AUSTIN POWDER E-STAR User manual

QUICK GUIDE

ELECTRONIC BLASTING SYSTEM

System Limits ....................................................................................................................................................................... 3

Working Procedure .............................................................................................................................................................. 4

E*STAR Tester ................................................................................................................................................................... 4

E*STAR Logger 2 .............................................................................................................................................................. 5

Programming Methods ................................................................................................................................................ 6

Manual .................................................................................................................................................................. 6

Data from PC ........................................................................................................................................................ 7

Auto Delay ............................................................................................................................................................ 8

Detonator List ............................................................................................................................................................... 10

Branching .......................................................................................................................................................................... 11

E*STAR Pronto Connector ................................................................................................................................... 12

Daisy Chaining Connection ................................................................................................................................. 13

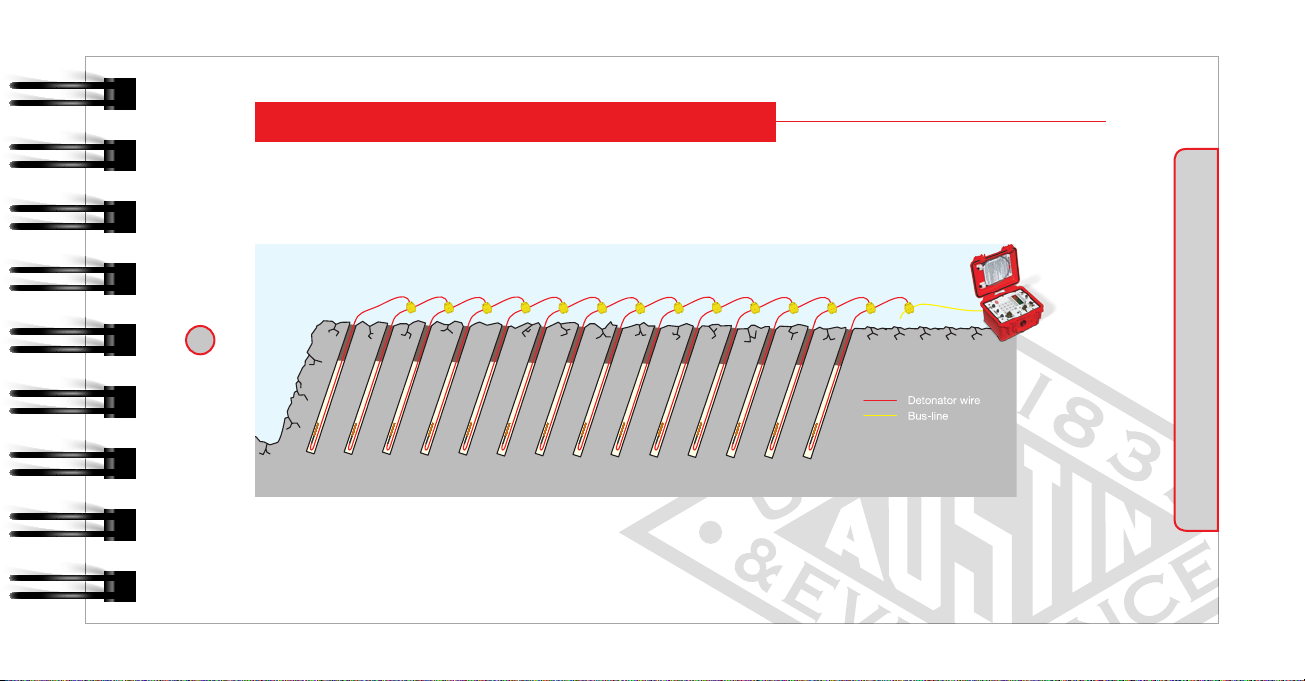

Bus-line Connection ............................................................................................................................................. 16

Verification ............................................................................................................................................................ 17

Branch Leakage Measuring ................................................................................................................................. 18

Leakage Troubleshooting ................................................................................................................................................. 19

Blasting Machine .............................................................................................................................................................. 21

Logger 2 Troubleshooting – Programming ......................................................................................................................... 23

Logger 2 Troubleshooting – Verification ............................................................................................................................. 25

Blasting Machine Troubleshooting – Verification .............................................................................................................. 26

Blasting Machine Troubleshooting – Charging of Capacitors ........................................................................................... 27

TABLE OF CONTENTS

TABLE OF CONTENTS

2

Max. 1,600 detonators per 1 Blasting Machine

Max. 3,200 detonators per 2 interconnected Blasting Machines

Max. 1,600 detonators per Logger

Max. 99 branches

Max. 100 detonators per branch (80 with Daisy Chaining)

Max. 26,200 ft branch wire (with Bus-line Cu 0.8 mm)

Max. 6,600 ft firing line (with Bus-line Cu 0.8 mm)

Max. 400 detonators when 6,600 ft firing line is used (with Bus-line Cu 0.8 mm)

Max. 1,310 ft firing line when 1,600 detonators are used (with Bus-line Cu 0.8 mm)

SYSTEM LIMITS

SYSTEM LIMITS

3

Measuring current by Tester

Press the ON/OFF button to turn on the device.

Detonator leakage is indicated by BUS-BUS on display.

The nominal value for detonator leakage is 0.08 or 0.09 mA.

Short press of the ON/OFF button switches the measuring

mode between BUS-BUS and BUS-SHELL.

Ground leakage is indicated by BUS-SHELL on display.

The nominal value for ground leakage is 0.00 mA.

Long press of the ON/OFF button turns off the device.

WORKING PROCEDURE | E*STAR TESTER

WORKING PROCEDURE | E*STAR TESTER

4

Press the ON/OFF button to turn on the device.

Enter security code.

Press ENTER.

Erase Detonator & EBR memory.

Before choosing a programming method, you have to choose

the way of programming – CONNECT or RFID.

CONNECT – attach the detonator to the adapter or terminals

on top of the Logger.

RFID – touchless communication between the Logger

and RFID Label.

WORKING PROCEDURE | E*STAR LOGGER 2

WORKING PROCEDURE | E*STAR LOGGER 2

5

E*STAR LOGGER 2 | PROGRAMMING METHODS - MANUAL

E*STAR LOGGER 2 | PROGRAMMING METHODS - MANUAL

6

All values are manually typed using the Logger keypad

In the main menu press #1 to PROGRAM, choose between Connect or RFID and select #1 MANUAL.

Set the BRANCH number, confirm by ENTER and set the DETONATOR NUMBER.

CONFIRM ALL and CONNECT detonator.

Use to move up and down and select the option you want to change (DELAY, BRANCH #

or DETONATOR #) if needed.

CHANGE by typing the new value.

When all values are OK press CONFIRM ALL – Detonator will be programmed.

This programming method uses blast timing prepared on PC (e.g. E*STAR PROGRAMMER, Paradigm, etc.).

In the main menu press #1 PROGRAM, choose between CONNECT or RFID

and select #2 – DATA FROM PC.

The screen will display delay time, det # and branch # for the detonator being programmed.

The displayed value from PC can be changed by pressing and confirming selected “CHANGE DATA

SETTINGS” by ENTER. It’s possible to skip any detonator. To perform the skip function, press to get to

“SELECT DATA BY DET #” option, then confirm by ENTER. In the next screen, type the desired DET # to

program.

E*STAR LOGGER 2 | PROGRAMMING METHODS - DATA FROM PC

E*STAR LOGGER 2 | PROGRAMMING METHODS - DATA FROM PC

7

This method of programming calculates the delays automatically from the previous delay. It isn’t necessary

to have any data prepared in advance from a PC. The delays are set at the beginning of programming in the

Logger, changes are possible during the programming.

In main menu press #1 PROGRAM, choose between CONNECT or RFID and select #3 - AUTO DELAY.

Set the BRANCH number, confirm by ENTER, set the DETONATOR NUMBER and confirm by ENTER.

Set up the AUTO DELAY values.

CONFIRM values by ENTER and start programming.

Type in the “FIRST DELAY” value = the delay of the 1st detonator. This delay must be confirmed by pressing

ENTER. Cursor will jump automatically to the “SECOND DELAY” = the 2nd delay is the delay of the 2nd detona-

tor (either 2nd detonator in the hole or detonator in the next hole depending on double or single priming). Con-

firm by ENTER. Cursor will move to “INTERVAL” value = delay between 1st and 3rd detonator. Type in the value

and change by pressing to set it as “decrement” (minus sign before the value) or to be “increment” (plus

sign before the value). Default setup is “increment”. Confirm by ENTER. Press to confirm the settings. You

can change the settings by pressing TO CANCEL THE SETTINGS and START FROM THE BEGINNING.

E*STAR LOGGER 2 | PROGRAMMING METHODS - AUTO DELAY

E*STAR LOGGER 2 | PROGRAMMING METHODS - AUTO DELAY

8

E*STAR LOGGER 2 | PROGRAMMING METHODS - AUTO DELAY

9

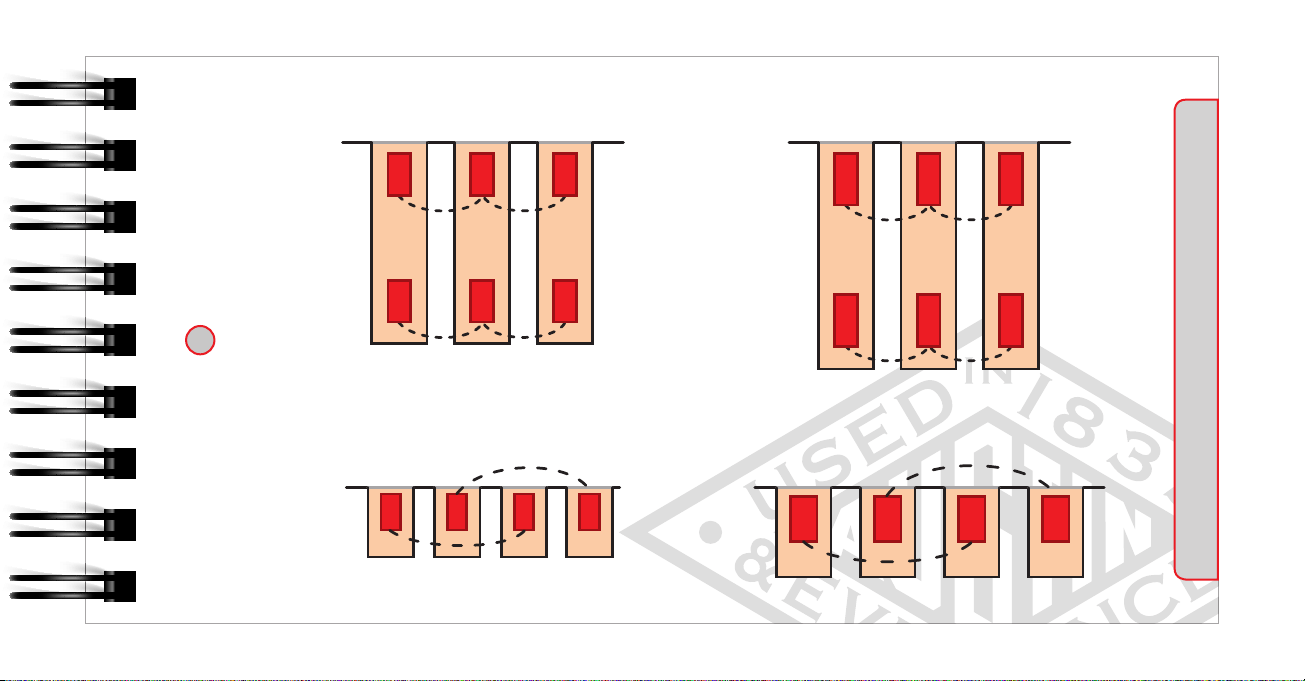

Double Priming Double Priming - example

Single Priming Single Priming - example

1st delay = 475 ms

2nd delay = 500 ms

interval = 17 ms

1 = 1st delay

2 = 2nd delay

3 = interval

1 = 1st delay

2 = 2nd delay

3 = interval

1st delay = 10 ms

2nd delay = 20 ms

interval = 20 ms

475 492 509

500 517 534

10 20 30

17 17

17 17

40

20

20

This function is used to check what values have been programmed.

“SHOW ALL” = detonator list with the cursor on the last programmed detonator. You can scroll through

the list to see the programming history

“SHOW EACH DETONATOR” - Logger will ask how you want to display the detonators.

You can choose “SEQUENTIAL BY DET#” or “ORDER DETS LOGGED”

“SELECT DETONATOR” = choose the detonator number to see detonator details

E*STAR LOGGER 2 | DETONATOR LIST

E*STAR LOGGER 2 | DETONATOR LIST

10

Once programming is completed, the detonators must be connected to the branch wires (Bus-line) according

to the programmed branch numbers. You can connect detonators to the Bus-line or use Daisy Chaining

Connection (described below).

EXAMPLE: DETONATORS THAT HAVE BEEN PROGRAMMED WITH BRANCH NUMBER 1

MUST BE CONNECTED TO BRANCH WIRE NUMBER 1.

WORKING PROCEDURE | BRANCHING

WORKING PROCEDURE | BRANCHING

11

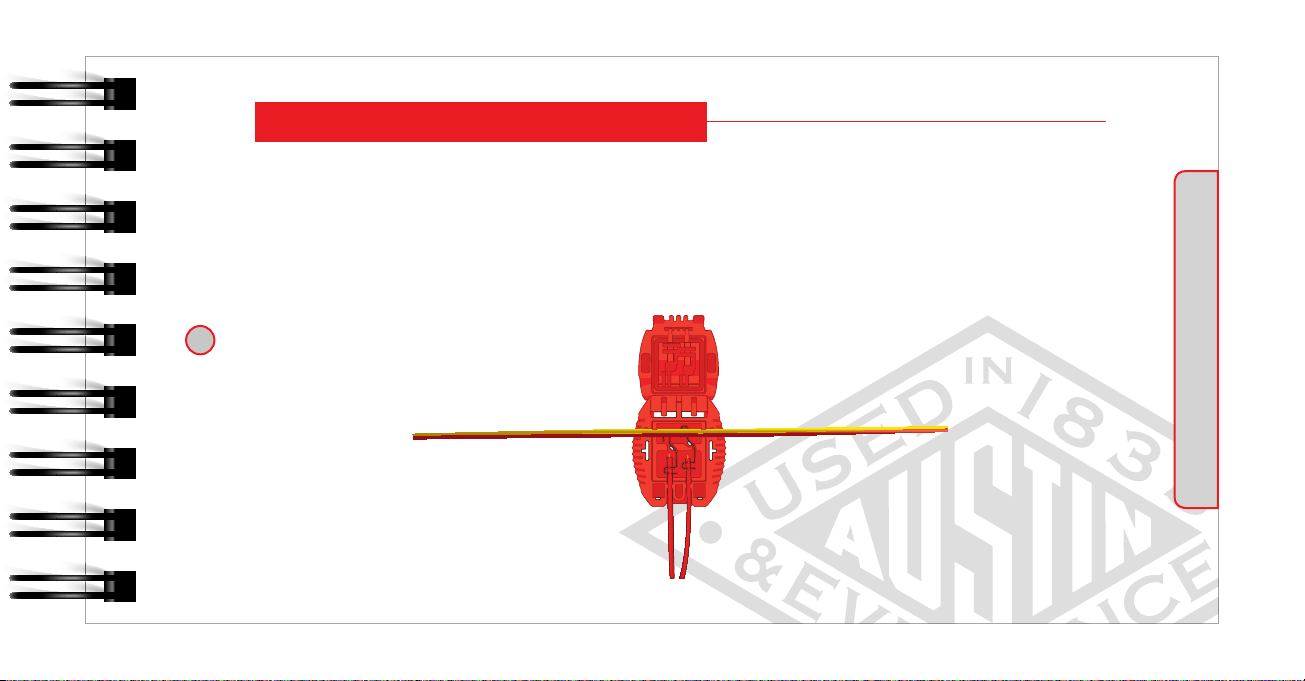

Can be used for:

Connection between branch wire and firing line

Fast extension of the firing line (Bus-line)

Fast extension of the branch wire (Bus-line)

Fast verification / leakage test from any point on firing

line or branch wire

Adding a spare connector in case of a damaged original

connector

BRANCHING | E*STAR PRONTO CONNECTOR

BRANCHING | E*STAR PRONTO CONNECTOR

12

Daisy Chaining connection is connection of one detonator to another detonator instead of Bus-line.

For illustration please see the schematic drawings below.

BRANCHING | DAISY CHAINING CONNECTION

BRANCHING | DAISY CHAINING CONNECTION

13

LESS IS MORE!

Connection between the branch and firing line can be done in several ways. It mostly depends on the connection

method in the specific branch.

The maximum number of detonators connected to one branch is 100, with Bus-line connection. A lower

number of detonators in a branch is always better for energy distribution.

If detonators are connected in the Daisy Chaining connection, the interconnection between branch and firing

line should be considered. The maximum number of detonators in one branch with Daisy Chaining connection

is 80. A lower number of detonators in the branch makes it easier to troubleshoot any issues.

Firing line length (ft)

Maximum dets per Blasting Machine (units)

Maximum detonators per Blasting Machine for E*STAR systems based on connection method

Legend:

—E*STAR Standard & Heavy Duty

(Bus-line connection)

-- E*STAR Standard

(Daisy Chaining connection = max. 80 dets/branch

& max. 19 ft connector to connector separation)

14

BRANCHING | DAISY CHAINING CONNECTION

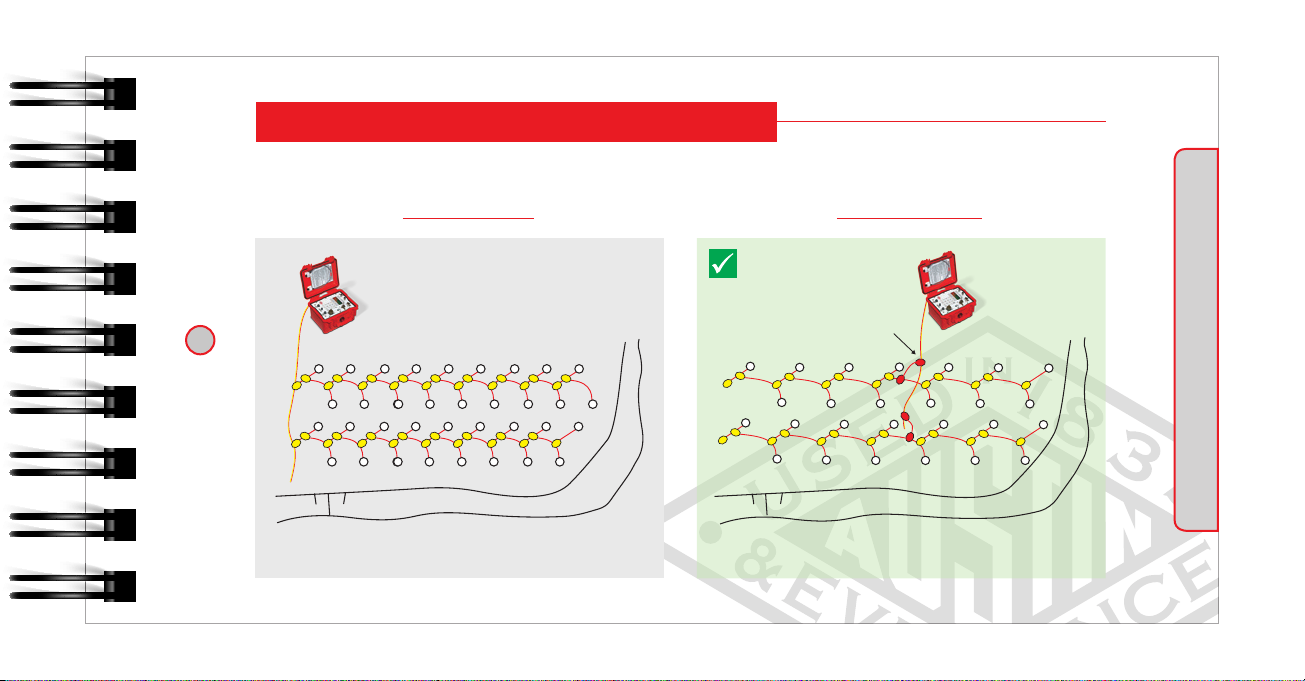

TO ACHIEVE THE BEST ENERGY DISTRIBUTION, IT IS HIGHLY RECOMMENDED TO CONNECT

THE FIRING LINE IN THE MIDDLE OF THE BRANCHES BY USING THE E*STAR PRONTO CONNECTOR!

BRANCHING | DAISY CHAINING CONNECTION

BRANCHING | DAISY CHAINING CONNECTION

15

Austin Powder RecommendationPossible Solution

crest cresttoe toe

E*STAR

Pronto

Connector

Austin Powder RecommendationPossible Solution

16

BRANCHING | BUS-LINE CONNECTION

BRANCHING | BUS-LINE CONNECTION

crest cresttoe toe

E*STAR

Pronto

Connector

E*STAR

Pronto

Connector

Verification is the process where the Logger is connected to the branch wire. The Logger communicates with

all programmed detonators to identify any unconnected, programmed detonators (MISSING), and detonators

that may not have been programmed but are connected to the branch wire (UNEXPECTED).

All issues must be resolved before proceeding to firing. During verification, the Logger compares what is in

the memory (what was programmed) and what is connected to the branch wires.

After successful verification, the Logger performs current measurements, informing the user about potential

Leakage problems. Explanation of the function is in the next chapter.

This same process must be completed for every branch in the blast.

Remember, 100 detonators are the maximum number of detonators permitted per branch!

BRANCHING | E*STAR PRONTO CONNECTOR

BRANCHING | VERIFICATION

17

Branch leakage is measured automatically during verification as its last step.

For separate branch leakage measuring, select “LEAKAGE” in “MAIN menu” and then “BRANCH”.

Type in the branch number for which you want to measure the leakage.

The measured values will appear on the screen, along with the branch number.

The third line is the expected value (calculated based on number of detonators times current

consumption 0.1 mA).

The fourth line displays the measured values in different directions / polarities.

When the values of expected and measured match, there is no excessive leakage.

When measured values are higher than expected, there is excessive leakage in the network, which must be

identified and remedied before proceeding.

When measured values are lower than expected ones, it means there are some missing detonators. Running

a new verification of the branch is advisable to identify the issue.

BRANCHING | BRANCH LEAKAGE MEASURING

BRANCHING | BRANCH LEAKAGE MEASURING

18

What is Leakage?

A leakage occurs when current is lost through a leak. The leak is caused by the damage of insulation of the

wires. It is an Achilles heel of all electronic blasting systems since they use of low energy to carry signals to

the detonators.

Types of leakage

Ground leakage (Bus-Shell)

Only one wire core is exposed - damage of insulation on that particular conductor core

It is detectable only when using ground rod connected to the E*STAR Tester, E*STAR Logger or

E*STAR Logger 2

Proper value, which must be read on the equipment, is 0.00 mA. Higher value means ground leakage is

present. Since there is damage on only one wire, it’s important to know which polarity the leakage exists.

Detonator leakage (Bus-Bus)

Two wire cores are exposed - damage of insulation

It is detectable by E*STAR Tester, E*STAR Logger or E*STAR Logger 2

LEAKAGE TROUBLESHOOTING

LEAKAGE TROUBLESHOOTING

19

LEAKAGE TROUBLESHOOTING

20

Leakage Tolerance

Logger, Logger 2 = max. 18 mA to read and program detonator or to do branch verification.

If you have 2 dets, each 12 mA, in the same branch, you will be able to program them but not verify the branch

because total branch leakage will be higher than 18 mA.

Blasting Machine = max. 550 mA to charge detonators and fire them.

If you will have 35 branches, each 18 mA, you will be able to verify them but not to fire them because total blast

leakage will be higher than 550 mA. The real mA value on Blasting Machine will not be 35*18 = 630 mA, but

higher, because Blasting Machine’s voltage is much higher than Logger’s voltage.

Table of contents

Other AUSTIN POWDER Test Equipment manuals

Popular Test Equipment manuals by other brands

Proceq

Proceq DYNA ESTRICH operating instructions

Senior Technologies

Senior Technologies WanderGuard 18029 operating instructions

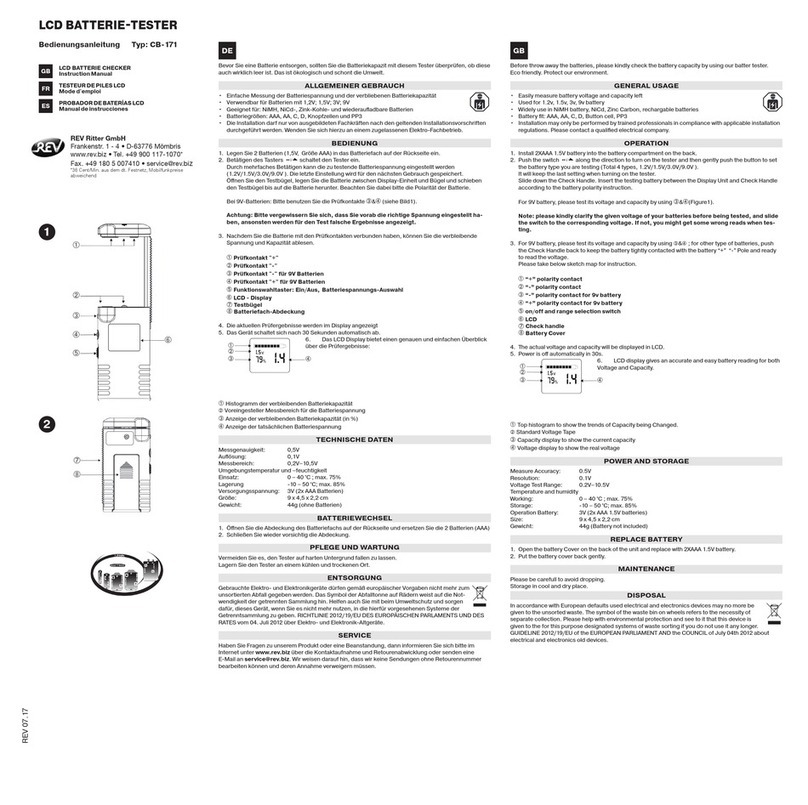

REV Ritter

REV Ritter CB-171 instruction manual

IDEAL

IDEAL 61-954 instruction manual

pico Technology

pico Technology PicoVNA 106 Programmer's guide

Tektronix

Tektronix TBS1000B-EDU Series Programmer's manual