attocube ANC300 User manual

Version:

3.

1

Modified:

January 2014

Products:

ANC300, ANM150, ANM200, ANM300

Fir ware:

18

-

04

-

2012

User Manual

Piezo Positioning Electronic

ANC300

Page 2

Open source software notice

The ANC300 and its odules (ANM150, ANM200, and ANM300) include certain

open source or other software originating fro third parties that is subject to the

GNU General Public License (GPL), GNU Library/Lesser General Public License

(LGPL) and different and/or additional copyright licenses, disclai ers and notices.

You ay obtain a co plete corresponding achine-readable copy of the source

code of such software under the GPL or LGPL fro attocube syste s. attocube sys-

te s offers to provide such source code to you on CD-ROM for a charge covering

the cost of perfor ing such distribution, such as the cost of edia, shipping and

handling, upon written request to:

attocube syste s AG

Königinstrasse 11a RGB

D-80539 München

Ger any

This offer is valid for a period of three (3) years fro the date of the distribution of

this product by attocube.

ATTOCUBE SYSTEMS AG MAKES NO REPRESENTATION ABOUT THE SUITABILITY OF

THIS SOURCE CODE FOR ANY PURPOSE. IT IS PROVIDED "AS IS" WITHOUT EXPRESS

OR IMPLIED WARRANTY OF ANY KIND. ATTOCUBE SYSTEMS AG DISCLAIMS ALL

WARRANTIES WITH REGARD TO THIS SOURCE CODE, INCLUDING ALL IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL ATTOCUBE SYSTEMS AG BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, OR ANY DAMAGES WHATSOEVER

RESULTING FROM LOSS OF USE, DATA OR PROFITS, WHETHER IN AN ACTION OF

CONTRACT, NEGLIGENCE, OR OTHER TORTIOUS ACTION, ARISING OUT OF OR IN

CONNECTION WITH THE USE OR PERFORMANCE OF THIS SOURCE CODE.

Part of the Software is Copyright © 1994–2011 Lua.org, PUC-Rio.

THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE

AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER

LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM,

OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE

SOFTWARE.

LabView

TM

is a trade ark of National Instru ents Corporation.

Page 3

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

Table of Contents

List of Abbreviations..........................................................................5

I.

Introduction ..........................................................................7

I.1.

Syste Overview.................................................................7

I.2.

Safety Infor ation..............................................................8

I.2.a.

Safety Sy bols on the Equip ent ....................................8

I.2.b.

Safety Sy bols in this Manual .........................................9

I.2.c.

Warnings .................................................................. 10

I.3.

Declarations of Confor ity ................................................. 11

I.4.

Waste Electrical and Electronic Equip ent (WEEE) Directive ....... 12

II.

Setup Procedure.................................................................... 13

II.1.

Mechanical Installation...................................................... 13

II.1.a.

Positioning .............................................................. 13

II.2.

Electrical Installation ........................................................ 13

II.2.a.

Connecting to the Voltage Supply ................................. 13

II.2.b.

Fuses...................................................................... 14

II.3.

Front Panel Controls and Indicators ...................................... 16

II.4.

Back Panel Connections ..................................................... 18

II.4.a.

How to connect a positioner ........................................ 18

II.5.

Pin Assign ent ................................................................ 20

II.5.a.

Trigger Port.............................................................. 20

III.

Description of the Controller and General Use .............................. 21

III.1.

Overview......................................................................... 21

III.2.

Main Graphical User Interface.............................................. 22

III.2.a.

Start-up Screens ......................................................22

III.2.b.

General Usage of the ANC300 GUI ................................ 23

III.2.c.

Main Configuration Dialogs......................................... 23

III.2.d.

Feature Codes.......................................................... 24

III.2.e.

Network Configuration Dialog ..................................... 24

III.2.f.

Trigger Configuration Dialog ....................................... 25

III.2.g.

Li its Configuration Dialog........................................ 26

III.3.

ANM300 Module ............................................................... 27

III.3.a.

ANM300 Front Panel Usage......................................... 28

III.3.b.

ANM300 Axis Screen Ele ents and Usage ...................... 29

III.3.c.

Stepping Functionality .............................................. 30

III.3.d.

Offset Voltage Functionality ....................................... 31

III.3.e.

DC-IN Functionality .................................................. 32

III.3.f.

AC-IN Functionality ................................................... 33

III.3.g.

Filter Settings ......................................................... 33

III.3.h.

GND Functionality .................................................... 34

III.3.i.

Capacitance Measure ent .......................................... 35

III.3.j.

Li it Functionality.................................................... 36

III.4.

ANM150 Module ............................................................... 38

III.4.a.

ANM150 Axis Screen Ele ents and Usage ...................... 39

III.5.

ANM200 Module ............................................................... 40

III.5.a.

ANM200 Axis Screen Ele ents and Usage ...................... 41

IV.

Re ote Control of the ANC300 ................................................. 43

IV.1.

Connecting the ANC300 ..................................................... 43

IV.1.a.

Ethernet Connection.................................................. 43

IV.1.b.

USB Slave Port ......................................................... 43

Page 4

IV.1.c.

USB Master Port........................................................ 44

IV.1.d.

RS232 Port.............................................................. 44

IV.2.

Re ote Control ................................................................ 44

IV.2.a.

Standard Console Co ands....................................... 45

IV.2.b.

Exa ple Console Session............................................ 47

IV.2.c.

Progra ing new patterns ......................................... 48

IV.2.d.

Lua Console............................................................. 49

IV.3.

LabView™ Drivers..............................................................53

V.

Upgrades and Add-ons ........................................................... 58

V.1.

Fir ware Upgrade............................................................. 58

V.2.

Re oval of an Axis Module..................................................59

V.3.

Installation of an Axis Module ............................................. 60

VI.

Preventive Maintenance.......................................................... 61

VI.1.

Safety Testing.................................................................. 61

VI.2.

Fuses ............................................................................. 61

VI.3.

Cleaning ......................................................................... 61

VII.

Questions & Answers.............................................................. 62

Page 5

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

List of Abbreviations

A A pere. The unit of electrical current.

AC Alternating Current.

AC-IN Input connector on the frontplate for AC voltages. Also used for the corre-

sponding ode, which (de-)activates this input.

ASCII A erican Standard Code for Infor ation Interchange. A character-encoding

sche e based on the ordering of the English alphabet.

BNC Bayonet Navy Connector. Standard connector for coaxial cables, here only

used for 50 Oh i pedance connectors/cables.

°C Degree Celsius. The unit of te perature. Co pare to K.

COM Port Co unications port. Used to identify RS232 serial ports in PC operating

syste s, such as Linux or Windows. Exa ples: COM1, COM2, etc.

CPU Central Processing Unit. The ain controller in the ANC300.

CR Carriage Return. ASCII character code 13.

DC Direct Current. Identifies constant offsets or slow changing voltage levels.

DC-IN Input connector on the frontplate for DC voltages. Also used for the corre-

sponding ode, which (de-)activates this input.

DHCP Dyna ic Host Configuration Protocol. Protocol to auto atically assign an IP

address on a LAN network.

DOS Disk Operating Syste .

EC European Co unity.

EMC Electro-Magnetic Co patibility. Refers to corresponding CE regulations.

ESD Electrostatic Discharge. Sudden current equilibrating the electrical poten-

tials of two different objects. ESD currents ay da age electronic equip-

ent.

ETH Short for Ethernet. Used as synony for LAN.

F Farad. The unit of electrical capacitance. F = As/V

FAT File Allocation Table. FAT16 or FAT32 are file syste architectures widely

used on any co puter syste s, especially Windows™ PCs.

FPGA Field Progra able Gate Array. An integrated circuit that can be configured

at runti e by uploading certain boot code. The FPGA in the ANC300 controls

fast actions such as stepping as well as co unication functions.

FRQ Frequency. Used in conjunction with the stepping functionality of the

ANC300.

FTP File Transport Protocol. A basic internet protocol for sending/receiving files

over a LAN network or the internet.

GND Ground. Connection of chassis ass. Also used as description of a controller

ode, in which the outputs are deactivated and connected to chassis ass.

GUI Graphical User Interface. The interface displayed on the screen for user in-

teraction

HTTP Hypertext Transfer Protocol. Standard protocol used on LANs and the inter-

net.

Hz Hertz. The unit of frequency.

IP Internet protocol. The underlying basic protocol to FTP, HTTP, and others.

I/O Input / Output

LAN Local Area Network. Standard way of connecting several PCs or devices for

exchanging data over the internet.

LED Light E itting Diode.

LF Line Feed. ASCII character code 10.

Page 6

LUA A progra ing language for e bedded devices. See www.lua.org.

LVTTL Low Voltage Transistor to Transistor Logic. Triggering standard for direct

electrical end-to-end connections between two devices. Voltage levels are 0

and 3.3V. Co pare to TTL.

Meter. The unit of length.

OEM Original Equip ent Manufacturer.

OSV Offset Voltage.

PC Personal Co puter.

PCB Printed Circuit Board.

RoHS Reduction of Har ful Substances. Directive of the European Co unity.

RS232 Industry standard that defines characteristics of a serial, binary, single-

ended port. Used as synony for COM port.

s Seconds. The unit of ti e.

STP Step. Used in conjunction with the stepping functionality of the ANC300.

Sub-D Sub iniature D-type connector. Industry standard for serial connectors,

which is subdivided by the nu ber of electrical pins on the connector, e.g.

Sub-D25. Often also called D-Sub.

TTL Transistor-Transistor Logic. Used to describe the TTL-co patible logic levels

for the in- and outputs of electronic instru ents. Voltage levels are 0 and

5 V. Co pare to LVTTL.

USB Universal Serial Bus. A single-ended serial bus.

V Volt. The unit of voltage.

VI Virtual Instru ent. A co plete progra or subunit within the Labview pro-

gra ing environ ent.

WEEE Waste Electrical and Electronic Equip ent. Directive of the European Co -

unity.

Page 7

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

I. Introduction

I.1. System Overview

The Piezo Positioning Electronic ANC300 is a odular positioner control unit

providing the suitable drive signals to actuate attocube syste s positioners

or scanners anually or under co puter control. The ANC300 is available as

a odular housing that can host up to seven odules. There are odules

that enable (individually or co bined):

-perfor ing single as well as continuous stepping,

-applying DC offset voltages,

-a plifying DC voltages,

-ixing in of AC voltages, and/or

-easure ent of the attached capacitance.

The ANC300 can be controlled either anually fro the front panel, or re-

otely using:

-a virtual COM port over an USB connection to a PC,

-a serial port via an USB/serial adapter on the USB aster port, or

-a ter inal connection via the LAN port (2 types).

As the ANC300 can be connected to the local area network using the LAN in-

terface (ETH), one can also access the unit by connecting via web browser or

FTP (for updates only). For exa ple, one can download the anual or the

USB drivers using the built in web server.

The attocube syste s positioners are to be connected to the outputs of the

ANC300 using either the cable delivered with the syste for table-top appli-

cations, or by using user supplied cabling for applications in extre e envi-

ron ents such as low te peratures or ultra-high vacuu . Please refer to

the sections below for a description of the respective cabling require ents.

Page 8

I.2. Safety Information

For the continuing safety of the operators of this equip ent and the protec-

tion of the equip ent itself, the operator should take note of the Warnings

Cautions and Notes throughout this user anual and, where visible, on the

ANC300 itself.

I.2.a. Safety Symbols on the Equipment

WARNING. Risk of electric shock. High voltages present.

WARNING. Risk of an i ediate hazard, which will lead to severe personal

injury or death danger. Refer to the anual for details on this hazard.

Caution. Hot surface. May cause injury when touched.

Caution. Electro-statically sensitive device. Equip ent ay get da aged if

touched by personnel not grounded. Only touch with earthed wristband at-

tached or otherwise connected to ground.

Functional (EMC) earth/ground ter inal.

Page 9

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

I.2.b. Safety Symbols in this Manual

It is i portant to recognize safety infor ation. The safety alert sy bol-

- is used to draw your attention to potentials for personal injury or

property da age. The signal words WARNING and CAUTION are used with the

safety alert sy bol and identify the level of hazard seriousness.

WARNING. An instruction, which draws attention to hazards or unsafe prac-

tices which could result in severe personal injury or death, if the security

advice is not obeyed.

CAUTION. An instruction, which draws attention to hazards or unsafe prac-

tices which ay result in inor personal injury or da age to the product,

process, or surroundings.

Note

. Clarification of an instruction or additional infor ation.

Page 10

I.2.c. Warnings

WARNING. Risk of electrical shock. The piezo translators and controllers,

as described herein, are high voltage devices, capable of generating high

output currents. They ay cause serious or even lethal injuries if used i -

properly. Never touch any part that might have connection to the high

voltage output. Working with high voltage devices requires adequately

educated operating personnel.

WARNING. Risk of electrical shock. If the outputs are enabled while

plugging cables in or out there is a risk of touching har ful voltages.

Never connect any cabling to the electronics when the electronics is not in

GND ode!

WARNING. Risk of electric shock. If covers are opened, there is a risk to

touch hazardous voltages. If alfunction is suspected, i ediately con-

tact attocube syste s for repair or replace ent. Modified or opened elec-

tronics cannot be covered by the attocube warranty any ore. Only per-

sonnel trained in the servicing and aintenance of this equip ent should

re ove its covers or atte pt any repairs or adjust ents. Follow the Gen-

eral Accident Prevention Rules.

WARNING. Risk of electrical shock. If this product is used in a anner

not specified by the anufacturer, the protection provided by the product

ay be i paired. Do not operate the product outside its rated supply volt-

ages or environ ental range.

•For laboratory use only.

•This product is intended for operation in the te perature range

5° to 40°C, 20% to 80% RH. In particular, excessive oisture

ay i pair safety.

•If the unit has been stored at a low te perature or in an envi-

ron ent of high hu idity, it ust be allowed to reach a bient

conditions before being powered up.

•The product ust be connected only to an earthed fused single-

phase supply of 100V, 115V or 230 V, 50/60 Hz.

•To ensure reliable operation the unit should not be exposed to

corrosive agents or excessive oisture, heat or dust.

Page 11

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

CAUTION. Risk of damage. Plugging or unplugging odules of the elec-

tronics while connected to power line will irreversibly da age the . In-

ternal capacitors need to be discharged before plugging in or out co po-

nents. To replace odules, disconnect the ANC300 fro ains power and

wait for about 5 minutes before proceeding.

CAUTION. Risk of damage. Using the electronics in conjunction or con-

nection with equip ent fro other anufacturers not approved by atto-

cube ay result in da age to the electronics or other equip ent. atto-

cube is not liable for any da age resulting fro wrong usage or usage in

conjunction with other equip ent

I.3. Declarations of Conformity

For Customers in Europe

The ANC300 has been tested and found to co ply with the EC Directives

89/336/EEC ‘EMC Directive’ and 73/23/EEC ‘Low Voltage Directive’ as

a ended by 93/68/EEC.

Co pliance was de onstrated by confor ance to the following specifica-

tions which have been listed in the Official Journal of the European Co -

unities:

Safety EN61010: 2001

EMC EN61326: 1997

Page 12

I.4. Waste Electrical and Electronic Equipment (WEEE) Direc-

tive

DE16963721

Compliance

As required by the Waste Electrical and Electronic Equip ent (WEEE) Di-

rective of the European Co unity and the corresponding national laws,

attocube syste s offers all end users in the EC the possibility to return

"end of life" units without incurring disposal charges.

This offer is valid for attocube syste s electrical and electronic equip-

ent:

•sold after August 13th 2005,

•arked correspondingly with the crossed out "wheelie bin" logo

(see logo to the left),

•sold to a co pany or institute within the EC,

•currently owned by a co pany or institute within the EC,

•still co plete, not disasse bled, and not conta inated.

As the WEEE directive applies to self contained operational electrical and

electronic products, this "end of life" take back service does not refer to

other attocube products, such as

•pure OEM products, that eans asse blies to be built into a unit

by the user (e. g. OEM electronic drivers),

•co ponents,

•echanics and optics,

•left over parts of units disasse bled by the user (PCB's, housings

etc.).

If you wish to return an attocube unit for waste recovery, please contact

attocube syste s or your nearest dealer for further infor ation.

Waste treatment on your own responsibility

If you do not return an "end of life" product to attocube syste s, you

ust hand it to a co pany specialized in waste recovery. Do not dispose of

the unit in a litter bin or at a public waste disposal site.

Ecological background

It is well known that WEEE pollutes the environ ent by releasing toxic

products during deco position. The ai of the European RoHS directive is

to reduce the content of toxic substances in electronic products in the fu-

ture.

The intent of the WEEE directive is to enforce the recycling of WEEE. A con-

trolled recycling of end of live products will thereby avoid negative i -

pacts on the environ ent.

Page 13

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

II.Setup Procedure

II.1. Mechanical Installation

II.1.a. Positioning

Carefully unpack and visually inspect the controller and stages for any

da age. Place all co ponents on a flat and clean surface.

When placing the ANC300, it should be positioned so as not to i pede the

operation of the ain power supply plug and switch on the rear panel. En-

sure that proper airflow is aintained to the ANC300.

WARNING. Risk of fire. If airflow fro the ANC300 is blocked, the unit

ay overheat. Do not obscure any ventilation holes.

Note.

In applications requiring the highest level of accuracy and repeat-

ability, it is reco ended that the controller unit is powered up approxi-

ately 30 inutes before use, in order to allow the internal te perature

to stabilize.

II.2. Electrical Installation

II.2.a. Connecting to the Voltage Supply

WARNING. Risk of electric shock. If this product is used in a anner not

specified by the anufacturer, the protection provided by the product ay

be i paired. The product ust be connected only to an earthed fused sin-

gle-phase supply of 100 V, 115 V or 230 V, 50/60 Hz. To change the syste

voltage, see section 0.

The ANC300 is shipped with appropriate power cables for use in Europe,

UK, USA, and Japan. When shipped to other territories the appropriate

power plug ust be fitted by the user. Use only power supply cables sup-

plied by attocube syste s, other cables ay not be rated to the sa e cur-

rent.

Page 14

II.2.b. Fuses

WARNING. Risk of electrical shock. To exchange fuses:

1) Switch off the power and disconnect fro ains voltage before re-

oving the fuse cover.

2) After switching off, always wait 2 inutes before opening the

ANC300, and before re oving or inserting any odule or card.

3) Always replace broken fuses with fuses of the sa e type and rating.

Two ain fuses are located on the back panel for the ains voltage.

Four additional fuses are located on the inside of the power supply od-

ule.

Inspecting the main fuses

For inspecting the ain fuses, switch off, re ove the ains power cable,

and wait 2 inutes. Then:

-Lift the catch of the fuse holder carefully up and pull it out.

-Inspect the fuses.

-If the fuses are ok, re-insert the fuse holder into the controller.

Changing the Internal Fuses

There are four fuses located on the power supply itself. Inspect and

change the as follows:

-Switch off and separate fro ains power.

-Wait 2 inutes before going on.

-Open and re ove the frontcover or the odule next to the power

supply.

-Open the four screws of the front cover of the power supply.

-Pull out the power supply by grabbing the cooling body inside the

ANC300. Do not pull on the frontplate!

WARNING. Risk of damage. If pulling excessively

on the front plate, the front plate holder ight

break. Pull the cooling body instead!

Page 15

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

-Check the four fuses and replace the if necessary.

Fuse name value

Fu 1 (left ost) 2 A /250V fast blow

Fu 2 1 A /250V slow blow

Fu 3 1 A /250V slow blow

Fu 4 (right ost) 1 A /250V slow blow

-Once all fuses are ok, re-insert the power supply.

-Close the front cover screws.

-Put back the front cover/ odule in the slot next to the power supply.

-Make sure to disconnect any BNC cabling for a first test.

-Connect to ains voltage and switch on to check the functionality.

Changing the System Voltage

For changing the syste voltage setting you will have to re ove the fuse

holder and replace the fuses:

-Lift the catch of the fuse holder carefully and pull it out.

-Re ove the right of the two fuse cartridges.

-Turn the white inner fuse cartridge so that it shows desired voltage

value in the window.

-Reinsert the fuse cartridge into the fuse holder. Double-check that the

correct voltage is shown in the window.

-Replace the fuses with the correct fuse for your ains voltage (see the

correct fuse values in the following table).

Mains voltage Fuses

230 VAC, 50 / 60 Hz 1 A /250V slow blow

115 VAC, 50 / 60 Hz 2 A /250V slow blow

100 VAC, 50 / 60 Hz 2 A /250V slow blow

-Once you have the correct fuses and the correct voltage setting, re-

insert the fuse holder into the controller.

-Make sure to disconnect any BNC cabling for a first test.

-Connect to ains voltage and switch on to check the functionality.

Page 16

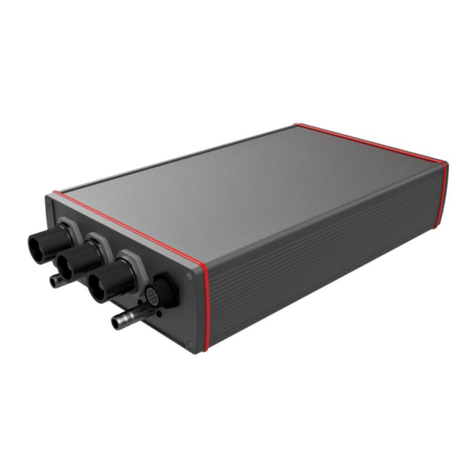

II.3. Front Panel Controls and Indicators

Figure 1:

Front panel of the ANC300 with seven ANM modules in place.

The front panel is arranged as follows:

1) Main display with touch screen functionality (CPU behind it),

2) View knob to ove the focus in the ain screen,

3) Edit knob to change values and activate options,

4) Power supply. There are fuses directly in the power supply that

can be checked in case of alfunctioning of the device. Unplug

the ANC300 fro ains before atte pting to open and slide out

the power supply.

5) 7 slots for odules.

See section III on how to use the controller. See section V.2 for re oving

and section V.3 for installing odules.

Here, the ANC300 is shown equipped with seven ANM odules. These

odules feature stepping as well as scanning functionality. There are dif-

ferent types of odules available. There are (see Figure 2):

•ANM150, stepping odule

•ANM200, scanning odule

•ANM300, co bined stepping and scanning odule.

2

1

3

4

5

Page 17

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

Figure 2:

Front panel of the ANM150 ANM200 and ANM300 modules. The different items are explained in the text.

On these odules, there are, dependent on the odel type:

1) OUT LED to indicate active outputs,

2) ACT LED to indicate activity such as stepping,

3) FRQ dial to change the frequency value for the respective axis,

4) AMP dial to change the stepping or offset a plitude,

5) AC-IN or MOD BNC connector to input AC voltages,

6) DC-IN BNC connector to input DC voltages,

7) STEP switch for triggering single steps up- or downwards (one

step per switching), and

CONT switch for triggering continuous stepping up- or downwards (step-

ping as long as pressed).

1

2

4

5

6

1

3

4

7

8

2

1

3

4

5

6

7

8

2

Page 18

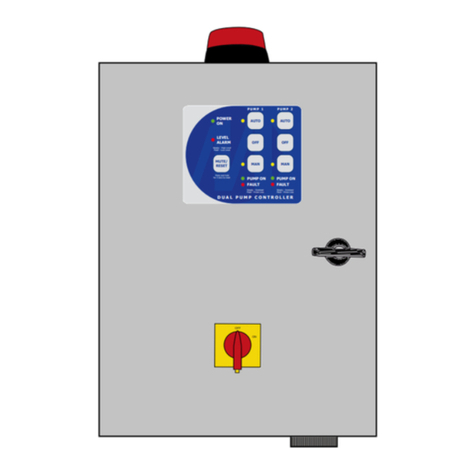

II.4. Back Panel Connections

Figure 3:

Back panel of the ANC 300 piezo positioning electronic

.

On the back panel, there are:

1) voltage selector (100 / 115 / 230 V) with integrated fuse holder

(see fuse description above),

2) ain power switch,

3) ain power supply connector, (IEC connector, 100 / 115 / 230 V,

each +/- 10%, 50 / 60 Hz, ax. 100 VA),

4) output BNC’s ( ax. 160 V DC, ax 4.5 A peak),

5) RS232 connector for serial connections to a PC,

6) 25 pin SubD in-/output connector for TTL triggering,

7) USB aster port for updates and USB / Serial adapters,

8) USB device port for connections to the PC,

9) Ethernet 10/100 port for LAN connections, and

10) CE label with serial nu ber and address of anufacturer.

II.4.a. How to connect a positioner

Positioner

Cable

optional

Vacuu

Extension Cable

Positioner

Vacuum

Feedthrough

1

2

3

4

5

6

7

8

9

10

Page 19

© 2001-2014 attocube syste s AG. Product and co pany na es listed are trade arks or trade na es of their respective

co panies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

Connecting a positioner is si ply done by connecting an adapter cable to

the BNC output port of the respective axis and to the connector of the

positioner.

WARNING. Risk of electric shock. Touching the inner connector of the

BNC connectors ay be dangerous, as there ight be high voltages pre-

sent. Do not touch the .

CAUTION. Risk of da age. Equip ent ay be da aged if not connected

correctly. The correct polarity is indicated by a red pin, which corresponds

always to the inner, positive contact of the BNC.

Page 20

II.5. Pin Assignment

II.5.a. Trigger Port

The pin assign ent of the 25 pin Sub-D connector (trigger port) as seen

on the back panel of the electronics is given in the table below:

Pin

No.

Trigger

Name

Default

Use

Pin

No.

Trigger

Name

Default

Use

1 1 Axis 1 UP 14 2 Axis 1 DOWN

2 3 Axis 2 UP 15 4 Axis 2 DOWN

3 5 Axis 3 UP 16 6 Axis 3 DOWN

4 7 Axis 4 UP 17 8 Axis 4 DOWN

5 9 Axis 5 UP 18 10 Axis 5 DOWN

6 11 Axis 6 UP 19 12 Axis 6 DOWN

7 13 Axis 7 UP 20 14 Axis 7 DOWN

8 15 21 16

9 Out 1 22 Out 2

10 Out 3 23 Out 4

11 reserved 24 reserved

12 3.3 V Supply 25 GND

13 3.3 V Supply

WARNING. Risk of injury and fire hazard. Do not, under any circu -

stances, atte pt to connect the digital I/O to any external equip ent that

is not galvanically isolated fro the ains or is connected to a voltage

higher than the li its specified in section II.2.

Note.

The output triggers have an output voltage level in high state of

about 3.3 V, with a axi u output current of about 20 A.

The axi u output current on the 3.3 V supply is about 300 A (10 Oh

output i pedance). The axi u reliable frequency is around 1.5 kHz.

13 12 11 10 9 8 7 6 5 4 3 2 1

25 24 23 22 21 20 19 18 17 16 15 14

Table of contents

Other attocube Controllers manuals

Popular Controllers manuals by other brands

Matelec

Matelec RPC-30030 Owner's operation manual

Fagor

Fagor 8055i FL EN operating manual

Leuze electronic

Leuze electronic MSI 100 SAFE IMPLEMENTATION AND OPERATION

Chauvet Professional

Chauvet Professional VIP Drive 21L Quick reference guide

ZPA Pecky, a.s.

ZPA Pecky, a.s. MODACT MOK 125 Installation and operating instructions

Rain Bird

Rain Bird ESP-TM2 user manual