AUTEM PLC-ANALYZER pro 6 User manual

PLC-ANALYZER pro

6 -

Driver Addendum

PILZ PSS / PNOZ - Ethernet TCP/IP

PILZ PSS / PNOZ - programming interface

Copyright © 1993 - 2022 AUTEM GmbH. All rights reserved. No part of this user manual, including excerpts, may

be reproduced, photocopied or electronically stored without the expressive written permission of AUTEM.

The software described in this manual is subject of a software license agreement and may only be used

according to the terms of this agreement.

AUTEM GmbH

Dithmarscher Straße 29

26723 Emden

Germany

+49 4921 9610 0

www.autem.de

AUTEM does not give any warranty for this manual as well as no express or tacit warranties on commercial

quality and suitability for a particular use. AUTEM does not take over adhesion for errors contained in it or for

damages that may occur as a result of using or applying this material.

The soft and hardware designations mentioned in this book are in most cases also registered trademarks and

are subject to the legal regulations as such.

For references, suggestions and improvement suggestions we are always grateful. Please send these to AUTEM.

1st Edition 2022

PLC-ANALYZER pro 6 -

PILZ PSS / PNOZ

2 / 7

Table of Contents

Signal source .................................................................................................................................................. 3

PILZ PSS / PNOZ ........................................................................................................................................ 3

Installation

.......................................................................................................................................... 3

Installing additional hardware ......................................................................................................... 3

Installing additional software .......................................................................................................... 3

Configuration

....................................................................................................................................... 4

Data acquistion .................................................................................................................................... 6

Supported PLC models and CPUs ..................................................................................................... 6

Recordable PLC addresses ............................................................................................................... 6

Number of recordable addresses .................................................................................................... 6

Time behaviour and particularities .................................................................................................. 7

PLC-ANALYZER pro 6 -

PILZ PSS / PNOZ

3 / 7

Signal source

PILZ PSS / PNOZ

This driver addendum describes the particularities of the following PLC drivers and gives you hints on

using them.

PILZ PSS / PNOZ - Ethernet TCP/IP

PILZ PSS / PNOZ - programming interface

With the PLC driver "PILZ PSS / PNOZ - Ethernet TCP/IP" PLC signals can be acquired via Ethernet (TCP/IP)

and the PLC driver "PILZ PSS / PNOZ - programming interface" via the serial communication port of the

PLC.

It is important that you read through the driver addendum before using a PLC driver. Please pay

attention to the WARNINGS that advise you on possible dangers when using PLC-ANALYZER pro.

!WARNING

Errors that may occur in the automated facility, endangering humans or causing large-

scale material damage, must be prevented by additional precautions. These precautions

(e.g. independent limit monitors, mechanical interlocks) must guarantee safe operation,

even in case of dangerous errors.

Installation

The PLC driver can be added to the project as a new signal source. If the driver you want is not yet in the

list of available signal sources, you must first activate the license for the PLC-driver with the AUTEM

LicenseManager on your computer.

Installing additional hardware

If you have already connected your PC to the PLC via a TCP/IP network or a serial cable, you normally do

not need to do anything else. Otherwise, connect your PC to the PLC.

Installing additional software

No software is required in addition to the PLC-ANALYZER pro basic module and the PLC driver.

PLC-ANALYZER pro 6 -

PILZ PSS / PNOZ

4 / 7

Configuration

Open driver settings

to set important parameters for data recording. If you have added the driver to the

project several times, you can set the properties individually for each individual driver.

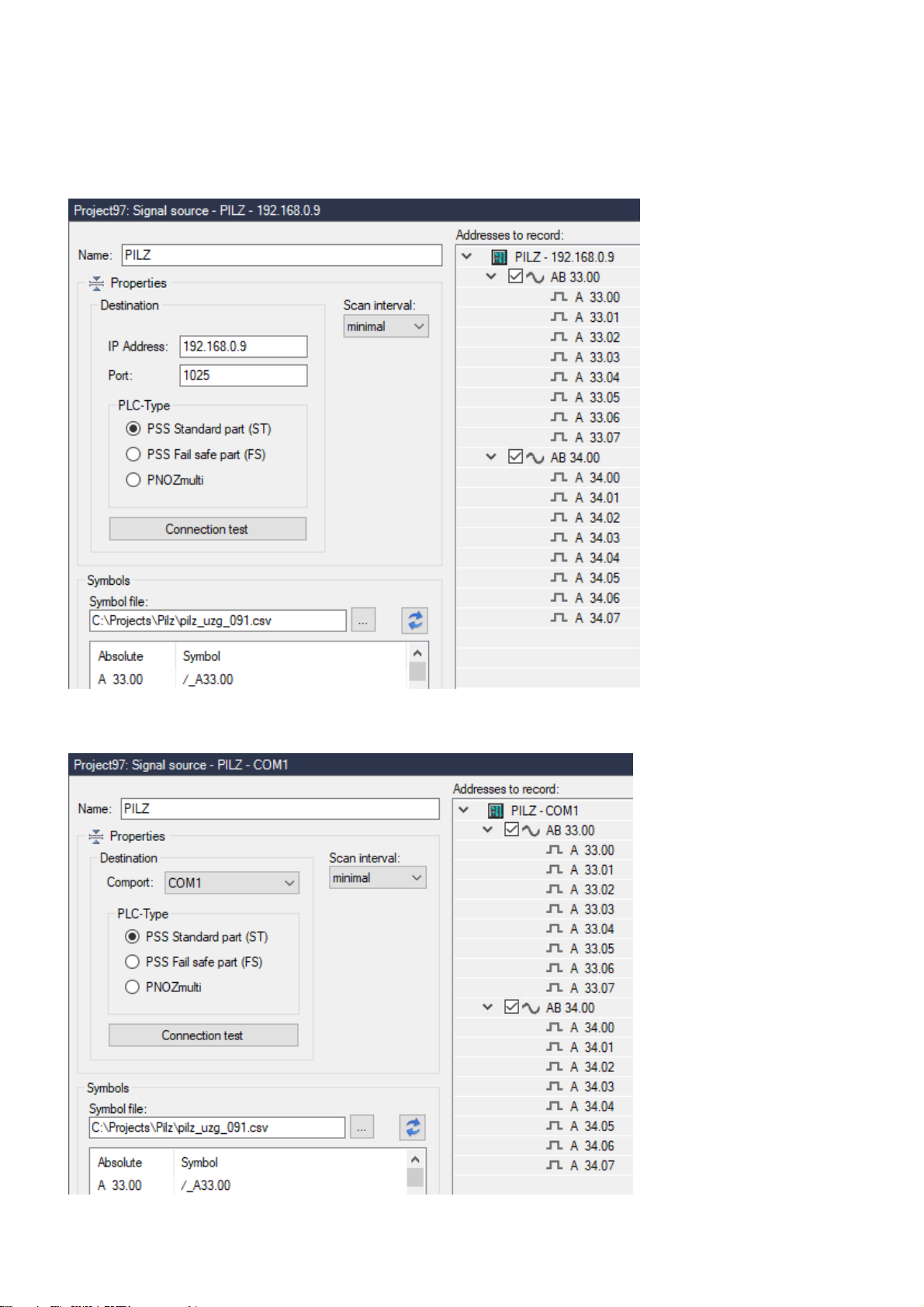

Fig. 1-1 Settings PILZ PSS - Ethernet TCP/IP

Fig. 1-2 Settings PILZ PSS - Ethernet TCP/IP

PLC-ANALYZER pro 6 -

PILZ PSS / PNOZ

5 / 7

First give the driver a meaningful

name

. Then set the IP Address and the

Port

of the PLC or the

Comport

to which the PLC is connected. These settings can be found in the configuration of your PSS WIN-PRO

project.

Under PLC type, specify whether you want to record data from the Standard part or from the

Fail-safe

part

of a PSS CPU or from a

PNOZmulti.

Press

Connection test

to check, whether a connection to the PLC can be established.

Under Scan interval

you specify the time interval at which measured values are read out from the PLC. A

longer sampling interval can be selected for signal paths that are not time-critical, e. g. temperature. As

a result, the generated signal files become smaller.

Under Symbols, select a Symbol file to make the symbols available for address selection. This makes it

possible to use symbolc identifiers when entering addresses. In addition to the absolute address, the

symbolic identifier and comment are also displayed and stored in a signal- or project file.

After setting the communication properties, add the PLC signals to be recorded. When a symbol file is

loaded, the signals to be recorded can be conveniently selected from the symbol list by double-click or

drag and drop.

PLC-ANALYZER pro 6 -

PILZ PSS / PNOZ

6 / 7

Data acquistion

Supported PLC models and CPUs

All models of the PILZ PSS 3000 series and the PNOZmulti are supported, which support a connection to

the programming software (PILZ Win-PRO) via the corresponding interface.

Recordable PLC addresses

The following table shows the recordable addresses and the corresponding address syntax:

Syntax

Address type

Example

A y.z

PSS output byte y, bit z

A 32.4

AB y.z

PSS output byte y

AB 9.24

AW x.z

PSS output word x.z

AW 14.00

E y.z

PSS input byte y, bit z

E 17.23

EB y.z

PSS input byte y.z

EB 23.24

EW x.z

PSS input word x.z

EW 14.16

O y.z

PNOZ output byte y, bit z

O 32.4

OB y.z

PNOZ output byte y

OB 9.24

OW x.z

PNOZ output word x.z

OW 14.00

I y.z

PNOZ input byte y, bit z

I 17.23

IB y.z

PNOZ input byte y.z

IB 23.24

IW x.z

PNOZ input word x.z

IW 14.16

M y.z Flag byte y, bit z M 3.07

MB y.z Flag byte y.z

MB 25.08

MW x.z

Flag word x.z MW 24.16

T x

Status Timer x T 2

Z x

Status Counter x

Z 5

ZW x

Counter x

ZW 5

y DL x

Left data byte x from DB y

82 DL 622

y DR x

Right data byte x from DB y

24 DR 346

y DW x

Dataword x from DB y

12 DW 600

Table 1-1 Address syntax PILZ PSS / PNOZ

Number of recordable addresses

A maximum of 16 million addresses can be acquired from up to 250 signal sources.

PLC-ANALYZER pro 6 -

PILZ PSS / PNOZ

7 / 7

Time behaviour and particularities

+

NOTE

Acquiring data with PLC-ANALYZER pro results in a small increase in cycle time in the

PLC to the same manner as it happens with programming software PSS WIN-PRO in

the online-mode.

The intervals between scan transfers from the PILZ PLC to the computer are depending on the following

items:

CPU type

cycle time of PLC

Number of recorded addresses.

For the PSS SB 3006-3 ETH-2 the scan interval for a address is approximately 5 ms, i.e. for a cycle time > 5

ms there is one scan for each cycle. For a longer PLC cycle time data transfer is synchronized with the PLC

cycle. For a shorter cycle time the computer does not obtain a scan for each cycle, resulting in a partial

loss of information. This loss can be compensated by repeated measurements of the interesting signals.

Every additional requested address leads to an increase in scan time of about 0.1 ms. The following

table exemplarily shows some values of time behaviour during acquisition:

Requested data Scan time

1 flag byte

5 ms

50 flag words

11 ms

100 flag words

22 ms

1 flag byte, 1 output byte

5 ms

50 flag byte, 50 data words

23 ms

10 flag words, 10 data words, 10 inputs, 10 outputs

10 ms

Table 1-2 Scan times on PSS SB 3006-3 ETH-2

The following table shows typical scan times for PILZ PSS 3046 (cycle time ca. 40ms):

Scandata Scan time

1 Byte

90 ms

32 Words

120 ms

Table 1-3 Recording time PILZ PSS 3046

Table of contents

Other AUTEM Industrial Equipment manuals