CONTENTS

MVS Series 1 710-03261-00D

Contents

Introduction ......................................................................................................................................3

Caution Statements ...................................................................................................3

General Description...................................................................................................4

2.1 Overview ................................................................................................4

2.2 About This Document ............................................................................4

2.3 Feature List ............................................................................................4

2.4 Part Number Format ..............................................................................5

Specifications.............................................................................................................6

3.1 Current Ratings......................................................................................6

3.2 Dimensions and Weights .......................................................................7

3.3 Key Components ...................................................................................8

3.4 General Technical Data .........................................................................8

Installation ......................................................................................................................................10

Key Features ...........................................................................................................10

Installation................................................................................................................11

4.1 Mounting Instructions - Power Assembly.............................................11

4.2 Mounting Instructions - MVS Controller ...............................................12

4.3 Power Terminations .............................................................................13

4.4 Earth Terminations...............................................................................14

4.5 Control Terminations............................................................................14

4.6 Terminal Block (MVS Controller) .........................................................14

Power Circuits..........................................................................................................15

5.1 Overview ..............................................................................................15

5.2 Main Contactor.....................................................................................15

5.3 Bypass Contactor.................................................................................15

5.4 Main Isolator/ Earth Switch ..................................................................16

5.5 R Rated Protection Fuses....................................................................16

5.6 Power Factor Correction ......................................................................17

5.7 Line Inductors ......................................................................................17

5.8 Transient/ Overvoltage Protection .......................................................17

5.9 Control Supply Transformer.................................................................18

5.10 Enclosures ..........................................................................................19

Control Circuits ........................................................................................................20

6.1 Electrical Schematic.............................................................................20

6.2 Internal Wiring......................................................................................21

6.3 Control Wiring ......................................................................................22

Setup Tools..............................................................................................................23

7.1 Simulation Tools ..................................................................................23

7.2 Low Voltage Test Mode .......................................................................23

Operation ........................................................................................................................................25

Key Features ...........................................................................................................25

User Interface ..........................................................................................................26

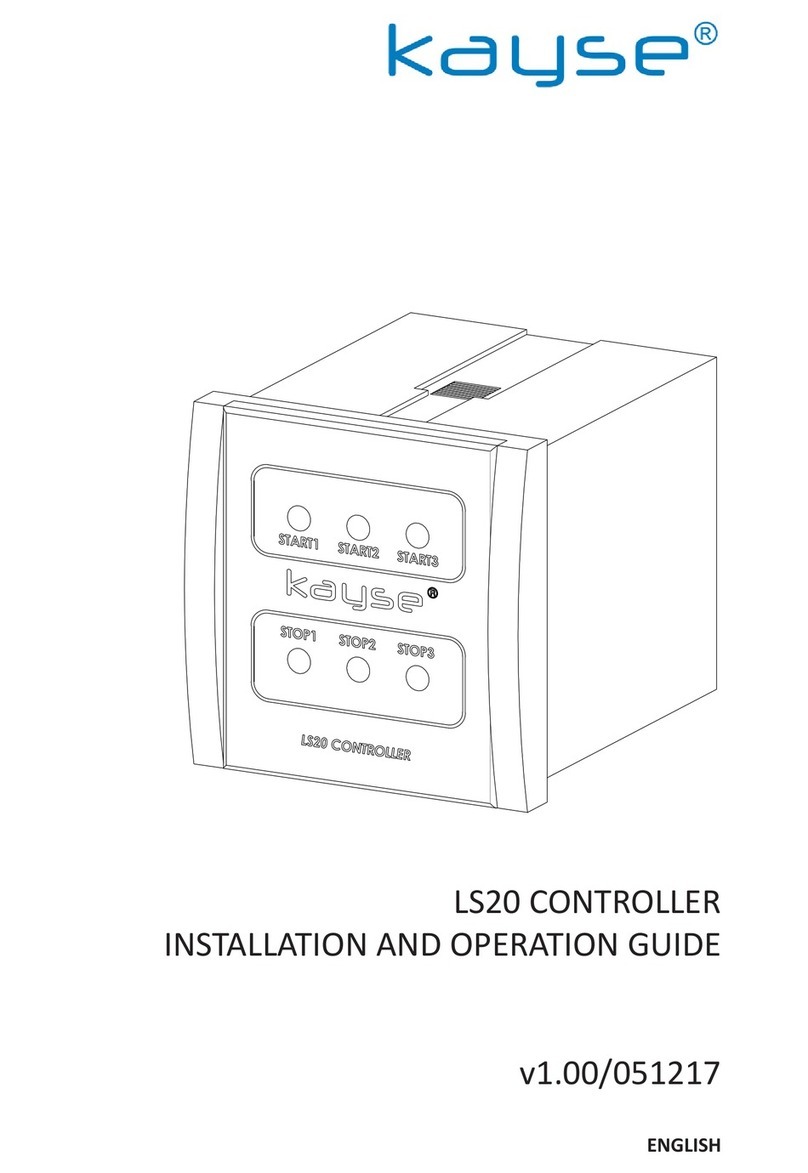

8.1 MVS Controller.....................................................................................26

8.2 Menus ..................................................................................................26

8.3 Security ................................................................................................27

8.4 LEDs ....................................................................................................28

8.5 Commissioning Menu ..........................................................................28