, regular checking of wearing parts and carrying out repairs in

good time prevents breakdowns and increases the service life of the machine.

hMake sure that no foreign matter enters the machine.

hAlways hose down and wipe clean the pick hammer after use.

Once a shift (after 8 hours of operation)

hCheck the wear in the chuck bushing. If the wear limit has been exceeded, the

insertion tool shank will wear more quickly, or become deformed. This will lead

to stoppages and increased insertion tool consumption.

hCheck the hoses, couplings and controls for leakage and damage.

hEvery day before using the pick hammer, blow out the air hose to clear it from

accumulated dirt and moisture.

hDrain the water separator (if one is used).

Once a week (after 40 hours of operation)

Carry out a basic check of all functions of the equipment.

Once a month (after 200 hours of operation)

hSend the pick hammer to a workshop for inspection. The local operating

conditions will determine whether or not this is a suitable interval for overhauling

the machine.

hClean out the water separator (if one is used).

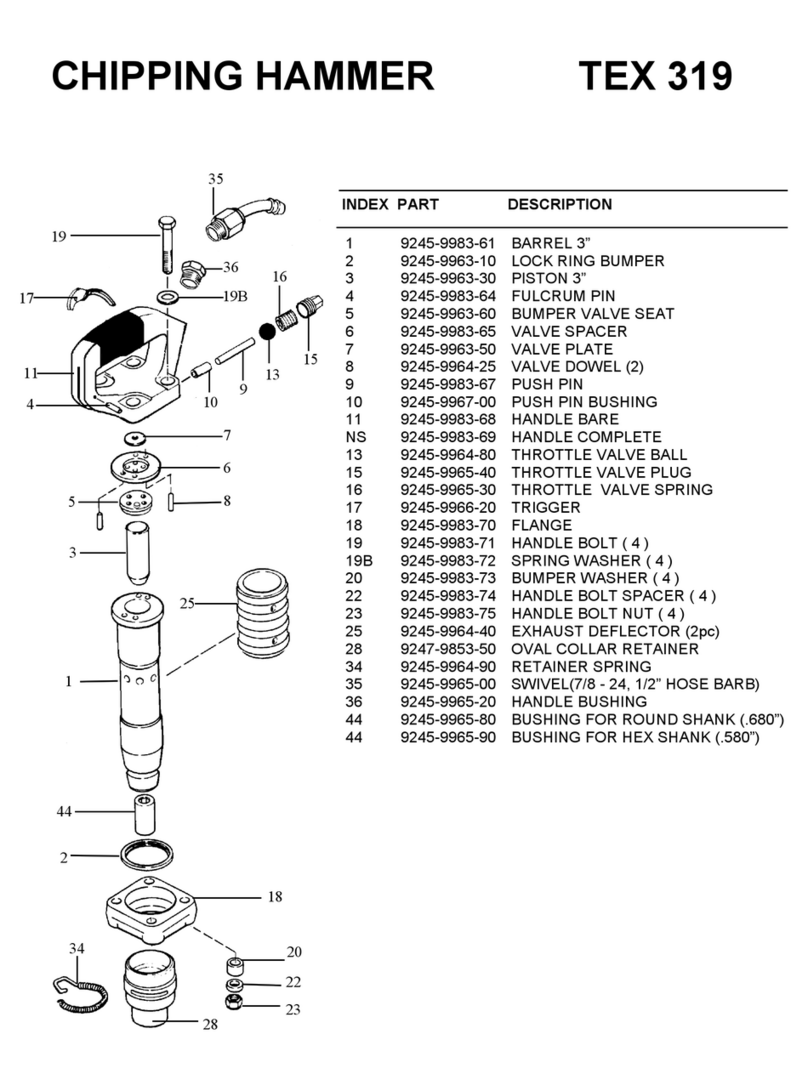

Selection of spare parts

Use only genuine parts for replacement, to ensure stable performance. Never

use pattern parts, which not only have a short working life but also cause

consequential damage to other parts, due to differing measurements and methods

of manufacturing.