AUSTIN POWDER Shock Star User manual

NON-ELECTRIC INITIATION SYSTEM

USER‘S GUIDE

CZECH REPUBLIC December 2019

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

2

CONTENT

INTRODUCTION ............................................................................................................................... 3

1 COMPONENTS OF NON-ELECTRIC INITIATION SYSTEM AND THEIR FUNCTION ............... 4

Shock*Star Surface ....................................................................................................................... 4

Shock*Star Bunch ........................................................................................................................ 4

Shock*Star Dual Delay .................................................................................................................. 4

2 OPERATION PRINCIPLE OF A NON-ELECTRIC SYSTEM ....................................................... 5

3 CONSTRUCTION AND TECHNICAL DESCRIPTION OF NON-ELECTRIC DETONATORS...... 6

3.1 IN-HOLE DETONATORS ............................................................................................ 6

3.2 Shock*Star Surface ..................................................................................................... 8

3.3 Shock*Star Bunch ....................................................................................................... 9

3.4 Shock*Star Dual Delay ................................................................................................ 9

3.4.1 Bench blast design Using Shock*Star Dual Delay, Shock*Star MS and Shock*Star

Surface ....................................................................................................................... 10

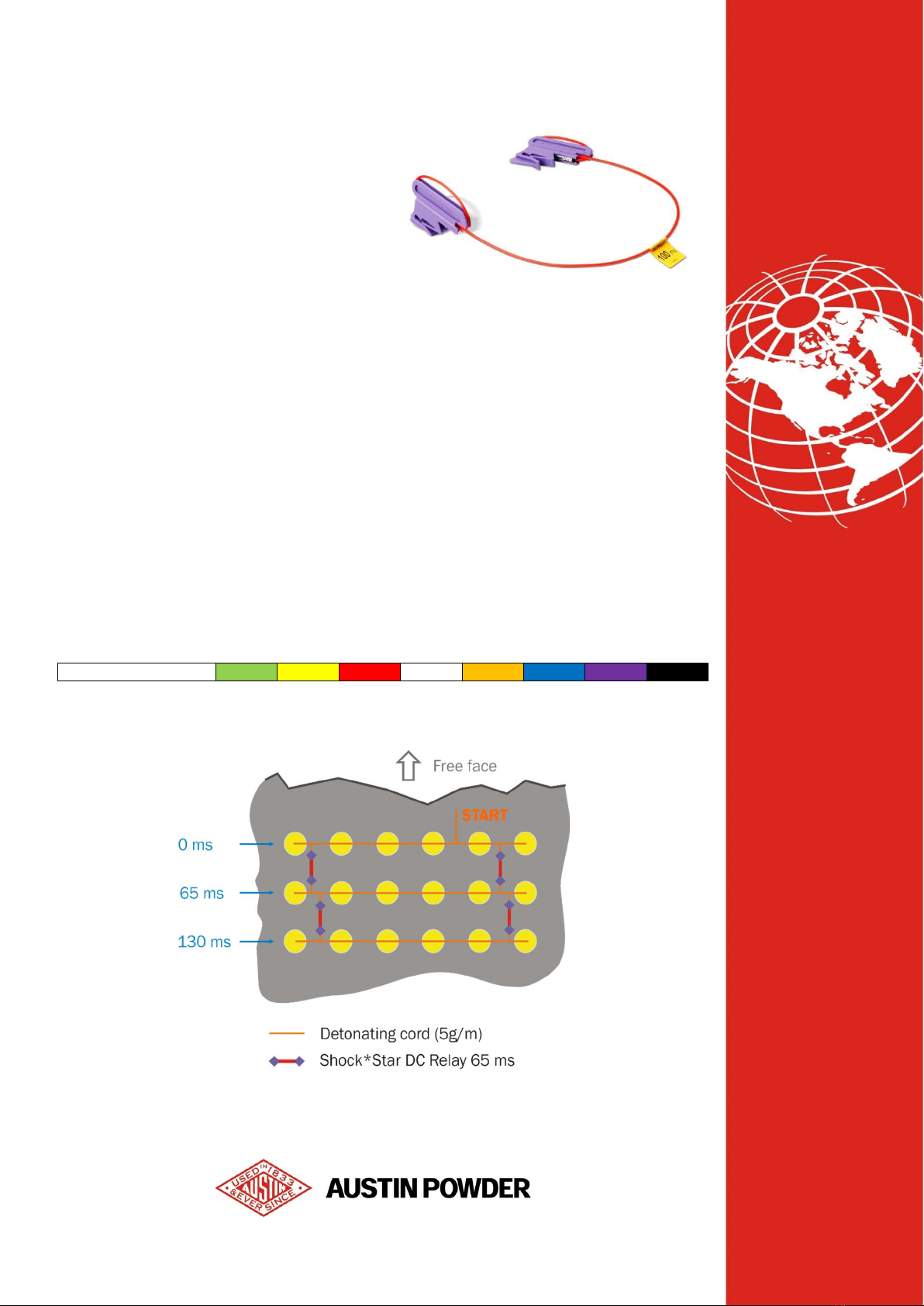

3.5 Shock*Star DC Relay ................................................................................................ 11

3.5.1 Simple blasting pattern using detonating cord and Shock*Star DC Relay ................. 11

4 PRACTICAL USE OF NON-ELECTRIC DETONATORS AND THE BENEFITS OF USE .......... 12

4.1 INSTRUCTION FOR USE OF Shock*Star MS, Shock*Star TS .................................. 12

4.2 USE of Shock*Star MS DETONATORS IN Surface APPLICATION ......................... 13

4.3 INSTRUCTION FOR USE OF Shock*Star Surface .................................................... 14

4.4 ADDED DELAY CREATED BY THE Shock Tube ..................................................... 17

4.5 INSTRUCTION FOR USE OF T-CONNECTOR (“J” HOOK) .................................... 18

4.6 INSTRUCTION FOR USE OF Shock*Star DC Relay ................................................. 19

4.7 NOTES ON DESIGNING BLASTING PATTERNS In surface applications ............... 19

4.7.1 Gradual initiation of blast holes ................................................................................. 19

4.7.2 Coupled initiation blasting pattern ............................................................................. 20

4.7.3 The bench blasting examples .................................................................................... 21

4.8 USING Shock*Star IN UNDERGROUND APPLICATIONS ....................................... 23

4.8.1 Creating the bunch and connection to bunch assembly ............................................ 23

4.8.2 Detonating cord end connection ................................................................................ 24

4.8.3 Always and Nevers when using Shock*Star Bunch................................................... 25

4.9 APPLICATION OF Shock*Star FOR DEMOLITION OPERATIONS.......................... 25

4.10 CONNECTING OF TWO Shock Tubes TOGETHER ................................................ 26

4.11 INITIATION OF NON-ELECTRIC SYSTEM .............................................................. 26

4.11.1 Instruction how to assemble Rock*Star Starter detonator ......................................... 28

4.11.2 Always and Nevers when using Rock*Star Starter .................................................... 30

4.12 REMOVAL OF NON-ELECTRIC INITIATION SYSTEM REMAINS AFTER USE ..... 30

5 PACKAGE, STORAGE AND SHELF LIFE ................................................................................. 31

5.1 PACKAGING ............................................................................................................. 31

5.2 SHELF LIFE AND STORAGE CONDITIONS ............................................................ 32

5.3 STORAGE AND TRANSPORTATION CLASSIFICATION ........................................ 32

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

3

INTRODUCTION

SHOCK*STAR IS A NON-ELECTRIC INITIATION SYSTEM DESIGNED BY AUSTIN

DETONATOR S.R.O., CZECH REPUBLIC. THIS INITIATION SYSTEM INCREASES SAFETY

AND ENSURES BETTER BLASTING RESULTS. THE SYSTEM WAS INTRODUCED TO THE

MARKET IN 1993 AND SINCE THEN HAS SEEN THREE MAJOR MODIFICATIONS TO THE

Surface CONNECTOR WHICH BROUGHT FURTHER RELIABILITY, PRECISION, AND SAFETY

TO BLASTING IN FIELD. THE LAST VERSION OF THE Shock*Star Surface CONNECTOR

BRINGS A NEW OPTIONAL FUNCTION OF SECURING CONNECTIONS BY LOCKING THE

TUBES IN THE BLOCK IN ORDER TO ELIMINATE DISCONNECTIONS IN SOME SPECIAL

APPLICATIONS, E.G. WHEN THE BLASTS NEED TO BE COVERED BY HEAVY MATS. THE

CONNECTOR BLOCK ALSO FURTHER INCREASES USERFRIENDLINESS WHEN MAKING

CONNECTIONS IN TEMPERATURES EXCEEDING - 15°C.

Using of non-electric system for blasting brings a number of benefits including:

Higher safety of blast work, as the system is immune to initiation by foreign sources of electric

energy (radio frequency, stray currents).

Higher variability of timing patterns enabling “tailor-made“ blasts corresponding to the conditions

in a given locality.

More effective work from the point of view of logistics and storage (smaller product range

necessary for achieving a given result).

All the mentioned benefits improve economy of blasting operations. Although the initial cost of

using non-electric system may be higher, the overall economics of blasting and quarrying

operations is more beneficial as opposed to traditional electric system.

The blasting results using non-electric system (fragmentation, vibration control) are much more

positive. Before the non-electric system was introduced, the only way to perform a non-electric blast

was using a detonating cord. The method is now almost abandoned as it has numerous undesired

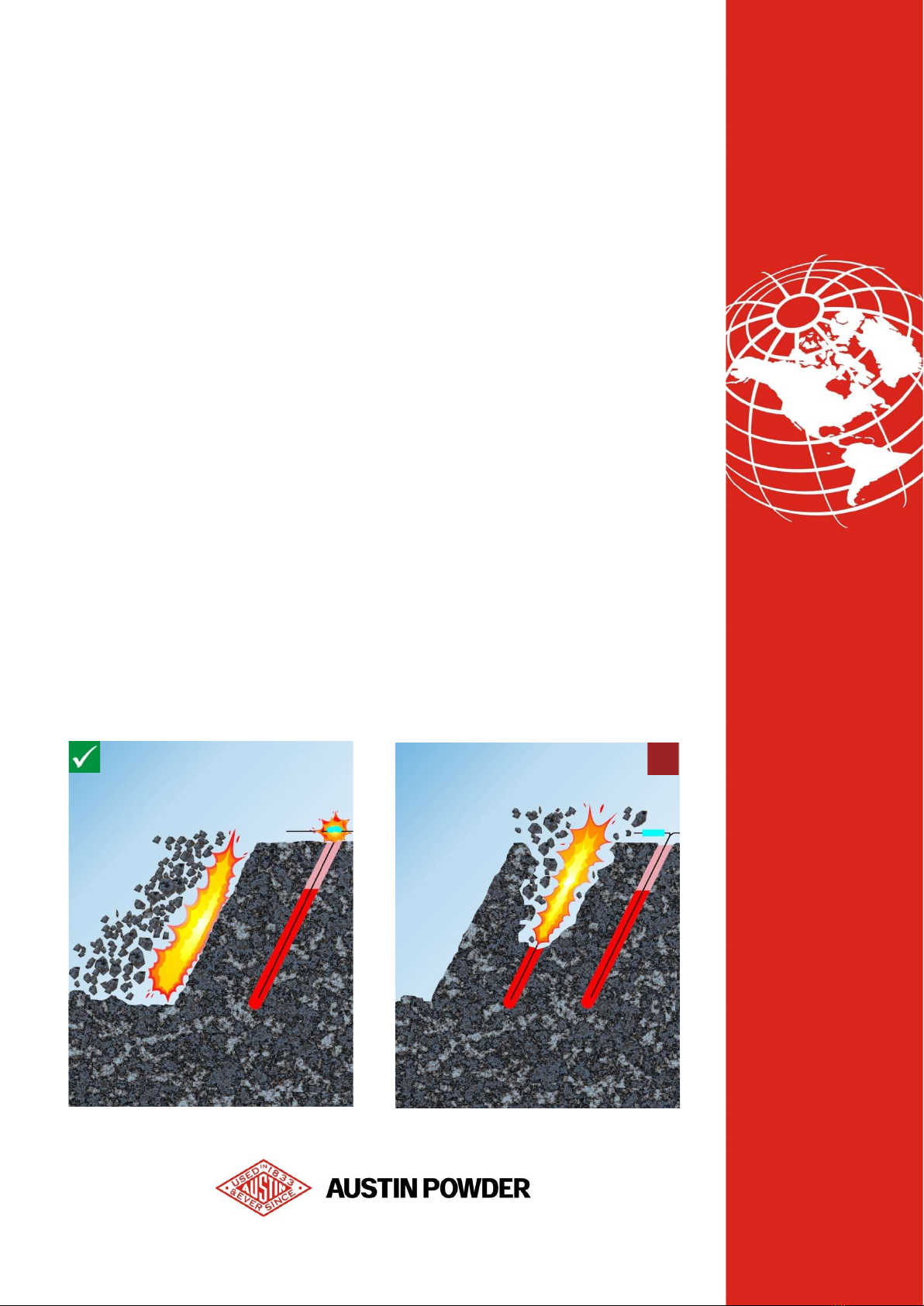

side effects. When initiating a blast using a detonating cord, the blast hole is opened from the top

which creates excessive fly rock because the stemming is destroyed as the detonation passes

through it. As a result, the energy created by detonation is used less effectively. In addition, when

used to initiate relatively insensitive explosives such as ANFO and certain emulsion explosives, the

detonating cord can cause dead-pressing of the explosive. Further disadvantages of using

detonating cord for initiation include excessive noise. Using of non-electric system enables to

initiate the blast hole from the bottom (see figure 0-1) which ensures better use of the blast energy.

Fig. 0-1 Fig. 0-2

X

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

4

1 COMPONENTS OF NON-ELECTRIC INITIATION SYSTEM AND THEIR

FUNCTION

Austin Shock Tube and all Austin Detonator products using Austin Shock Tube can be initiated by

regular electric, electronic or non-electric detonator, detonating cord, plain detonator, Shock*Star

Bunch, Shock*Star Surface, proper blasting machine (from an open end of the Shock Tube only)

and Rock*Star Starter.

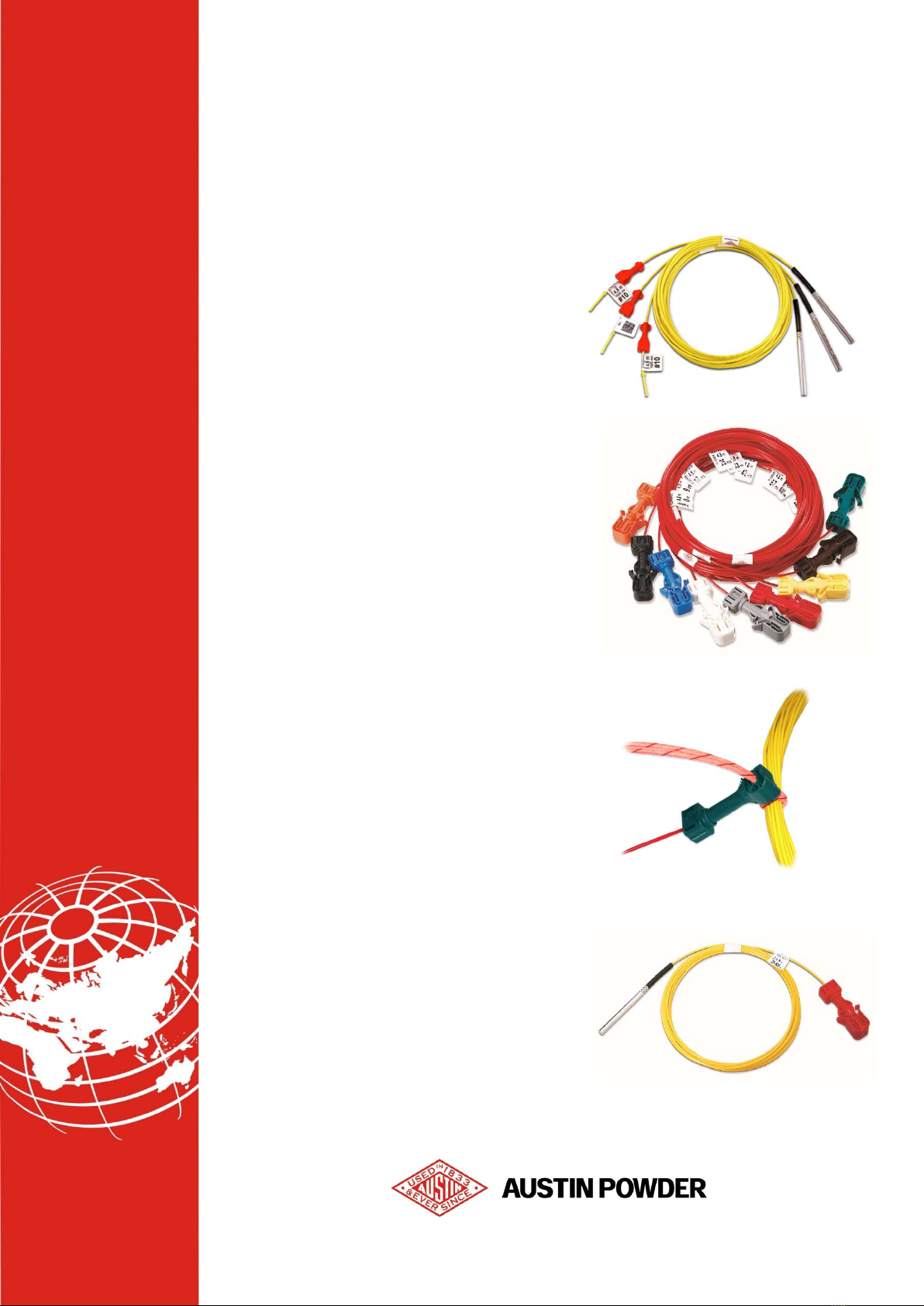

Shock*Star MS-Shock*Star TS-Shock*Star LP

These are in-hole detonators with millisecond

delay (steps 25 ms and 50 ms) and long period

delay (steps 100 ms, 200 ms and 500 ms)

detonators used for initiation of explosive in a

hole. Shock*Star MS is used for surface

applications, Shock*Star TS in underground

tunnel applications where are high accuracy of

delay required. Shock*Star LP is used for

underground mining applications, where is no

emphasis for restriction of seismic impact of

blasting. These detonators can be initiated either

by Shock*Star Surface, Shock*Star Bunch

detonators or by detonating cord. For initiation by

detonating cord they can be fitted with a T-

connector (available on request).

Shock*Star Surface

Shock*Star Surface is a millisecond delay

detonator enclosed in a color coded plastic block.

This detonator has a smaller base charge

designed for initiation of Shock Tube only.

Shock*Star Bunch

The base charge of these detonators is designed

for initiation of a 5 g/m PETN detonating cord,

which is attached to it. The detonator is enclosed

in a plastic block and the detonating cord is

inserted in the plastic block. The detonator is

used for initiation of up to 20 Shock Tubes tied in

a bunch, which is closely described later in this

manual. The detonator is mostly used in

underground applications.

Shock*Star Dual Delay

Shock*Star Dual Delay is composed of

Shock*Star Surface and an in-hole detonator

Shock*Star MS or Shock*Star TS. Dual Delay

detonator is used in the same way as the two

detonators of which it is composed. The benefits

of Dual Delay detonators include faster handling,

easier connections and decrease of excessive

Shock Tube during connecting, thus making it

easier to overview the connections on the blast

site.

Fig. 1-2

Fig. 1-3

Fig. 1-4

Fig. 1-1

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

5

NOTICE

For a successful blast it is necessary that a hole is initiated well before the initiation

network is destroyed by the blast itself. This is ensured by suitably designed blast pattern.

2 OPERATION PRINCIPLE OF A NON-ELECTRIC SYSTEM

The basic principle of initiation in blasting pattern is transferring initiation from Surface Connector to

a detonator in a hole and to another surface connector.

The figure 2-1 shows properly timed blasting pattern - the holes are initiated well before the rock

starts moving.

Fig. 2-1

Fig. 2-2

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

6

3 CONSTRUCTION AND TECHNICAL DESCRIPTION OF NON-ELECTRIC

DETONATORS

3.1 IN-HOLE DETONATORS

Shock*Star MS (with 25 or 50 ms delay interval)

Shock*Star TS (with 50, 100, 200 and 500 ms delay interval)

These detonators have base charge of

720 mg. The detonators are made of

aluminum shell containing the primary

charge, delay composition system, Shock

Tube, antistatic sealing plug, stopper and

delay tag.

The detonators can be fitted with a T-

connector / “J” hook (see figure 3-2 and 3-3)

for detonating cord compatibility and they

are used to initiate primers (boosters) or

directly commercial cap sensitive

explosives.

The T-connectors are applied only during

production in the factory.

TECHNICAL DATA

Detonator Shell

Material: Aluminum

Marking: nominal delay time

letter „V“ at the shell bottom

Shock Tube

Color: yellow

VOD: 2,000 m/s

Marking: delay tag:

production series number

detonator type

nominal delay time/delay number

Shock Tube length

traceability code

Fig. 3-1

Fig. 3-2 Fig. 3-3

T

-

connector

T-connector

Traceability

tag

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

7

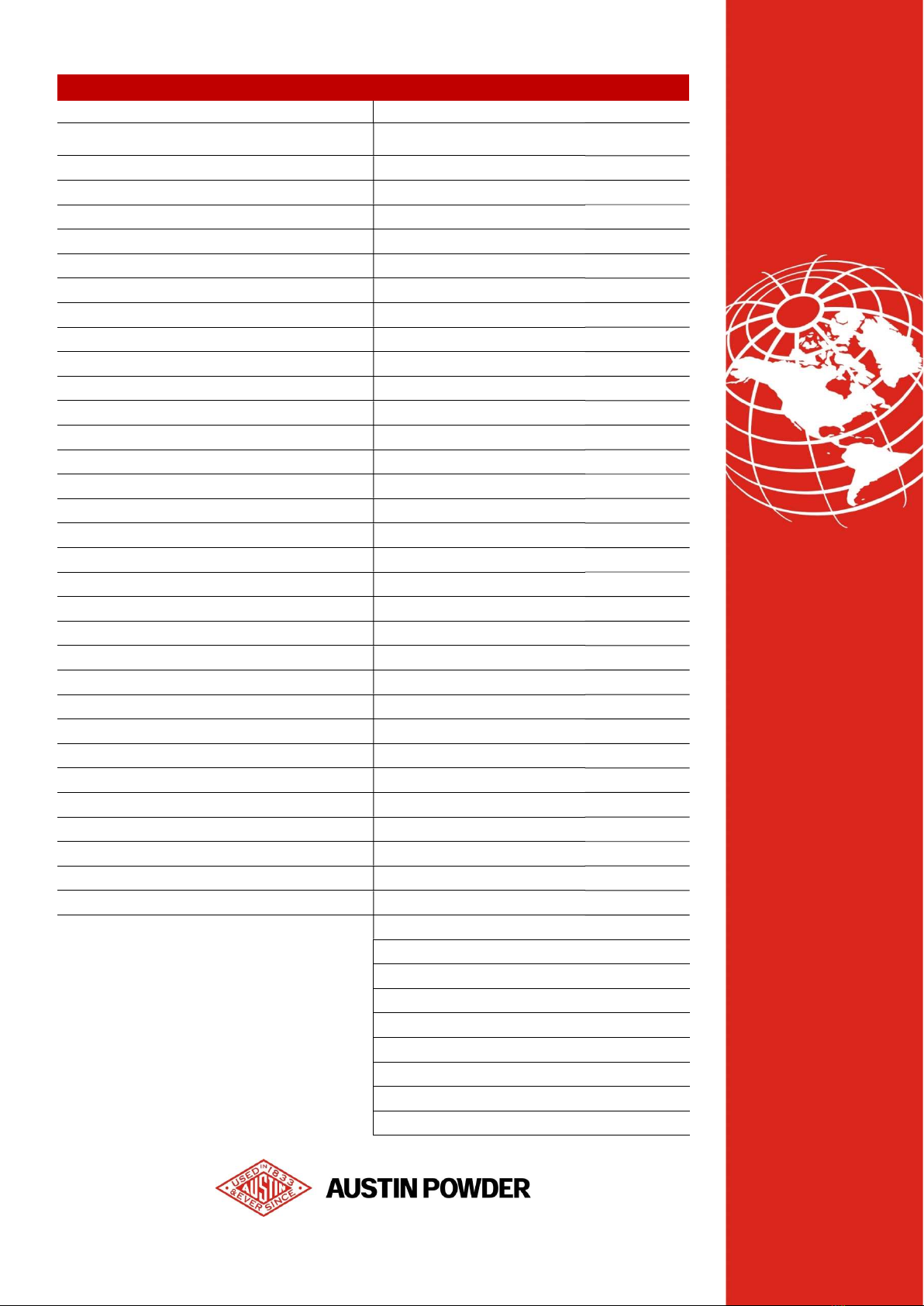

IN-HOLE DETONATORS DELAY TIMES

Shock*Star MS Shock*Star TS

Delay

number

Nominal delay

time (ms)

Delay interval

(ms)

Delay

number

Nominal delay

time (ms)

Delay interval

(ms)

00 0000 - 00 0025 02-

01 0025 25 01 0100 75

02 0050 25 011/2 0150 050

03 0075 25 02 0200 050

04 0100 25 021/2 0250 050

05 0125 25 03 0300 050

06 0150 25 031/2 0350 050

07 0175 25 04 0400 050

08 0200 25 041/2 0450 050

09 0225 25 05 0500 050

10 0250 25 051/2 0550 050

11 0275 25 6 0600 050

12 0300 25 061/2 0650 050

13 0325 25 7 0700 050

14 0350 25 071/2 0750 050

15 0375 25 8 0800 050

16 0400 25 081/2 0850 050

17 0425 25 9 0900 050

18 0450 25 091/2 0950 050

19 0475 25 10 1,000 050

20 0500 25 11 1,100 100

21 0550 50 12 1,200 100

22 0600 50 14 1,400 200

23 0650 50 16 1,600 200

24 0700 50 18 1,800 200

25 0750 50 20 2,000 200

26 0800 50 25 2,500 500

27 0850 50 30 3,000 500

28 0900 50 35 3,500 500

29 0950 50 40 4,000 500

30 1,000 50 45 4,500 500

50 5,000 500

55 5,500 500

60 6,000 500

65 6,500 500

70 7,000 500

75 7,500 500

80 8,000 500

85 8,500 500

90 9,000 500

Tab. 1

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

8

NOTICE

The Shock*Star Surface is an

assembly composed of two main parts:

a plastic connector and a small

detonator with a Shock Tube attached.

The plastic connector houses the

detonator. The entire unit is assembled

by the manufacturer and makes a

permanent assembly. The disassembly

may result in damage to the unit.

Surface detonators must not be used to

initiate explosives and detonating cord!

3.2 Shock*Star Surface

The Shock*Star Surface is a highly user-

friendly product bringing substantial time-

savings when connecting initiation network.

The design of the connector virtually

eliminates the shrapnel cut-off concerns, and

makes easier the composition of initiation

network. The connector has 9 delays. Base

charge of Shock*Star Surface detonators is

120 mg. The detonators are composed of an

aluminum shell containing a base charge and

a highly accurate delay composition system,

antistatic rubber plug, Shock Tube fitted with a stopper and a delay tag (see fig. 3-4). The stopper

prevents the tube end from coming out of the connector block. The detonator is enclosed in a color

coded plastic block. These units are specially designed for creating delay patterns and are used to

initiate Shock*Star MS and TS, and to relay the initiation impulse to the next Shock*Star Surface

connector(s) in sequence.

TECHNICAL DATA

Detonator Shell

Material: Aluminum

Connector

Body color: as per nominal delay

Shock Tube

Color: red

VOD: 2,000 m/s

Marking: delay tag:

production series number

detonator type

nominal delay time

Shock Tube length

traceability code

NOMINAL DELAYS

Shock*Star Surface

Nominal delay time (ms) Color

0 green

9 brown

17 yellow

25 red

33 grey

42 white

67 blue

100 black

200 orange

Fig. 3-4

Tab. 2

Traceability

tag

Stopper

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

9

Tab. 3

3.3 Shock*Star Bunch

This detonator is fitted with a Bunch Connector with a

5 g/m PETN detonating cord. The detonator base

charge of 160 mg is designed to initiate the attached

detonating cord. Shock*Star Bunch is available in

the following delays: 0, 9, 17, 25, 33, 42, 67, 100,

200 ms.

TECHNICAL DATA

Detonator Shell

Material: Aluminum

Connector

Body color: as per nominal delay

Shock Tube

Color: red

VOD: 2,000 m/s

Marking: delay tag:

production series number

detonator type

nominal delay time

Shock Tube length

traceability code

NOMINAL DELAYS

Shock*Star Bunch

Nominal delay time (ms) Color

0 green

9 brown

17 yellow

25 red

33 grey

42 white

67 blue

100 black

200 orange

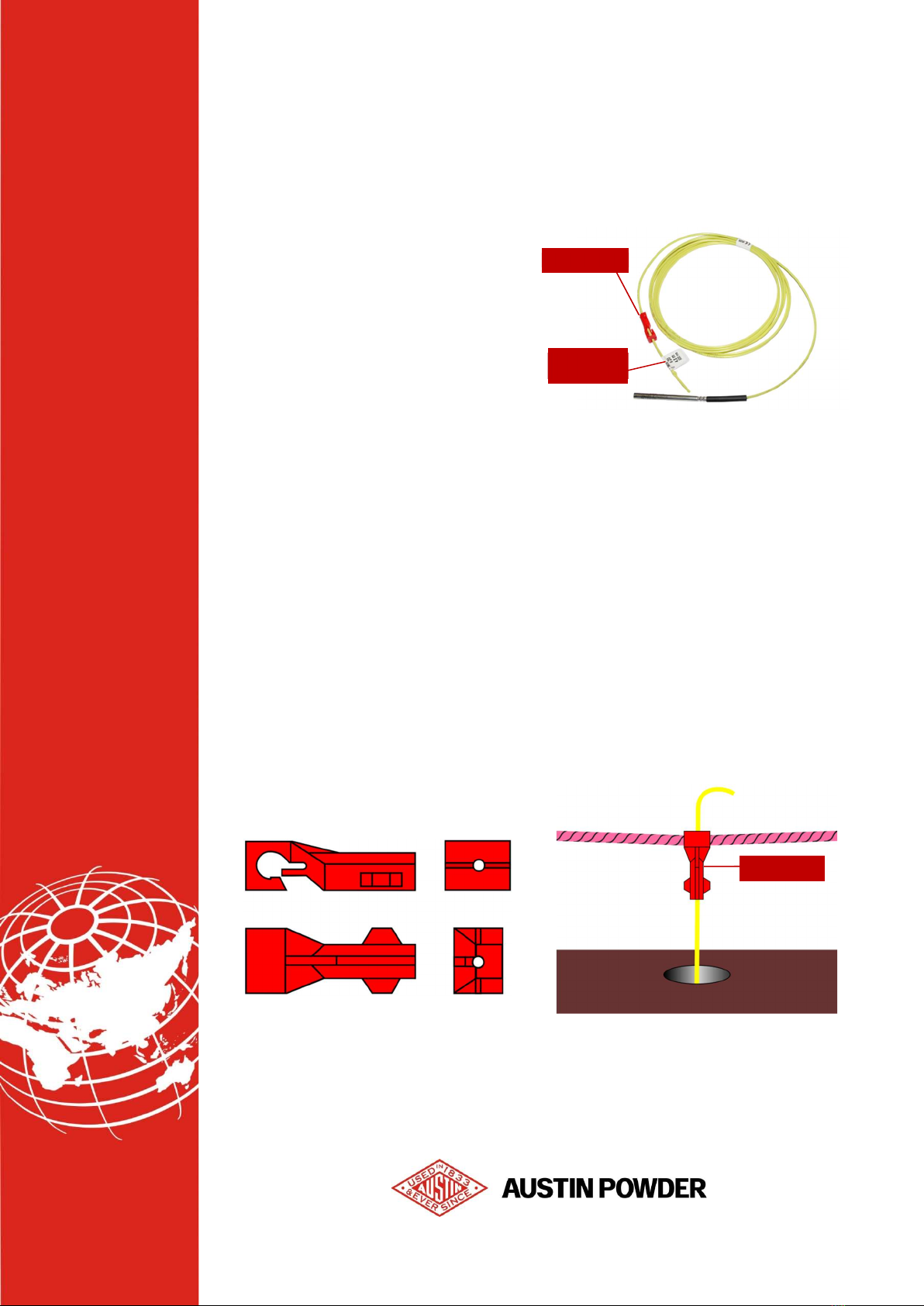

3.4 Shock*Star Dual Delay

Shock*Star Dual Delay detonator is a

combination of Shock*Star Surface

(nominal delays 25, 100 ms) and

Shock*Star MS or Shock*Star TS (nominal

delays 475, 500, 9,000 ms). Shock*Star

Dual Delay detonators are used in surface

bench blasts and underground blasts.

Their use results in smaller number of

detonators needed for one blast.

Fig. 3-5

Fig. 3-6

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

10

Tab. 4

Fig. 3-7

Use of Shock*Star Dual Delay detonators brings the following advantage:

reduced handling and storage requirements

faster composition of initiation network

reduced number of connections between units

easier and more reliable visual inspection of connection

TECHNICAL DATA

Shock Tube

Color: yellow

VOD: 2,000 m/s

Marking: delay tag

production series number

detonator type

nominal delay time

Shock Tube length

traceability code

Shock*Star Dual Delay

NOMINAL DELAYS

Shock*Star Surface Shock*Star MS

Shock*Star TS

025 ms 475, 500 ms

100 ms 475, 500, 9,000 ms

3.4.1 Bench blast design Using Shock*Star Dual Delay, Shock*Star MS and Shock*Star Surface

Shock Tube color:

• Shock*Star Surface

• Shock*Star MS

• Shock*Star Dual Delay

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

11

Fig. 3-8

3.5 Shock*Star DC Relay

Shock*Star DC Relay detonators are designed

to provide accurate delay timing between the

individual rows of blast holes using detonating

cord as a primary initiation system. They can be

used for developing various delay patterns.

DC Relay consists of a 45 cm Shock Tube, two

detonators and two plastic blocks. The

detonators are attached to each end of the

Shock Tube and are inserted into plastic

connector blocks. The connector blocks are

specially designed for fast and easy detonating

cord connections. This detonator is suitable for

bidirectional use.

TECHNICAL DATA

Detonator Shell

Material: Aluminum

Connector

Body color: as per nominal delay

Suitable for 5 g detonating cord

Shock Tube

Color: red

Detonation velocity: 2,000 m/s

Marking: delay tag:

production series number

detonator type

nominal delay time

Shock Tube length

traceability code

Nominal delay (ms) 9 17 25 35 50 65 100 200

Tab. 5

3.5.1 Simple blasting pattern using detonating cord and Shock*Star DC Relay

Fig. 3-9

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

12

Fig. 4-5 Fig. 4-6

WARNING

Non-electric detonators Shock*Star

must not be used in underground

worksites with a risk of ignition of coal

dust and methane atmosphere under

any condition.

Fig. 4-1 Fig. 4-2

Fig. 4-3 Fig. 4-4

4 PRACTICAL USE OF NON-ELECTRIC DETONATORS AND THE

BENEFITS OF USE

Shock*Star detonators are used for initiation of

commercial explosives used for blasting both

surface and underground.

Condition of use:

temperatures ranging from -30 °C to +60 °C

in water pressure of max 0.3 MPa / 7 days

Advantages:

fit for use in wet conditions and under water

high variability of timing

highly safe product

reduction of vibration during blast

4.1 INSTRUCTION FOR USE OF Shock*Star MS, Shock*Star TS

1. Prepare a hole in the middle of primer

towards to center of primer using priming

tool. (Fig. 4-1)

2. Put the detonator into the hole. (Fig. 4-2)

3. Be sure that the detonator is in the correct

position - whole length of shell must be

inside the primer. (Fig. 4-3, Fig. 4-4)

4. Prepare a Shock Tube loop. (Fig. 4-5)

5. Put a loop on the primer and tighten it.

(Fig. 4-6)

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

13

Fig. 4-7

Fig. 4-8

6. Use double loops for longer primers

(≥700 mm). (Fig. 4-7)

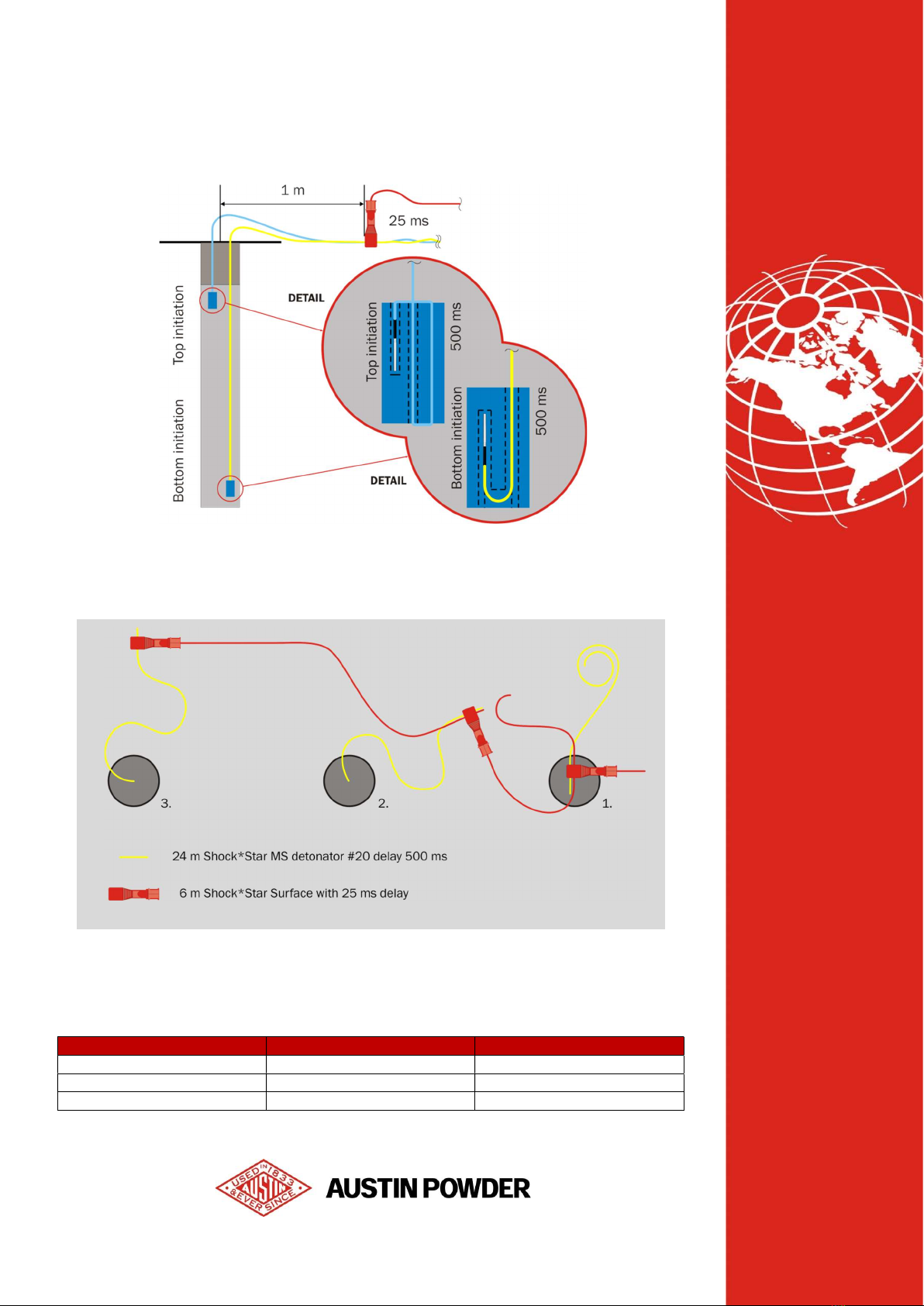

4.2 USE of Shock*Star MS DETONATORS IN SURFACE APPLICATION

The explosive in the blast hole is usually

initiated by two in-hole detonators

Shock*Star MS. One detonator is located at

the bottom (lower) part of the drill hole. The

other detonator is positioned at the top

(upper) part of the drill hole, under the

stemming. Normally, a 475 ms detonator is

used at the bottom and a 500 ms detonator at

the top of the drill hole.

Detonators should be positioned such, that

the detonator bottom is directed towards the

longer part of the explosive column.

The lower detonator should point upwards and

the upper detonator should point downwards. The

in-hole detonators are initiated by Shock*Star Surface.

The initiation of explosive in this fashion brings the most effective consumption of energy

released during explosion.

The detonation velocity of the Shock Tube impulse is 2,000 m/s. The Shock Tube then presents a

delay of 1 ms / 2 m of tube. The delay caused by Shock Tube therefore needs to be taken into

consideration when designing the blasting patterns. See chapter 4.4 for more information. Where

detonators of identical nominal delay time in drill hole are used, the explosive in the drill hole is

initiated from the top causing less effective consumption of energy released during explosion.

PRECAUTIONS

The detonator bottom must be directed towards the longer part of explosive

charge column.

When designing a blast pattern, a Shock Tube added delay time of 1 ms / 2

meters must be taken into consideration.

With drill holes longer than 10 m, two priming assemblies should always be

used. If the drill hole is shorter than 10 m, only one priming assembly may be

used provided the drill hole walls are smooth and the risk of interruption of

explosive column during charging is eliminated.

The minimal length of the Shock Tube coming out of priming assembly and out

of the drill hole is 0.6 m.

Make sure that connector-to-connector distances are identical in aII

connections.

Do not cut short the Shock Tube. Water or humidity may make the Shock Tube

non-functional. Cut only the Shock Tube immediately prior the blast for testing

the blasting machine and for the blast itself.

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

14

Fig. 4-9 Correct way to pull the tube

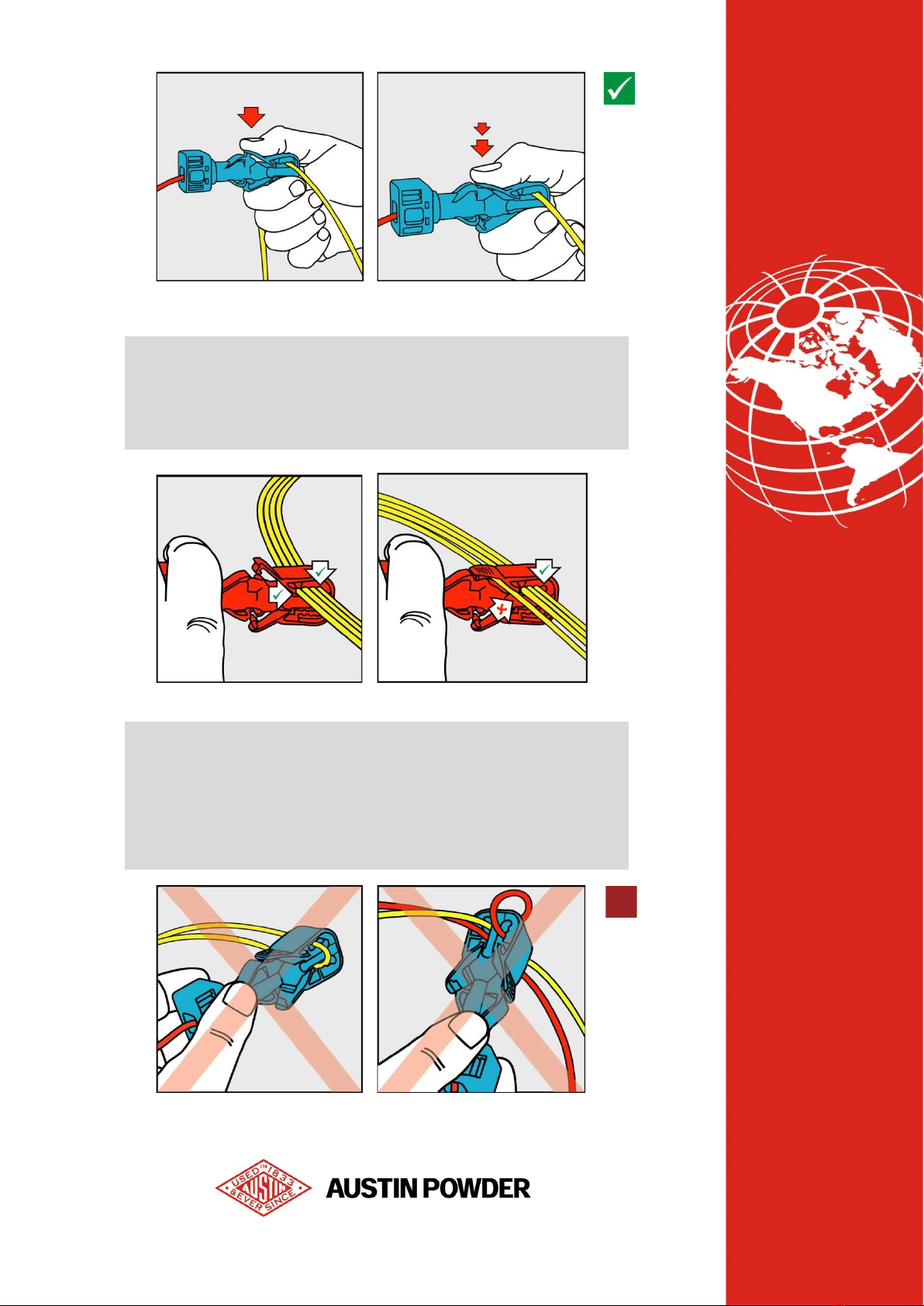

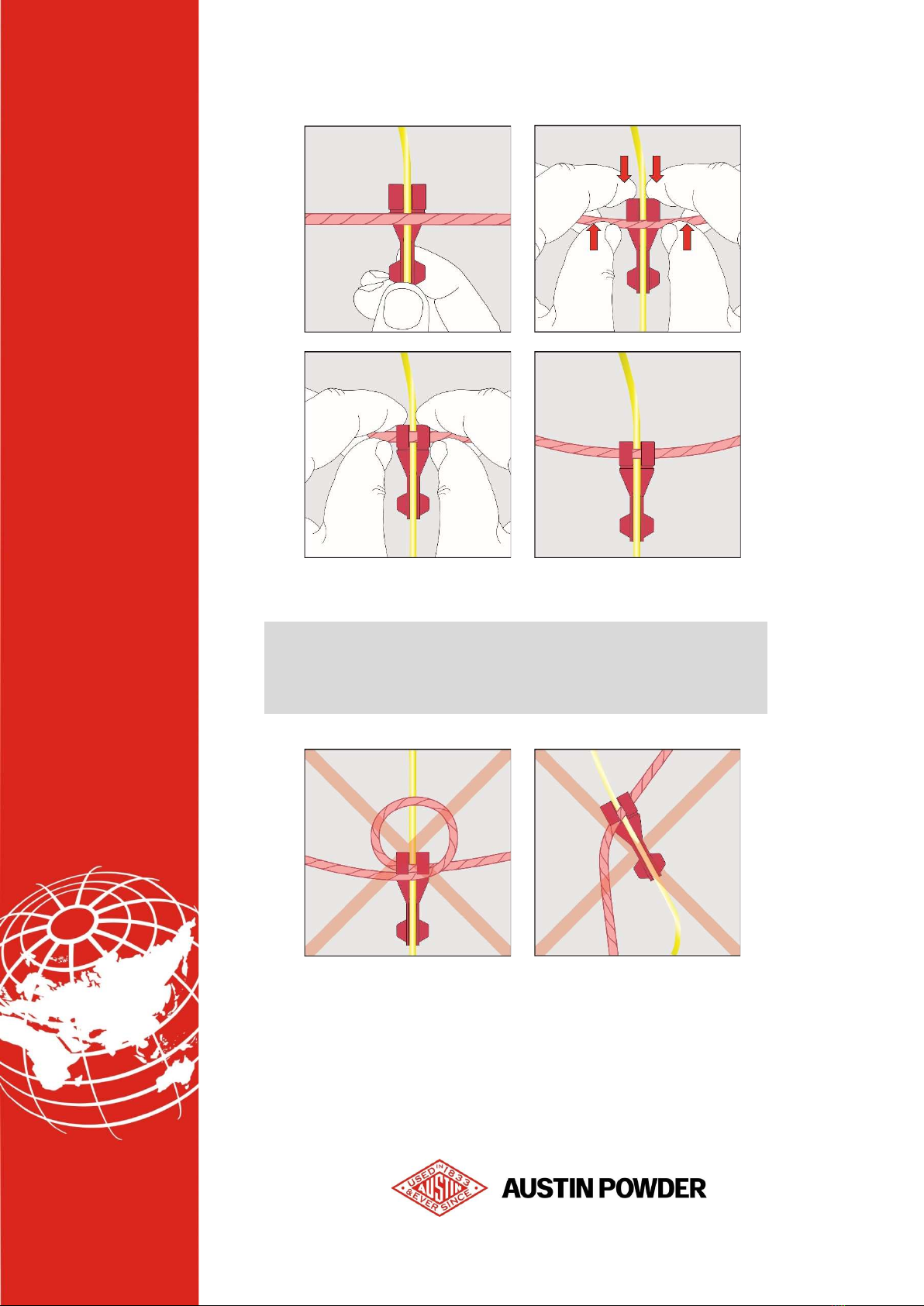

4.3 INSTRUCTION FOR USE OF Shock*Star Surface

CONNECTING

Prepare a loop a shown in the picture.

When connecting the tube in the connector, always pull the tube in the direction towards the middle

of the connector block cavity for tubes. This method puts the least demand on strength needed for

making a connection.

If needed, it is possible to lock the tubes in to secure the connection. The connector is however fully

functional in both locked and unlocked position provided the tubes are inserted properly.

NOTICE ON THE SAFETY OF SHOCK TUBE

Snap & Shoot Effect

In the history of use of the non-electric (Shock Tube) initiation system, there

occurred several instances of accidental tube initiation when the tube was

pulled till its breakage. The instances were recorded during tubing production,

detonator manufacture and also charging operations in the field.

Based on the recorded events, a study was performed and published in the

SAFEX newsletter No. 38, 3rd Qtr. 2011, where the phenomenon is reported in

detail and is confirmed as existing.

We advise the customers to study the phenomenon in that document, be

aware of it and take all safety precautions to prevent the tube from SNAP

(being pulled till breakage) and potential SHOOT (initiation by this breakage) or

any other impact that might resemble this kind of condition during their

operations.

For advice or if in doubt, please contact us using the below mentioned contacts

for technical support.

It will be noted that this phenomenon is inherent in any Shock tubing from any

manufacture and is not related to any particular Shock Tube brand of

manufacture method.

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

15

Fig. 4-10 Locking the tubes into connector

CAUTION

During connection make sure that the tubes are properly inserted into the

connector block and that they are not crossed inside the connector block.

Each side of the connector block can hold up to 4 tubes; the total

capacity of the block is 8 tubes.

Fig. 4-11 Correct way to insert the tubes into the connector

CAUTION

Do not use any version of „double hooking“ as a safety precaution

against preventing the Shock Tube from slipping out of the Shock*Star

connector. For this purpose, every Shock Tube is fitted with a plastic

sleeve (the stopper) at its end. Double hooking is a nonstandard

connection not compliant with the design of the Shock*Star product, and

it may result in improper function.

Fig. 4-12 Nonstandard connection of „double hooking“

X

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

16

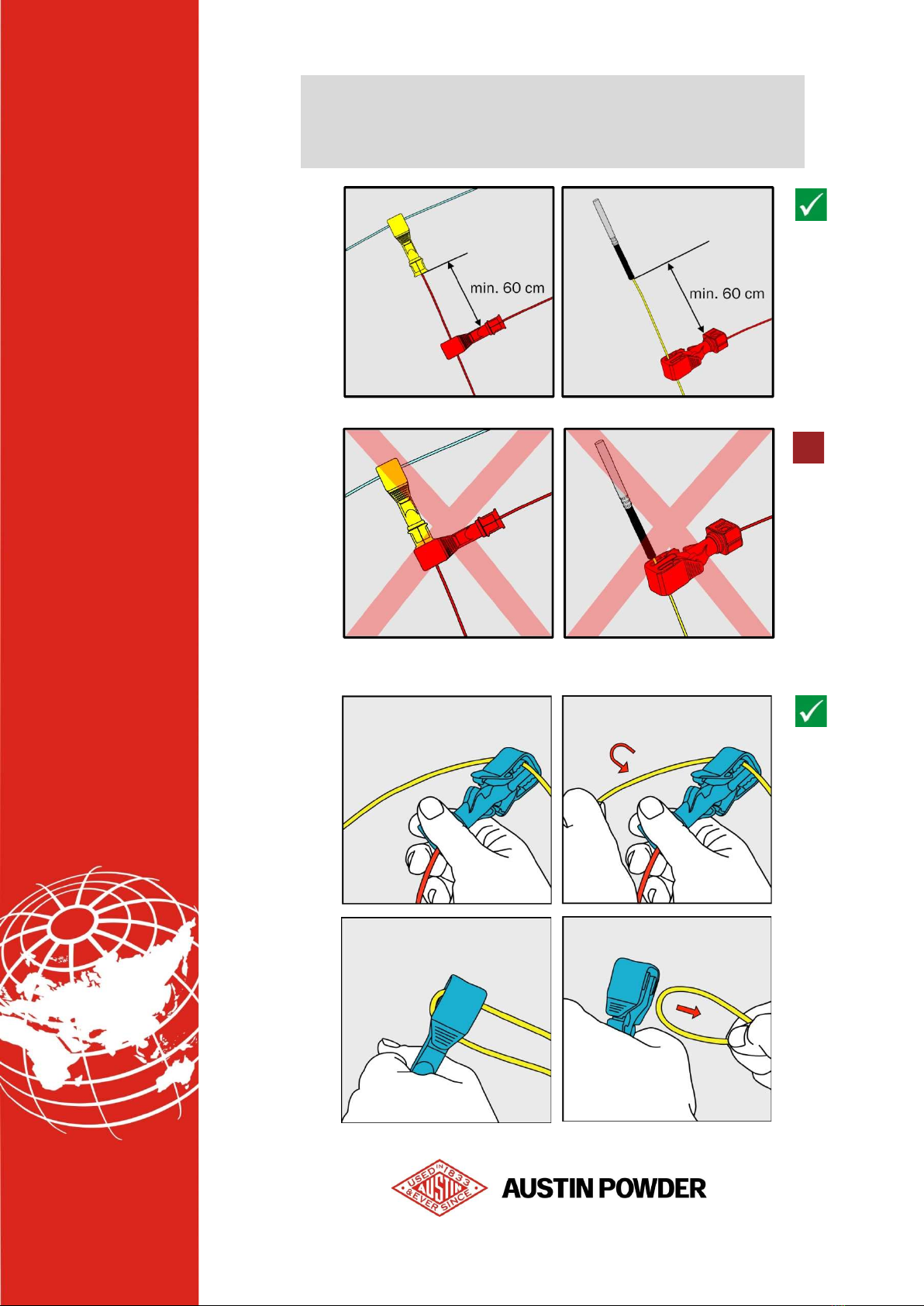

CAUTION

Connect, place the connector at the distance at least 60 cm from the next

connector or in-hole detonator. (Fig. 4-13, 4-14)

Fig. 4-13

Fig. 4-14

Fig. 4-15 Correct way to disconnect the tubes

DISCONNECTING

Hold the loop as when connecting and pull the tube out from the connector block.

X

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

17

4.4 ADDED DELAY CREATED BY THE Shock Tube

As described Austin Shock Tube has velocity of detonation 2,000 m/s. This speed creates delay of

1 ms per every 2 m of Shock Tube. From this reason it is necessary to count with added delay by

the Shock Tube and its variation based on place where connection to the Shock*Star Surface

connector is been made. Practical examples are presented in figures below.

In the case of figure 4-16 the delay for top initiation is 527.5 ms and for bottom initiation 536.5 ms

instead of theoretical 525 ms (connector plus in-hole detonator delay). This will cause the hole to be

started from the top.

Figure 4-17 display fragment of one row of 19 m long holes and variation in connection points of

Shock*Star MS and Shock*Star Surface detonators. Such a connection has influence on final

detonator timing as indicated in the table 6.

Hole num

b

er

Theoretical delay

Real

delay

1 525 ms 534.5 ms

2 550 ms 563.5 ms

3 575 ms 591.5 ms

Fig. 4-16

Fig. 4-17

Tab. 6

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

18

Fig. 4-18 Correct way to connect Shock*Star detonators equipped by T-connector

(“J” hook) to detonating cord

NOTICE

Make sure that the detonating cord is straight in the T-connector

(“J” hook) and well fixed. Do not connect the detonating cord twice or

bent it in any way in the connector.

Fig. 4-19 Examples of incorrect connection of T-connector (“J” hook) to the detonating

cord

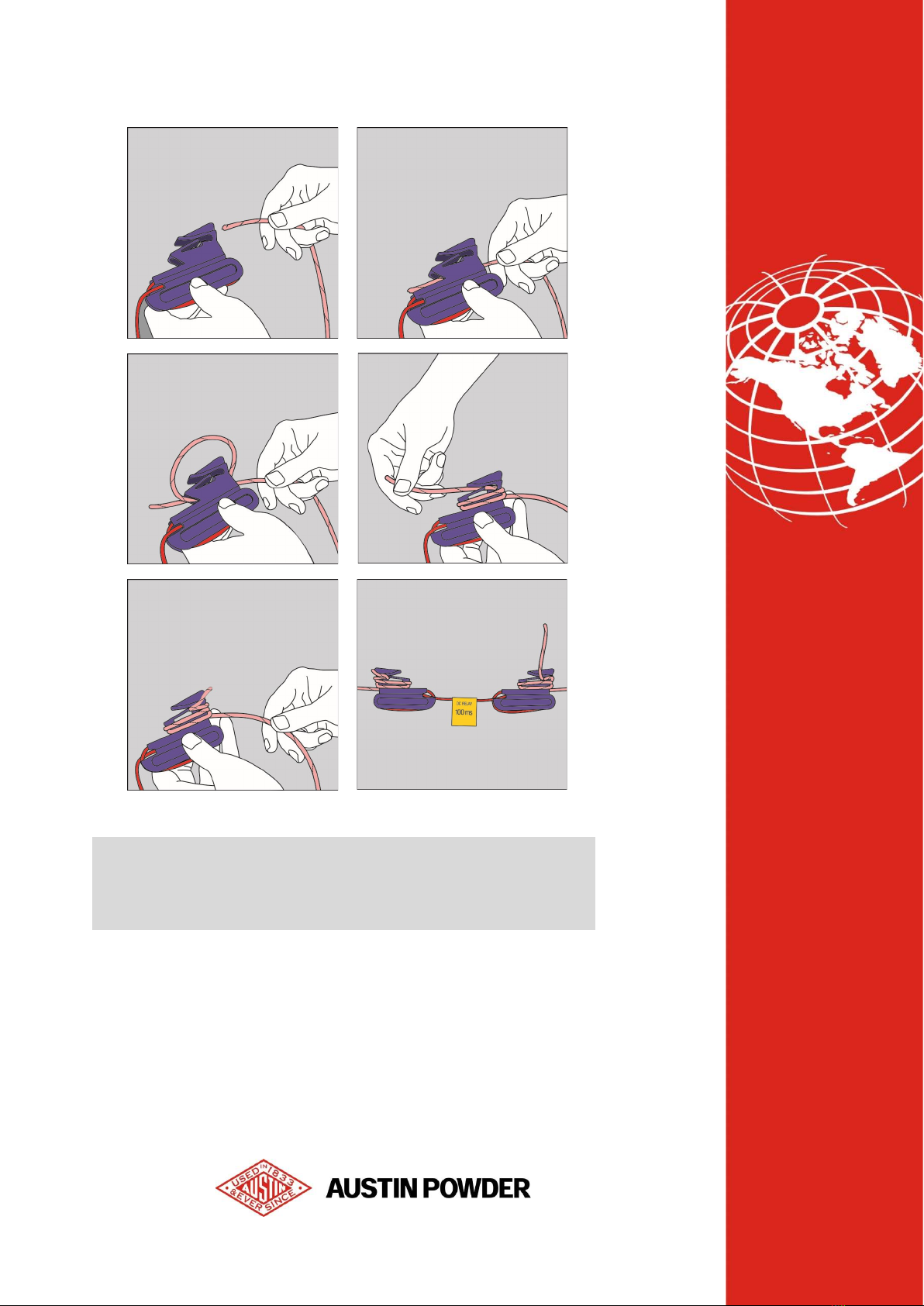

4.5 INSTRUCTION FOR USE OF T-CONNECTOR (“J” HOOK)

Steps to follow to make proper CONNECTION

1. 2.

3. 4.

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

19

NOTICE

For easy connection it is important to have a clean cut of the detonating

cord. Place the cord on a wooden plate and cut the cord at right angles

using a sharp knife.

Fig. 4-20 Correct way to connect Shock*Star DC Relay

4.6 INSTRUCTION FOR USE OF Shock*Star DC Relay

Steps to follow to make proper CONNECTION

4.7 NOTES ON DESIGNING BLASTING PATTERNS IN SURFACE APPLICATIONS

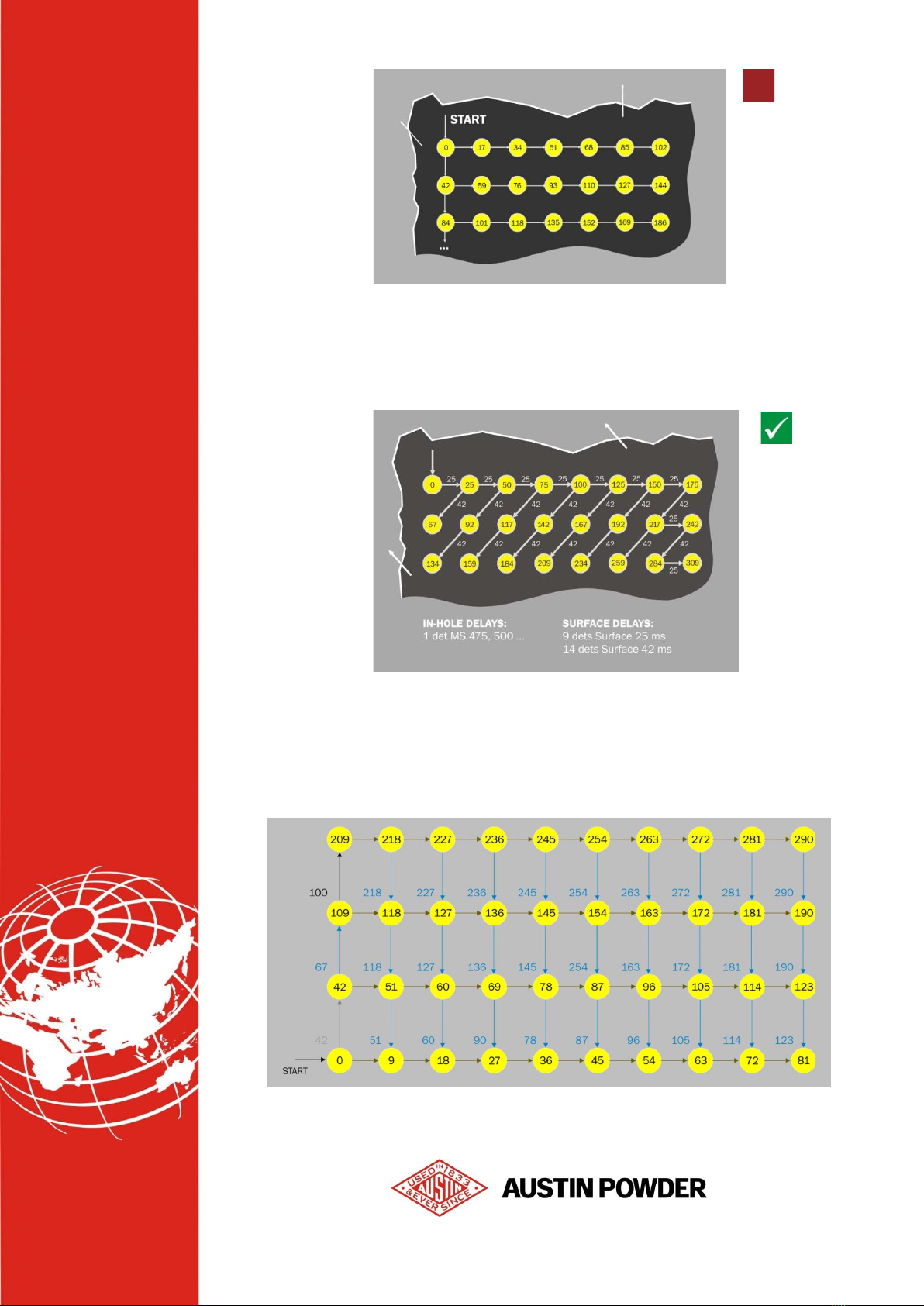

4.7.1 Gradual initiation of blast holes

Very frequently, the blast pattern is designed such that rows are initiated from one side as shown in

figure 4-19. This method brings time savings during connecting the blast pattern. The method has

disadvantage however. If initiation is stopped in a row, the entire initiation process is not stopped

but continues. Problem which results from an undetonated row in an otherwise finished blast could

be costly.

1. 2.

3. 4.

5. 6.

Austin Detonator s.r.o., Jasenice 712, 755 01 Vsetín, Czech Republic

Phone: +420 571 404 001 | Fax: +420 571 404 002 | Email: marketing.info@austin.cz | www.austin.cz

PAGE

20

Fig. 4-21

Fig. 4-22 Three-row one-side-initiated bench blast delay pattern

Fig. 4-23 Blasting pattern with coupled initiation

Austin Detonator, on the other hand, recommends designing the blasting pattern in such a way, that

if in one element, the initiation is stopped, entire initiation process is stopped and only properly

initiated holes blast. This method is shown in figure 4-22 and is considered by blasters as an

important preventive measure which could be taken to avoid problems with removing misfires.

4.7.2 Coupled initiation blasting pattern

Another means of ensuring a successful blast is a blasting pattern is using initiation of a blast hole

from two sources of initiation (two connectors). This blasting pattern can be used when two detonators

are used in a hole. The initiation impulse is brought to the hole from two sources, bringing extra

ensuring feature to blasting operations.

X

Table of contents

Other AUSTIN POWDER Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started