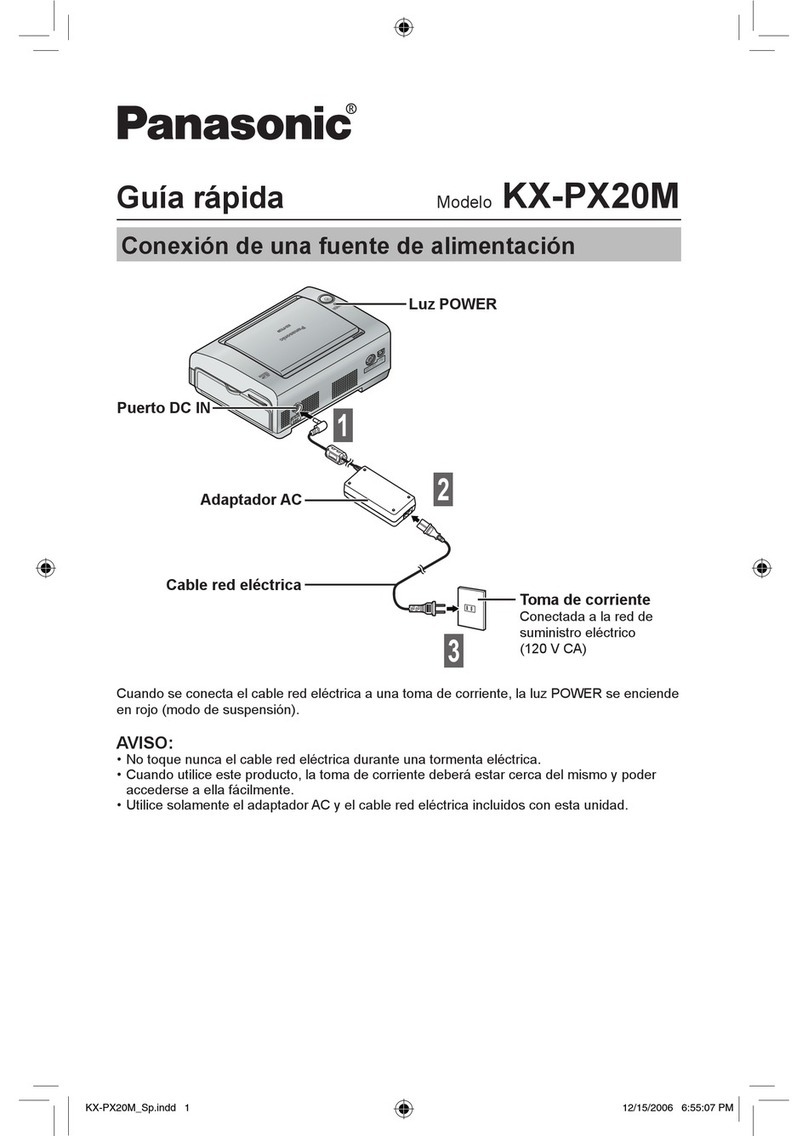

AURES ODP 300 User manual

ODP300

Dot Printer

Technical manual

ODP300 Technical Manual

2

TABLE OF CONTENTS

1. General Specifications

Printing Specifications

Character Specifications

Auto Cutter

Paper Roll Supply Device

Paper Specification

Printable Area

Printing and Cutting Positions

Internal Buffer

Electrical Characteristics

EMI and Safety Standards Applied

Reliability

Environmental Conditions

2. Configuration

Interface

RS-232 serial interface

Specifications

Switching between on-line and off-line

Interface connector terminal assignments and signal functions

Serial interface connection example

Centronics parallel interface

Data Receiving Timing(Compatibility Mode)

USB Interface

Interface Connector

3. Connectors

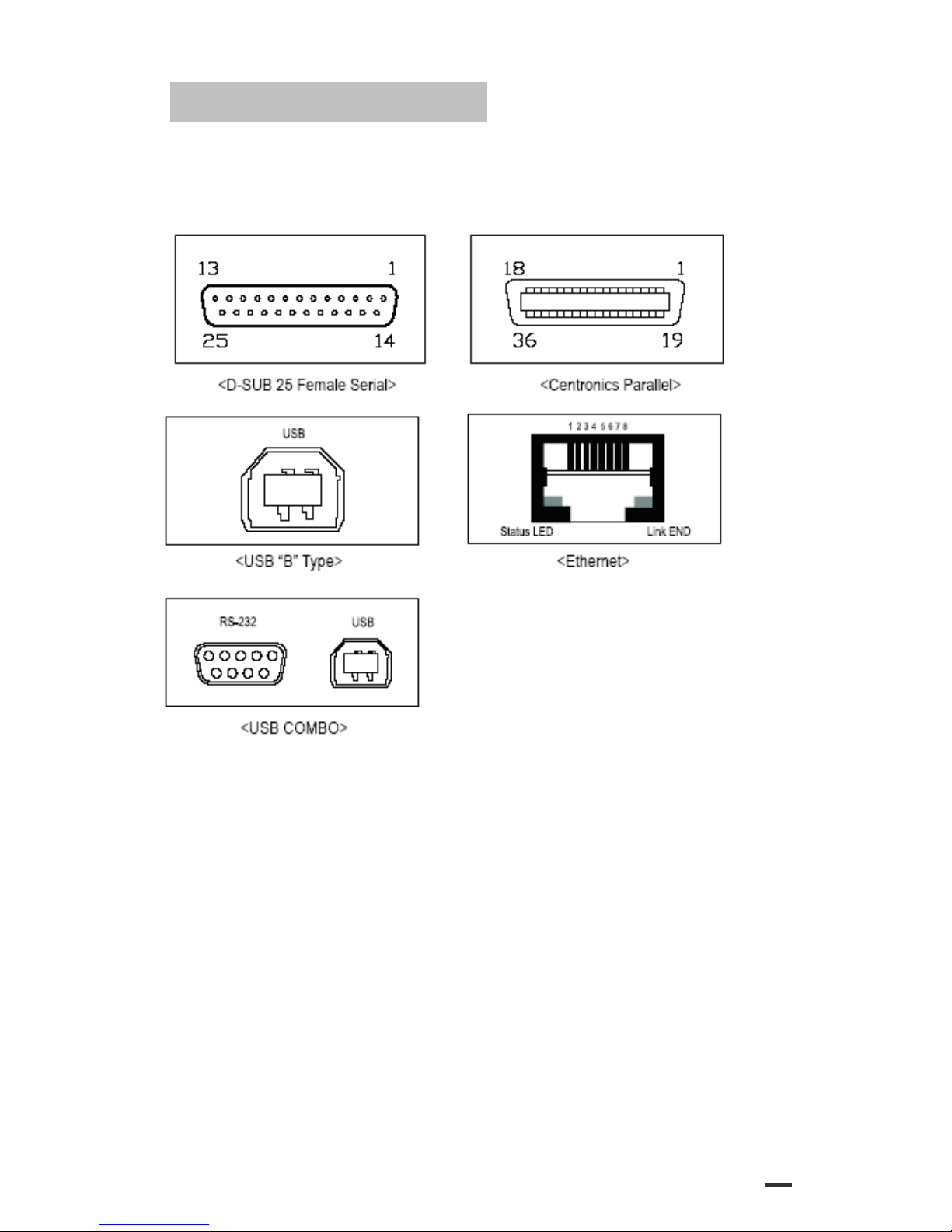

Interface Connectors

Electrical Characteristics

Drawer kick-out Connector (Modular Connector)

4. Control Command Summary

ODP300 Technical Manual

3

1. General Specifications

1.1 Printing Specifications

1) Printing method: 9pin serial impact dot method

2) Printing direction: Bi-directional

3) Printing width: 63.5 mm (2.5")

4) No. of Columns: 42/35, 40/33 (EPSON TM-U200 Emulation)

40/33 (Others Emulation)

5) Printing speed: 5 lines/second

(at 40 Characters per line)

☞NOTE: Speeds are switched depending on the applied voltage to the printer and head temperature

conditions automatically.

6) Line spacing (default): n/144 inch

1.2 Character Specifications

1) Number of characters: Alphanumeric characters: 95

Extended graphics 128 × 7 pages

(including one space page)

International characters: 32

①English

②Hangul

③Chinese (GB2312,Big5)

④Kanji

2 ) Character structure: Font A: 7 ⅹ9

Font B: 9 ⅹ9

Font A is selected as the default

ODP300 Technical Manual

4

3) Print Format:

7 X9 Dots

9 X9 Dots

FONT

A

B

C

D

X

Y

Z

7 X9

0.397

1.19

1.49

1.998

0.352

2.11

2.46

9 X9

0.397

1.588

1.888

2.382

0.352

2.11

2.46

ODP300 Technical Manual

5

1.3 Auto Cutter

Partial cut: Cutting with one point center uncut

NOTE: To prevent dot displacement, after cutting, paper must be fed

approximately 1mm(14/360 inches) or more before printing.

1.4 Paper Roll Supply Device

1) Supply method: Drop-in paper roll

2) Near-end sensor:

a) Detection method: Photo Reflector

b) Paper roll spool diameter: Inside: 12.7mm(0.5″)

Outside: 18.4mm(0.72″)

d) Remaining amount: Fixed position #1 (approximately 23mm(0.9″))

#2 (approximately 27mm(1.06″))

NOTE: You can use a command to stop printing upon detection of a paper near-end.

1.5 Paper Specification

1) Paper type: Roll Paper

2) Paper width:

76.2 ±0.5mm (3.23" ±0.02")

69.5 ±0.5mm (2.74" ±0.02")

57.5 ±0.5mm (2.26" ±0.02")

3) Paper roll size: Roll diameter : Maximum 80mm

Take-up paper roll width:

76.2 ± 0.5, 1.0mm(3 "±0.020", 0.04")

4) Paper roll spool diameter: Inside: 12.7mm(0.5")

Outside: 18.4mm(0.72")

NOTE: Paper must not be pasted to the paper roll spool.

ODP300 Technical Manual

6

1.6 Printable Area

A

(Paper Width)

B

(Printable Area)

C

(Blank Area)

Left

Right

76.2 mm

63.2 mm (200dots,400positon)

7 mm

6 mm

69.5 mm

56.8 mm (180dots,360position)

7 mm

5.7 mm

57.5 mm

47.4 mm (150dot,300position)

6 mm

4.1 mm

ODP300 Technical Manual

7

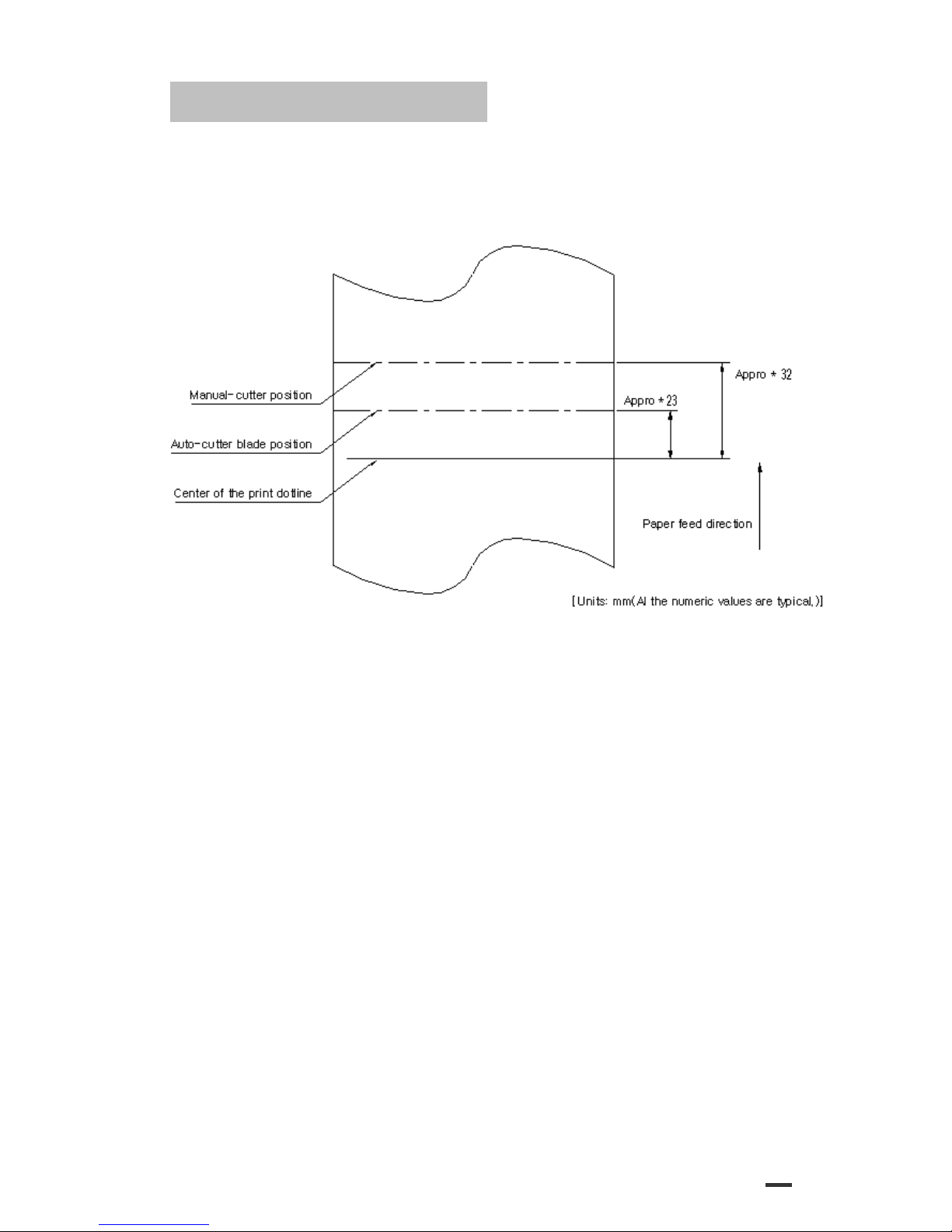

1.7 Printing and Cutting Positions

Figure 1.7.1 Printing and Cutting Positions

NOTE: Numeric values used here are center values to be used in designing. The values may vary slightly as a result of

paper slack or variations in the paper. Take this into account when setting the cutting position of the autocutter.

ODP300 Technical Manual

8

1.8 Internal Buffer

1) Data buffer: 16kbyte

1.9 Electrical Characteristics

1) 형태: 외부 아답터

2) 입력: 120VAC, 230VAC

3) 출력: 24VDC ⅹ2.5A

1.10 EMI and Safety Standards Applied

1) Europe: EMI –EN55022 CLASS A

EMS –EN61000-3-2, EN61000-3-3, EN50082-1

Safety Standard: EN60950

2) North America: EMI - FCC Part#15 Class A

Safety Standards- UL / c-UL(No.60950)

1.11 Reliability

1) MCBF: 18 million lines

2) Cutter Life: the cutter performs 1,000,000 cuts with thickness 65 ㎛, and/or 300,00cuts with

thickness 100 ㎛to the paper

3) HEAD 150 million characters

1.12 Environmental Conditions

1) Temperature: Operating: 5 to 40 C

Storage: -20 to 60 C

(except for paper)

2) Humidity: Operating: 10 to 80%RH

Storage: 5 to 95%RH (except for paper)

ODP300 Technical Manual

9

2. Configuration

2.1 Interface

2.1.1 RS-232 serial interface

2.1.2 Specifications

Data transmission: Serial

Synchronization: Asynchronous

Handshaking: DTR/DSR or XON/XOFF control

Signal levels: MARK= -3 to –15V: Logic “1”

SPACE= +3 to +15V: Logic “0”

Baud rage: 4800, 9600, 19200, 38400 bps

Data word length: 7 or 8 bits

Parity Settings: None, even, odd

Stop bits: 1 or more

Connector (printer side): Female DSUB-25 pin connector

NOTE: The data word length, baud rate, and parity depend on the

DIP switch settings.

2.1.3 Switching between on-line and off-line

The printer does not have an on-line/off-line switch.

The printer goes off-line:

•Between when the power is turned on (including reset using the interface) and when the

printer is ready to receive data.

•During the self-test.

•When the cover is open.

•During paper feeding using the paper feed button.

•When the printer stops printing due to a paper-end (in cases when an empty paper supply

is detected by either paper roll end detector or the paper roll near-end detector with a

printing halt feature by

ESC c4).

•During macro executing stand by status.

•When a temporary abnormality occurs in the power supply voltage.

•When an error has occurred.

2.1.4 Interface connector terminal assignments and signal functions

PIN

SIGNAL

I/O

DESCRIPTION

2

TXD

-

Printer transmit data line RS-232C level

3

RXD

-

Printer receive data line RS-232C level

4, 20

DTR

Output

Printer handshake to host line RS-232C level

6

DSR

Input

Data Send Ready

1,7

GND

-

System Ground

ODP300 Technical Manual

10

2.1.5 Serial interface connection example

Host side Printer side

TXD ………………………………… RXD

DSR ………………………………… DTR

RXD ………………………………… TXD

DTR ………………………………… DSR

FG ………………………………… FG

SG ………………………………… SG

DETAILS: ◦Set the handshaking so that the transmit data can be received.

◦Transmit data to the printer after turning on the power and initializing the printer.

< Figure 2.1 Serial transmission bit frame >

< Figure 2.2 Line transmission with protocol >

1 Bit

7 or 8

Bit

None or

1 Bit

1 or 2

Bit

ODP300 Technical Manual

11

2.1.6 Centronics parallel interface

1) Specifications

Data transmission: 8-bit parallel

Synchronization: STROBE pulse supplied by host computer.

Handshaking: ACK and BUSY

Connector: D-SUB 36(female) or equivalent

DATA Data n Data n+1

tHold

nStrobe

tSetup tSTB

Busy Peripheral Busy

tReady tBUSY

nAck

tReply tACK tnBUSY

tNext

PIN

SIGNAL

I/O

DESCRIPTION

1

STROBE-

Input

Synchronize signal Data received

2-9

DATA0-7

Input

Data bit Transmitted 0-7

10

ACK-

Output

Data receiving competed

11

BUSY

Output

Impossible to printer data receiving

12

PE

Output

Paper empty

13

SELECT

Output

Printer’s status for ON/OFF line

14

AUTO FEED-

Input

ND

15

GROUND

-

System Ground

16

GROUND

-

System Ground

17

NC

-

18

LOGIC-H

-

+5V

19-30

GROUND

-

System Ground

31

INIT-

Input

Initialize

32

ERROR-

Output

Printer Error

33

GROUND

-

System Ground

34

NC

-

35

+5V

-

+5V

36

SELECT IN-

Input

ND

ODP300 Technical Manual

12

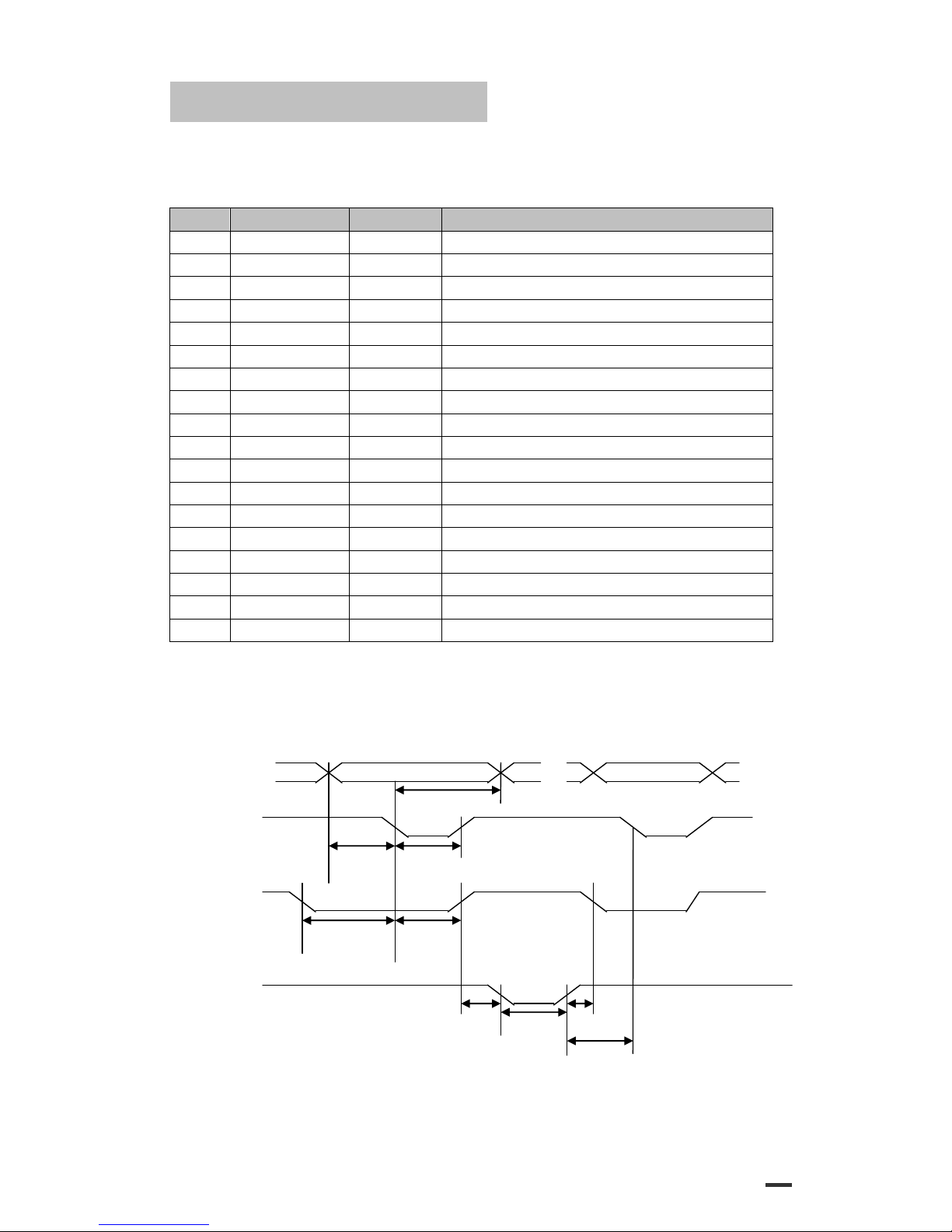

2.1.7 Data Receiving Timing (Compatibility Mode)

Characteristics

Symbol

Specifications

Min [ns]

Max [ns]

Data Hold Time (host)

tHold

750

--

Data Setup Time

tSetup

750

--

STROBE Pulse Width

tSTB

750

--

READY Cycle Idle Time

tReady

0

--

BUSY Output Delay Time

tBUSY

0

500

Data Processing Time

tReply

0

ACKNLG Pulse Width

tACK

500

10us

BUSY Release Time

tnBUSY

0

ACK Cycle Idle Time

tNEXT

0

--

The printer latches data at a nStrobe ↓timing

2.1.8 USB Interface

PIN

SIGNAL

I/O

DESCRIPTION

1

+5V

-

+5V

2

DATA-

-

Printer transmit data line

3

DATA+

-

Printer transmit data line

4

GND

-

System Ground

1) Specifications

Data transmission: USB 2.0

Connector: USB “B” type connector

2) USB interface connection example

Host side Printer side

VCC ………………………………… VCC

DATA+ ……………………………… DATA+

DATA- ……………………………… DATA-

GND ………………………………… GND

ODP300 Technical Manual

13

2.1.9 Interface Connector

ODP300 Technical Manual

14

3. Connectors

3.1 Interface Connectors

Refer to Section 2.1, Interface

3.2 Electrical Characteristics

1) Input Voltage: DC 24V ± 10%

2) Current Consumption: Operating: Approx. 1.5 A (at ASC∥printing)

Peak: Approx. 10 A (at print duty 100%, For 10 seconds or less)

Stand-by: Approx. 0.15 A

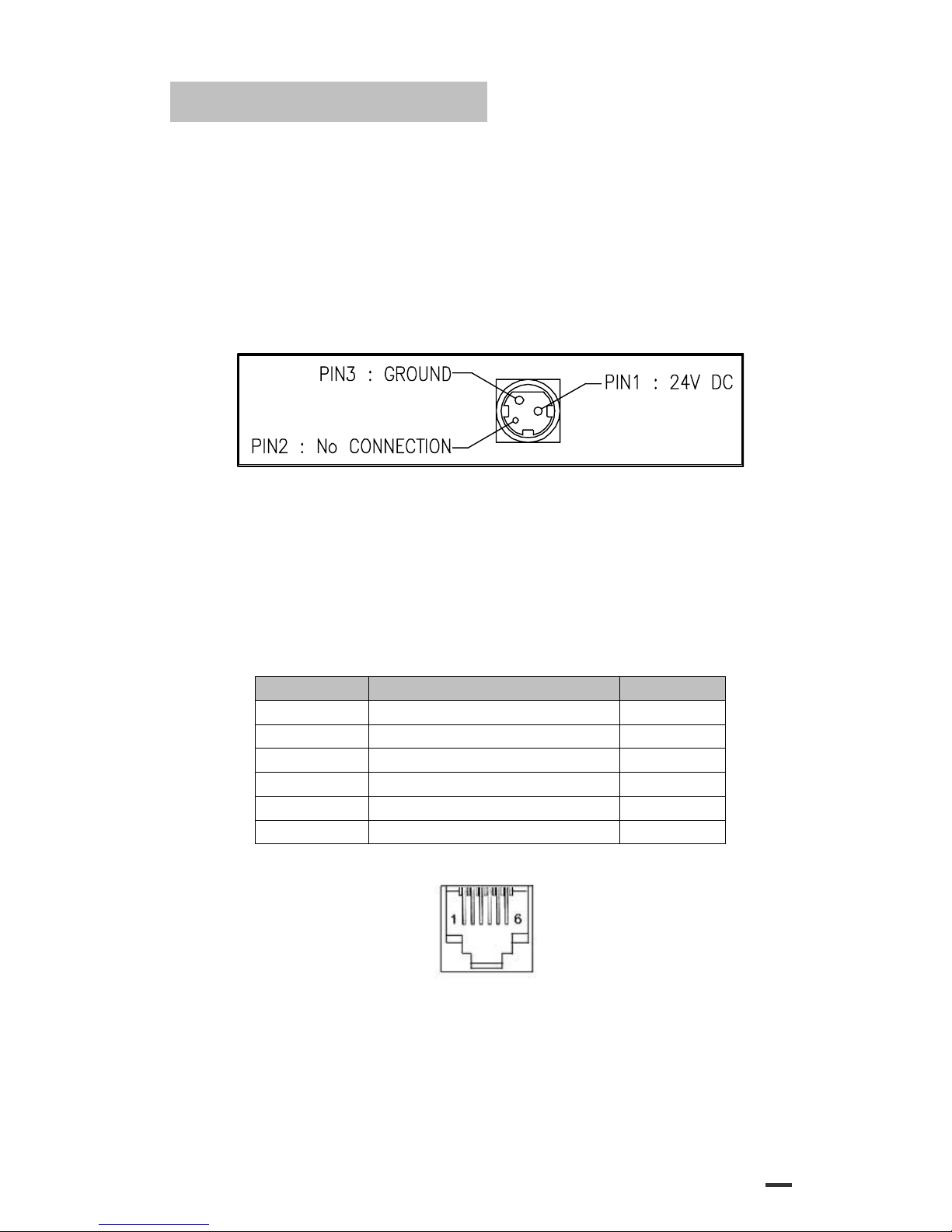

3) Power Connector

3.3 Drawer Kick-out Connector (Modular Connector)

The pulse specified by ESC p or DLE DC4 is output to this connector.

The host can confirm the status of the input signal by using the

DLE EOT,GS a, or GS r commands.

1) Pin assignments: Refer to Table 2.2.2

2) Connector model:

Printer side: DAEEUN DEK-623PCB-6-B or Equivalent

User side: 6-position 6-contact (RJ12telephone jack)

< Drawer Kick-out Connector Pin Assignments >

Pin Number

Signal Name

Direction

1

Frame GND

-

2

Drawer kick-out drive signal 1

Output

3

Drawer open/close signal

Input

4

+24V

-

5

Drawer kick-out drive signal 2

Output

6

Signal GND

-

+24V is output through pin 4 when the power is turned on. However, pin 4 must by used only for the drawer.

< Figure 3.1 Drawer Kick-out Connector >

3) Drawer kick-out drive signal

Output signal: Output voltage: Approximately 24V

Output current: 1A or less

ODP300 Technical Manual

15

CAUTION: To avoid an overcurrent, the resistance of the drawer kick-out solenoid

must be 24 Ω or more.

Output waveform: Outputs the waveforms in Figure 3.2 to the points A and B

in Figure 3.3

t1 (ON time) and t2 (OFF time) are specified by ESC p or

DLE DC4.

< Figure 3.2 Drawer Kick-out Drive Signal Output Waveform >

4) Drawer open/close signal

Input signal level (connector pin 3): “L”= 0 to 0.8V

“H”= 3 to 5V

< Figure 3.3 Drawer Circuitry >

NOTE: 1. Use a shielded cable for the drawer connector cable.

2. Two driver transistors cannot be energized simultaneously.

3. The drawer drive duty must by as shown below.

ON time

≤ 0.2

(ON time + OFF time)

4. Be sure to use the printer power supply (connector pin 4) for the drawer power source.

5. The resistance of the drawer kick-out solenoid must not be less than the specified. Otherwise, an

overcurrent could damage the solenoid.

6. Do not connect telecommunication network to the drawer kick-out connector.

Other manuals for ODP 300

1

Table of contents

Other AURES Printer manuals

AURES

AURES ODP-200H-III User manual

AURES

AURES ODP 444 User manual

AURES

AURES Posligne ODP-1000 User manual

AURES

AURES SMP 58 Instruction sheet

AURES

AURES SMP 58 User manual

AURES

AURES TRP100 User manual

AURES

AURES TRP100-III User manual

AURES

AURES ODP 300 User manual

AURES

AURES TRP100 User manual

AURES

AURES SLP 580 User manual