AuCom MVSxxxx-V03 User manual

CONTENTS

1

1About This Manual .......................................................................................3

1.1 User Manual Version............................................................................................................. 3

2 Caution Statements......................................................................................4

3 General Description.....................................................................................6

3.1 Overview...................................................................................................................................... 6

3.2 Feature List.................................................................................................................................. 6

3.3 Key Features............................................................................................................................... 7

3.4 Model Code ............................................................................................................................... 8

4 Specifications....................................................................................................9

4.1 Key Components..................................................................................................................... 9

4.2 Dimensions and Weights..................................................................................................10

4.3 General Technical Data .....................................................................................................11

4.4 Panel Specifications...............................................................................................................13

5 Receiving and Storage.............................................................................. 16

5.1 Receiving.....................................................................................................................................16

5.2 Storage.........................................................................................................................................16

6 Installation ...................................................................................................... 17

6.1 Clearance Requirements...................................................................................................17

6.2 Foundation Requirements................................................................................................18

6.3 Fastening Panels to the Foundation............................................................................19

6.4 Earth Termination .................................................................................................................20

6.5 Assembling the Switchgear Line-up............................................................................21

6.6 Mounting Instructions - Power Assembly................................................................23

6.7 Mounting Instructions - Controller..............................................................................25

6.8 Power Terminations ............................................................................................................26

6.9 Earth Terminations ...............................................................................................................28

6.10 Control Terminations..........................................................................................................28

6.11 Wiring Terminations on the Controller...................................................................28

6.12 Wiring Terminations on the Power Interface Board........................................29

6.13 Ground Current.....................................................................................................................30

6.14 Power Circuits.........................................................................................................................31

7 Internal Wiring –X10................................................................................ 36

8 Keypad and Feedback............................................................................... 37

8.1 The Controller........................................................................................................................37

8.2 Menu Shortcuts ......................................................................................................................37

8.3 Displays........................................................................................................................................37

9 Configuration................................................................................................ 38

9.1 Programming Menu..............................................................................................................38

9.2 Standard Menu........................................................................................................................39

9.3 Extended Menu......................................................................................................................40

9.4 Load/Save Settings................................................................................................................43

9.5 Parameter Descriptions .....................................................................................................43

10 Commissioning ............................................................................................ 57

10.1 Commissioning Menu (Tools)........................................................................................57

10.2 Set Date and Time ...............................................................................................................57

10.3 Simulation Tools.....................................................................................................................57

10.4 Input/Ouput Status...............................................................................................................59

10.5 Reset Thermal Models .......................................................................................................60

Contents

710-13937-00C MVS Panel User Manual 1

CONTENTS

10.6 Low Voltage Test Mode....................................................................................................60

1

11 Monitoring...................................................................................................... 62

11.1 Logs Menu.................................................................................................................................62

12 Operation....................................................................................................... 64

12.1 Start, Stop and Reset Commands ...............................................................................64

12.2 Using the Soft Starter to Control a Motor.............................................................64

12.3 Using the MVS to Control a Slip-Ring Motor.......................................................65

12.4 Operating States ....................................................................................................................68

12.5 Motor Protection...................................................................................................................69

12.6 Operating Feedback.............................................................................................................70

13 Troubleshooting.......................................................................................... 72

13.1 Protection Responses .........................................................................................................72

13.2 Trip Messages ..........................................................................................................................72

13.3 General Faults..........................................................................................................................76

14 Maintenance.................................................................................................. 78

14.1 Safety ............................................................................................................................................78

14.2 Maintenance Schedule........................................................................................................78

14.3 Tools required.........................................................................................................................78

14.4 Thermal Image ........................................................................................................................78

14.5 Contactor Maintenance.....................................................................................................78

14.6 Isolation Switch Maintenance.........................................................................................79

14.7 Isolator Microswitch Adjustment..................................................................................79

14.8 Phase Arm Assembly Alignment (model V13)....................................................80

14.9 Removing Phase Arms (model V13)..........................................................................81

15 Appendix........................................................................................................ 83

15.1 Parameter Defaults...............................................................................................................83

15.2 Accessories................................................................................................................................86

2 MVS Panel User Manual 710-13937-00C

ABOUT THIS MANUAL

The examples and diagrams in this manual are included solely for illustrative purposes. The information contained

in this manual is subject to change at any time and without prior notice. In no event will responsibility or liability be

accepted for direct, indirect or consequential damages resulting from the use or application of this equipment.

W

WARNING

Indicates a hazard that may cause personal injury or death.

C

CAUTION

Indicates a hazard that may damage the equipment or installation.

NOTE

Provides helpful information.

1.1 User Manual Version

This user manual (710-13937-00C) is compatible with MVS soft starters using version 1.29 control software and

version 2.30 interface software. For other software versions, please contact AuCom for the correct user manual.

The control software version is displayed on the Controller screen at power up.

Ready

Welcome

1.05 / 1.29 / 2.30 Software versions: Controller, control software, interface software

1 About This Manual

© 2015 AuCom Electronics

L

Ltd. All Rights Reserved.

As AuCom is continuously improving its products it reserves the right to modify or change the specification of its products at any

time without notice. The text, diagrams, images and any other literary or artistic works appearing in this document are

protected by copyright. Users may copy some of the material for their personal reference but may not copy or use material for

any other purpose without the prior consent of AuCom Electronics Ltd. AuCom endeavours to ensure that the information

contained in this document including images is correct but does not accept any liability for error, omission or differences with the

finished product.

710-13937-00C MVS Panel User Manual 3

CAUTION STATEMENTS

Caution Statements cannot cover every potential cause of equipment damage but can highlight common causes of

damage. It is the installer's responsibility to read and understand all instructions in this manual prior to installing,

operating or maintaining the equipment, to follow good electrical practice including applying appropriate personal

protective equipment and to seek advice before operating this equipment in a manner other than as described in

this manual.

Read and understand the entire manual before installing operating, or maintaining the MVS. Follow all

applicable local and national codes.

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices.

Use only electrically insulated tools and clothing and insulated protective gear when working around

electrical equipment.

Disconnect all power and ensure that the MVS is de-energised before servicing the equipment.

Do not rely on visual indications such as switch position or fuse removal for determining a de-energised

condition. Always assume that a terminal is energised until it is checked with a properly rated meter to

ensure that a terminal is de-energised and grounded.

Isolate the MVS completely from the power supply before attempting any work on the MVS or motor.

Always use a properly rated voltage sensing device to confirm power is off.

Before servicing the MVS, ensure that all static charge has been discharged by grounding it with an

appropriate grounding device.

Metal swarf in the cabinet can cause equipment failure.

Do not apply voltage to the control input terminals. These are active 24 VDC inputs and must be

controlled with potential free contacts.

Contacts or switches operating the control inputs must be suitable for low voltage, low current switching

(ie gold flash or similar).

Cables to the control inputs must be segregated from mains voltage and motor cabling.

Some electronic contactor coils are not suitable for direct switching with PCB mount relays. Consult the

contactor manufacturer/supplier to confirm suitability.

W

WARNING

-

-ELECTRICAL SHOCK HAZARD

The MVS contains dangerous voltages when connected to mains voltage. Only a qualified electrician should

carry out the electrical installation. Improper installation of the motor or the MVS may cause equipment

failure, serious injury or death. Follow this manual and local electrical safety codes.

SHORT CIRCUIT

The MVS is not short circuit proof. After severe overload or short circuit, the operation of the MVS should

be fully tested by an authorised service agent.

GROUNDING AND

BRANCH CIRCUIT PROTECTION

It is the responsibility of the user or person installing the MVS to provide proper grounding and branch circuit

protection according to local electrical safety codes.

ARC FLASH HAZARD

Medium voltage equipment has a potential risk of arc flash. When insulation or isolation between electrified

conductors is breached or can no longer withstand the applied voltage, a short circuit occurs through the air.

This may cause a phase-to-ground and/or a phase-to-phase fault.

Although unlikely, arc fault can be caused by:

Contamination in the insulation caused by deterioration over time

Inadequate insulation system on cable terminals

Overvoltage

Incorrect protection coordination settings

Overheating of the contact area, due to incorrect tightening of connections

Introduction of foreign matter, including swarf, vermin, tools or maintenance equipment left in the

starter

AuCom medium voltage equipment has been designed to mitigate an arc fault, however it is the

responsibility of the site engineer to ensure that personnel are protected from serious injury that may result

from an arc fault.

2 Caution Statements

4 MVS Panel User Manual 710-13937-00C

CAUTION STATEMENTS

S

STORAGE

The MVS must be stored in its original packaging in a clean and dry environment. The MVS should be

unpacked only after the equipment room is ready for installation. Particular care should be taken to avoid

exposure of the electronics to cement and/or concrete dust.

710-13937-00C MVS Panel User Manual 5

GENERAL DESCRIPTION

3.1 Overview

The MVS provides compact and robust soft start solutions for control of medium voltage motors. MVS soft

starters provide a complete range of motor and system protection features and have been designed for reliable

performance in the most demanding installation situations.

The two primary components of a MVS soft starter are:

a power assembly

a controller module

The power assembly and controller module are supplied as a pair and share the same serial number. Care should

be taken during installation to ensure that the correct controller and power assembly are used together.

3.2 Feature List

S

Starting

Constant Current

Current Ramp

S

Stopping

Coast To Stop

Soft stop

P

Protection

Undervoltage / Overvoltage

Mains frequency

Phase sequence

Shorted SCR

Motor Overload (thermal model)

Instantaneous Overcurrent (two stages)

Time-overcurrent

Ground Fault

Undercurrent

Current Imbalance

Motor thermistor

Excess Start Time

Power circuit

Auxiliary trip

E

Extensive input and output options

Remote control inputs

(3 x fixed, 2 x programmable)

Relay outputs

(3 x fixed, 3 x programmable)

Analog output

(1 x programmable)

Serial port (with module)

C

Comprehensive feedback

Starter status LEDs

Date and time stamped event logging

Operational counters (number of starts, hours-run,

kWh)

Performance monitoring (current, voltage, power

factor, kWh)

User-programmable monitoring screen

Multi-level password protection

Emergency stop pushbutton

P

Power connection

50 A to 500 A, nominal

2300 VAC to 13800 VAC

A

Accessories (optional)

Communication modules: Ethernet (Profinet,

Modbus TCP, Ethernet/IP), Profibus, DeviceNet,

Modbus RTU, and USB

Synchronous motor control

PC software

Overvoltage protection

Control supply transformer

MV/LV Control transformer

3 General Description

6 MVS Panel User Manual 710-13937-00C

GENERAL DESCRIPTION

3.3 Key Features

MVS soft starters offer several special functions to ensure ease of use and to provide optimal motor control in all

environments and applications.

Customisable Protection

The MVS offers comprehensive protection to ensure safe operation of the motor and soft starter. The protection

characteristics can be customised extensively to match the exact requirements of the installation.

Use

4 Protection Settings

on page 45 to set the conditions in which each protection mechanism will activate.

E

Example:

use parameter 4C

Undercurrent

to set the level for an undercurrent trip and parameter 4D

Undercurrent Delay

to set a delay on the trip.

Use

16 Protection Action

on page 56 to select the soft starter's response when a protection mechanism activates.

Each protection can be set to trip the starter, activate a warning flag, or be ignored. All protection activations are

recorded in the event log, regardless of the protection class setting.

Example:

Use parameter 16C

Undercurrent

to select the response for an undercurrent trip (trip, warn or

write to log). The default response is trip.

NOTE

MVS soft starters have built-in trip points to ensure operation remains within the soft starter's

capability. These internal trips cannot be overridden. Certain faults within the MVS will also prevent

the soft starter from operating. Refer to

Troubleshooting

on page 72 for details.

Advanced Thermal Modelling

Intelligent thermal modelling allows the soft starter to predict whether the motor can successfully complete a start.

The MVS uses information from previous starts to calculate the motor's available thermal capacity, and will only

permit a start which is predicted to succeed.

This feature can be enabled or disabled using parameter

4N Motor Temperature Check

.

Comprehensive Event and Trip Logging

The MVS has a 99-place event log to record information on soft starter operation. A separate trip log stores

detailed information about the last eight trips.

Informative Feedback Screens

A digital display screen allows the MVS to display important information clearly. Comprehensive metering

information, details of starter status and last start performance allow easy monitoring of the starter's performance at

all times.

Dual Parameter Set

The MVS can be programmed with two separate sets of operating parameters. This allows the soft starter to

control the motor in two different starting and stopping configurations.

The secondary motor settings (parameter groups 9 and 10) are ideal for conventional (squirrel-cage) motors which

may start in two different conditions (such as loaded and unloaded conveyors).

NOTE

MVS soft starters are not suitable for controlling two separate motors. The secondary parameter set should

only be used for a secondary configuration of the primary motor.

The MVS will use the secondary motor settings to control a start when instructed via a programmable input (refer

to parameters 6A and 6F,

Input A or B Function

).

Fibre Optics

The MVS uses two-line fibre optic connections between the low voltage control module and the high voltage

power assembly for electrical isolation. This fibre optic link simplifies installation of chassis mount MVS starters into

custom panels.

710-13937-00C MVS Panel User Manual 7

GENERAL DESCRIPTION

3.4 Model Code

MVS- – –

C

Control

V

Voltage

C12 = 110~130 Vac & 220~240 Vac

S

Supply Voltage

V02 = 2300 Vac 50/60 Hz

V03 = 3300 Vac 50/60 Hz

V04 = 4160 Vac 50/60 Hz

V06 = 6600 Vac 50/60 Hz

V07 = 7200 Vac 50/60 Hz

V13 = 13800 Vac 50/60 Hz

C

Current Rating

0080 = 80 A @ AC53b 4-20 : 1780

0159 = 159 A @ AC53b 4-20 : 1780

0200 = 200 A @ AC53b 4-20 : 1780

0230 = 230 A @ AC53b 4-20 : 1780

0321 = 321 A @ AC53b 4-20 : 1780

0500 = 500 A @ AC53b 4-20 : 1780

8 MVS Panel User Manual 710-13937-00C

SPECIFICATIONS

4.1 Key Components

Key Components (models V02 ~ V07)

03993.D

2

3

5

1

1

Control transformer

2

Control voltage terminal block

3

Power interface board

4

Phase arm (x3)

5

Power assembly

Key Components (model V13)

1

2

07235.C

1

Phase arm

2

Control voltage terminal block

3

Power interface board

4

Phase arm

5

Controller

6

Phase arm

4 Specifications

710-13937-00C MVS Panel User Manual 9

SPECIFICATIONS

4.2 Dimensions and Weights

Models V02 ~ V07 (Power Assembly)

Aa

b

Bc

Cd

e

Front view Side view Phase arm extended

A

B

C

a

b

c

d

e

Weight

(phase

arm)

Weight

(power

assembly)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

kg

(lb)

kg

(lb)

MVSxxxx-V02 772

(30.4)

669

(26.3)

667

(26.3)

750

(29.5)

658

(25.9)

650

(25.6)

1302

(51.3)

531

(20.9)

29

(63.9)

165

(363.8)

MVSxxxx-V03

MVSxxxx-V04

MVSxxxx-V06 832

(32.8)

875

(34.5)

817

(32.2)

810

(31.9)

864

(34.0)

800

(31.5)

1559

(61.4)

551

(21.7)

44

(97)

217

(478.4)

MVSxxxx-V07

NOTE

For models MVSxxxxV02 to MVSxxxxV04, these dimensions apply up to 321 A. For the same models with

current ratings of 500 A, the MVSxxxxV06 dimensions apply.

Model V13 (Power Assembly)

07233.C

e

d

c

C

b

B

A

a

e

Front view Side view Phase arm extended

A

B

C

a

b

c

d

e

Weight

(phase

arm)

Weight

(power

assembly)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

kg

(lb)

kg

(lb)

MVSxxxx-V13 2225

(87.6)

1300

(51.2)

1175

(46.3)

2200

( 86.6)

1150

(45.3)

1150

(45.3)

1785

(70.3)

510

(20.1)

127

(279.9)

720

(1587)

10 MVS Panel User Manual 710-13937-00C

SPECIFICATIONS

Controller

The controller is suitable for use with all MVS soft starters.

340.0

(13.39)

220.0 (8.66)

80

(3.14)

1

INPUTB

INPUTA

RESET

STOP

START

Run Trip LocalReady

Exit M enu

St ore

Log s Alt To ols

R ese t L CL

RM T

St o pS ta rt

Dimensions are shown in mm (inch).

Weight: 2.1 kg (4.63 lb)

1

Control input LEDs

2

Keypad

4.3 General Technical Data

Supply

Mains Voltage

MVSxxxxV02 ............................................................................................................................................................................ 2.3 kV Phase-phase

MVSxxxxV03 ............................................................................................................................................................................ 3.3 kV Phase-phase

MVSxxxxV04 ............................................................................................................................................................................ 4.2 kV Phase-phase

MVSxxxxV06 ............................................................................................................................................................................ 6.6 kV Phase-phase

MVSxxxxV07 ............................................................................................................................................................................ 7.2 kV Phase-phase

MVSxxxxV13 ......................................................................................................................................................................... 13.8 kV Phase-phase

Rated Frequency (fr) ............................................................................................................................................................................................ 50/60 Hz

Rated lightning impulse withstand voltage (Up)

MVSxxxxV02 ~ V04 .......................................................................................................................................................................................... 45 kV

MVSxxxxV06 ~ V07 .......................................................................................................................................................................................... 45 kV

MVSxxxxV13 .......................................................................................................................................................................................................... 85 kV

Rated power frequency withstand voltage (Ud)

MVSxxxxV02 ~ V04 ...................................................................................................................................................................................... 11.5 kV

MVSxxxxV06 ~ V07 .......................................................................................................................................................................................... 20 kV

MVSxxxxV13 .......................................................................................................................................................................................................... 35 kV

Rated normal current (lr)

MVS0080-Vxx .......................................................................................................................................................................................................... 80 A

MVS0159-Vxx ....................................................................................................................................................................................................... 159 A

MVS0200-Vxx ....................................................................................................................................................................................................... 200 A

MVS0230-Vxx ....................................................................................................................................................................................................... 230 A

MVS0321-Vxx ....................................................................................................................................................................................................... 321 A

MVS0500-Vxx ....................................................................................................................................................................................................... 500 A

Rated short-time withstand current (symmetrical RMS) (lk)

MVSxxxxV02 ~ V07 ...................................................................................................................................................................................... 48 kA 1

MVSxxxxV13 ...................................................................................................................................................................................................... 75 kA 2

Form designation .................................................................................................................. Bypassed semiconductor motor starter form 1

Control voltage

MVSxxxxV02 ~ V07 .................................................................................................................................... 110 ~130 or 220 ~ 240 VAC

MVSxxxxV13 ...................................................................................................................................................................................... 85 ~ 275 VAC

Rated Frequency ..................................................................................................................................................................................................... 50/60 Hz

Typical power consumption

MVSxxxxV02 ~ V07 ............................................................................................................................................................. 70 W continuous 3

MVSxxxxV13 .......................................................................................................................................................................... 100 W continuous 3

Control Inputs

Start (C23, C24) ....................................................................................................................................................................... 24 VDC, 8 mA approx

Stop (C31, C32) ....................................................................................................................................................................... 24 VDC, 8 mA approx

Reset (C41, C42) ..................................................................................................................................................................... 24 VDC, 8 mA approx

Input A (C53, C54) ................................................................................................................................................................... 24 VDC, 8 mA approx

Input B (C63, C64) .................................................................................................................................................................. 24 VDC, 8 mA approx

Motor thermistor (B4, B5) ......................................................................................................................................................... Trip point > 2.4 kΩ

NOTE

All control inputs are potential free. Do not apply external voltage to these inputs.

710-13937-00C MVS Panel User Manual 11

SPECIFICATIONS

O

Outputs

Outputs on power interface board

Main contactor (13, 14) ............................................................................................................................................................. Normally Open

Bypass contactor (23, 24) ......................................................................................................................................................... Normally Open

Run Output/ PFC (33, 34) ....................................................................................................................................................... Normally Open

Fan control output (43, 44) ..................................................................................................................................................... Normally Open

Outputs on Controller

Output Relay A (43, 44) ........................................................................................................................................................... Normally Open

Output Relay B (51, 52, 54) ............................................................................................................................................................ Changeover

Output Relay C (61, 62, 64) ........................................................................................................................................................... Changeover

Analog output (B10, B11) ............................................................................................................................................ 0-20 mA or 4-20 mA

Characteristics

.............................................................................................................................................................................................. 10 A @ 250 VAC resistive

............................................................................................................................................................................................. 6 A @ 250 VAC 15 p.f. 0.3

................................................................................................................................................................................................. 10 A @ 30 VDC resistive

Environmental

Degree of Protection

Power Assembly ...................................................................................................................................................................................................... IP00

Controller ........................................................................................................................................................................................... IP54/ NEMA 12

Operating temperature ....................................................................................................... - Ý&WR&ZLWKGHUDWLQJWR&

Humidity ................................................................................................................................................................ 5% to 95% Relative Humidity

Storage temperature ....................................................................................................................................................................... - Ý&WRÝ&

Humidity ................................................................................................................................................................ 5% to 95% Relative Humidity

Operating Altitude ............................................................................................................................ 0 - 1000 m, above 1000 m with derating

Pollution degree ................................................................................................................................................................................. Pollution Degree 3

Vibration ....................................................................................................................................................................................... Designed to IEC 60068

EMC Emission

Equipment class (EMC) ........................................................................................................................................................................................... Class A

Conducted radio frequency emission ......................................................................................... 10 kHz to 150 kHz: < 120 - 69 dB μV

........................................................................................................................................................................... 0.15 MHz to 0.5 MHz: < 79 dB μV

............................................................................................................................................................................... 0.5 MHz to 30 MHz: < 73 dB μV

Radiated radio frequency emission ......................................................................................... 0.15 MHz to 30 MHz: < 80-50 dB μV/m

................................................................................................................................................................ 30 MHz to 100 MHz: < 60-54 dB μV/m

.................................................................................................................................................................. 100 MHz to 2000 MHz: < 54 dB μV/m

This product has been designed as Class A equipment. Use of this product in domestic environments may cause

radio interference, in which case the user may be required to employ additional mitigation methods.

EMC Immunity

Electrostatic Discharge ................................................................................................................. 6 kV contact discharge, 8 kV air discharge

Radio Frequency Electromagnetic Field ...................................................................................................... 80 MHz to 1000 MHz: 10 V/m

Fast Transients 5/50 ns (main and control circuits) ....................................................................... 2 kV line to earth, 1 kV line to line

Surges 1.2/50 μs (main and control circuits) ................................................................................... 2 kV line to earth, 1 kV line to line

Voltage dip and short time interruption (safe shutdown) .......................................................... 5000 ms (at 0% nominal voltage)

Standards Approvals

C....................................................................................................................................................................................................... EMC requirements

CE ......................................................................................................................................................................................................... EMC EU Directive

1Short circuit current, with appropriate R rated fuses fitted.

2It is critical that the circuit breaker and associated protection relay are set to trip <150 ms. Failure to do so could

result in SCR rupture and subsequent arc fault.

3Excludes contactors and/or circuit breakers.

12 MVS Panel User Manual 710-13937-00C

SPECIFICATIONS

4.4 Panel Specifications

AuCom switchgear panels are categorised as follows:

Soft starter panel (SSP)

Standard panels

NOTE

Panel layout views depict only typical panel configuration options.

Soft Starter Panel (SSP)

The soft starter panel is designed to house the primary soft starter components and associated switchgear.

Typical Soft Starter Panel

14560.A

Front view Side view

1

2

3

4

5

6

7

8

14079.B

1

Incoming supply 1

2

Isolator/Earth switch

3

R-Rated protection fuses

4

Main switching apparatus 2

5

Power assembly

6

Current transformer

7

Bypass switching apparatus 2

8

Cables to motor 3

1Cables (top or bottom entry) or horizontal busbar system. Cables and busbars are not supplied with the standard

product, but AuCom can supply a horizontal busbar system on request.

2Contactor (a circuit breaker may be fitted instead, on request). Installations with a circuit breaker do not require

R-rated protection fuses.

3Outgoing motor cables (top or bottom exit).

710-13937-00C MVS Panel User Manual 13

SPECIFICATIONS

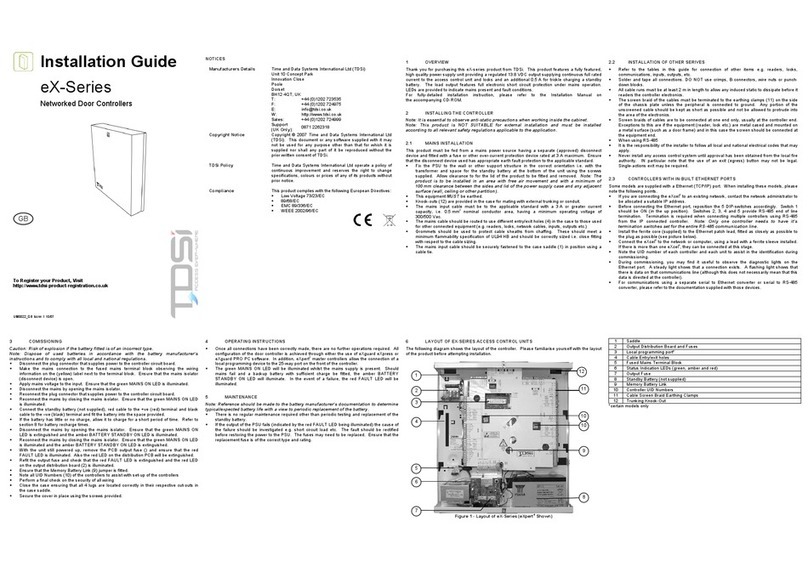

Standard Panels

AuCom standard panels are designed to be installed individually or connected to an AuCom soft starter panel (SSP)

in a panel line-up. Standard panels may be equipped with customisable switchgear options and are available as

follows:

Transition panel (TRP)

Power factor correction panel (PFP)

Transition Panel (TRP)

Transition panels are used to connect cables or busbars between two different panels in a line-up. A transition panel

may also be used to connect cables from one panel to busbars in another.

Typical Transition Panel

12960.A

Front view Side view

14080.A

1

2

3

4

5

1

Horizontal busbar system

2

Isolator/Earth switch (optional)

3

Current transformer (optional)

4

Voltage transformer (optional)

5

Incoming supply cables or busbar

system (customer)

14 MVS Panel User Manual 710-13937-00C

SPECIFICATIONS

Power Factor Correction Panel (PFP)

A power factor correction panel consists of capacitor banks which are switched by means of a contactor. This

contactor is controlled by the soft starter or power factor controller, which measures power factor in an electrical

network.

Typical Power Factor Correction Panel

14123.A

Front view Side view

14081.A

1

2

3

4

5

6

1

Incoming supply 1

2

Isolator/Earth switch 2

3

E-rated protection fuses 2

4

Line contactor 2

5

Inrush reactors (3x single phase)

6

PFC capacitor bank (3-phase)

1Cables (top or bottom entry) or horizontal busbar system. Cables and busbars are not supplied with the standard

product, but AuCom can supply a horizontal busbar system on request.

2Not required when incoming supply is fed from the soft starter panel (SSP).

710-13937-00C MVS Panel User Manual 15

RECEIVING AND STORAGE

All AuCom panels are individually packed and securely braced for shipment. Depending on the size and weight, it

may be necessary to ship the equipment in several sections to facilitate handling.

Panels may include relatively delicate equipment. Handle all sections with care when unloading. Some electrical

components may be shipped separately and then installed on-site. The shipping inventory should account for all

individual components.

5.1 Receiving

Inspect equipment as soon as possible for any damage that may have occurred during transit. Before accepting

delivery, examine packaging for any signs of damage. A damaged package may indicate that the panel and internal

components may also be damaged.

Check that the shipping manifest accounts for all equipment delivered. Any missing or damaged equipment should

be noted on the freight bill and the carrier notified immediately. A record of the missing or damaged equipment

should also be sent to AuCom.

NOTE

Avoid using heavy or sharp-edged tools while unpacking, as these may damage the equipment. Use nail

pliers to separate all four sides of the wooden packaging box.

5.2 Storage

If immediate installation is not possible, the equipment should be stored in its original packaging in a clean and dry

area indoors. Always store panels upright on their wooden pallets to keep them off the floor and allow air to pass

under it freely.

NOTE

Equipment can be stored for a maximum of 12 months from the date of packaging as the quality of the

packaging material degrades over time.

The following storage conditions should be met (IEC 60721-3-1, classification 1K3):

Temperature -5 °C ~ 40 °C

Relative humidity 50 ~ 95%

Rate of change of temperature 0.5 °C/min

The following general precautions should be followed when storing equipment indoors:

Do not unpack the panel or other components until they are ready for installation.

If electrical components such as circuit breakers are to be stored for more than three months in humid

conditions, space heaters should be used in the storage area to limit condensation. Switchgear panels with

in-built anti-condensation heaters may be powered from an external supply during storage.

Rats and other vermin may cause considerable damage and periodic inspection is necessary to minimise

the danger they pose.

Ensure the floor of the storage area is smooth and level to prevent mechanical strain to the structure and

components.

5 Receiving and Storage

16 MVS Panel User Manual 710-13937-00C

INSTALLATION

Site installation of panels should only be carried out by specially trained and skilled personnel. The location must be

adequately prepared with wall openings, ventilation ducts and cabling connections to the power supply.

6.1 Clearance Requirements

While installing AuCom switchgear panels, ensure that minimum clearance requirements are met.

600

1200

600

2800

14091.A

2322

600

Plan view Side view

NOTE

Standard panels may be mounted closer to the wall from the rear if required. Consult AuCom if closer

wall mounting is required.

6 Installation

710-13937-00C MVS Panel User Manual 17

INSTALLATION

6.2 Foundation Requirements

NOTE

The maximum tolerance for switchroom floor is ± 2 mm per metre (with a maximum of ± 5 mm over

the entire panel line-up). Failure to comply with these recommendations may impair the

electro-mechanical functionality of some components and the structural integrity of the entire panel

system.

The base of the panels is suitable for mounting directly to the switchroom floor. It is recommended that buried steel

channels are installed in a level concrete floor to support the equipment. The surfaces of the buried steel channels

should be level with the finished floor and aligned with each other prior to final anchoring. The panel’s base should

be evenly supported by the concrete floor. If the panel is raised above the floor level by the mounting channels, the

entire base frame must be supported at the same level. If the panel is part of a line-up, all channels must be level

and aligned with each other.

14082.B

The figure below illustrates typical methods for anchoring panels to buried steel channels.

14083.A

1 2 1 2 3

3

1

Anchor bolt

2

Panel connection

3

Buried steel channel

Beam-type channel C-type channel

NOTE

Anchor bolts, channels, and other materials are not supplied as part of the switchgear arrangement.

18 MVS Panel User Manual 710-13937-00C

INSTALLATION

6.3 Fastening Panels to the Foundation

Switchgear panels must be fastened securely to a level floor which has been adequately prepared.

Soft Starter Panel (SSP)

It is recommended that all four bolt holes are used to securely bolt the panel to the floor using 10mm (0.39in) bolts.

14096.A

1

800

570

1200

1230

Plan view

1

Removable non-ferrous gland plate

Width

mm (inch)

Depth

mm (inch)

MVSxxxx-V02

MVSxxxx-V03 800 (31.5) 1200 (47.2)

MVSxxxx-V04

MVSxxxx-V06

MVSxxxx-V07 1000 (39.3) 1200 (47.2)

MVSxxxx-V13

710-13937-00C MVS Panel User Manual 19

This manual suits for next models

6

Table of contents

Other AuCom Controllers manuals

AuCom

AuCom CSX-007 User manual

AuCom

AuCom MVS0080 User manual

AuCom

AuCom EMX3-1600C User manual

AuCom

AuCom EMX3 User manual

AuCom

AuCom MVS User manual

AuCom

AuCom CSX-007 User manual

AuCom

AuCom MVE series User manual

AuCom

AuCom CSXI-007 User manual

AuCom

AuCom Modbus RTU Card User manual

AuCom

AuCom CSX-007 User manual

Popular Controllers manuals by other brands

Tridonic

Tridonic luxCONTROL DaLI Msensor 5DPI 14 product manual

National Instruments

National Instruments GPIB-232CT-A IBCL EPROM Getting started

LINOVISION

LINOVISION IOT-CPANEL quick start guide

Siemens

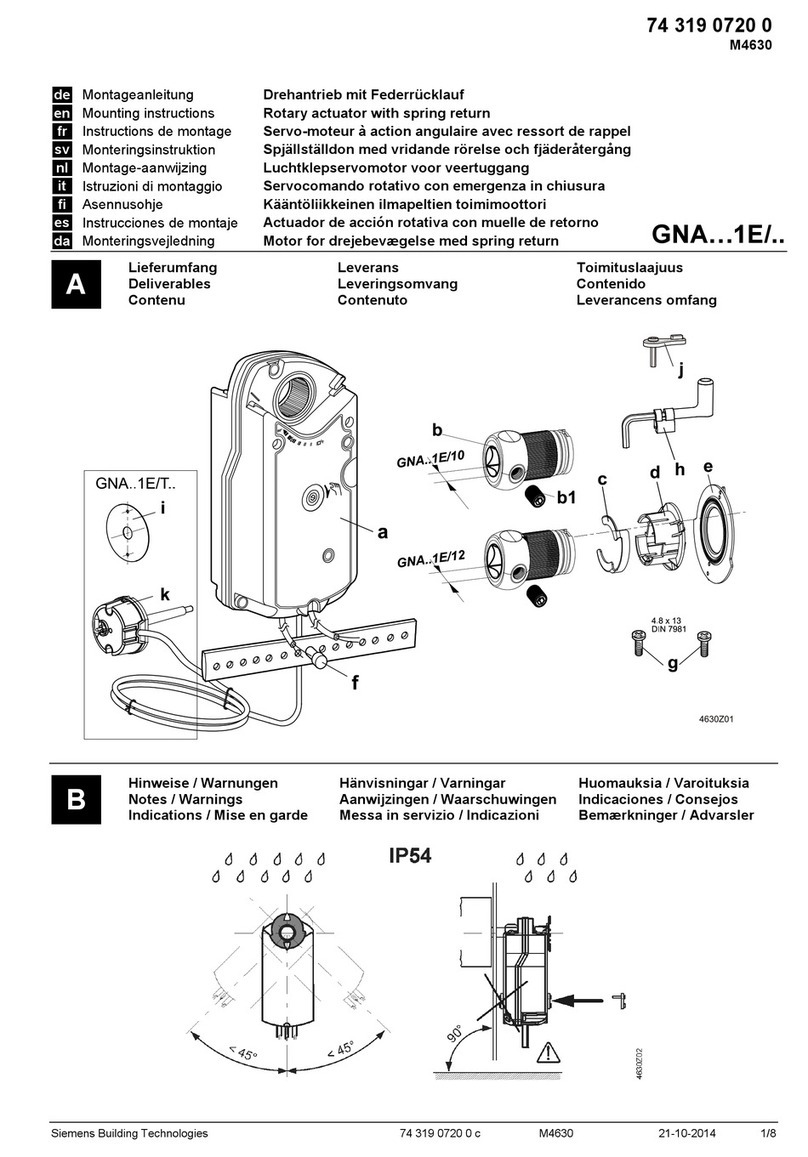

Siemens GNA 1E Series Mounting instructions

Dinstar

Dinstar SBC300 user manual

Allen-Bradley

Allen-Bradley AADvance manual