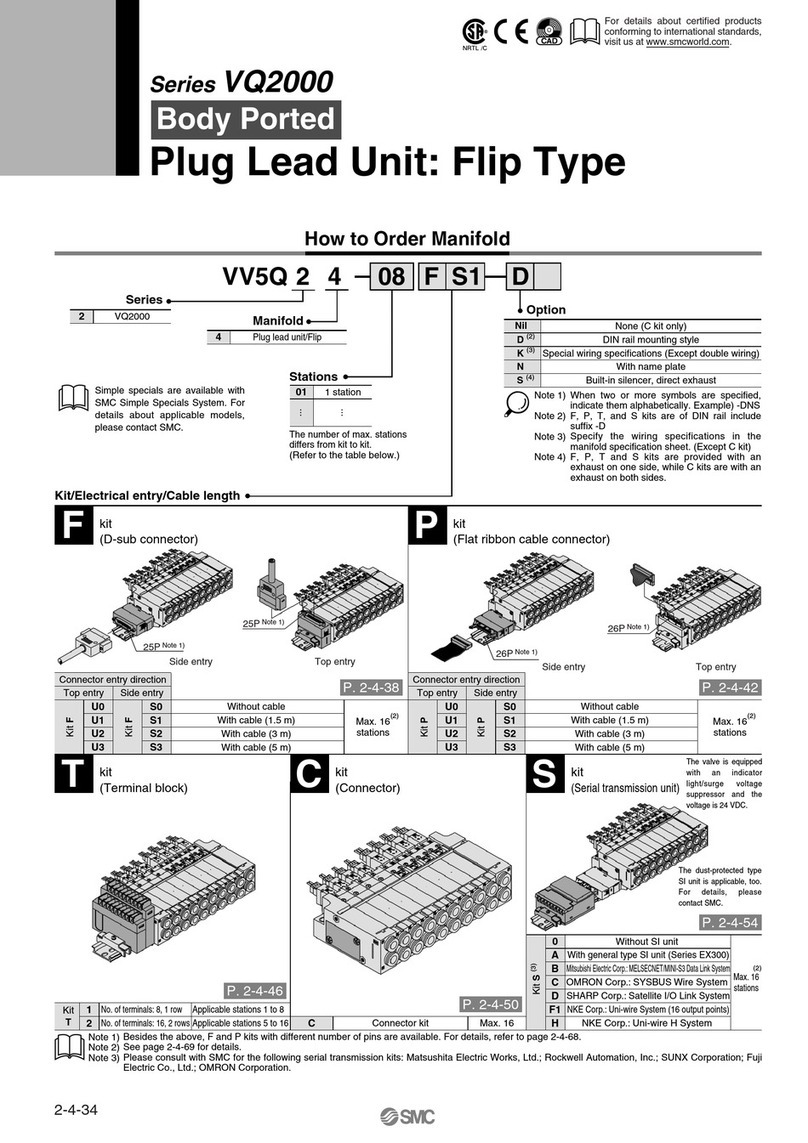

Mounting Bracket Part No.

Bore size (mm)

Foot (1)

Flange (2)

Single clevis

Double clevis (3)

CS1-F12

CS1-C12

CS1-D12

CS1-F14

CS1-C14

CS1-D14

CS1-F16

CS1-C16

CS1-D16

Accessory

Mounting bracket

—

Standard equipment

Option

Clevis pin

Rod end nut

Single knuckle joint

Double knuckle joint (With pin)

With rod boot

—————

Basic style Foot style

Rod side style

Flange side style

(kg)

Bore size (mm)

Basic style

Foot style

Flange style

Single clevis style

Single knuckle joint

Double knuckle joint (With pin)

Rod end nut

125

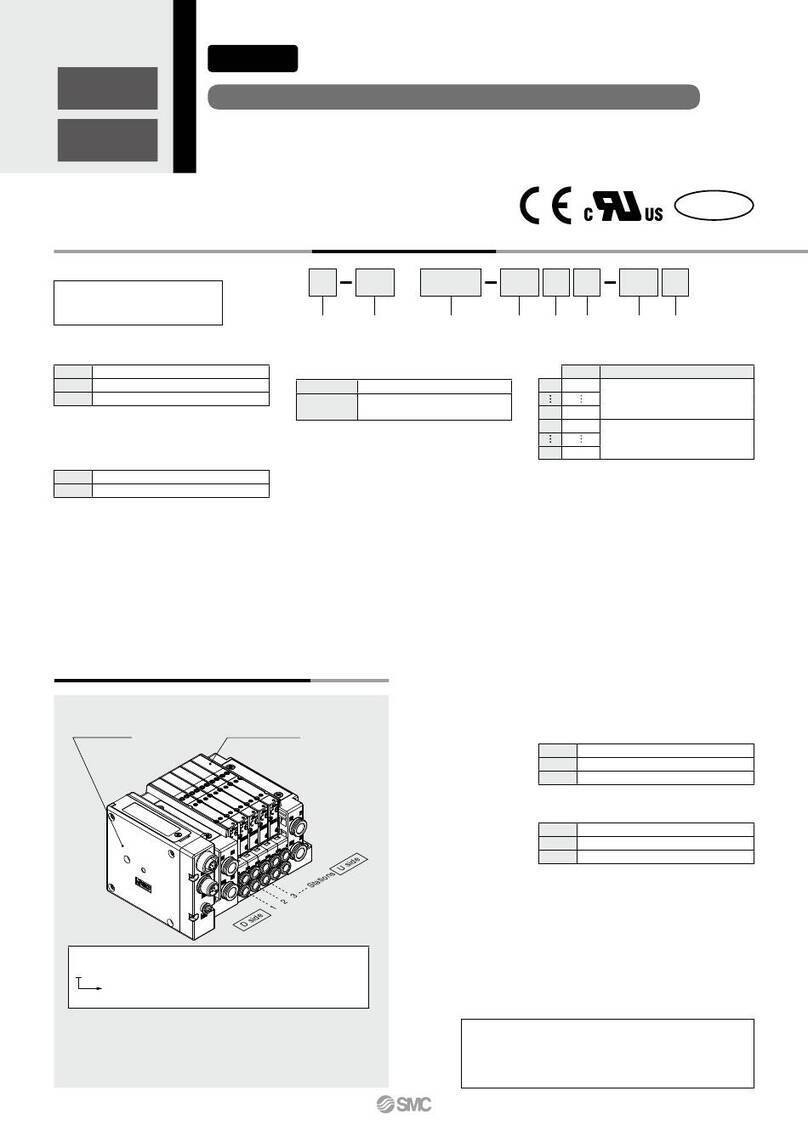

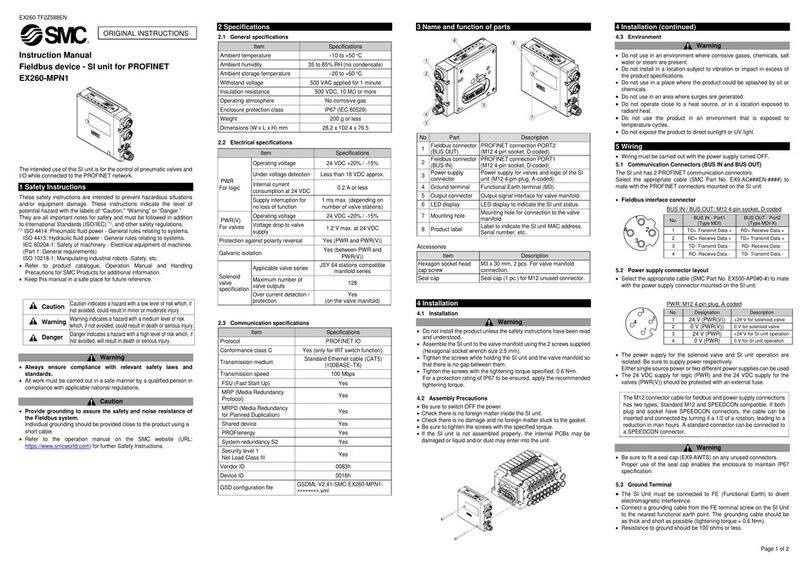

Construction Principle

Basic weight············ 40.19 (Foot style, ø140)

Additional weight ···· 1.96/100 stroke

Cylinder stroke ······· 100 stroke

40.19 + 1.96 x 100/100 = 42.15 kg

Spring locking (Exhaust lock)

The spring force which acts upon the taper ring is

magnified by a wedge effect, and is conveyed to all

of the numerous steel balls which are arranged in

two circles. These act on the brake shoe holder and

brake, which locks the piston rod by tightening

against it with a large force.

Unlocking is accomplished when air pressure is

supplied to the unlocking port. The release piston

and taper ring oppose the spring force, moving to

the right side, and the ball retainer strikes the cover

section A. The braking force is released as the steel

balls are removed from the taper ring by the ball

retainer.

Locked state Unlocked state

140 160

14.40

28.79

(30.26)

30.42

(31.89)

31.47

(32.94)

31.86

(33.33)

32.32

(33.79)

32.92

(34.39)

1.77

(2.66)

0.91

1.37

0.16

20.20

37.67

(39.48)

40.19

(42.00)

42.67

(44.48)

41.96

(43.77)

42.71

(44.52)

43.40

(45.21)

1.96

(3.01)

1.16

1.81

0.16

30.60

55.31

(57.52)

58.11

(60.32)

61.70

(63.91)

60.80

(63.01)

61.65

(63.86)

62.71

(64.92)

2.39

(3.58)

1.56

2.48

0.23

Lock unit weight

Trunnion style

Double clevis style

(Including clevis pin

and cotter pin)

Brake shoe holder

Brake shoe

Release piston

Air pressure exhaust

Air pressure supply

Steel ball

Ball retainer

Taper ring

Brake spring

Calculation: (Example) CNSL140-100

Note 1) When ordering foot bracket, order 2 pieces per cylinder.

Note 2) ø125 to ø160 rod side flange styles use Series CS1 long stroke

flanges.

Note 3) Clevis pin, plain washer, and cotter pin are shipped together with

double clevis style.

Head side

flange style

Double clevis

style

Center trunnion

style

Single clevis

style

Additional weight per each

100 mm of stroke

Basic

weight

Accessory

bracket

Series CNS

Weight/( ): Denotes the values for steel tube.

125 140 160

CS1-L12 CS1-L14 CS1-L16