Copyright information

Description of common icons

Essential knowledge for users

Safety precautions

Disclaimer

WARNING

WARNING

Warning Misuse of this product may lead to serious injury or death to the user.

Caution Misuse of this product may lead to serious injury to the user or material damage to the object involved.

The design of this product (including internal software) and its accessories is under the protection of relevant state-laws.Any

violation of the relevant rights of our company will be subject to legal sanctions. Users shall consciously abide by the relevant state

laws when using this product.

Thank you for using our products. Before using the product, please read this manual carefully and pay attention to the relevant

warnings and cautions mentioned in this manual.

Users are required to have basic knowledge of common sense and electrical operations before using the product. Minors shall

use the product under the guidance of a professional or guardian.

[Caution]:To avoid damaging the equipment and keep the safety of the operational environment,please read this manual

carefully and keep it well so that you may read it atanytime when necessary.

To avoid electric shock or injury to the human body or fire hazard,the following basic rules must be observed when using the

equipment.In order to ensure personal safety,only parts and accessories approved or recommended by the original factory

canbe used,otherwise serious consequences may occur!

When using this product, the soldering pencil/soldering tip, with the temperature up to 150-480℃, may cause burns to the

user or cause a fire due to improper application.

So Users shall strictly observe the following rules:

●

Keep this product away from flammable materials.

●

Keep the product out of children's reach.

●

Do not use this product if you are inexperienced or have no sufficient necessary knowledge without the guidance of

related personnel.

●

Do not use this product under wet environment or with wet hands to avoid electric shock.

●

Do not modify this product and its accessories without authorization.

●

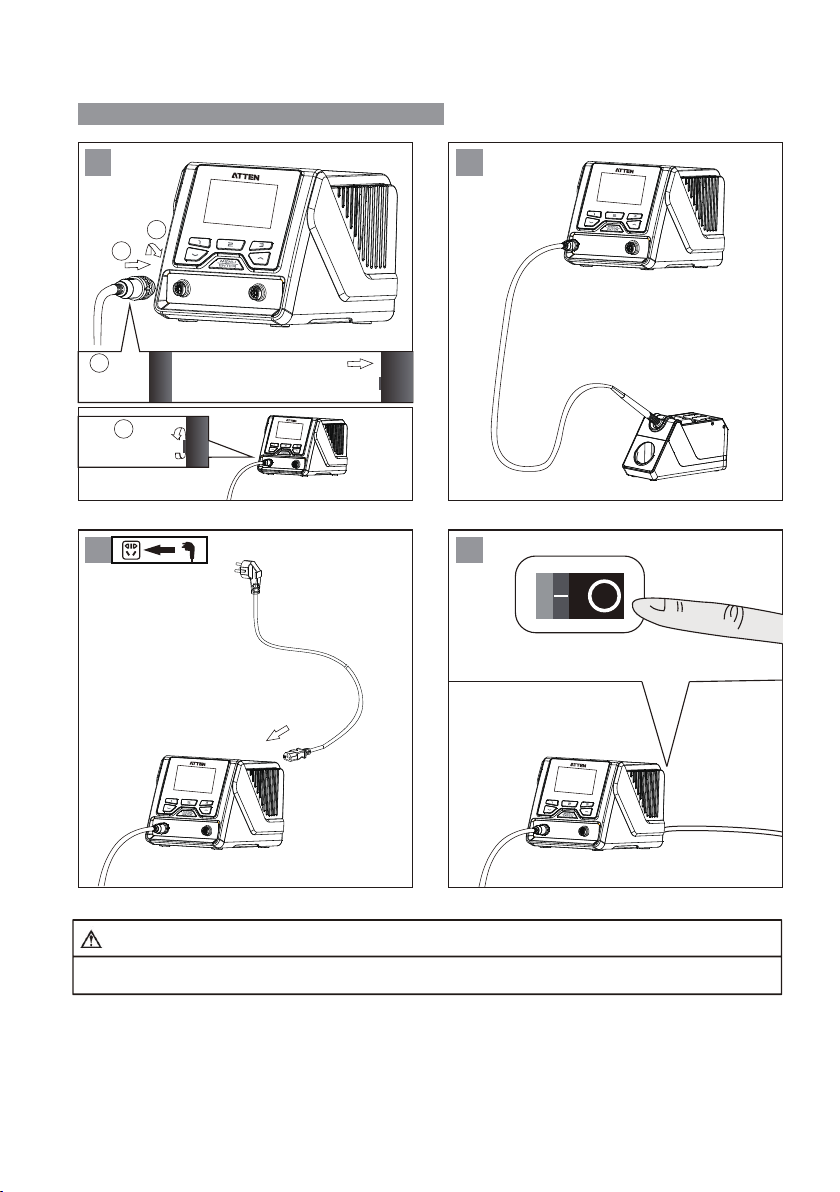

Please turn off the power when replacing parts and iron tips, and not resume the use until the equipment is completely

cooled down.

●

Please use the accessories from the original factory When replacing the product parts.

●

Make sure to turn off the power switch when the equipment is temporarily stopped or out of use.

●

To ensure the normal operation of this product’s ESD function,only three-core power cord shall be used as the host

connectingline.

●

Smoke will be generated during the soldering operations. So please pay attention to the smoke evacuation.

●

Do not play or do other similar dangerous actions during using this equipment, because it can easily lead to injury to

others or yourself.

●

Do not use this product for purposes other than soldering.

●

Do not modify this product and accessories, otherwise the original warranty will be invalidated or damage may occur to

the product.

●

When plugging and unplugging the power cord and handle plug, please hold the plug body and do not pull the cord.

●

Do not hit the product or its accessories too hard during the operation, otherwise damage may occur to the product.

We will take no responsibility for any personal injury or property damage caused by reasons other than the product quality

problem, which may include force majeure (natural disasters,etc.) or personal behavior during the operation of this product.

This manual is organized, compiled and released by SHENZHEN ATTEN TECHNOLOGY CO.,LTD. according to the latest

product features. We will not responsible for further notice of the subsequent improvement of the product and this Manual.