Table of contents

Table of contents

1 Introduction ...................................................................................................................................................... 7

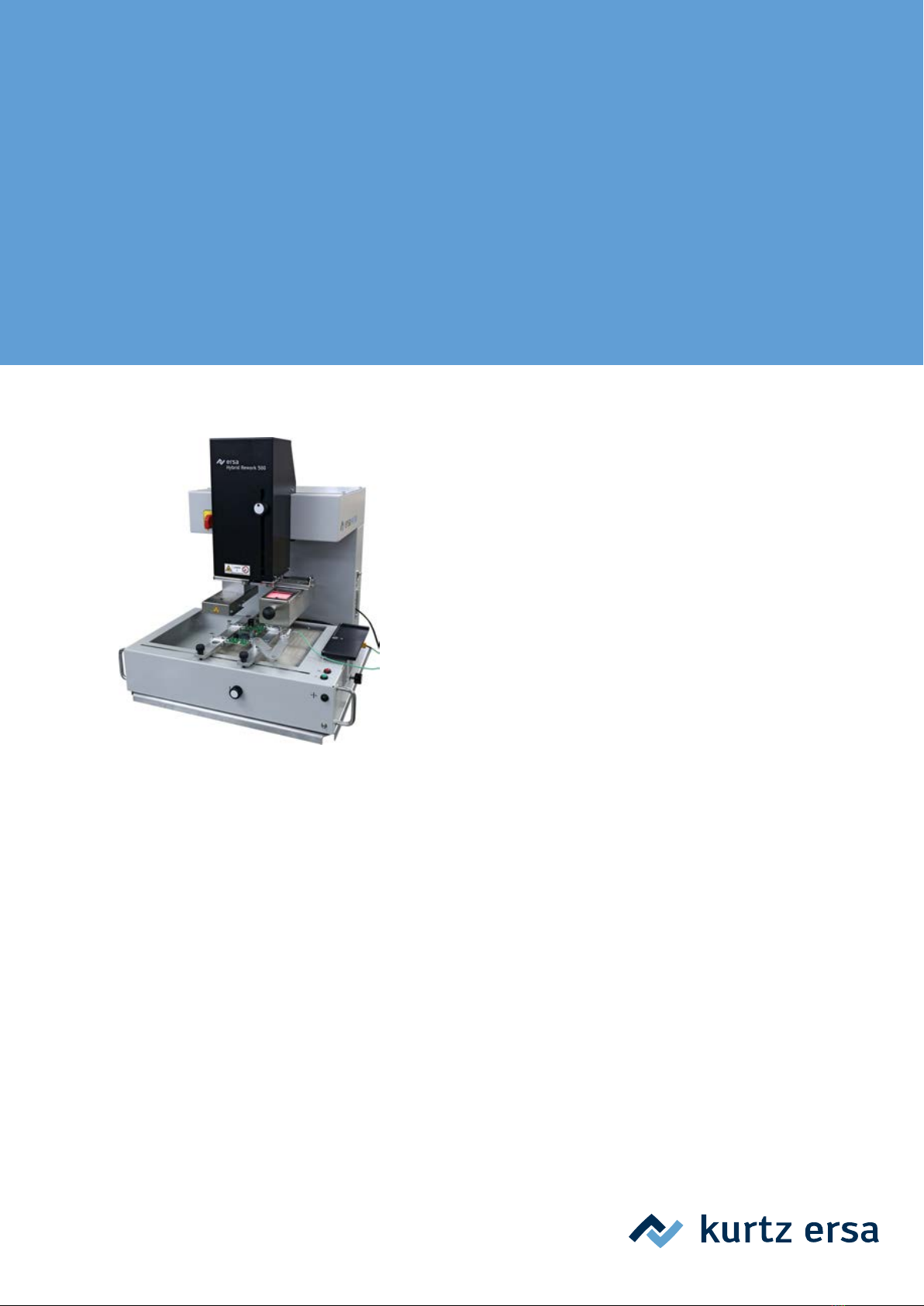

1.1 Product information.......................................................................................................................................... 8

1.1.1 General information about the product.............................................................................................8

1.1.2 Intended use.......................................................................................................................................8

1.1.3 Retrofitting, changes ..........................................................................................................................8

1.1.4 Warranty.............................................................................................................................................8

1.2 Information about this manual ......................................................................................................................... 9

1.2.1 Pictogram and symbol explanations.................................................................................................10

1.2.1.1 Prevailing term definitions in this instruction manual....................................................11

1.2.1.2 Warnings.........................................................................................................................12

1.2.1.3 Rule notices ....................................................................................................................13

1.2.1.4 Prohibition notices..........................................................................................................14

1.2.2 Target readers group ........................................................................................................................15

1.2.3 Copyright, liability.............................................................................................................................15

2 Technical data ..................................................................................................................................................17

2.1 Connection data.............................................................................................................................................. 18

2.2 Printed circuit boards and components.......................................................................................................... 18

2.3 General data.................................................................................................................................................... 18

2.4 Ambient conditions......................................................................................................................................... 18

2.5 Heating system................................................................................................................................................ 18

2.6 Axis system...................................................................................................................................................... 19

2.7 Cameras .......................................................................................................................................................... 19

2.8 PC system requirements ................................................................................................................................. 19

3 For your safety..................................................................................................................................................21

3.1 General safety instructions ............................................................................................................................. 22

3.1.1 Nationally valid safety and accident prevention regulations ...........................................................22

3.1.2 Fire protection ..................................................................................................................................22

3.2 Subject-related safety instructions ................................................................................................................. 22

3.2.1 Dealing with electrical equipment....................................................................................................22

3.2.2 Dealing with process materials and substances ...............................................................................22

3.3 Safety instructions for certain operating phases ............................................................................................ 23

3.4 Safety instructions for maintenance, service, specific work, troubleshooting ............................................... 23

3.5 Safety instructions for certain machine and system parts..............................................................................24

3.5.1 Hot device.........................................................................................................................................24

3.5.2 Laser equipment...............................................................................................................................24

3.5.3 Using a solder fume extractor, plug available ..................................................................................24

3.6 Retrofitting and changes................................................................................................................................. 24

4 Transport, installation, storage, disposal ..........................................................................................................25

4.1 Information concerning machine transport and storage................................................................................ 26

4.2 Information on how to unpack the machine .................................................................................................. 26

4.3 Packaging with TIP n TELL indicator ................................................................................................................ 26

4.4 Scope of delivery............................................................................................................................................. 27

4.5 Available options............................................................................................................................................. 27

4.6 Unpacking, setting up and connecting the Rework System............................................................................ 29

4.6.1 Unpacking .........................................................................................................................................29

4.6.2 Set up................................................................................................................................................29

4.6.3 Remove the transport lock ...............................................................................................................30

4.6.4 Connecting the machine...................................................................................................................30

Ersa GmbH Operating_instructions HR 500 DE 3BA00246-01|Rev. 1 iii/124