AUTEM ST300 User manual

www.autemvacuumlifters.co.uk

Manual for ST300

ELEVATING EXPECTATIONS

ST300

Our portable Slab Trolley has a lifting capacity of 300 kgs and is designed to be

used with ease by one person, keeping your manning levels to a minimum.

The ST300 Is powered by a 12volt battery and it has audio/visual alarms making it

both versatile and safe.

The ST is capable of lifting stacked slabs from a 90degree angle to horizontal for

laying. Perfect for lifting/laying slabs and kerb stones.

Pads are hardwearing and easily replaced.

All of our machines are UKCA/CE certified so you can be assured of their quality.

www.autemvacuumlifters.co.uk

Manual for ST300

Contents:

•Safety First

•Training

•Lift Plan

•Temperature Range

•Lifting Accessories

•Positioning of pads

•Pre –Checks

•Warnings

•Storage

•Operating Procedures

•SWL

•Lifting

•Maintenance

•Troubleshooting

•Parts List

•Wiring Diagram

•Pad Specification

•Declaration of Conformity

www.autemvacuumlifters.co.uk

Manual for ST300

Safety First

PERSONAL PROTECTIVE EQUIPMENT SHOULD BE WORN WHEN CONDUCTING ANY LIFTS

Caution Training:

The Vacuum Lifting equipment should be operated only by competent persons who have been

adequately trained in the safe use of the equipment and the findings of any risk assessment.

Training should cover:

•potential dangers from use of vacuum lifting equipment.

•factors which may cause equipment or lifting operation failure and how to avoid them.

•limitations on the use of the equipment.

•instructions on planning and carrying out safe lifting operations, including safe systems

of work.

•specific instructions on safe use issued by the manufacturer/supplier.

•location and operation of the equipment controls.

•scheme examination, maintenance requirements and system for reporting defects.

•emergency arrangements.

Caution Lift Plan:

www.autemvacuumlifters.co.uk

Manual for ST300

The responsible person/operator is required to conduct a lift plan which must address the

foreseeable risks involved in the lifting of the load and identify the appropriate resources

(including people) necessary for safe completion to the lift.

Factors to include may be any or all off the following:

•working under suspended loads (note; loads should not be lifted above personnel)

•visibility

•attaching/detaching and securing loads

•environment

•location

•overturning

•proximity hazards

•derating

•lifting people

•overload

•pre-use checking

•continuing integrity of the equipment

The plan should set out clearly the actions involved at each step of the operation and identify

the responsibilities of those involved. The degree of planning and complexity of the plan will

vary and should be proportionate to the foreseeable risks involved in the work.

The position of mobile lifting equipment or the location of fixed installations can have a

dramatic effect on the risks involved in a lifting operation. It is vital to take all practical steps to

avoid people being struck by loads or the equipment itself during use.

Warning Temperature Range:

The Vacuum Lifting devices should operate in a temperature range of -40°C to +60°C

Warning Lifting Accessories:

Lifting accessories (eg chains, links, slings, shackles etc.), used with the Vacuum Lifting

Attachments are subject to the Health and Safety at Work etc Act (HSWA) 1974 and LOLER

www.autemvacuumlifters.co.uk

Manual for ST300

https://www.hse.gov.uk/work-equipment-machine/loler.htm and must therefore be tested and

thoroughly examined accordingly.

Warning Positioning of Pads:

It is essential to position the pads correctly and it is also essential to wipe all surfaces prior to

the lift, as loose materials can cause leaks and HAVE caused loads to drop.

Warning Equipment Pre- Checks:

All checks should be carried out by competent personnel only.

Care should be taken to ensure that the materials lifted are those for which the attachment was

designed. Particular care should be taken when handling thin sheets of flexible material that

require careful positioning to avoid peeling away from the pad due to excessive overhang.

Sliding of inclined sheets across the pads can also occur. (Note: inclined loads should not be

lifted). It is essential to position the pads correctly and it is also essential to wipe all surfaces

prior to the lift, as loose materials can cause leaks and HAVE caused loads to drop.

The following checks should be conducted before use at the beginning of each shift/day,

•check the vacuum level reaches the minimum suction pressure of 40% each time before

use (Note: a green vacuum light gives conformation of pressure)

•check the battery is fully charged.

•check all warning information labels are clearly visible.

•Test alarm systems (check warning siren and red flashing light work and can be seen by

the operator throughout the lift).

Vacuum Lifting devices should not be treated as ‘general purpose’ lifting equipment as they are

designed for particular types of loads and environments. Users should seek advice from

autemvacuumlifters.co.uk on the suitability of an existing device for other new applications.

Warning Equipment Maintenance:

www.autemvacuumlifters.co.uk

Manual for ST300

The manufacturer’s instructions for the regular inspection and maintenance of the vacuum

lifting equipment must be followed.

Warning Equipment Weekly Checks:

The following components should be inspected on a weekly basis,

•pipeline inspection should cover material damage, pinching or rubbing during operation

can cause wear which results in a failure of the hose, environmental damage.

•connections.

•check valves are clean and free from debris.

•gauges.

•filters.

Warning Equipment Monthly Checks:

The following components should be inspected on a monthly basis,

•inspect shackles and suspension points if applicable (when the cross section is reduced

by over 10% replace immediately).

•check filter element on filter between reservoir and valve is clean.

Warning Alarm Activation:

Measures to be taken as soon as the warnings are actuated

•stop and lower the load to the floor where safe to do so.

•check vacuum level visually for any noticeable decrease.

•check battery connections.

•check condition of the vacuum connections and hoses.

•check the condition of the suction pads.

In the event of damage to any item it must be replaced before commencing another lift.

www.autemvacuumlifters.co.uk

Manual for ST300

Warning LOLER Inspections:

The Vacuum Lifting device should be thoroughly examined by a competent person at

appropriate intervals, where the vacuum lifting attachment is permanently fixed to a crane,

gantry or similar, it must be thoroughly examined at 12 monthly in accordance with a written

scheme of examination. Where it is uded in the same manner as a sling or other lifting tackle, ie

moved between different lifting machines, it is therefore considered as a lifting accessory and

must be thoroughly examined at 6 monthly intervals in accordance with the Lifting Operations

and Lifting Regulations 1998 (LOLER) https://www.hse.gov.uk/work-equipment-

machine/loler.htm.

Warning Construction Sites:

Where vacuum lifting equipment is used on construction sites, LOLER applies requiring the load

to be adequately secured to prevent danger from slipping or displacement. In applications such

as the lifting of industrialised building components which have to be raised above the ground

there is a risk that if the vacuum pump fails and there is significant or rapid leakage, there may

not be time to lower the load after the alarm rings. Therefore, for high lift applications, ie,

above 10metres, safety arms should be used. These arms should be engaged while the load is

being lifted or some other effective means should be provided of preventing the load from

falling in the event of loss of vacuum.

ELEVATING EXPECTATIONS

Operational Instructions

Stability During Storage

When not required for use it should be possible to set down the attachment so that it is stable

during storage. To be regarded as stable it shall not tip over when tilted to an angle of 10° in any

direction. This shall be achieved either by the shape of the attachment or by means of additional

equipment such as a stand.

www.autemvacuumlifters.co.uk

Manual for ST300

Machines kept in particularly moist/wet or dusty conditions may require frequent attention, so a dry

atmosphere is preferable.

Operating Procedures

The ST300 should only be operated by staff who have been trained in the use of the vacuum

lifting attachment and who fully understand the safe operating systems.

The vacuum lifting attachment utilises the creation of a vacuum via suction pads for attaching

itself to the load being lifted. The attached suction pads fit directly onto the surface of the load

thus enabling a vacuum to be created between the suction pads and the load. The suction pads

are an integral part of the lifting attachment. The electric-powered suction pump is an

independent unit that is connected to the lifting attachment forming a complete detachable

lifting accessory. The lifting attachment is generally suspended from lifting equipment (e.g.

hoist/crane/excavator/forklift truck) and can be attached by means of a hook arrangement,

accessories or other mechanical means. The vacuum attachment can also be an integral part of

the lifting equipment.

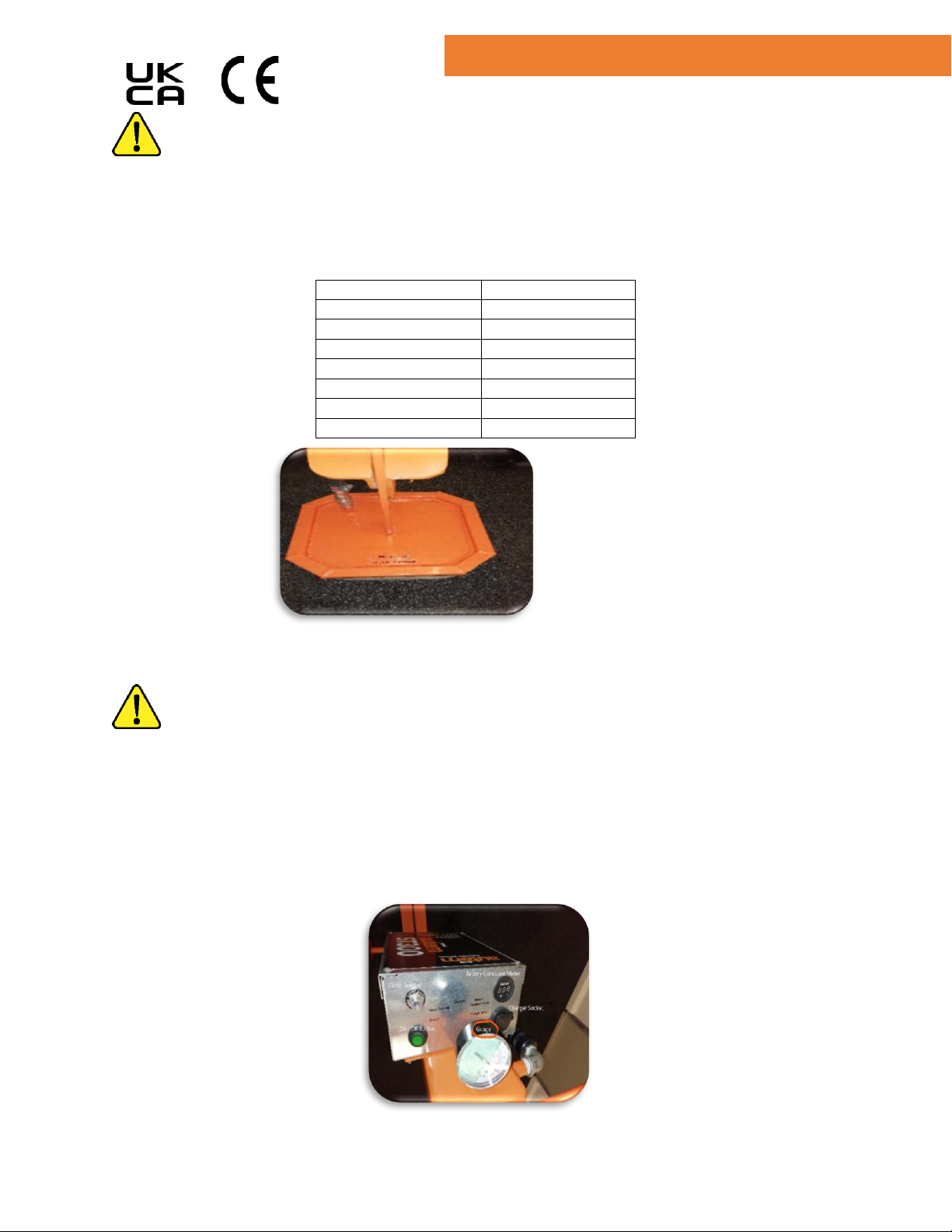

The power source is a battery power pack which drives a vacuum pump which evacuates a

reservoir tank fitted with a vacuum guage. This reservoir is connected to the suction pads. A

control valve is located in the vacuum line between the reservoir and the lifting pads. For

maximum efficiency the power pack is located as close as

possible to the lifting pads which are mounted on a metal frame. The suction is formed utilising

flexible pipe connection to the reservoir and fitted with a control valve.

The A weighted time averaged emission sound pressure (LEQ) measured at a horizontal

distance of 1m from the centre of the unit does not exceed 70DB (A)

The vacuum lifting attachment is fitted with Audio/Visual status and alarm system,

•a green vacuum conformation light.

•warning siren for low vacuum.

•red xenon flash light for low vacuum.

The warning siren red flashing light will be in multiples so the operator can have clear visibility

when a low vacuum occurs.

www.autemvacuumlifters.co.uk

Manual for ST300

Caution

The unit should be centred on material to be lifted then lowered ensuring that the pad/pad’s

do not overlap material being lifted.

Caution

The material being lifted must be free from dust and debris.

To activate control, push valve up as indicated, full vacuum will be achieved in seconds. To

release, pull valve down as indicated whilst assuring material is supported and that the

operator is clear of the load. Before lifting, make sure:

•the unit capacity is adequate for the load.

•the surface of load is free from dirt/detritus that could affect effective sealing.

•the surface of load has no holes/flaws which may prevent the pad for sealing

www.autemvacuumlifters.co.uk

Manual for ST300

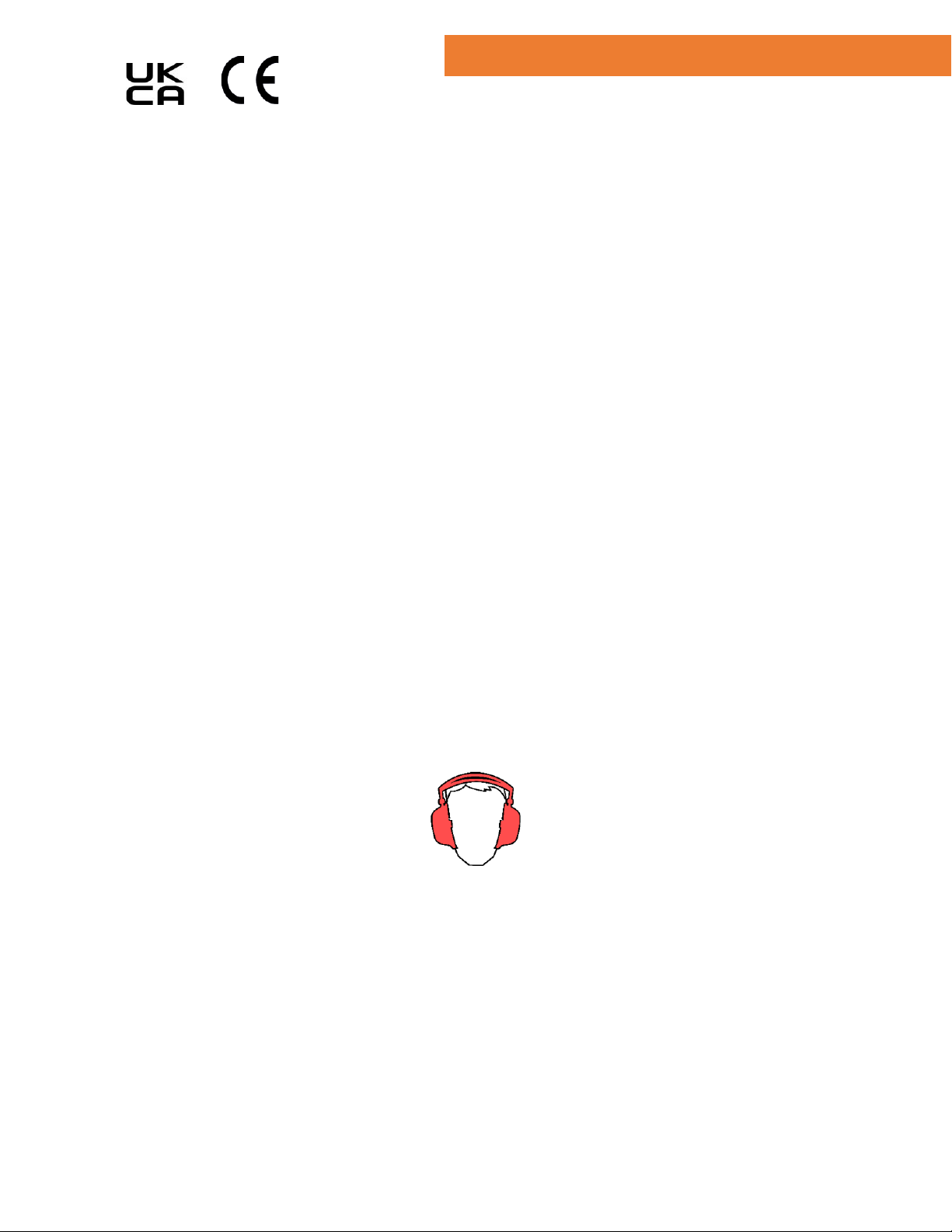

Caution

Before lifting any material ensure the load to be lifted is within the safe working load of the

vacuum lifting attachment which is indicated on the equipment

Pad Dimensions

SWL

300 x 300

187kg

200 x 800

480kg

400 x 400

480kg

500 x 300

450kg

500 x 500

625kg

600 x 300

540kg

900 x 450

1 tonne

Lifting

The machine may be used to lift loads of up to indicated safe working load when it has achieved

a vacuum level of 40% or above as indicated by the vacuum guage. The operator must have a

clear view of the vacuum guage and warning lights.

www.autemvacuumlifters.co.uk

Manual for ST300

`Warning

Do not attempt to lift load if the vacuum guage is not in the green zone or if alarm sounds

and/or red light is flashing.

In the event of the vacuum dropping below 40% whilst lifting a load, or if an alarm sounds,

lower the load to a safe position immediately.

Max Lift inclination: To 30° from horizontal

•To 30° from horizontal

MAINTENANCE INSTRUCTIONS

All checks should be carried out by competent personnel only.

Daily Checks:

•check vacuum level reaches the minimum suction pressure of 40% each time before use

(note; a green vacuum light gives confirmation of pressure).

•check the battery is fully charged.

•at the beginning of each shift/day, all suction pads should be inspected for damage

and/or wear.

•check all warning labels are clearly visible.

•test alarm systems.

Weekly Checks:

•examine all hoses and fittings for damage and/or wear.

•check valve is clean and moving freely.

www.autemvacuumlifters.co.uk

Manual for ST300

•check all suspension points/pins for damage.

Please note that conditions in which machine is stored will affect the amount of attention the

unit will require.

Monthly Checks:

•inspect shackles and suspension points if applicable (when the cross section is reduced

by over 10% replace immediately).

•check filter element on filter between reservoir and valve is clean.

•

Annual or Bi-Annual Checks

A full inspection and re-certification at 12 monthly intervals or 6 monthly checks dependent on

application in accordance with the Lifting Operations and Lifting equipment Regulations 1998

(LOLER) by a competent person.

TROUBLESHOOTING

Vacuum System:

Vacuum percentage is below 40%, cause:

•leakage in the vacuum hoses or badly applied hose clips.

•the seals in the suction pads have been damaged.

•the filter is blocked.

Remedy:

•change the vacuum hoses or clips.

•change the seal in the suction pads.

•clean the filters.

•demount the in-line valve, clean blast with air and remount.

www.autemvacuumlifters.co.uk

Manual for ST300

Electrical System:

The vacuum pumps cannot be started, cause:

•the MCB fuse has tripped off.

•low battery level –check the battery level on the voltmeter.

Remedy:

•reset MCB’S and retry.

•put unit on charge.

Here at Autem Vacuum Lifters, we pride ourselves on the quality of the products we supply, so

you can rely on us to have the replacement parts as and when you need them. To maintain the

certification of the product you can only use authorised parts supplied by Autem, any

modifications will also null and void the certification without prior authorisation from the

manufacturer.

ELEVATING EXPECTATION

Part No

Item Description

Product Code

SB6B.25

Spiral Wrap Sleeving

Size: 6mm OD (bundle dia. 5-

30mm) Length; 25m bag

P00299-25

R13-112B2G12

On/Off Round Mini Rocker

Switch with Green Light –12v

P00727

CG 1001

DIN ISO 4165 Plug –16a Max

P00776

JH-RS-5015

Panel Mounted DIN ISO

4165/Hella Power Socket-20A

Max

P01961

IA06-M-04G

¼ BSP ISO A Q/R Female Prob

IA06-F-04G

¼ BSP ISO A Q/R Female CA

# 0-381-65

Circuit Breaker 12/24 Volt

#-381-99

Circuit Breaker Dust Cap BG

www.autemvacuumlifters.co.uk

Manual for ST300

#0-531-24

Switch Rocker Round On/Off

10amps

#0-534-10

Voltmeter Illuminated FOR 12v

#0-562-12

Buzzer 1amp

200017

Sensor 3amp

200018

Red Warning Light 1amp

200019

Charger 4amp

200020

Filter

RPZF1

Pin Relay Socket DIN Rail

124-0201

ROLP/R/S/3

Red 32 Tone Sounder 9-28v dc

102db

529-4424

RPM12JD

Non-Latching Relay SPDT 15a

@ 250 v ac

179-7311

ZBY2303

Legend Plate

342-2942

ZB5AH053

Round Orange-Latching

Harmony XB5 Series,22mm

746-9175

1SNA176667R0400

BJMI Jumper Bar

447-428

ZBVJ55

Harmony XB Light Block 12V

553-866

Part No

Item Description

Product Code

ZBE1015

Harmony XB Contact Block

1NO

553-973

1SNA118368R1600

FEM End Section

424-866

1SNK900001R0000

BAM4 Series ATEX End Stop

666-3357

QBS-0202

Red LED Beacon 11-35Vdc

309-6010

RXZE2S111M

Pin Relay Socket DIN Rail 250v

884-1288

ISNA115116RO700

Standard Din Rail Terminal

800V ac

424-759

ISNA115657R2500

Fused DIN Rail 630v

210-4570

ISNA116951R1500

FEM End Section

484-3952

XB54AZ101

Harmony XB5 Contact Block-

1NO

331-0445

QB0203

Flashguard QBS Green Xenon

Beacon, 12v dc, 24v dc

312-5398

RXM3AB2JD

Coil Non-Latching Relay 3PDT,

10a Switching Current Plug In

884-1528

200023

Main Frame

200022

Pad

Pneumatic 14” Wheels

5056051480-433

Hose Clamp

200024

2 x Nuts

200025

Cotter Pin and Clip

200026

Electrical Control Box

200027

4 x Bolts to attach Electric Box

200028

Handgrips

www.autemvacuumlifters.co.uk

Manual for ST300

MOSS25 –60 X 50 50LE

Rubber Seal

Wiring Kit

Dual Head Pump

200023

Galvanised Box with Lid

Only replace part using components sourced directly from Autem Vacuum

Lifters Ltd www.vacuumlifters.co.uk

www.autemvacuumlifters.co.uk

Manual for ST300

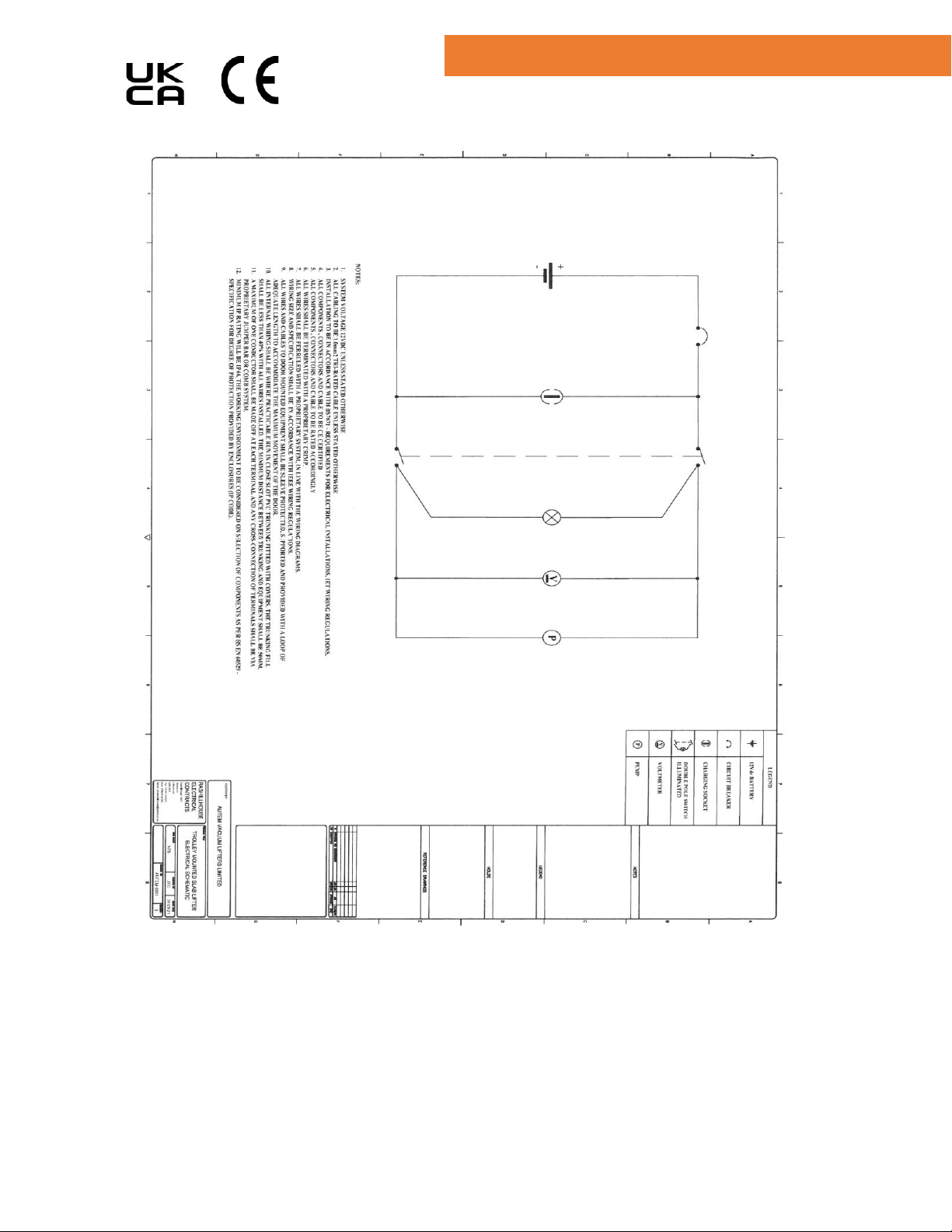

Wiring Diagram

www.autemvacuumlifters.co.uk

Manual for ST300

Drawing Number: WFBOO2

Revision: 002

Autem Vacuum Lifters Ltd

Westacre, Fenwick, Kilmarnock KA3 6AS

Product Vacuum Lifting Device

Model/Type

Serial Number

Un-Laden Weight

Year of Construction 20

Minimum Load

S.W.L

“Warning –Lifting above 1.8 M is prohibited

Until a lifting plan is in place”

Size = 100mmX 70mm

Material= 1.0mm Satin Silver Aluminium

Colour = Black

Adhesive = Nitto D9605

Tolerance = ±0.5mm

www.autemvacuumlifters.co.uk

Manual for ST300

GB Declaration of Conformity

In accordance with of European Parliament and Council Decision No 768/2008/EC Annex III

www.autemvacuumlifters.co.uk

Manual for ST300

1. Product model / product:

Product

Vacuum Lifter

Model/type

ST300

Batch/serial no.

20201

2. Manufacturer

Name

Autem Vacuum Lifters

Address

Westacre, Fenwick, Kilmarnock KA3 6AS

3. This declaration is issued under the sole responsibility of the manufacturer.

4. Object of the declaration: Vacuum Lifter

Product

Swl 300kgs /Battery Powered

5. The object of the declaration described above is in conformity with the relevant Union harmonisation

legislation:

SI 2008 No 1597

Supply of Machinery (Safety) Regulations 2008 (Amendment) Regulations 2011)

SI 2016 No 1091

Electromagnetic Compatibility (EMC) Regulations 2016

SI 2012 No 3032

The Restriction of Hazardous Substances Directive (Amendment) Regulations

2019

6. References to the relevant harmonised standards used or references to the other technical

specifications in relation to which conformity is declared:

Reference & Date

Title

BS EN 12100:2010

Safety of machinery General principles for design Risk assessment and risk

reduction

BS EN 13155:2003+

A2:2009

Cranes —Safety —Non-fixed load lifting attachments

BS EN 60204-1:2018

Safety of machinery. Electrical equipment of machines. General

requirements

BS EN IEC 61000-6-

2:2019

Electromagnetic compatibility (EMC). Generic standards. Immunity

standard for industrial environments

BS EN IEC 61000-6-

4:2019

Electromagnetic compatibility (EMC). Generic standards. Emission

standard for industrial environments

Signed for and on behalf of:

Autem Vacuum Lifters Ltd

Place of issue:

Westacre, Fenwick, Kilmarnock KA3 6AS

Date of issue:

Name:

David Speirs

Function:

Director

Signature:

Other AUTEM Industrial Equipment manuals