MAINTENANCE

The Universal Ladder is made from durable materials

and is intended for outdoor use. However, minor

maintenance may be required periodically.

The Universal Ladder may be cleaned with warm soapy

water. Be sure to thoroughly rinse with clean water to

retain finish. May be towel or air-dried.

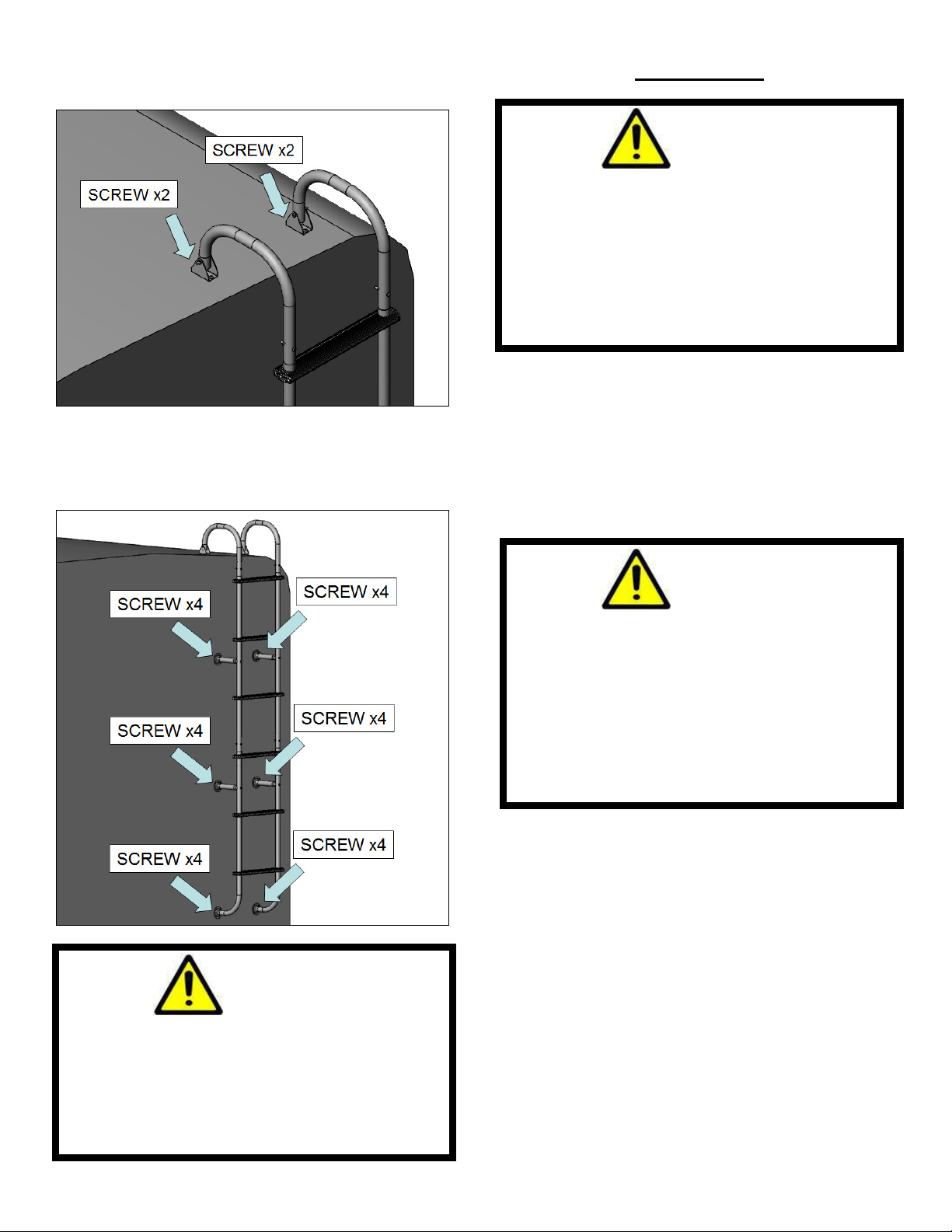

Check to make sure all fasteners are tight before and

after each use, and replace any missing fasteners before

use. Do not use Universal Ladder if any fasteners are

damaged, broken or missing.

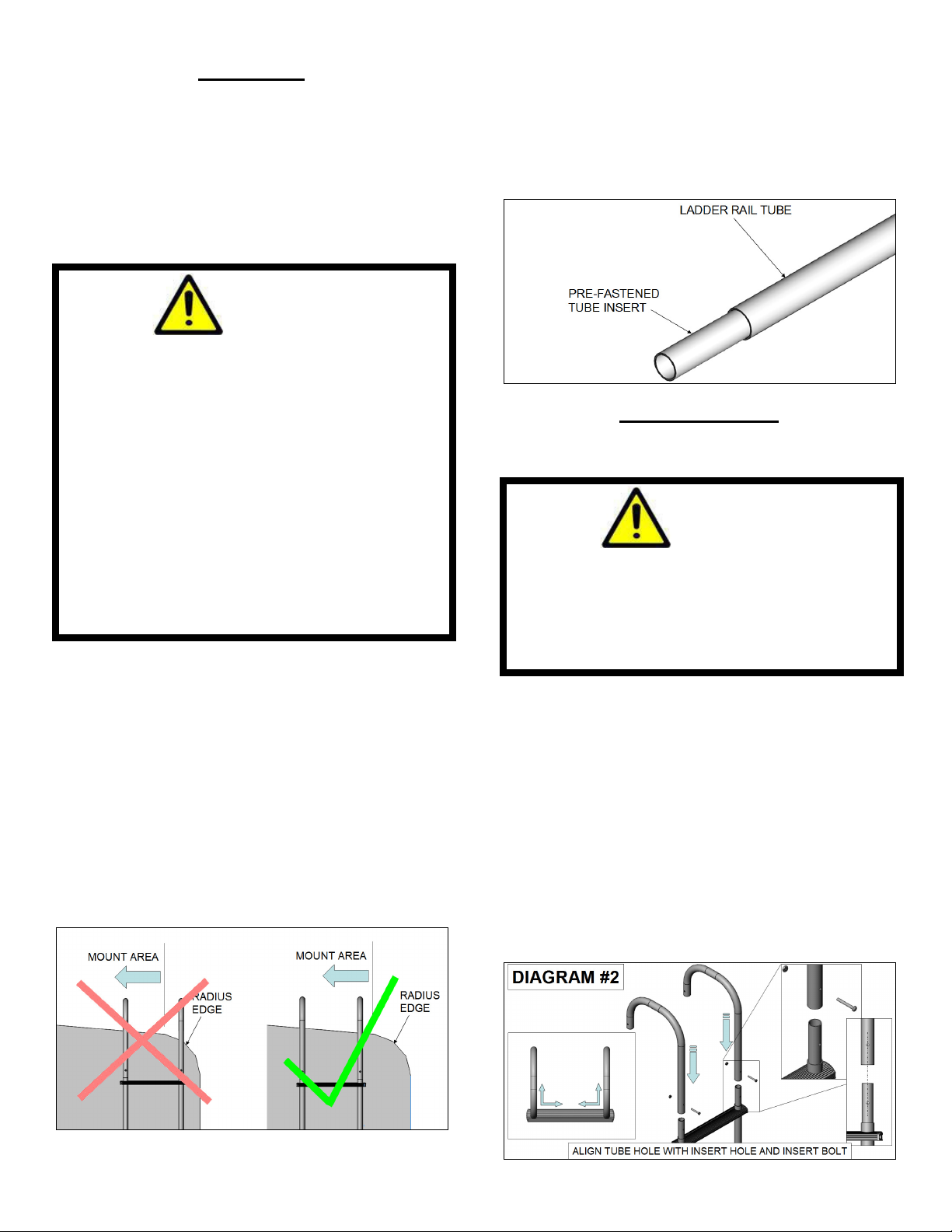

Periodically inspect the Universal Ladder tubing and

components for any damage, cracks or broken pieces.

Replace the Universal Ladder if damaged, cracked or

broken. Do not use Universal Ladder if any components

are damaged, broken or missing.

The Universal Ladder is intended to be a permanent

fixture. When vehicle is in storage or parked for

extended periods, the Universal Ladder should be

covered as minimizing the Universal Ladder

components’ exposure to the elements or other hazards

will prolong the life of the Universal Ladder and its

components.

ATWOOD MOBILE PRODUCTS LLC

LIMITED WARRANTY

Atwood Mobile Products LLC warrants to the original retail customer of products

manufactured by Atwood Mobile Products LLC and subject to the below

mentioned conditions, that this product will be free of defects in material and

workmanship for the below specified period of time from the original date of

purchase or manufacture. For the remainder of this document Atwood Mobile

Products LLC will be referred to as Atwood. Atwood’s liability hereunder is limited

to the replacement of the product, repair of the product, or replacement of the

product with a reconditioned product at the discretion of the manufacturer. This

warranty is not transferable and is intended for original purchaser only. This

warranty is void if the product has been damaged by accident, unreasonable use,

neglect, tampering, or other causes not arising from defects in material or

workmanship. The warranty extends to the original owner of the product and is

subject to the following conditions.

1) Atwood will repair or replace any part defective in material or

workmanship, after inspection by Atwood. This warranty includes labor

charges per Atwood’s Flat Rate Schedule as required to remove and

replace the part. Service calls to customer’s location and diagnostic time

are not considered part of these charges and, therefore may be the

responsibility of the owner.

2) In the event of a warranty claim, service may be performed at any

approved OEM dealer location

3) Parts being replaced must be shipped to Atwood “Prepaid” in first class

saleable condition and identified with a return goods number, unless other

arrangements have been made. Credit for shipping costs will be included

with the warranty claim. The defective parts become the property of

Atwood and must be returned to Atwood.

4) Returned goods – Goods may not be returned without our consent.

Requests for returns should be made within 10 days from receipt of our

invoice. If the parts being returned are not defective, Atwood reserves the

right to apply a 20% restocking fee. We cannot accept material which has

been custom fabricated or modified from its original design.

5) This warranty applies only if the product is installed, repaired, maintained

and operated according to the installation/service instructions. Any

deviations from these recommended specifications must be approved in

writing by Atwood.

6) The warranty period on replacement parts is the unused portion of the

original warranty period.

7) Damage or failure resulting from misuse (including failure to seek proper

repair service), misapplication or alterations is the owner’s responsibility.

8) Atwood does not assume responsibility for any loss of use, loss of time,

inconvenience, expense for gasoline, telephone, travel lodging, loss or

damage to personal property, or revenues. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the

above limitations or exclusions may not apply to you.

9) Any implied warranties are limited to the product’s warranty period. Some

states do not allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you. This warranty gives you

specific legal rights and you may also have other rights, which vary from

state to state.

10) Replacement parts purchased outside of the original warranty carry a 90-

day warranty.

11) Any action to enforce this warranty shall not be commenced more than 3

months after the expiration of this warranty.

12) THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY AND ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

WITHOUT LIMITATION THE IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR PURPOSE.

Product Specifications for products listed below are designed for use for their

specific application. Any other use, unless authorized in writing by the Atwood

Engineering Department, voids this warranty. Original date of purchase of unit

refers to the date the consumer purchases the vehicle from a dealer. Date of

manufacture refers to the date the item was produced by Atwood Mobile

Products.

Ladders – Two (2) years from original date of purchase of unit.

1) This limited warranty is valid only when the product is applied, installed,

maintained and operated in accordance with this Atwood Installation,

Maintenance and Operating Manual. Any deviation from these

recommended specifications must be approved in writing by Atwood.

2) Any implied warranties are limited to the duration of this limited warranty

as stated above. Atwood does not assume responsibility for

consequential damage or loss, including loss of vehicle, loss of time,

inconvenience, expense for gasoline, telephone, travel, lodging, loss or

damage to personal properties, or loss of revenues. Atwood’s maximum

liability shall not exceed the cost of the goods. Some states do not allow

limitations on how long an implied warranty lasts or limitations on

consequential damages, so the above limitations may not apply to you.

This limited warranty gives you specific legal rights which may vary from

state to state.