7

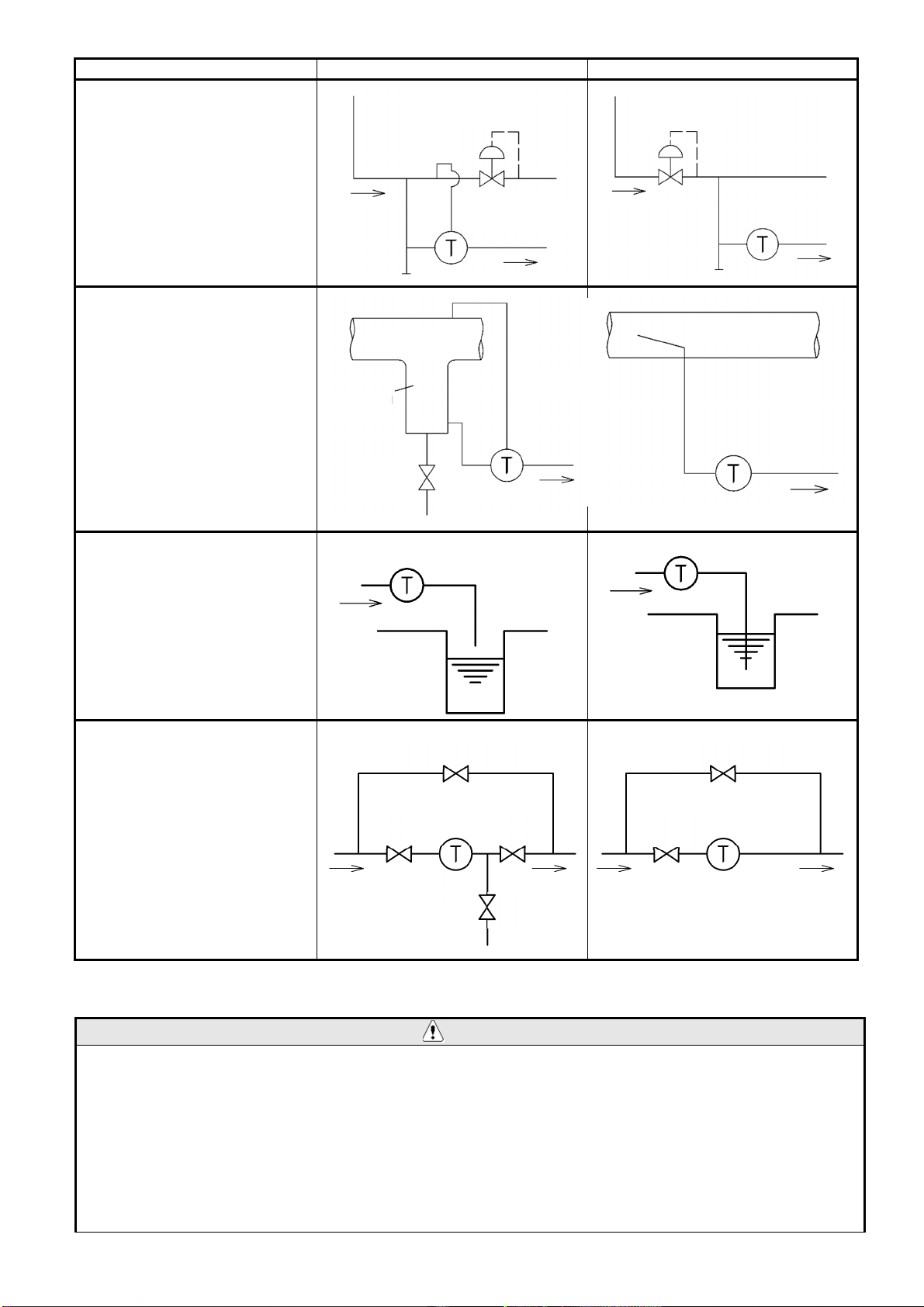

9. Slope

the piping and place the product at as a low position as possible in order to make condensate

flow into the product by its own weight.

10. To install the product in a main pipe, provide a drip leg at the inlet side of the product.

11. Install a strainer (mesh size of 80 or more is recommended) at the inlet side of the product.

12. Install the product so that it is not subjected to the shock of water hammer. Do not install a quick operating

valve before and/or after the product.

* Failure to follow this notice may result in malfunction due to damage to the float, or may result in scalds

or injury due to blow off when the product is subjected to an excessive shock and damaged.

13. Install a bypass line.

* The system has to stop operation while inspection and maintenance of the product if the bypass line is

not installed.

14. Be sure to install an equalizing line to prevent condensate accumulation.

*Install an equalizing line above the condensate level in the product.

7. Precaution for operating procedure

Warning

1. Before leading fluid, make sure that the product is securely connected to piping and that there is no

loose.

* Failure to follow this notice may result in scalds or injury due to blow-off.

2. Do not touch the product with bare hands while the product operates when using high temperature fluid.

* Failure to follow this notice may result in scalds.

3. Do not stand in front of the outlet opening of the product while the product operates.

* Failure to follow this notice may result in scalds or injury due to blow-off.

Caution

1. Slowly open each stop valve to prevent water hammer.

* Opening stop valves quickly may result in damage to other equipments due to hunting or water

hammer.

2. Do not turn the cock while the product operates.

* Do not turn the cock unless the pressure inside of the product and piping is completely discharged.

Forcing the cock to turn may result in damage to the cock.

* Wrong direction of the cock hampers proper operation.

8. Precaution for maintenance

Warning

1. When using high temperature fluid, do not touch the product with bare hands.

* Failure to follow this notice may result in burns.

2. Be sure to completely release the internal pressure of the product, piping, and equipment when

disassembling and maintenance. In the case of high temperature fluid, please cool the product body

until it touches with bare hands.

* Failure to follow this notice may result in scalds or injury due to residual pressure.