© 2009 Austin Kontore LLC Page 2 of 54

Introduction

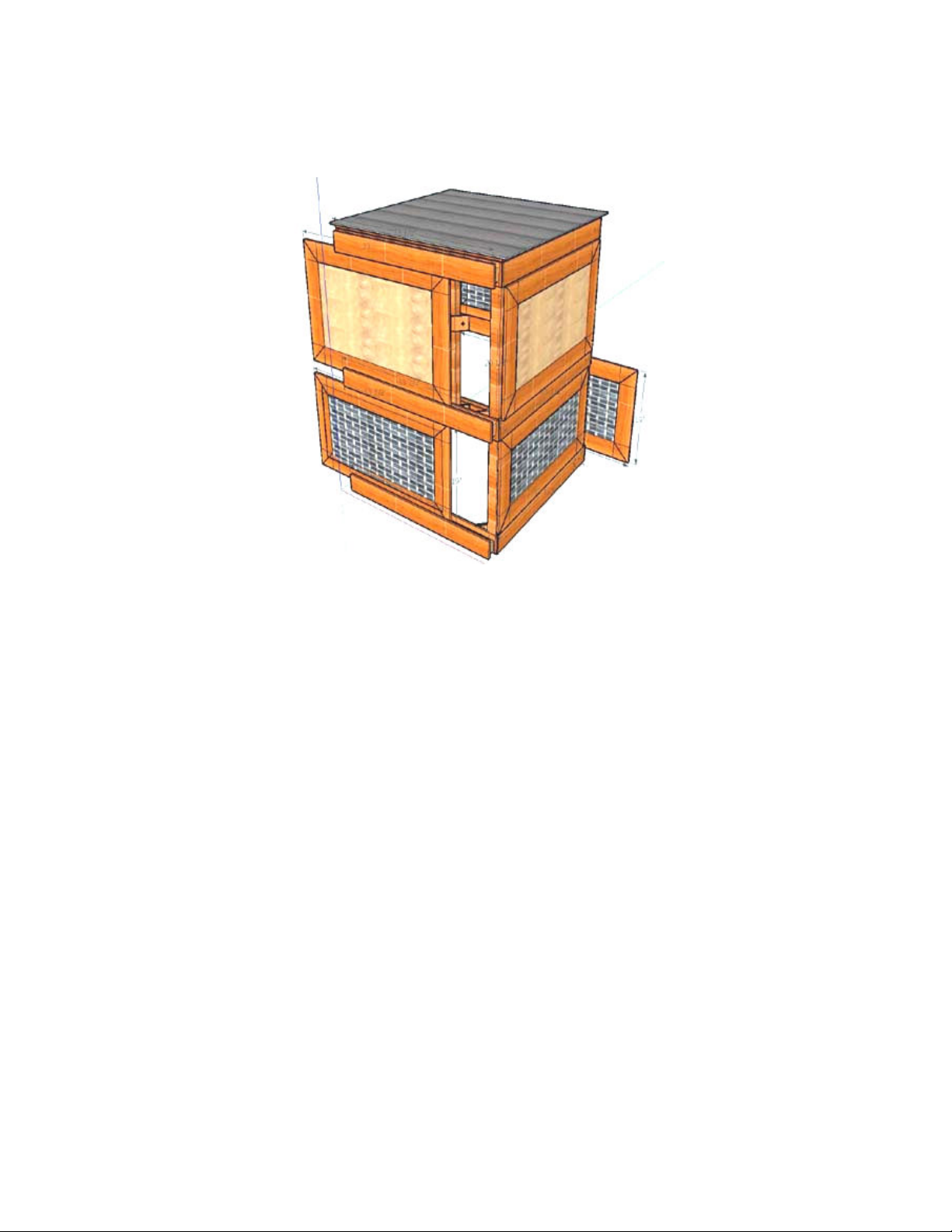

Thank you for purchasing our Crestview Chicken Coop kit. We are sure it will give you years of

enjoy ent.

Technical Support

If you have any questions during asse bly, please give us a call at 512-436-0512 or send an e- ail with

Special Symbols

Repeat

The preceding step, or series of steps, will need to be repeated. This is often

the case when ore than one Door or Fixed Panel needs to be built, with each

ite being built in an identical anner.

I portant

An i portant note, which should be read before perfor ing a step, or series

of steps. Used to avoid potential asse bly proble s.

Goal More infor ation on what you are trying to acco plish during a given step.

Note An infor ational note, used to further explain the reasoning behind a step.

Assembly Overview

1. Build Panel Units (fixed panels and panel door). There are three of these.

2. Build Screen Units (fixed screens and screen doors). There are five of these.

3. Asse ble the Core Structure, ade of prefabricated squares and posts.

4. Mount Door Slide Rails. There are five of these.

5. Mount Inside Rails. A set of two.

6. Install pre-fabricated Roof.

7. Install final Fixed Screen Unit.

8. Test Door action.

9. Install Extras, like the Roost and Nesting Box slats.

10. Sand and Stain the co pleted coop.