3|Page

TABLE OF CONTENTS

Safety Consideraons......................................................................................................... 4

Before You Begin ................................................................................................................ 4

Water Quality Parameters .................................................................................................. 5

Assembly ............................................................................................................................ 6

System Sizing ...................................................................................................................... 8

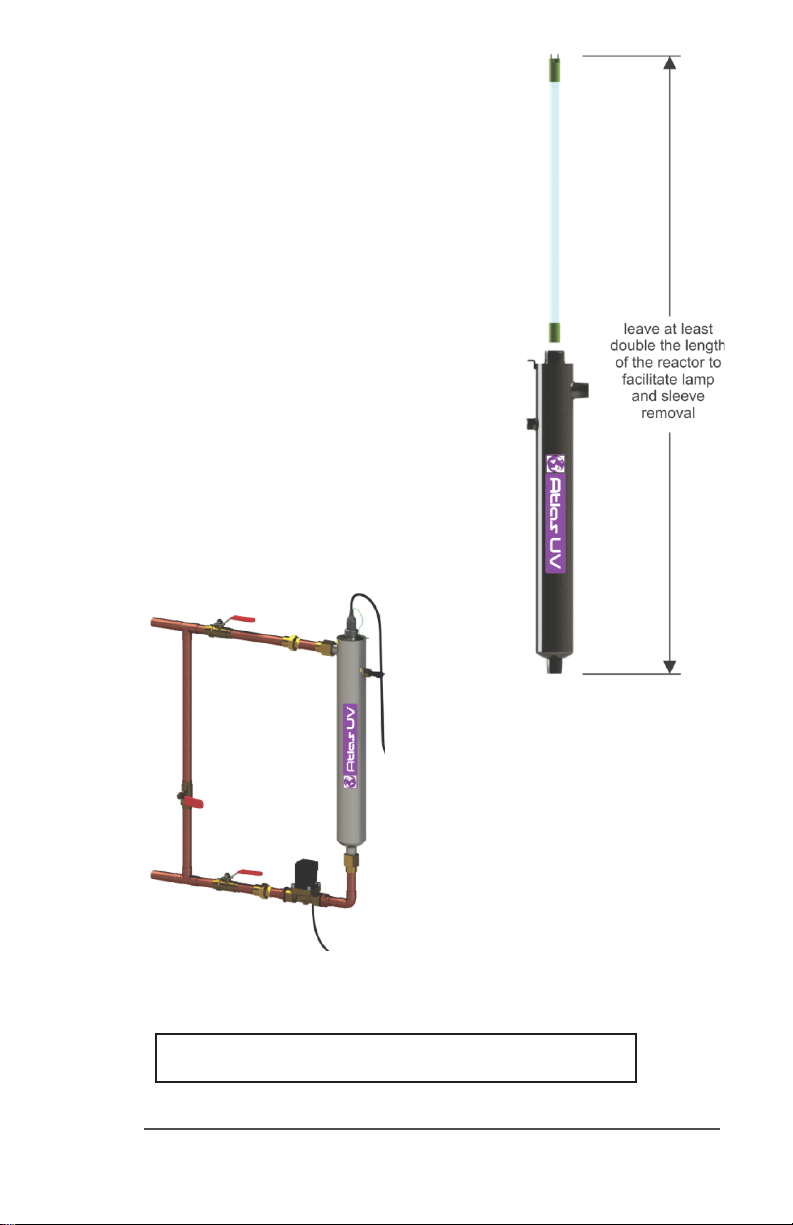

Locaon.............................................................................................................................. 8

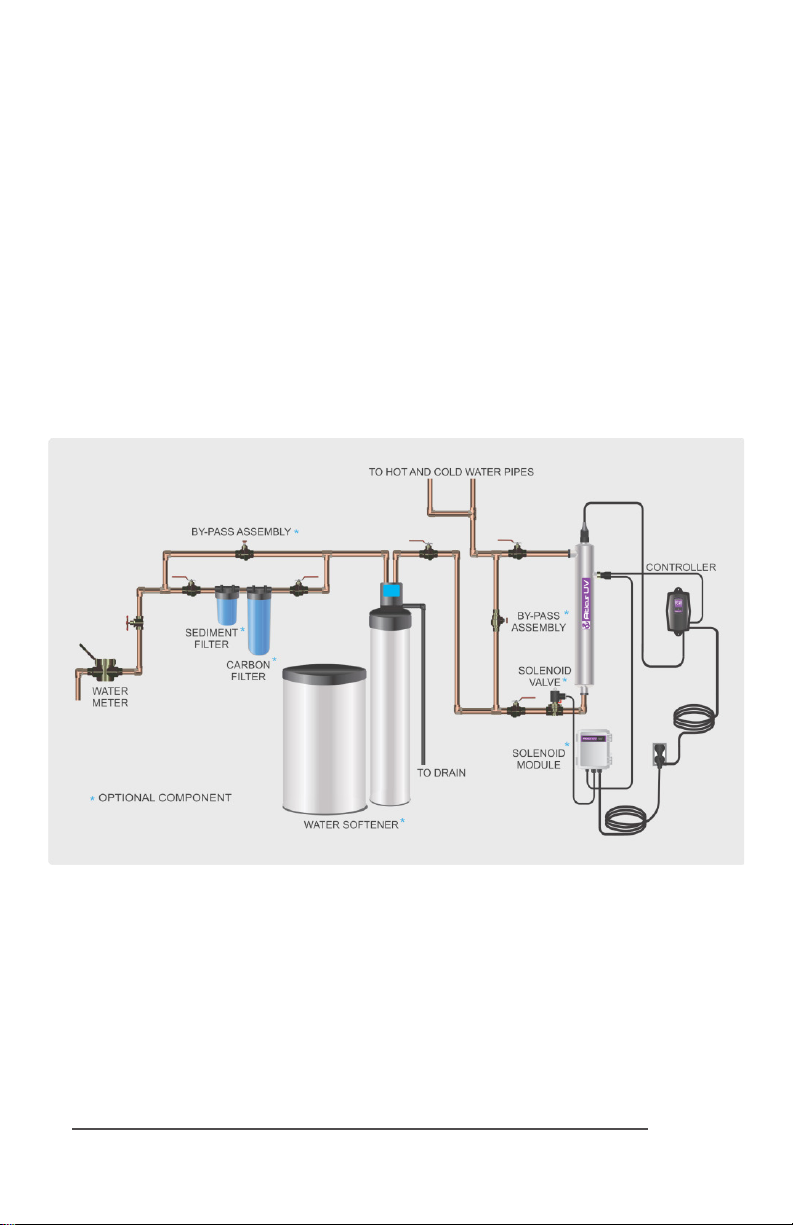

Installaon ......................................................................................................................... 9

System Disinfecon .......................................................................................................... 12

Cleaning the Quartz Sleeve .............................................................................................. 12

Cleaning the UV Sensor .................................................................................................... 13

Operaon ......................................................................................................................... 14

Controller............................................................................................................... 14

Power-up Sequence ............................................................................................... 14

Operaonal Screens............................................................................................... 15

Operaonal Screens with UV Monitor Upgrade .................................................... 16

UV Intensity (with UV Monitor Upgrade) .............................................................. 16

Lamp Countdown Sequence.................................................................................. 17

Lamp Countdown Reset Sequence ........................................................................ 17

Failure Modes ........................................................................................................ 18

QR Codes .......................................................................................................................... 18

Expansion Modules .......................................................................................................... 19

Atlas UV Standard Output System Specicaons............................................................. 20

Atlas UV High Output System Specicaons .................................................................... 21

Limited Warranty Statement: ........................................................................................... 22

Warranty Registraon ...................................................................................................... 23