5

B. Equipment storage and installation requirements.

The equipment should be stored or installed in a shady, normal temperature,

ventilated and dry place.

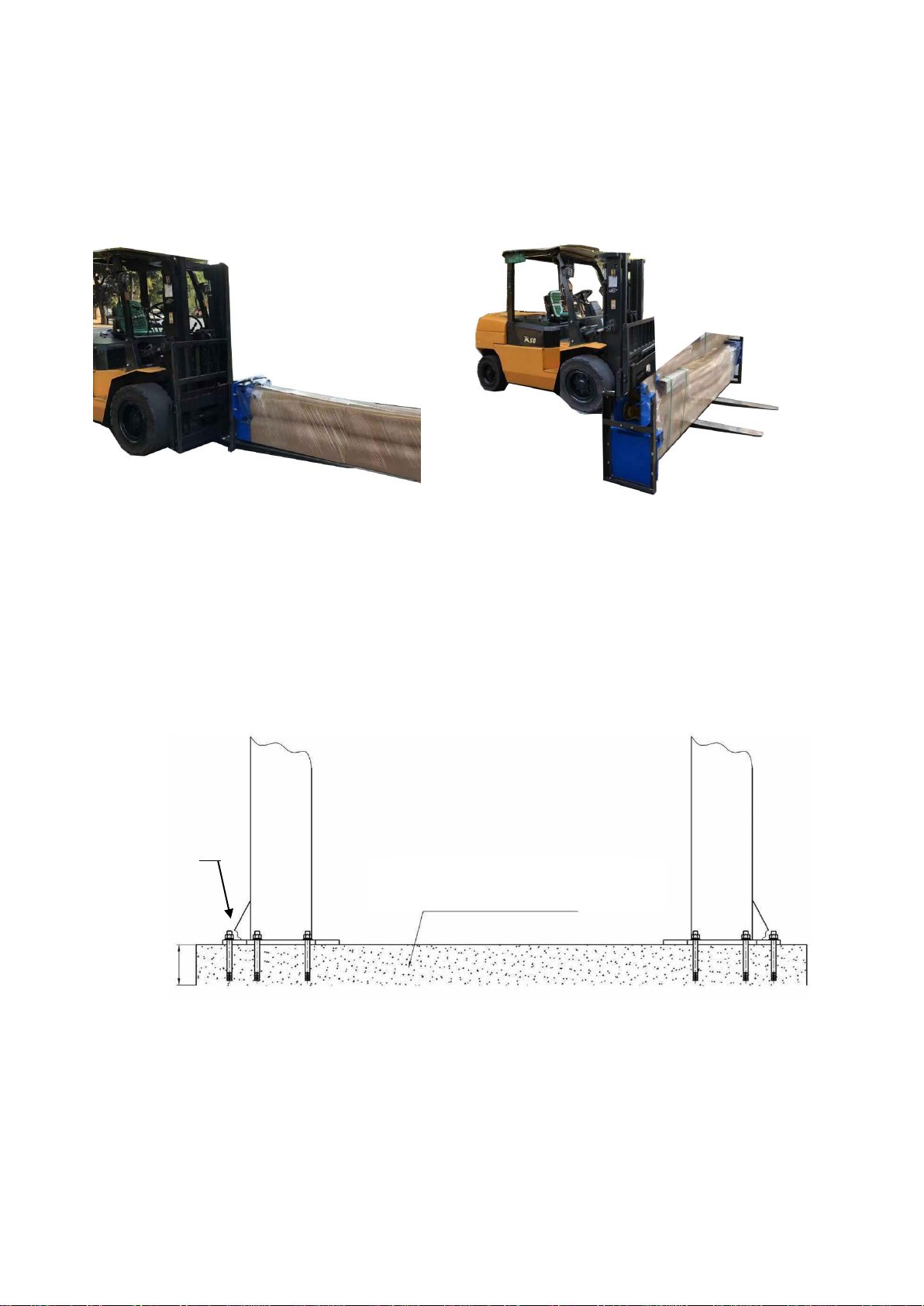

C. The equipment should be unloaded and transferred by forklift.

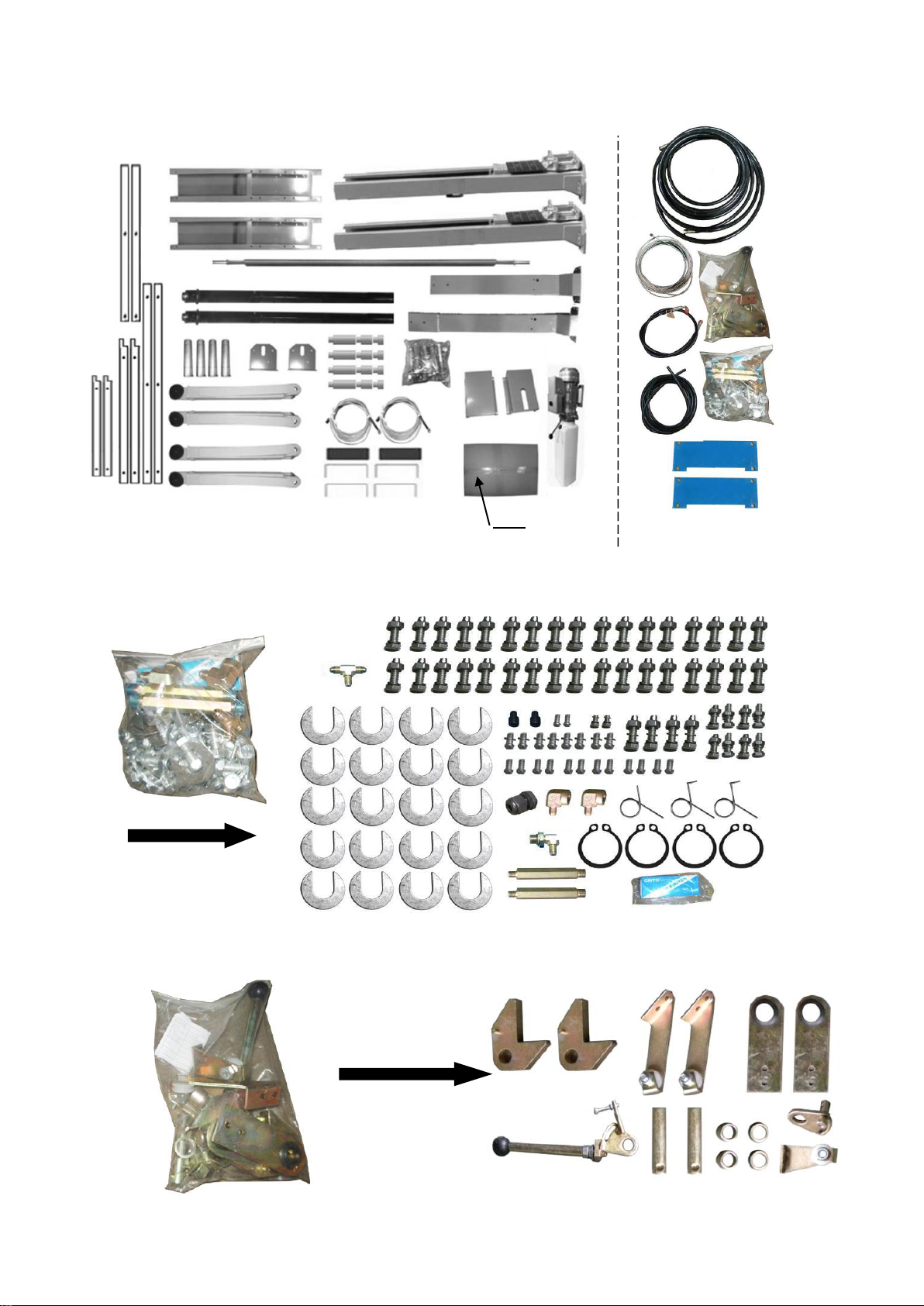

D. SPECIFICATIONS OF CONCRETE (See Fig. 5)

Concrete must adhere to the specifications listed below, failure to do so

may result in lift and/or vehicle falling.

1. Concrete must be thickness 6”minimum and without reinforcing steel bars, and

must be totally dry before lift installation.

2. Concrete must be in good condition and must be of test strength 3,000psi

(245kg/cm²) minimum.

3. Floors must be level with no cracks or holes.

E. POWER SUPPLY

220volt single phase source on a 30amp breaker with minimum of 10 gauge

wire running to the power unit. Operating voltage range is 208v-230v.