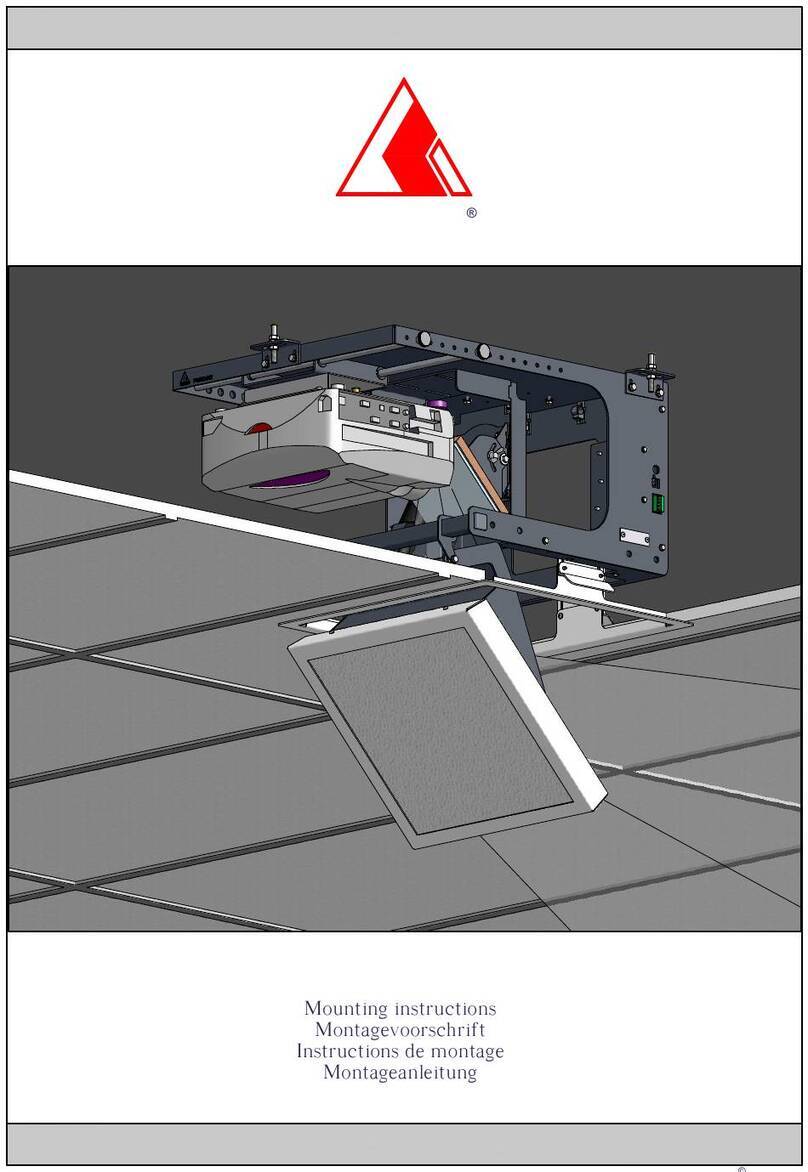

Audipack Rota-Kit PRK-250 User manual

PRK-250/500/750

Projector Rota Kit

Mounting instructions

ii

Safety instructions:

Check the unit for damages caused by transport. In case of damage please

report directly to the transporter and Audipack to provide a quick solution.

Read the manual carefully before installing.

Never install more load on the product than it is allowed.

Unplug before maintenance works.

Please keep this manual for later use.

Index

iii

Table of Contents

1 General features................................................................................... 6

2 Specifications ....................................................................................... 6

2.1 Technical data ................................................................................ 6

2.2 Scope of delivery ............................................................................ 6

2.3 Accessories .................................................................................... 6

3 Tools required for installation ................................................................. 7

4 Mounting the product ............................................................................ 7

4.1 Preparations for ceiling/ floor/ wall mounting ...................................... 7

4.2 Mounting on ceiling ......................................................................... 8

4.2.1 Drilling hole pattern ................................................................... 8

4.3 Mounting to false ceiling................................................................... 8

4.4 Mounting the monitor/ projector ....................................................... 8

4.4.1 Prerequisites of the monitor/ projector (Monitor/ projector info) ...... 8

4.4.2 Adjusting the projector............................................................... 9

5 Required for installation....................................................................... 10

5.1 Homing........................................................................................ 10

5.1.1 The procedure for homing is as follows:...................................... 10

5.1.2 Homing can be activated by:..................................................... 10

6 Connection to mains ........................................................................... 11

7 Control by inputs 6-pole connector........................................................ 12

7.1 Moving to memory positions ........................................................ 12

7.2 To set a memory position ............................................................ 12

8 Control by inputs 5-pole connector........................................................ 13

8.1 Moving to memory positions ........................................................ 13

9 Control by RS-232 serial communication................................................ 14

9.1 Connection of the RS232 ............................................................. 14

9.2 Moving the lift by serial communication (RS-232) ........................... 14

10 General information ......................................................................... 17

10.1 Definitions .............................................................................. 17

10.2 End switches ........................................................................... 17

10.3 Memory positions and directions................................................ 17

Index

iv

10.4 Memory position control ........................................................... 18

10.5 Error reset .............................................................................. 18

11 Program rotary switch (SW1) ............................................................ 19

11.1 Precautions............................................................................. 19

11.2 Rotary switch positions versus functions ..................................... 19

11.3 Rotary switch positions versus product examples......................... 20

12 Function dipswitches (J14) ................................................................ 20

13 Serial communication RS-232............................................................ 22

13.1 Connections ............................................................................ 22

13.2 Software................................................................................. 24

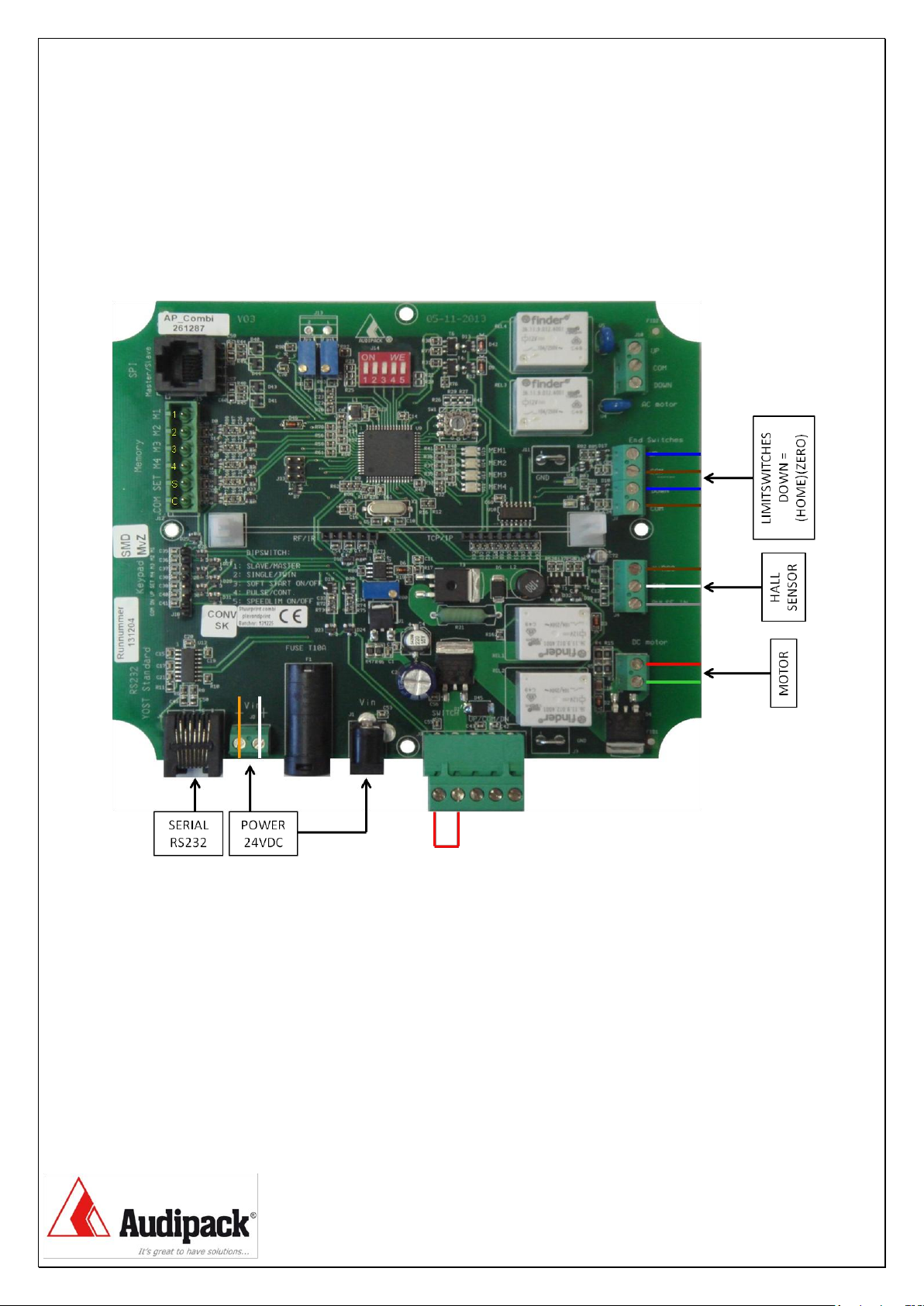

14 Electric connections.......................................................................... 25

15 Keypad (261288) .......................................................................... 27

16 Instructions RS232........................................................................... 28

16.1 TERMINAL INPUT INSTRUCTIONS .............................................. 28

16.2 INSTRUCTIONS TO CONTROL THE MOTOR.................................. 28

16.3 INSTRUCTIONS TO MOVE THE MOTOR TO A MEMORY POSITION ... 28

16.4 PROGRAM MEMORY POSTIONS.................................................. 28

16.5 FACTORY MODE....................................................................... 28

16.6 MISCELLANIOUS INSTRUCTIONS............................................... 29

16.7 REGISTER R1000 [Device Name]............................................... 29

16.8 REGISTER R1001 [Input Status]................................................ 30

16.9 REGISTER R1002 [Control Function] .......................................... 31

16.10 REGISTER R1003 [UP/DOWN Status] ......................................... 32

16.11 REGISTER R1004 (Motor Status] ............................................... 33

16.12 REGISTER R1005-R1008 [Memory Preset Values) ........................ 34

16.13 REGISTER R1009 [Request Count]............................................. 35

16.14 REGISTER R1010 [Motor Position Count] .................................... 35

16.15 REGISTER R1011 [Motor Error] ................................................. 36

16.16 REGISTER R1012 [Motor Speed Slow mode] ............................... 37

16.17 REGISTER R1013 [Memory Preset Status] .................................. 38

16.18 REGISTER R1014 [Delta pulse].................................................. 39

16.19 REGISTER R1015 [Master/Slave Mode]....................................... 39

Index

v

16.20 REGISTER R1016 [Single/Parallel Mode] ..................................... 40

16.21 REGISTER R1017 (Soft Start Mode] ........................................... 40

16.22 REGISTER R1018 [Pulse/Continue Mode).................................... 41

16.23 REGISTER R1019 [Adjustable Speed Limit Mode]......................... 41

16.24 REGISTER R1021 [limit switch hysteresis homing] ....................... 42

16.25 REGISTER R8888 [Software Version] ......................................... 42

17 Maintenance of the product ............................................................... 43

18 Dimensions and illustrations .............................................................. 44

19 Frequently asked questions ............................................................... 45

Product

6

1General features

Electric rotating system with 4 freely programmable preset positions to rotate a

projector or a flat panel in the horizontal plane. Product height 250/500/750 mm

2Specifications

2.1 Technical data

Power supply 24 Volt, 1.88 A

4 programmable positions

Maximum rotation 350 degrees

Controllable by contact closures, RS232 and optional IR/RF remote.

Max. projector load 30 Kg

Built according CE and EMC norms

2.2 Scope of delivery

Product

Manual

Power adapter

Power cable

5-pole connector with jumper

6-pole connector

2.3 Accessories

Remote control for IR-unit incl. AA battery

Mounting help P3660

Adapter RS232 serial communication RJ45 Sub-D9f (Part number 320137)

Cable serial adapter Sub-D9 (male) USB (Part number 320139)

Assembling

7

3Tools required for installation

drill

drill bit

ring spanner

screwdriver

spirit level

ceiling fixing

hex spanner

tape measure

4Mounting the product

4.1 Preparations for ceiling/ floor/ wall mounting

Make sure the mounting surface area is flat. Make sure there is enough clearance

to operate the product. (Keep in mind free space for future maintenance)

Assembling

8

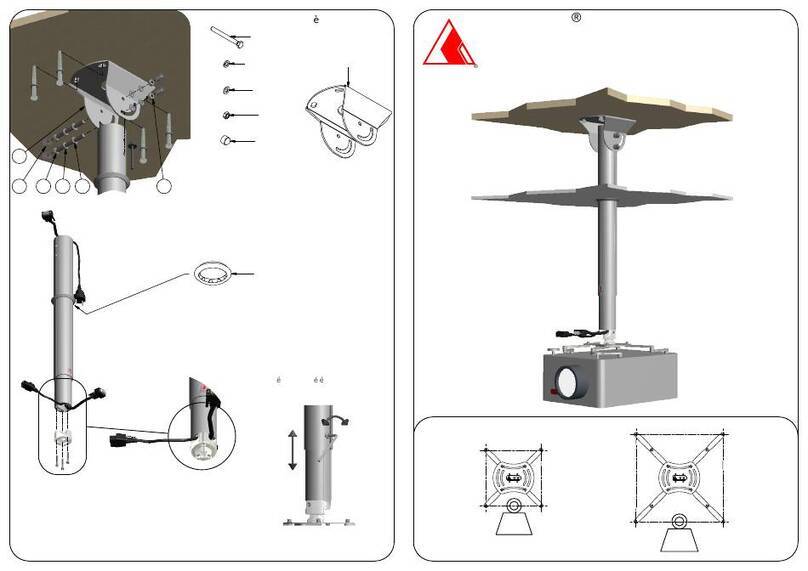

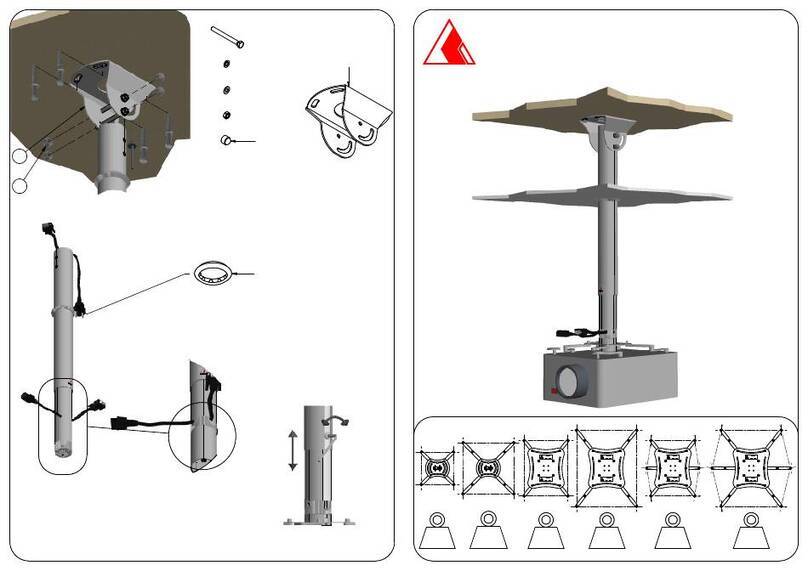

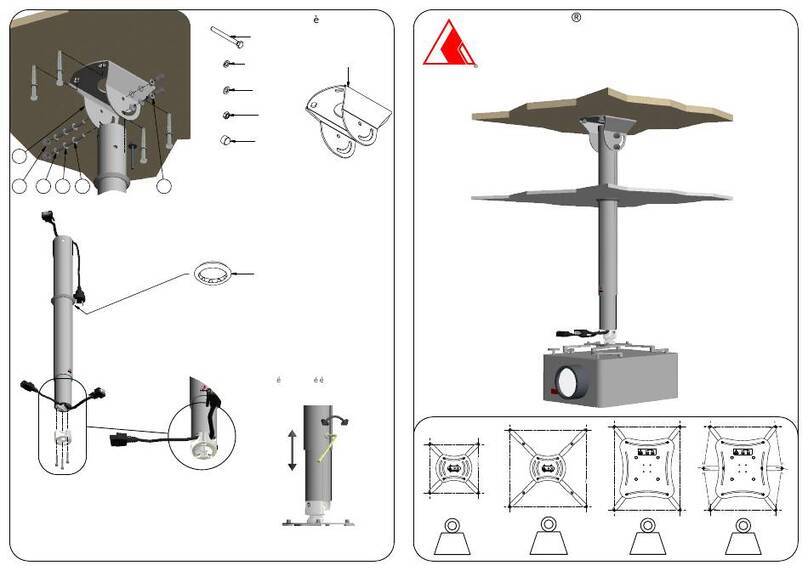

4.2 Mounting on ceiling

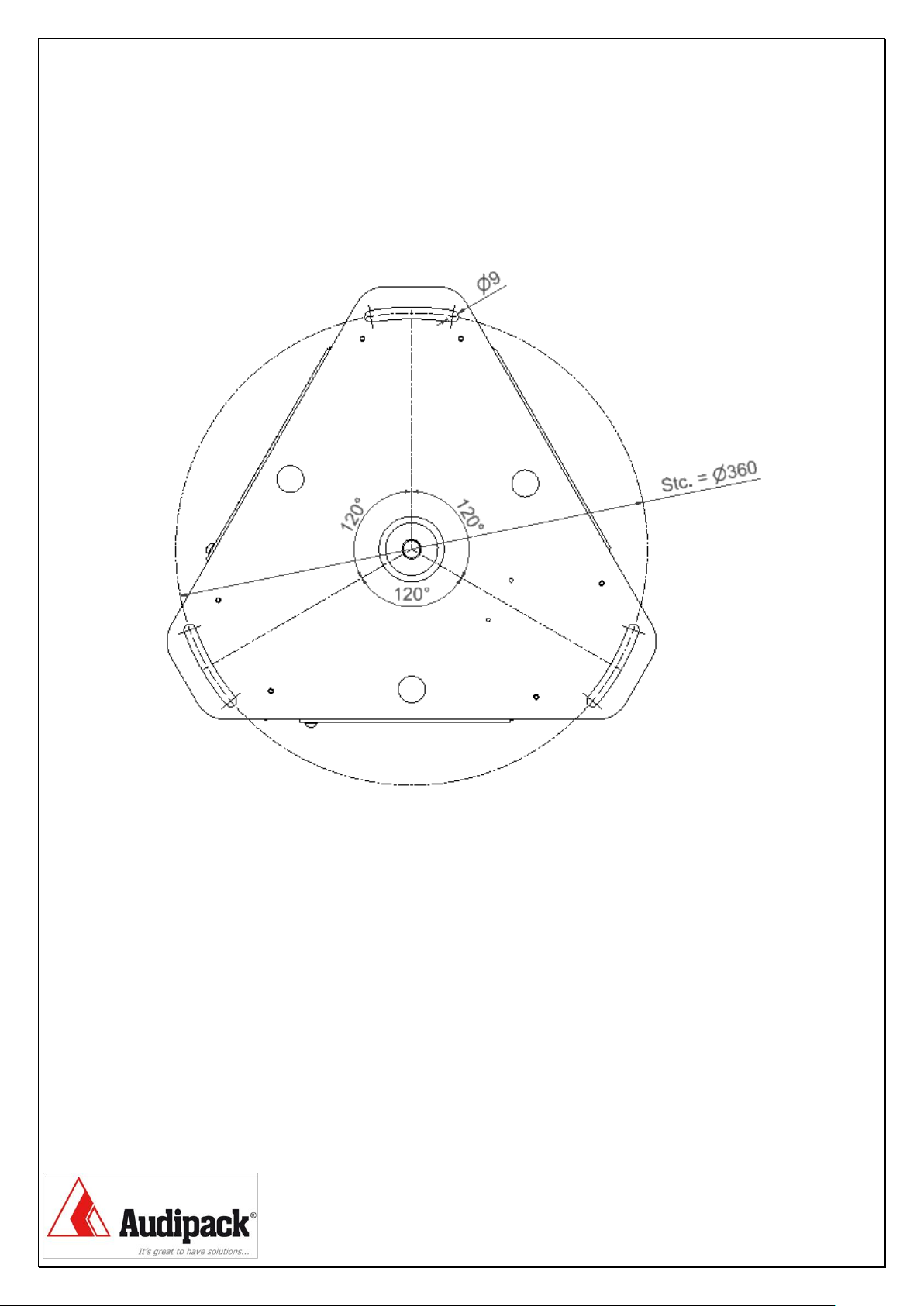

4.2.1 Drilling hole pattern

4.3 Mounting to false ceiling

When mounting to false ceiling, make sure a strong enough support exist to

handle the max load of PRK and monitor/projector combined.

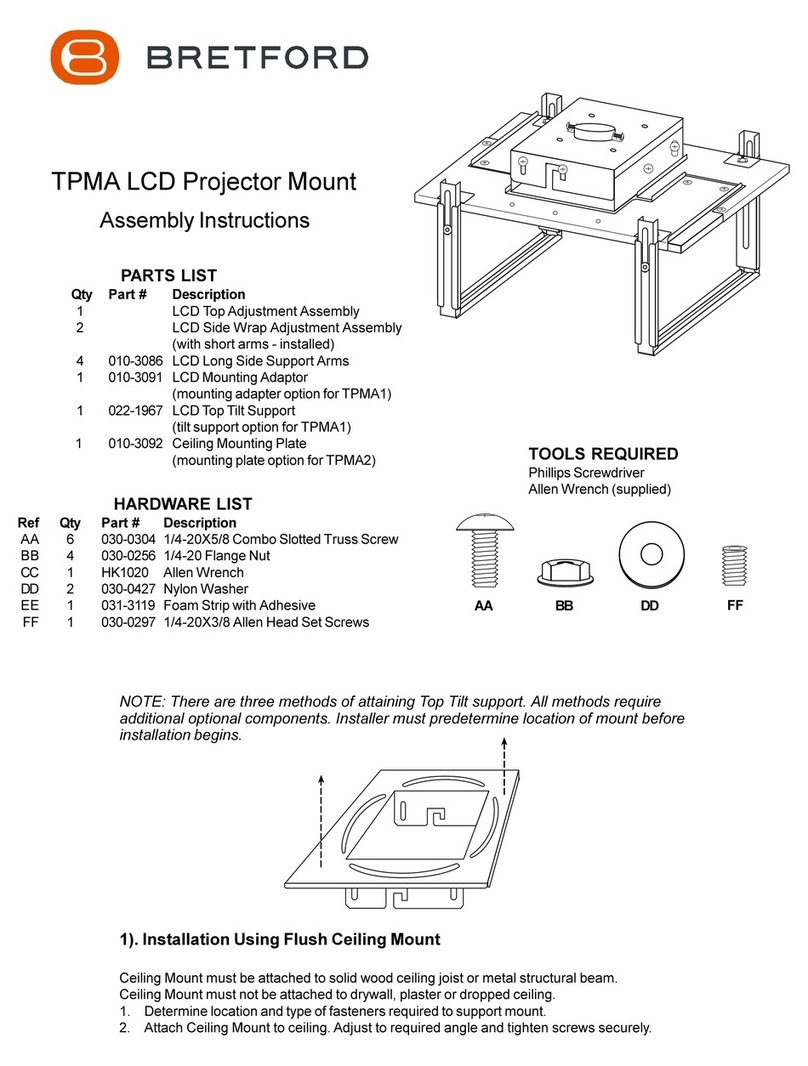

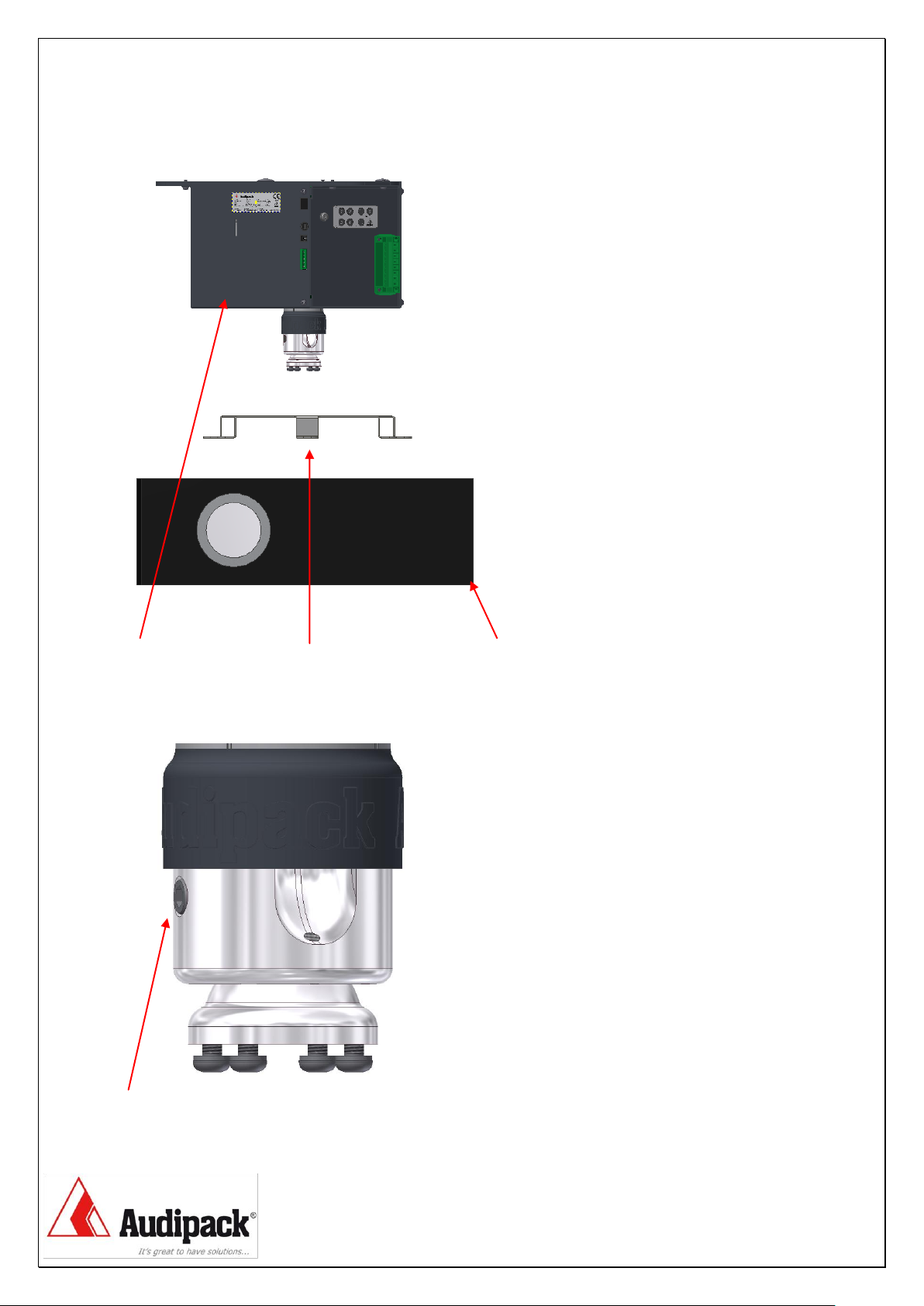

4.4 Mounting the monitor/ projector

4.4.1 Prerequisites of the monitor/ projector (Monitor/ projector info)

Mounting a monitor or projector on the PRK can only be accomplished using a

mounting plate that is suitable.

Assembling

9

PRK Mounting bracket Projector

4.4.2 Adjusting the projector.

To adjust the monitor or projector can be done as follows.

Loosen the hex screw, adjust to desired position and fasten hex screw.

Initial Setup

10

5Required for installation

5.1 Homing

If the control board will be used with position control the reference or home

position have to be set.

Position control is available on program number “1”, “2”, “3” en “5”.

5.1.1 The procedure for homing is as follows:

The motor runs in low speed to down limit switch

The motor stops when the (down) limit switch is activated

The motor runs in low speed in de reverse direction

The motor stops 10 count after the (down) limit switch is deactivated

!! In program number “5” homing is in the opposite direction !!

(limit switch “UP” will be activated)

5.1.2 Homing can be activated by:

Keypad +

RS-232 home, enter

Program number “2” auto homing

Motor control by input terminals

11

6Connection to mains

Never use damaged devices. Before mounting the PRK check the specifications

on the label with those of the local power supply. Do all mounting and

maintenance works with the power supply switched of.

Motor control by input terminals

12

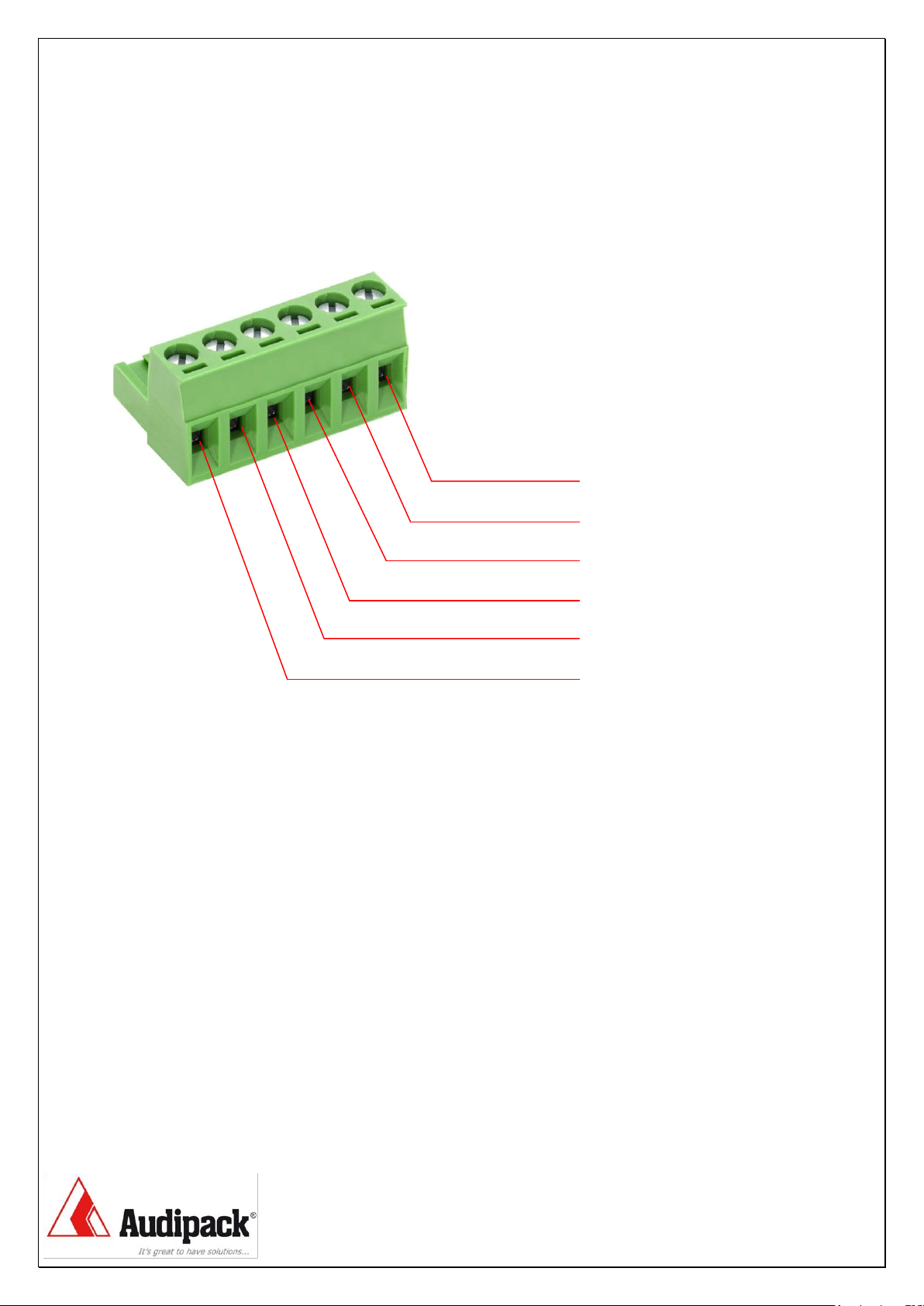

7Control by inputs 6-pole connector

M1

M2

M3

M4

SET

COM

7.1 Moving to memory positions

Move to memory position 1 make a connection between COM + M1

Move to memory position 2 make a connection between COM + M2

Move to memory position 3 make a connection between COM + M3

Move to memory position 4 make a connection between COM + M4

7.2 To set a memory position

To set a memory position:

Make an interconnection between COM + SET

Maintain this interconnection, and

Make an interconnection between COM + M1, M2, M3 or M4,

depends on the memory you want to store.

Disconnecting all the above connections will set the required memory

position. (an audible “click” is notable)

Motor control by input terminals

13

8Control by inputs 5-pole connector

The connection of the jumper can be replaced by a safety or emergency contact.

Removing the jumper completely disconnect the power from the control board.

8.1 Moving to memory positions

Move to memory position 1 or down/left direction make a connection between

COMMON and DOWN.

Move to memory position 2 or up/right direction make a connection between

COMMON and UP.

Motor control by RS-232

14

9Control by RS-232 serial communication

9.1 Connection of the RS232

9.2 Moving the lift by serial communication (RS-232)

Moving up = “o” enter (alphabetic letter)

Moving down = “n” enter (alphabetic letter)

To M1 = “m1” enter

To M2 = “m2” enter

To M3 = “m3” enter

To M4 = “m4” enter

For more information see register manual 1.1 and 1.2

Motor control by RS-232

15

10 Control by wireless remote

To control the Rota-Kit by wireless remote the next options are possible.

2 programmable projection positions

Use IR remote 260214, or use radio 868 Mhz RF remote 260215 for internal

installation.

The receiver pcb will be installed inside the PRK.

4 programmable projection positions

Use IR remote 260214, or use radio 868 Mhz RF remote 260215 for internal

installation. 1 receiver pcb will be installed inside the PRK and 1 external receiver

will be installed to the connector of the PRK.

Use external IR remote 260218, or use radio 868 Mhz RF remote 260219 for

external installation. 1 receiver pcb will be installed inside the PRK and 1 external

receiver will be installed to the 8-way connector of the PRK.

11 Control by wireless remote 2-positions

Open the PRK by removing the panel with the green connector. Undo the

keyboard connector from the PCB.

On the PCB 260192 select the desired channel (1is standard).

Install the receiver PCB on the 261377 in the small connector between the white

PCB holders (see image).

Motor control by RS-232

16

Insert the batteries in the hand remote and test the product after closing up the

PRK. Lead the antenna or IR receiver cable outside the PRK.

12 Control by wireless remote 4 positions

Install the internal PCB as mentioned before (see 11) or use 2 sets of below

listed external remotes.

Apply the external remote 260218 or 260219 and connect the PCB with the Up-

common-down connection to the 8-way external control connector on the PRK.

On the PCB 260192 inside the 260218 or 260219, select the desired channel

(2is standard for position 3&4 for the PRK). Connect C+3+4.

General information

17

13 General information

13.1 Definitions

Homing - Move motor to zero or reference point (counter)

Twin mode - Parallel or synchronous mode for 2 separate drive units

13.2 End switches

End switches, also called limit switches restrict the movement of the motor in

both directions.

The limit switches are related to the rotation direction of the motor.

It is important to connect the motor so that the direction of motion corresponds

to the controls and limit switches.

In any case the movement stops on both switches, but when the motion

direction and limit switch do not match, the two led’s (U2 and U3) of the

corresponding limit switches on the PCB start blinking.

13.3 Memory positions and directions

The memory positions M1 to M4 must be set in a specific order in between the

two limit switches. They differ of the selected program and are also related to the

buttons of the remote control.

Program “0” and “4”

M1 correspond with the left/down direction

M2 correspond with the right/up direction

M3 is not assigned

M4 is not assigned

Program “1”

M1 correspond with the left/down memory position between M3 and M4, and

down position of the RC (free programmable)

M2 correspond with the right/up memory position between M3 and M4, and up

position of the RC (free programmable)

M3 lowest memory position, close to limit switch down (factory setting)

M4 upper memory position, close to limit switch up (factory setting)

Program “2”, “3” and “5”

M1 correspond with down position of the RC (free programmable)

M2 correspond with the up position of the RC (free programmable)

M3 memory position is free programmable

M4 memory position is free programmable

General information

18

13.4 Memory position control

Memory position M1 to M4 can be set in three different ways.

By the keypad on the electrical control box

By the memory and motor control terminal

By serial communication via RS-232

In program number “1” M3 and M4 are protected and can only be stored using a

PIN-code.

Set the memory position by the keypad

13.5 Error reset

All errors can be reset by disconnecting the power from the control board.

Take at least 10 seconds to power up.

The only exception is if two control boards are in twin mode.

If an synchronous error occurs then both motors have to be reset and homed

separately. Taking into account of mechanical damage.

Settings

19

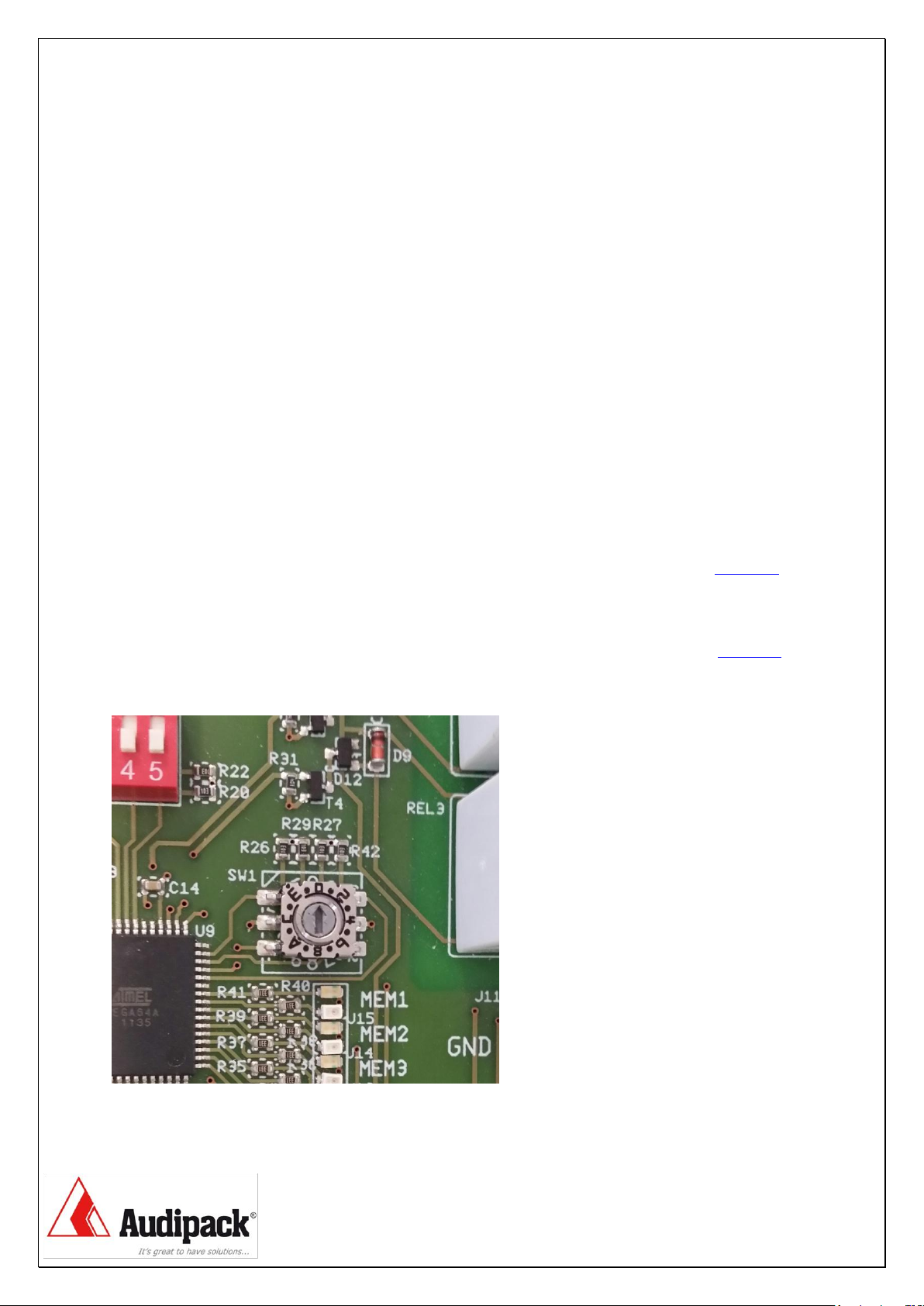

14 Program rotary switch (SW1)

14.1 Precautions

Before changing the program state disconnect the power from the control board.

Set memory positions under load. Place the projector or flat screen before

storing the memory positions.

14.2 Rotary switch positions versus functions

Rotary switch on position “0” = DC motors up to 30VDC without position control

Rotary switch on position “1” = DC motors up to 30VDC, column lifts with intern

limit switches and position control.

Rotary switch on position “2” = DC motors up to 30VDC with external limit

switches and position control, auto homing.

Rotary switch on position “3” = DC motors up to 30VDC with external limit

switches and position control, manual homing.

Rotary switch on position “4” = Single phase AC tube motors with external limit

Switches .

Rotary switch on position “5” = Single phase AC tube motors with external limit

Switches and position control, manual homing.

(4 & 5 not applicable on PCB 261377)

Settings

20

14.3 Rotary switch positions versus product examples

Rotary switch on position “0” = MKT-150WS, MKT-200WS, MKT-250WS,

MKT-265WS

Rotary switch on position “1” = FFCL-XXXX, Column lifts

Rotary switch on position “2” = PRK-250, PRK-500, PRK-750, PCL-M350,

PCL -X350 and MKT-C150

Rotary switch on position “3” = PRK-250, PRK-500, PRK-750, PCL-M350,

PCL -X350 and MKT-C150

Rotary switch on position “4” = Universal AC tube motors

Rotary switch on position “5” = PCL-1070, PCL-2050, PCL-3050, PCL-5050

Switches and position control, manual homing.

(4 & 5 not applicable on PCB 261377)

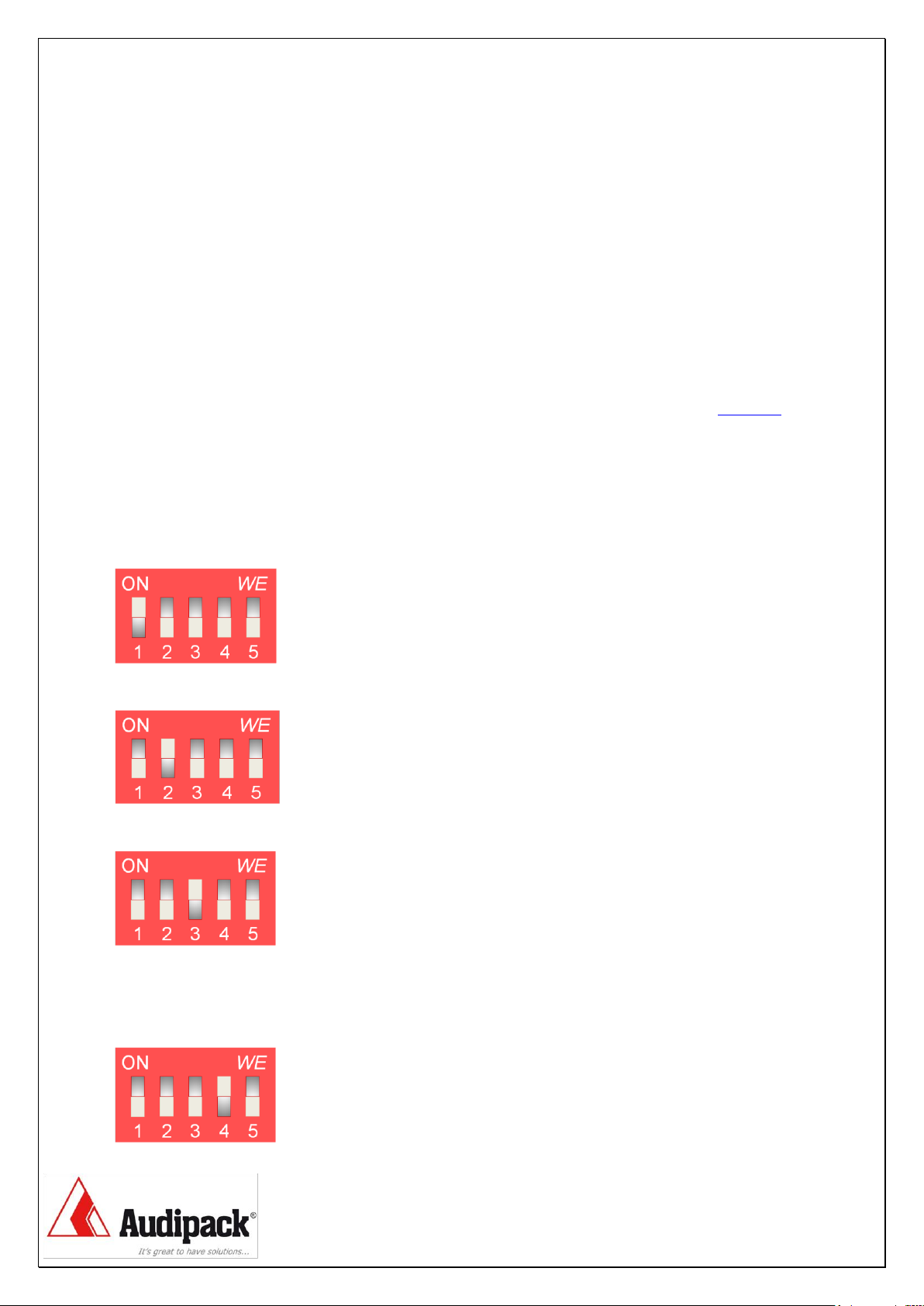

15 Function dipswitches (J14)

Dipswitch position 1 = Master/slave - slave “on” (in twin-mode only)

Dipswitch position 2 = Single/twin - single mode “on”

Dipswitch position 3 = Soft start/stop on/off - soft start/stop “on”

Dipswitch position 4 = Pulse/continue - pulse “on”

!! When pulse is “on”, the direction buttons are working as a latching switch !!

This manual suits for next models

2

Table of contents

Other Audipack Projector Accessories manuals

Popular Projector Accessories manuals by other brands

Christie

Christie Vivid Blue 38-VIV301-01 instructions

Pen Laboratory

Pen Laboratory Smart Sheet user manual

PEERLESS

PEERLESS PRG-UNV-S Installation and assembly

Monoprice

Monoprice 15495 user manual

Premier Mounts

Premier Mounts PSD-VHSA installation manual

PEERLESS

PEERLESS PSM-UNV Installation and assembly

Black Box

Black Box Wireless HDMI Presentation System (WHPS) user manual

Claypaky

Claypaky C52323 operating instructions

Omnimount

Omnimount 3N1-PJT instruction manual

Omnimount

Omnimount OM1004108 instruction manual

Black Box

Black Box Wireless Video Presentation System III... Quick installation guide

Panasonic

Panasonic ET-D75LE8 Spec file