3. Technical data

Part-turn actuators AUMA NORM require external controls. AUMA offers actuator controls AUMA MATIC AM or AUMATIC AC.

These can also easily be mounted to the actuator at a later date.

Features and functions

Type of duty 1) SG: Short time duty S2 - 15 min

SGR: Intermittent duty S4 - 25 %

Motors Standard: 3-ph AC asynchronous motor, type IM B9 according to IEC 34 (SG and SGR)

Options: 1-phase AC motor

DC shunt motor (SG only)

Insulation class Standard: F, tropicalized

Option: H, tropicalized (3-phase AC motors only)

Motor protection Standard: Thermoswitches (NC)

(DC motors without motor protection)

Option: PTC thermistors (according to DIN 44082)

Self-locking yes

Swing angle Standard: 80° to 110° adjustable between min. and max. value.

Options: 30° – 40°, 40° – 55°, 55° – 80°, 110° – 160°, 160° – 230° or 230° – 320°

Limit switching Counter gear mechanism for end positions CLOSED and OPEN

Standard: Tandem switch (2 NC and 2 NO) for each end position

Options: Single switch (1 NC and 1 NO) for each end position

switches galvanically isolated

Triple switch (3 NC and 3 NO) for each end position,

switches galvanically isolated

Intermediate position switch (DUO limit switching),

available for any intermediate position

Torque switching infinitely adjustable torque switching for direction OPEN and CLOSE

Standard: Single switch (1 NC and 1 NO) for each direction

Options: Tandem switch (2 NC and 2 NO) for each direction, switches galvanically isolated

Non-intrusive setting (option) Magnetic limit and torque transmitter MWG

(only possible in combination with actuator controls AUMATIC)

Position feedback signal,

analogue (options) Potentiometer or 0/4 – 20 mA (RWG)

For further details see separate data sheet

Torque feedback signal,

analogue (option) Only in combination with magnetic limit and torque transmitter MWG and controls

AUMATIC AC

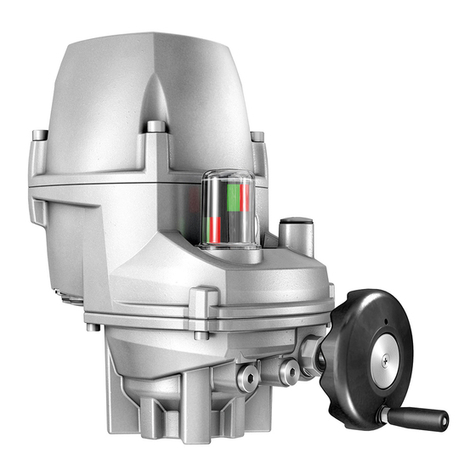

Mechanical position indicator Continuous indication, adjustable indicator disc with symbols OPEN and CLOSED

Running indication (option) Blinker transmitter

Heater in switch compartment Standard: self-regulating PTC heater, 5 – 20 W, 110 – 250 V AC/DC

Options: 24 – 48 V AC/DC or 380 – 400 V AC

A resistance type heater (5 W, 24 V DC) is installed within the actuator in combination with

the actuator controls AM or AC.

Motor heater (option) 12.5 W

Manual operation Manual drive for setting and emergency operation, handwheel does not rotate during

electrical operation.

Option: Handwheel lockable

Electrical connection Plug/socket connector with screw type connection

Threads for cable glands Standard: NPT-threads

Options: Pg-threads, NPT-threads, G-threads

Terminal plan KMS TP 100/001 (basic version with 3-phase AC motor)

Splined coupling for connection

to the valve shaft Standard: Coupling without bore

Options: Machined coupling with bore and keyway, square bore or bore with two-flats

according to EN ISO 5211

Valve attachment Dimensions according to EN ISO 5211

1) Based on 68 °F ambient temperature and at an average load with running torque.

For 1-phase AC motors, please note: When reversing, a pause of at least 100 ms is required.

Part-turn actuators SG 05.1 – SG 12.1 / SGR 05.1 – SGR 12.1

Operation instructions AUMA NORM