System Operations Manual

www.paceworldwide.com Page 7 of 50

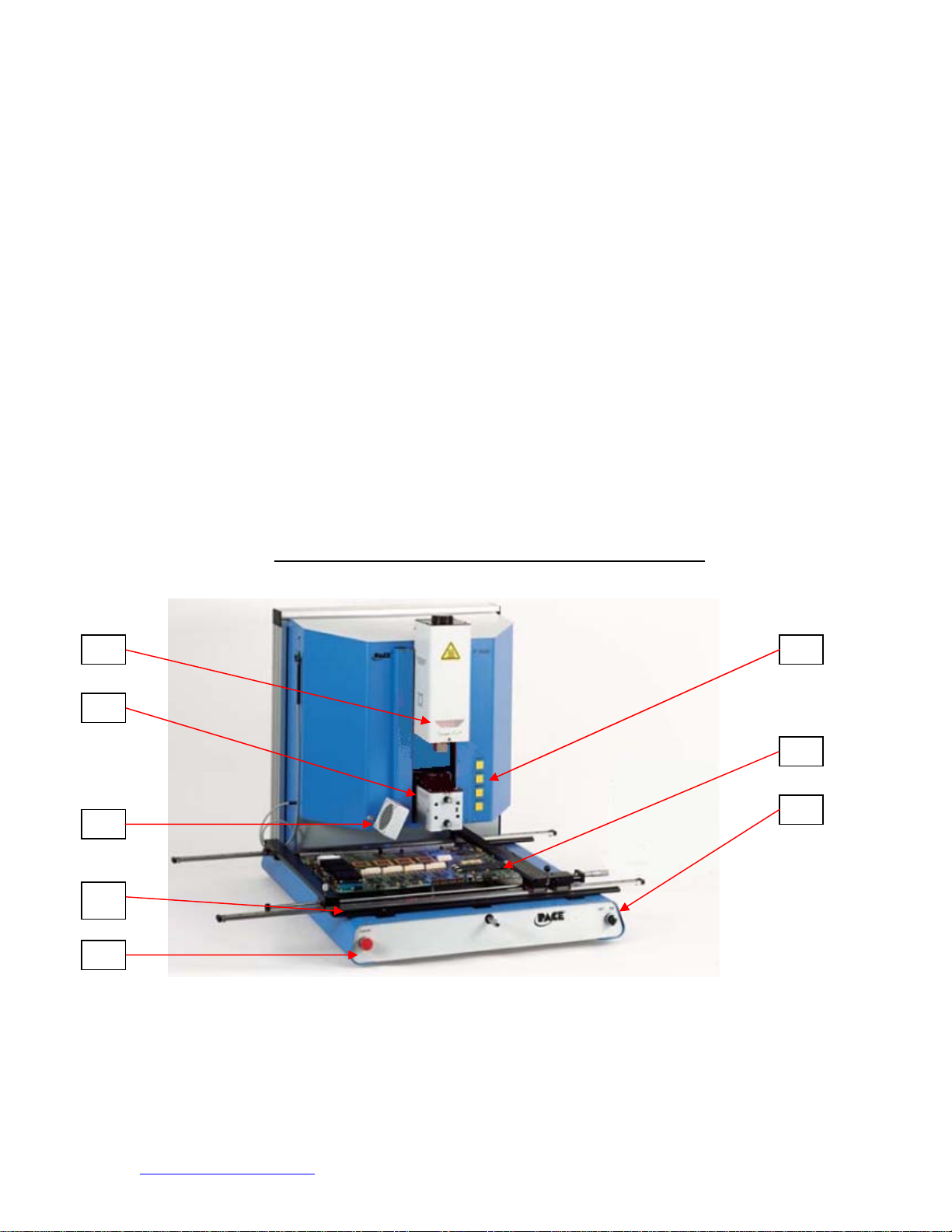

to use. The TF 1700 and TF2700 are a PC driven, semi-automated system that

requires a Pentium ® 4 PC featuring Windows XP® Professional OS. The unique

standard software package offers much more than just an operator interface.

PACE BGA Rework Stations advanced vision and placement system is highly

accurate and can quickly magnify even the smallest components for easy

alignment. TF 1700 and TF 2700 uses a combination of convective top heating

coupled with powerful IR bottom heating for an effective, repeatable heating

process.

c. Economical and easy to use, PACE BGA Rework Systems deliver high-end

BGA/CSP functionality, moving far beyond expensive, bulky rework machines by

offering unparalleled performance at an affordable price.

d. REFLOW FUNCTION

i. Unequalled programmability and process control ensures successful,

repeatable installation.

ii. The powerful and responsive 1200 Watt top heater, with closed loop

temperature control, coupled with proven nozzle design ensures uniform

temperature distribution when heating.

iii. High power bottom heater allow for successful and repeatable reflow at

safe, low temperatures.

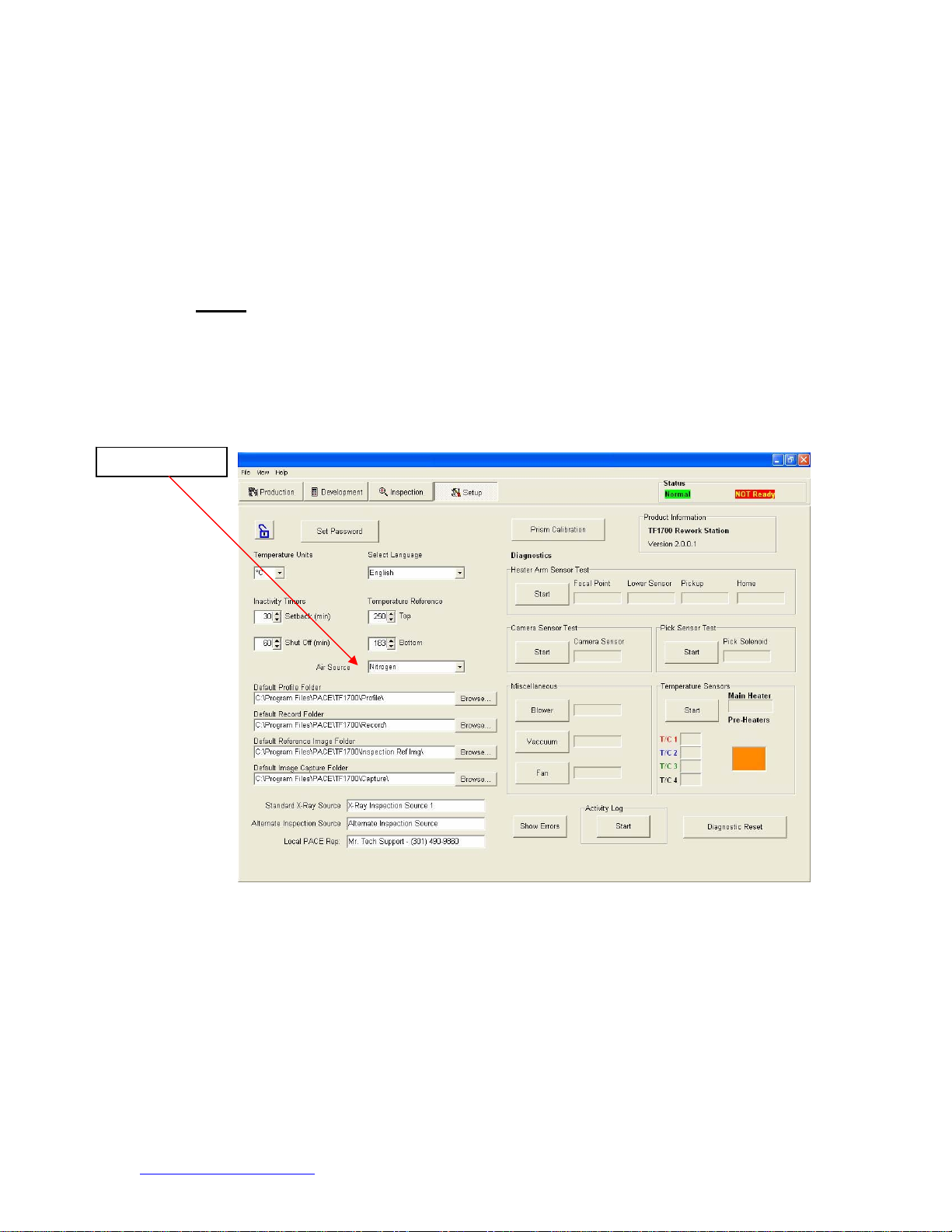

iv. Profiles are programmed through the PC software.

v. Creating the perfect profile is easy with real time adjustment of profile

parameters through the PC.

vi. Store and recall an infinite number of profiles.

vii. Two pre-defined profiles for use as baselines when developing custom

profiles are included.

viii. Self contained, no external air supply or vacuum connections required.

Can also be used with N2from external source.

ix. Semi-automated, motorized reflow head.

x. Four thermo-couple sensor inputs ensure successful profile development

and monitoring.

xi. External fan to cool PCB and component to below solder melt

temperatures after reflow.

e. ALIGNMENT AND PLACEMENT FUNCTION

i. The component is held by a precision vacuum placement pick, which is

located within the heater assembly.

ii. High resolution Color Vision Overlay System (VOS) with color camera

and dichroic prism. VOS does not require routine calibration, eliminating

costly downtime and operator frustration.

iii. Color Camera with 72x zoom capability, featuring auto-focus.

iv. Lighting system uses “Ultra Bright” White LEDs for maximum contrast of

lands and solder balls on component.

v. Independent lighting controls for component and PCB to maximize

overlay contrast.

vi. Retractable optics housing protects VOS from dirt and contamination.

vii. Accurately places any array package up to 65mm (2.5") square and as

small as 1 mm (.04”) square.

viii. Precise micrometer adjustment for X, and Y axis with Theta adjustment

ensures placement accuracy.

ix. High-flow vacuum pick holds component securely.

x. Images are viewed through the PC in standard or full screen viewing

options.

f. PRE-HEAT FUNCTION AND BOARD HOLDER