Tektronix 515 User manual

Other Tektronix Test Equipment manuals

Tektronix

Tektronix 531 User manual

Tektronix

Tektronix SD-24 User manual

Tektronix

Tektronix TDS 430A Use and care manual

Tektronix

Tektronix 502 series User manual

Tektronix

Tektronix 2221 User manual

Tektronix

Tektronix 2245A User manual

Tektronix

Tektronix MDO32 Installation and maintenance instructions

Tektronix

Tektronix 485 User manual

Tektronix

Tektronix 314 User manual

Tektronix

Tektronix 1A1 User manual

Tektronix

Tektronix 7B70 User manual

Tektronix

Tektronix 222 User manual

Tektronix

Tektronix TDS3000C Series Installation and maintenance instructions

Tektronix

Tektronix TBS1000 Series User guide

Tektronix

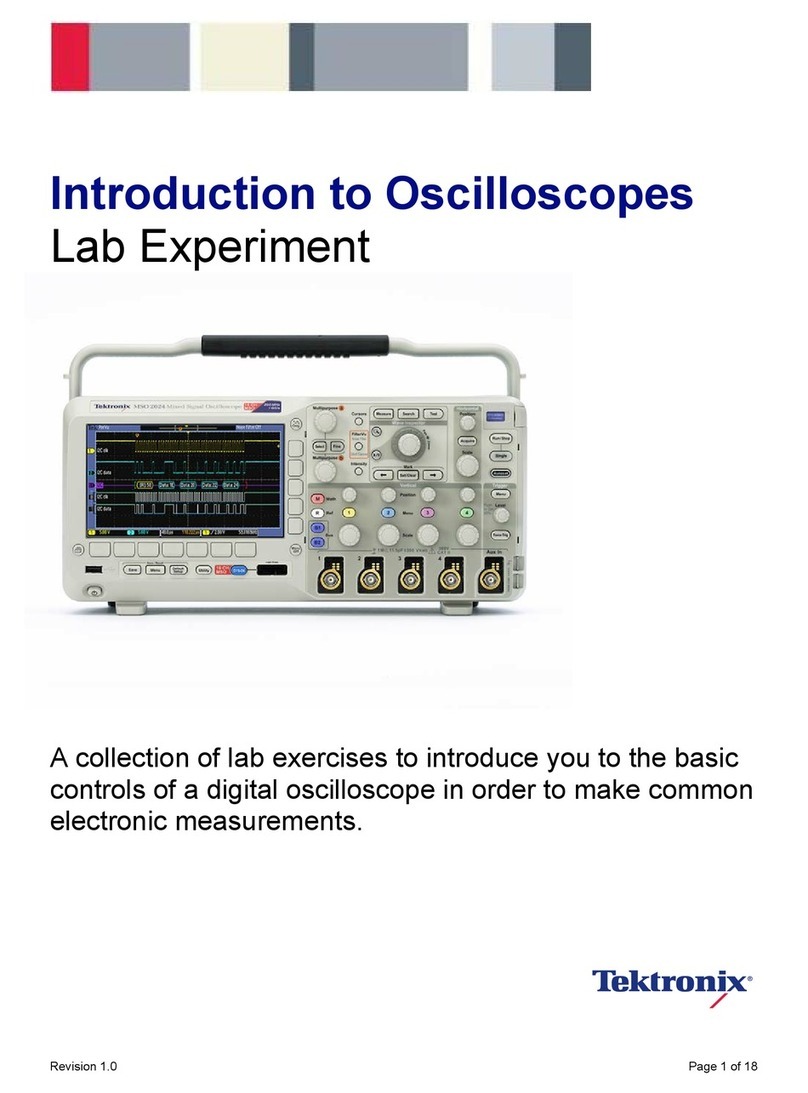

Tektronix MSO2024B User manual

Tektronix

Tektronix 511 User manual

Tektronix

Tektronix MSO2000 Series User manual

Tektronix

Tektronix T921 User manual

Tektronix

Tektronix TMS 540 User manual

Tektronix

Tektronix 2445A User manual