AUMA SAEx 25.1 User manual

Other manuals for SAEx 25.1

3

This manual suits for next models

13

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SAI 07.2 User manual

AUMA

AUMA PROFOX PF-Q80 User manual

AUMA

AUMA PROFOX PF-M25 User manual

AUMA

AUMA NORM Series User manual

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA NORM SQ 05.2 Administrator Guide

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA TIGRON TR-M30X Manual

AUMA

AUMA SGM Series User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA AUMATIC AC 01.2 User manual

AUMA

AUMA SGR 05.1 User manual

AUMA

AUMA SA Series User manual

AUMA

AUMA SAV Series User manual

AUMA

AUMA SBA 12 User manual

AUMA

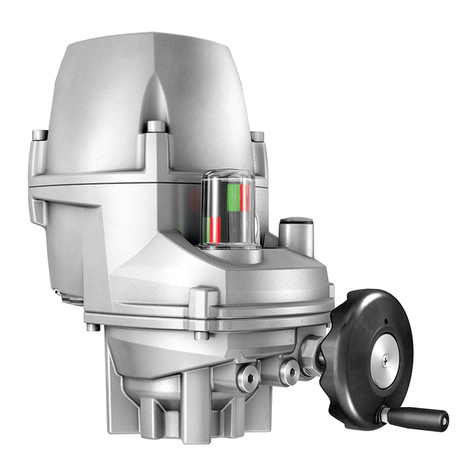

AUMA VARIOMATIC SARV 10.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA ACVExC 01.2 Series Manual

AUMA

AUMA TIGRON TR-M30X Manual

Popular Controllers manuals by other brands

McDonnell & Miller

McDonnell & Miller 150E Series Installation & maintenance instructions

Belimo

Belimo LMQB24-MFT Technical data

Formula Sound

Formula Sound AT-1 user manual

Heatcraft Refrigeration Products

Heatcraft Refrigeration Products H-IM-79D Installation & operation manual

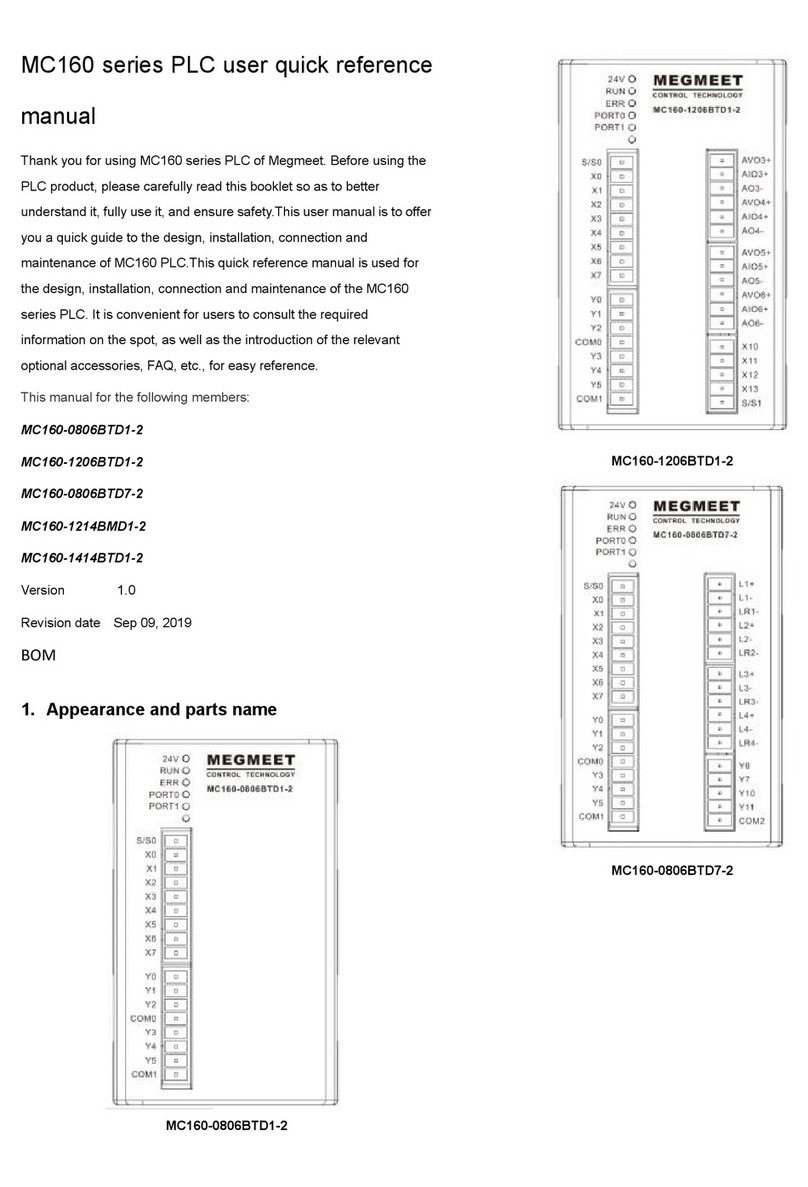

Megmeet

Megmeet MC160 PLC Series User quick reference manual

Omron

Omron TRAJEXIA-PLC manual

Texas Instruments

Texas Instruments TMS320x2833 series reference guide

Kantech

Kantech IoPass SA-500 installation manual

avantor

avantor VWR VC100 instruction manual

Pride Mobility

Pride Mobility Controller Flight Basic operation instructions

KE2 Therm Solutions

KE2 Therm Solutions Temp+Valve installation manual

Rinnai

Rinnai MC502S Operation & installation manual

Johnson Controls

Johnson Controls M9220-GG-3 Series installation guide

Kaden

Kaden KD Series manual

Reo Elektronik

Reo Elektronik REOTRON MEW operating instructions

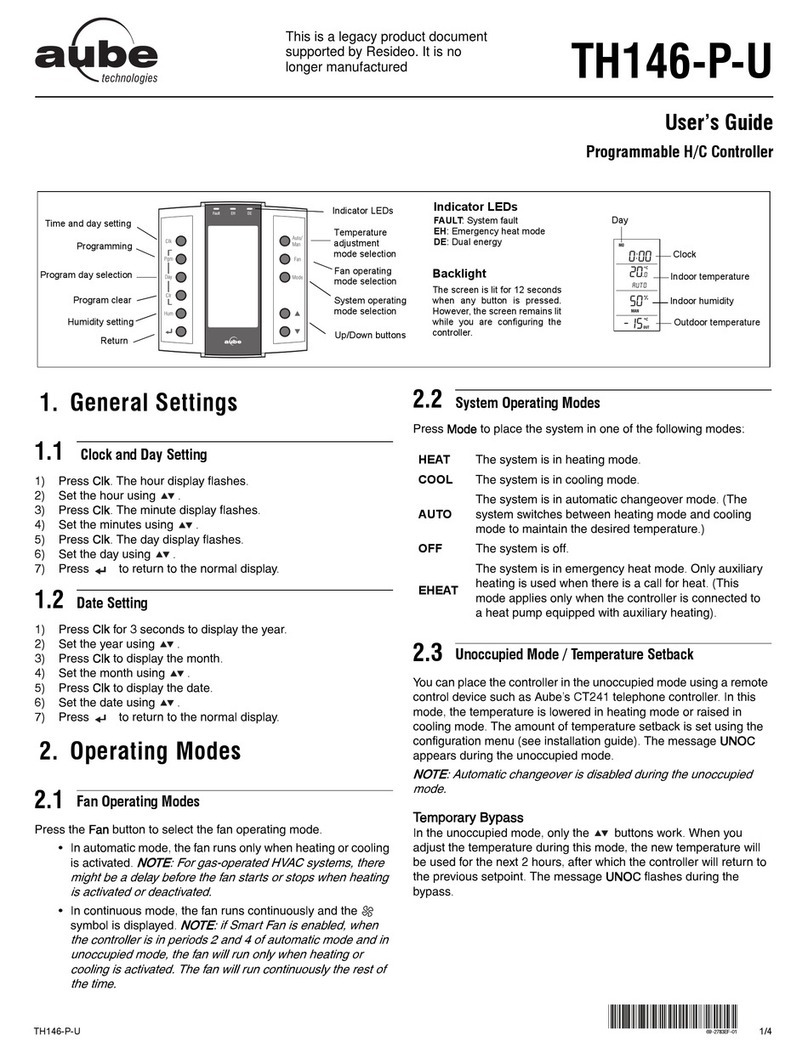

Aube Technologies

Aube Technologies TH146-P-U user guide

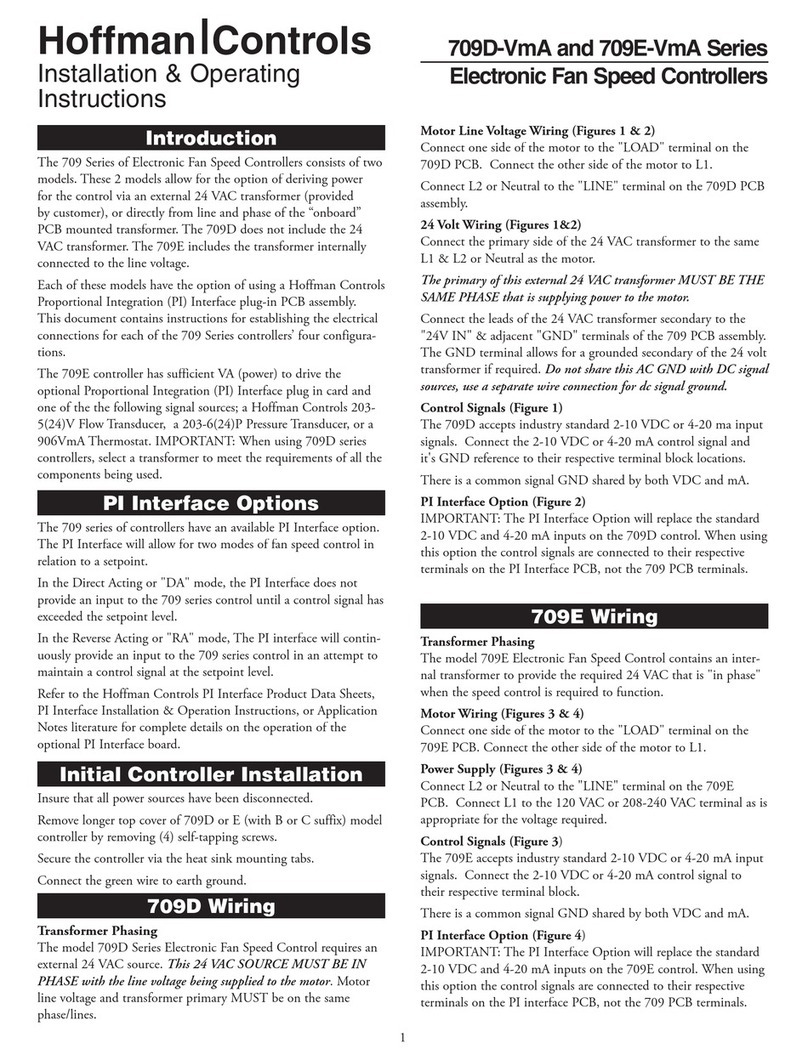

Hoffman

Hoffman 709D-VmA Series Installation and operating instructions

ABB

ABB M2301 product manual