Aqua Treatment Service ©2013 • www.aquat.com

8

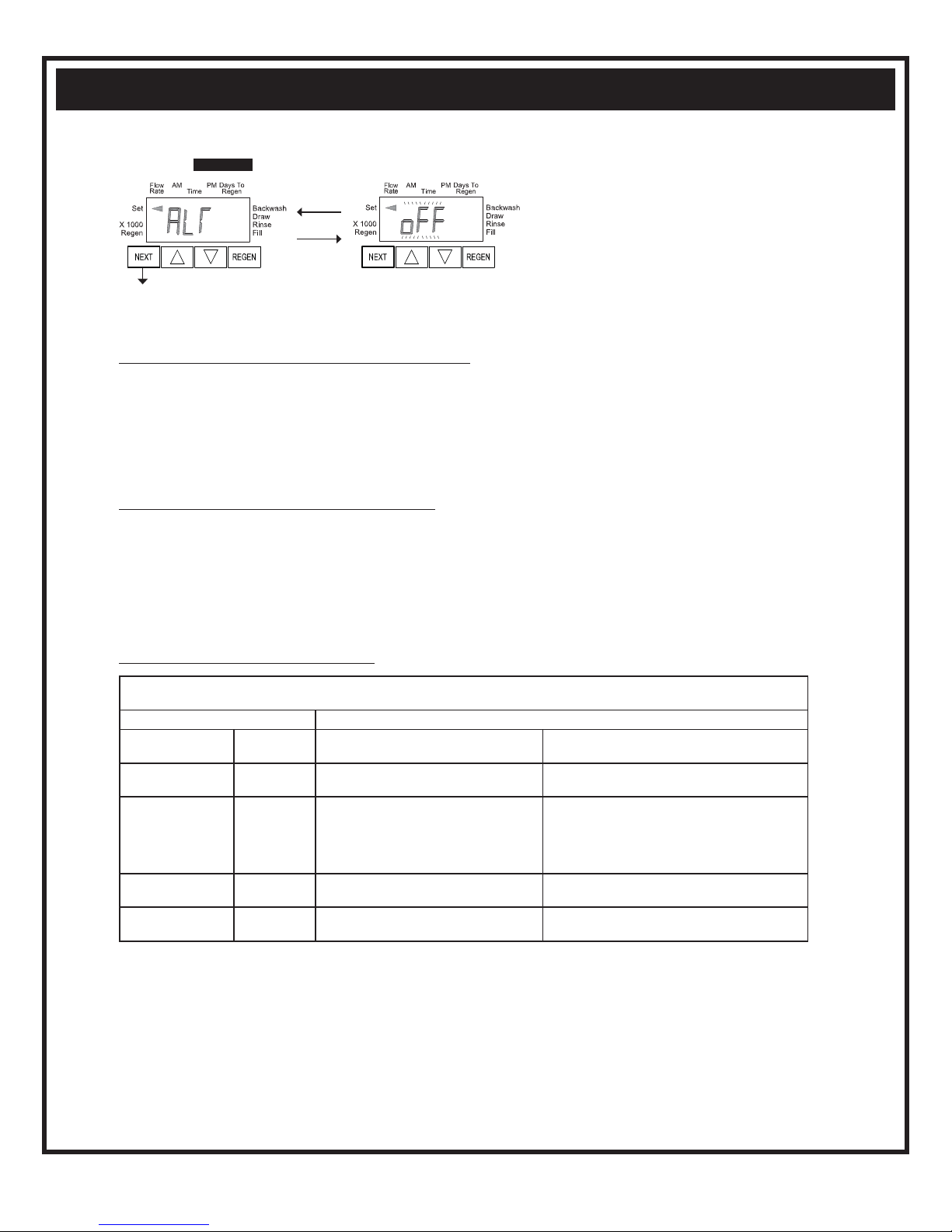

Step 5CS – - Allows selection of one of the following

using the Vor Wbuttons:

• the Control Valve to have no hard water bypass;

• the Control Valve to act as an alternator; or

• the Control Valve to have a separate source during the

regeneration cycle.

Select OFF when none of these features are used.

Only use Clack No Hard Water Bypass Valves or

Clack Motorized Alternating Valves (MAV) with these

selections. Clack No Hard Water Bypass Valves (1” or 1.25” V3070FF or V3070FM) are not designed to be used with the alternator or separate

source functions. The V3063 and V3063BSPT motorized alternating valves are not designed to be used as a no hard water bypass or separate

source inlet if the pressure differential is more than 60 psi.

Conguring the Control Valve for No Hard Water Bypass Operation:

Select nHbP for control operation. For no hard water bypass operation the three wire connector is not used.

Selection requires that a connection to MAV or a Clack No Hard Water Bypass Valve is made to the two pin connector labeled ALTERNATOR

DRIVE located on the printed circuit board. If using a MAV, the A port of the MAV must be plugged and the valve outlet connected to the B

port. When set to nHbP the MAV will be driven closed before the rst regeneration cycle that is not FILL or SOFTENING or FILTERING, and

be driven open after the last regeneration cycle that is not FILL.

NOTE: If the control valve enters into an error state during regeneration mode, the no hard water bypass valve will remain in its current state

until the error is corrected and reset.

Conguring the Control Valve for Separate Source Operation:

Select nHbP for control operation. For separate source operation the three wire connector is not used.

Selection requires that a connection to a Clack Motorized Alternator Valve (MAV) is made to the two pin connector labeled ALTERNATOR

DRIVE located on the printed circuit board. The C port of the MAV must be connected to the valve inlet and the A port connected to the separate

source used during regeneration. The B port must be connected to the feed water supply.

When set to nHbP the MAV will be driven closed before the rst regeneration cycle, and be driven open after the last regeneration cycle.

NOTE: If the control valve enters into an error state during regeneration mode, the MAV will remain in its current state until the error is

corrected and reset.

Selecting the Control Valve to act as an alternator:

Prior to starting the programming steps, connect the interconnect cable to each control valve board’s three pin connector labeled

“INTERCONNECT”. Also connect the meter cord to either control valve to the three pin connector labeled “METER”.

Valve Programming Steps

Conguration

Settings Step 3CS Select Volume Set Volume

Conguration

Settings Step 4CS Set regeneration time option to “On O”. Set regeneration time option to “On O”.

Conguration

Settings Step5CS

Set to ALTA

Connect ALTA valve to the MAV’s A

port and connect the MAV’s two pin wire

connector to the two pin connector labeled

“DRIVE” on the ALTA valve

Set to ALTb

Connect ALTb valve to the MAV’s B port. No

connections between the ALTB valve and the MAV

are made.

Installer Display

Setting Step 2I Enter the Volumetric Capacity for the System Enter the Volumetric Capacity for the System (the

same as Valve A)

Installer Display

Setting Step 3I Set Day Over ride to “oFF” Set Day Over ride to “oFF”

NOTE: If the control valve is in an error state during regeneration mode the MAV will close the B port and keep open the A port until the error is

corrected and reset.

For Clack Corporation alternator systems using the WS1, WS1.25, WS1.5 and WS2L valves the stand by tank will be periodically brought on

line for a short time to keep its bed fresh. The logic is that once a tank is in standby and the time has passed either 6 AM or 6 PM (18:00) at the

next and all subsequent 6 AM and 6 PM times the stand by tank will be brought on line until 10 gallons (37.8 liters) has passed through it. It

will then be placed back on standby.

For Clack Corporation alternator systems using the WS2 valve, when NEXT is pressed after selecting ALTA or ALTb, a display will allow the

user to set the amount of pre-service rinse time for the stand by tank just prior to returning to service.

Press NEXT to go to Step 6CS. Press REGEN to return to previous step.

Step 5CS

Volume Volume

Control Valve cont: