Auto Anchor AA570 User manual

AutoAnchor 570

2

3

AutoAnchor 570 Owner’s Manual

Part 1 Important Information 4

Part 2 Installation 7

Part 3 Set Up 18

Part 4 Operation 30

Part 5 Maintenance 36

Part 6 Troubleshooting 37

TABLE OF CONTENTS

To the best of our knowledge the information in this manual was correct at the time

of printing. However,the AutoAnchor products are continuouslybeing reviewed

and improved and product specications may be changed without notice. The

latest product specications may not be reected in this version of the manual. The

documentation relating to the AutoAnchor products is created in the English language

and may be translated from English to another language. In the event of any conict

between translated documents, the English language version will be the ofcial version.

AutoAnchor documents are available on www.autoanchor.co.nz

4

•The AA570 should only be installed by a qualified marine electrician. Do not

attempt to install the AA570 unless you are suitably qualified.

• ThismanualsupportstheuseoftheAA570only.Theappropriatemanufacturer’s

instructionsmustbefollowedfortheinstallationanduseofthewindlassitisset

uptocontrol.

• Theremustbeanalternativemethodavailabletooperatethewindlass.

•The AA570 can be fitted to most vertical windlasses. A horizontal windlass may

requireasensorholderoracustomdesignedsensorwhichisnotincludedinthe

standardpack.CheckwithyoursupplierortheAutoAnchormanufacturer.

•The AA570 must be fitted to a windlass with a dual direction control box or

solenoidpack.

• InformationforinstallationandoperationoftheAA570issupplied,including

pre-set windlass prole lists, wiring diagrams, the Owner’s Manual and

theQuickUserGuide.All documents must be left on board for the owner.

• Noncompliancewiththeinstructionscouldimpairthewindlassandthe

AA570operation,andcouldresultinpersonalinjuryand/ordamagetotheboat.

• Noncompliancewiththeinstructionswillnegatethemanufacturer’swarranty.

• TheAA570manufacturerandsupplieracceptnoliabilityforpersonalinjuryor

propertydamageresultingfromfailuretofollowtheinstallationandoperation

instructionsortheuseoftheAA570inawaythatmaycauseaccidentsor

damageorthatmayviolatethelaw.

•All the technical and cable specications must be checked and adhered to.

•Wiring diagrams must be followed without modication.

• BeforeusetheAA570mustbecorrectlysetupforthewindlassitistocontroland

testedinasafeenvironment.TheAA570willnotcountcorrectlyifthewindlass

selectioniswrongorthewindlassisnotstandard(egitisinstalledwithadifferent

chainwheelormotor).

•All installations must be carried out in accordance with USCG, ABYC, NMMA and

BMEA requirements.

• Whenthisproductreachestheendofitsusefullifeitmustbedisposedofin

accordancewithlocalregulations.

PART 1 IMPORTANT INFORMATION

READ BEFORE INSTALLING OR USING THE AUTOANCHOR

5

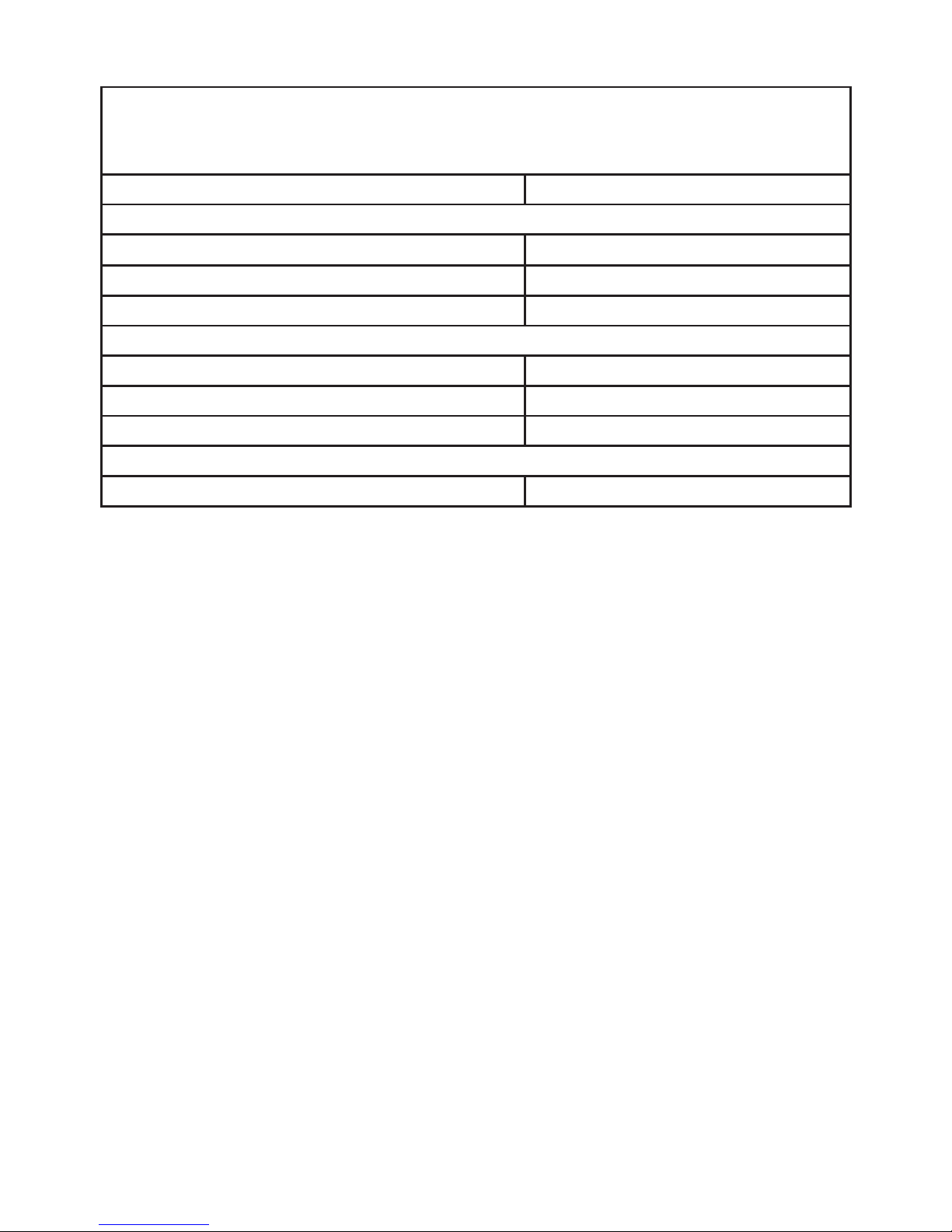

TECHNICAL SPECIFICATIONS AA570

Parameter AA570 Remote Console AA702 Base Station

Power Supply 12V/24V DC

Maximum Voltage 30V dC

Current Consumption 50mA

Output Maximum

Current Draw

12V DC: 3.5A

24V DC: 3.5A

The system has internal current

limiting and thermal shutdown.

Output Minimum

Current Draw

12V DC: 10mA

24V DC: 20mA

IP Rating IP67 IP67

Operating Temperature

Range

23oF to 140oF (-5oC to 60oC) 23oF to 140oF (-5oC to 60oC)

Wireless Transmission 2.4GHz ISM Band, IEEE 802.15.4 Compliant, 64 Bit Unique ID

Wireless Range Typical Minimum 10m (30ft). Range depends on installation.

System Supports Up to 3 base stations and 3 consoles

Rode - Chain Only Stainless or galvanised steel.

Rode - Rope and Chain Must have a minimum of 10ft (3m) of chain. Chain must be

galvanised steel. Rope should be a good quality, nylon anchor

rope. Type 66 or equivalent.

DC windlasses require a dual direction solenoid

12V/24V DC

30V dC

50mA

12V DC: 3.5A

24V DC: 3.5A

12V DC: 10mA

24V DC: 20mA

AA570 equipment (AA702 base station, AA710 remote and AA570 console) must be

installed least 3ft (1m) away from any equipment transmitting or cables carrying radio signals

eg VHF radios, modified sine wave inverters, cables and antennas or radar antennas; and at

least 6ft (2m) away from any SSB equipment. AA702 cables must be installed at least

1.5ft (500mm) away from such items.

Tips For Optimal Wireless Connectivty

base station must be positioned to avoid this or an antenna can be tted.

Contact your supplier or the AutoAnchor manufacturer for options.

Best reception for wireless signal is from top side of base station. See diaram page 14.

Alloy, steel or carbon fibre will restrict the wireless communication. The AA702

6

RAdIO FREqUENCy COMPLIANCE

FCC Information:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Modications not expressly approved by the manufacturer could void the user’s authority to

operate this equipment.

This device generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the manufacturer’s instructions, may cause harmful

interference to radio communications.

ESTI Information (CE):

This device is compliant with the essential requirements of the R&TTE Directive 99/5/EC,

meeting the European harmonized EMC and low-voltage/safety standards.

ELECTROMAGNETIC COMPATIBILITy (EMC)

FCC Information:

This device complies with CFR47 Part 15 of FCC Rules for Class B equipment.

ESTI Information (CE):

This device meets the relevant standards set out in European Standard EN 60945:2002 for

maritime navigation and radio communication equipment and systems. These standardsThese standards

are intended to provide reasonable protection against interference by other emission

generating products on the boat. Compliance with these standards is no guarantee that

interference will not occur in a particular installation. The installation instructions must be

followed to minimise the potential for interference.

Note: If shielded cable is not used for the sensor connections this will compromise the

EMC and may invalidate the warranty.

AA570 equipment (AA702 base station, AA710 remote and AA570 console) must be

installed least 3ft (1m) away from any equipment transmitting or cables carrying radio signals

eg VHF radios, modified sine wave inverters, cables and antennas or radar antennas; and at

least 6ft (2m) away from any SSB equipment. AA702 cables must be installed at least

1.5ft (500mm) away from such items.

7

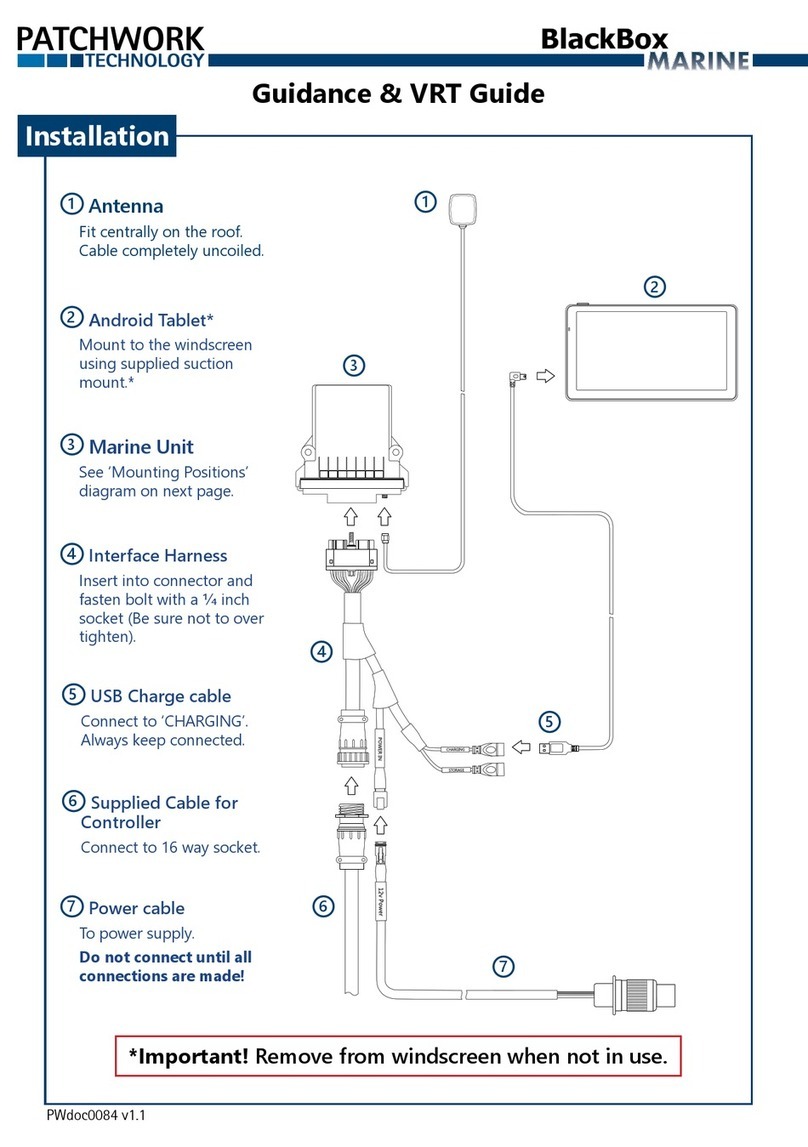

PART 2 INSTALLATION

2.1 MAGNET AND SENSOR INSTALLATION

PLEASE READ BEFORE COMMENCING INSTALLATION

Correct magnet and sensor installation is critical for successful AutoAnchor

operation.

The AutoAnchor can be installed on vertical windlasses, drum winches and most

horizontal windlasses. Installation differs depending on the windlass type and on the

rode (all-chain or rope and chain). Please follow the instructions for your windlass

and rode. If it is not possible to comply with these instructions please check with the

AutoAnchor manufacturer or your supplier for other options or if you are not sure how to

proceed.

See www.autoanchor.co.nz for contact information.

2.1.1 MAGNET INSTALLATION OVERVIEW

Check before starting: Your chainwheel may be pretted with a magnet or predrilled

ready for you to t the magnet.

Magnet Polarity: Not relevant when using the grey AA sensor (#9067) or a reed switch

sensor. If retrotting, using the black AA sensor (#9008) the south pole (marked side) of

the magnet must face the sensor.

Magnet Seal: Insert the magnet into the hole and cover it with a minimum of 1mm of epoxy

to protect it against corrosion.

Magnet Size and Position: Refer to the instructions for your specic windlass type.

2.1.2 SENSOR INSTALLATION OVERVIEW

Vertical Windlasses: The sensor is tted in the deckplate. Some deckplates are predrilled

for the sensor. Others have a dimple or mark to show where the sensor should be tted.

If the windlass is not factory drilled, drill a hole 10.3mm (13/32”) diameter through the

windlass deckplate. See the instructions for your specic windlass type.

Horizontal Windlasses: Sometimes it is not possible to t the sensor to a horizontal

windlass or it may need to be tted by the windlass manufacturer. Before starting

check with the AutoAnchor manufacturer or supplier that it is possible to t the

sensor to your windlass. You may need a special tting.

Drilling the Deck: Before drilling into the deck, ensure there is nothing below the deck that

could be damaged and that any hole you drill will not weaken the boat’s structure. Drill a

hole 10.3mm (13/32”) diameter through the deck. Ensure this hole is directly in line with the

sensor hole in the deckplate.

8

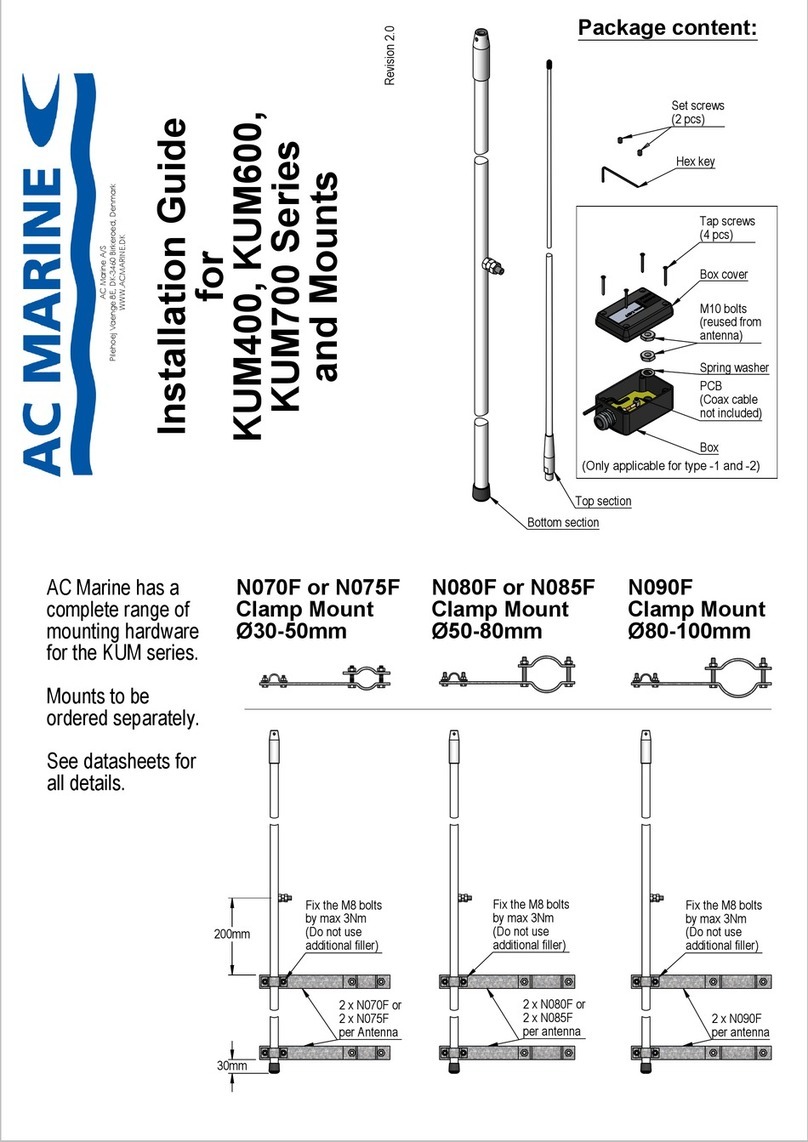

Part #9507 Male Field Connector

Part #9508 Female Field Connector

If there is no plug on the sensor cable attach the AA eld

connector to the wires and use the connecting cable as above.

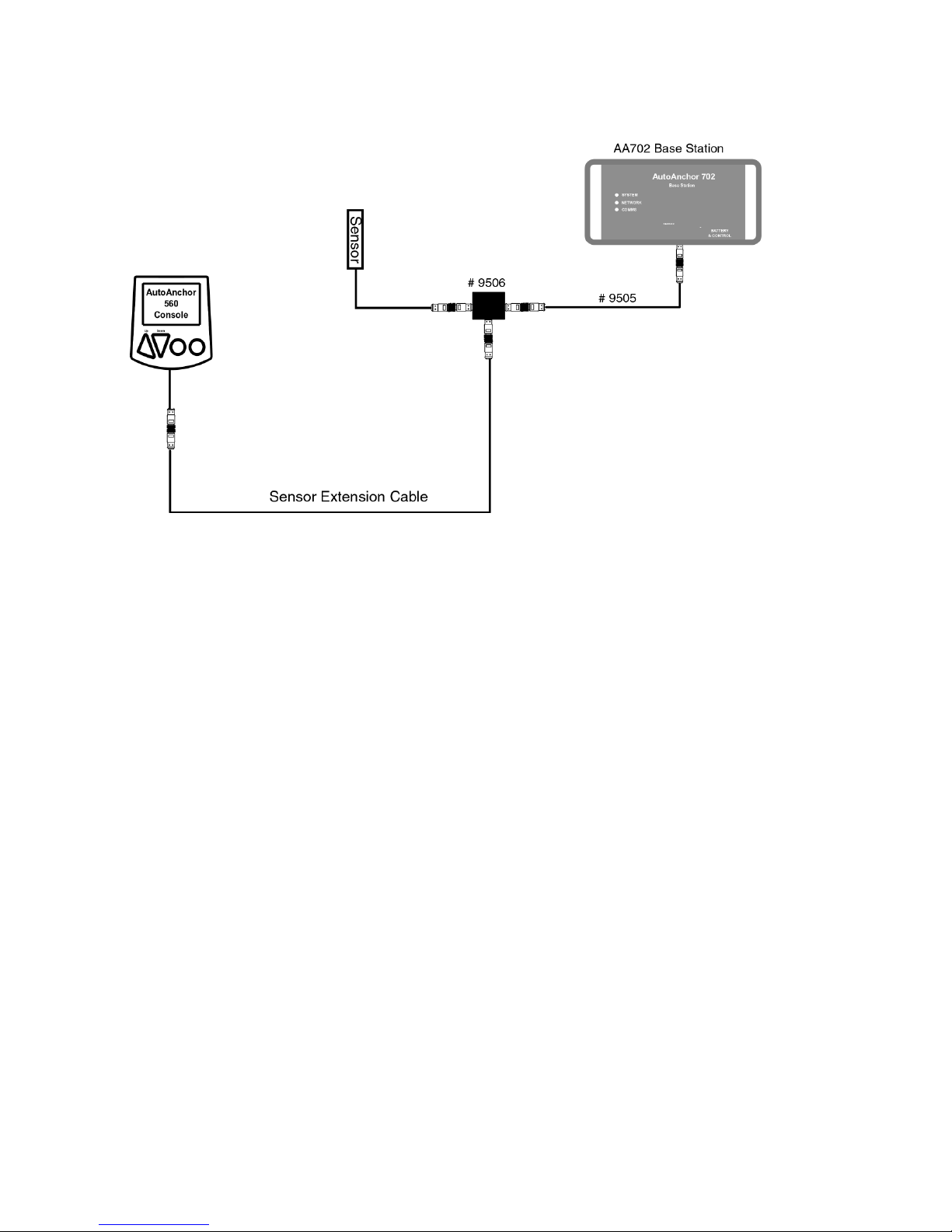

2.1.4 PLUG AND PLAY SENSOR CABLE

The AutoAnchor plug and play sensor cable is 2 core tinned shielded cable. It must be

used to connect the sensor to the console unit. Ensure the connectors are rmly screwed

together.

The warranty does not apply if the sensor cable plugs are removed.

The sensor cable is tted with a female plug to connect direct to the male connector on the

AA702 base station. If a longer length is required, sensor connecting cable, with a male

plug at each end, is available in the following lengths:

6.5 m (21.33 ft) Part #9500

10 m (32.81 ft) Part #9501

15 m (49.21 ft) Part #9502

20 m (66.62 ft) Part #9503

25 m (82 ft) Part #9504

35 m (114.83 ft) Part #9514

A 2m male/female cable (Part #9505) plus a gender changer (Part #9510) will be required

to connect the extension cable to the base station.

Field Connectors

Sensor Connection: The sensor is plugged direct into the AA702 base station. Do not

leave the cable hanging loose, it must be tied in place with cable ties. Extension cable,

gender changers and eld connectors are available if required.

Sensor Plug

Fitting the Sensor: Do not force the sensor into the hole. Hammering the sensor head

can damage the internal electronics. Ensure the sensor head is positioned so that it will not

be hit by the chainwheel during windlass operation and that it is at least 300mm (1ft) away

from the battery and motor cables. Secure the sensor using a good quality neutral cure

silicone or a strong adhesive eg. Sikaex 291 or 3M 5200.

Connecting 2 cables together:

If you need to extend the cable length - 2 cables can be joined

together using Part #9510 Gender Changer.

Antenna Plug

9

Dual Installation with Other AA Products

Use the T adaptor Part #9506 and the 2m Male/Female extension cable

Part #9505.

2.1.5 REED SWITCH SENSORS

Some windlasses are supplied pre-tted with a reed switch sensor. Reed switch sensors

must have a 10mm x 8mm magnet (#9061) and the gap between the reed switch sensor

and the magnet must be a minimum of 3mm and a maximum of 5mm. This sensor requires

a eld connector.

The AutoAnchor will operate with a reed switch sensor for all-chain rode. If using

combination rope and chain rode the reed switch sensor provides a reasonably accurate

count of rode deployed but on retrieval the display may be incorrect because it cannot

allow for the stretch in the rope.

For an accurate rope and chain count, the reed switch sensor should be replaced with the

AA grey sensor (#9067).

2.1.6 SENSOR TUNING

When the AutoAnchor is completely installed the sensor must be tuned. See the

instructions on page 28.

10

Magnet Fit: Drill a hole 10.3mm (13/32”) diameter and 9.5mm (3/8”) deep to t the

magnet in the underside of a spoke in the bottom of the chainwheel. Cover the magnet

with a minimum of 1 mm epoxy. The magnet should be aligned with the sensor. See Fig 1.

2.1.7 INSTALLATION ON A VERTICAL WINDLASS - CHAIN ONLY

Magnet Size: Standard size is 10mm x 8mmm (#9061). This may be replaced with the

smaller 6mm x 4mm (#9009) magnet if required for your windlass.

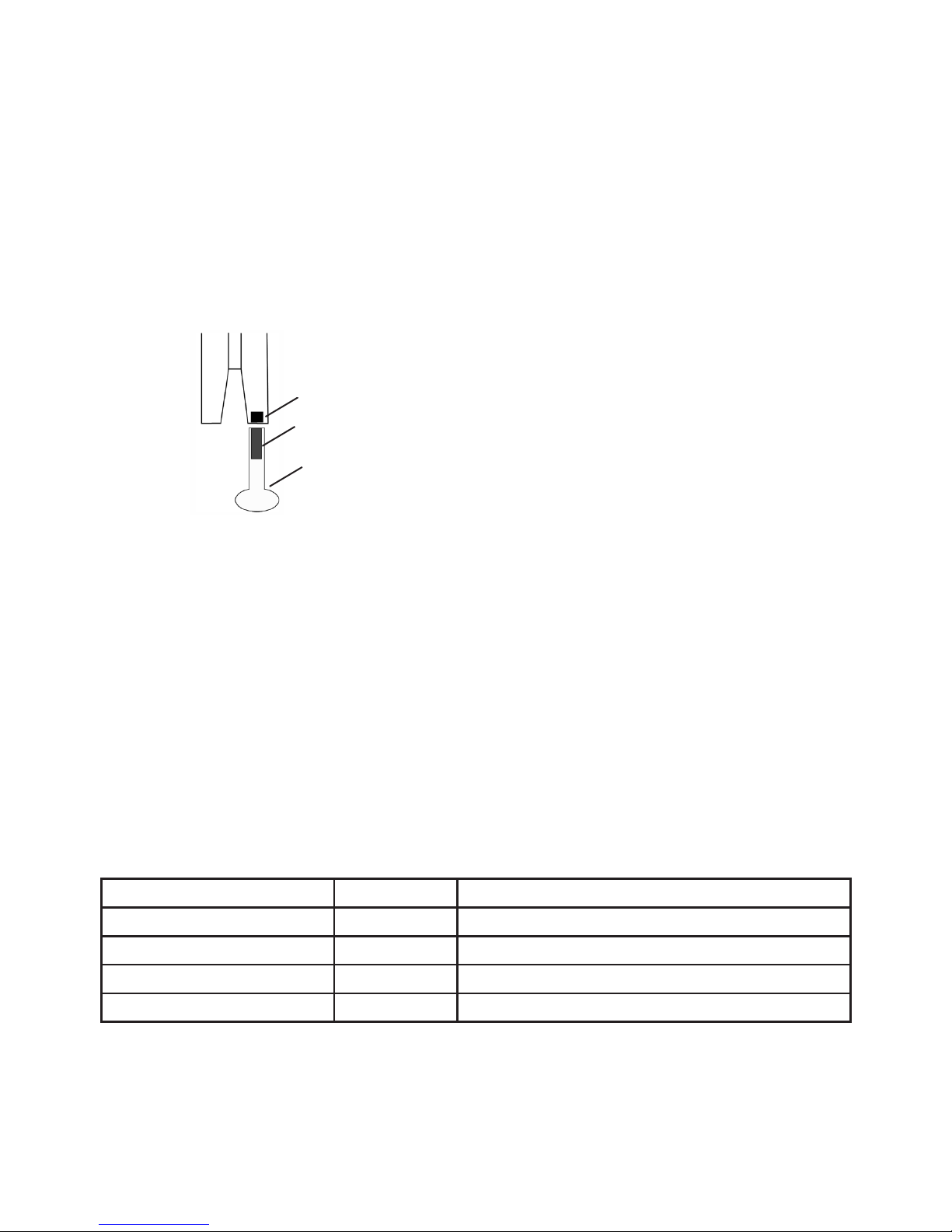

Fig 1 - All sensors

Seal with minimum 1mm epoxy.

Magnet

Sensor

Gap Between the Sensor and Magnet:

Sensor Magnet Size Gap

AA Grey Sensor #9067 6mm x 4mm Minimum 3mm - Maximum 30mm

AA Grey Sensor #9067 10mm x 8mm Minimum 3mm - Maximum 50mm

AA Black Sensor #9008 All Magnets Minimum 3mm - Maximum 8mm

Reed Switch Sensor 10mm x 8mm Minimum 3mm - Maximum 5mm

Chainwheel

Deckplate

Refer to the Overview Notes on page 4before starting installation.

Sensor Connection: Ideally the sensor should be plugged directly into the AA702 base

station. If longer cable is required use the AA 2m male/female extension cable (Part

#9505) or one of the AA standard male/male extension cables plus the 2m cable and a

gender changer. Ensure the connectors are rmly screwed together.

Loose cable should be tied in place with cable ties and kept clear of chain.

Sensor Position: The AA black sensor and the reed switch sensor must be tted direclty

in line with the magnet in the chainwheel. See Fig 1 above. The AA grey sensor may be

tted up to 20mm out of alignment. The gap between the sensor and magnet must be as

per the table below.

Note: If it is not possible to

align the sensor and magnet

exactly the AA grey sensor may

be tted up to 20mm out of

alignment. The AA black sensor

and the reed switch sensor must

be directly aligned.

11

2.1.9 INSTALLATION ON A HORIZONTAL WINDLASS - CHAIN ONLY

Fig 6

Magnet in rim of chainwheel and standard

sensor in sensor holder screwed to the deck

Magnet & Sensor Fitting for Chain Only Horizontal Windlasses

Magnet Size: 6mm x 4mm magnet (#9009).

Magnet Fit: If your windlass is not predrilled drill a hole 6.5mm (1/4”) diameter and 5mm

(3/16”) deep in the edge of the chainwheel. Cover the magnet with a minimum of 1mm

epoxy.

Gap Between the Sensor and Magnet:

Sensor Magnet Size Gap

AA Grey Sensor #9067 6mm x 4mm Minimum 3mm - Maximum 30mm

AA Grey Sensor #9067 10mm x 8mm Minimum 3mm - Maximum 50mm

AA Black Sensor #9008 All Magnets Minimum 3mm - Maximum 8mm

Reed Switch Sensor 10mm x 8mm Minimum 3mm - Maximum 5mm

Sensor Connection: If longer cable is required the AutoAnchor plug and play sensor

extension cable must be used to connect the sensor to the AA702 base station. Ensure

the connectors are rmly screwed together.

Loose cable should be tied in place with cable ties and kept clear of chain.

Refer to the Overview Notes on page 4before starting installation. It is not

possible to set out a single installation method for horizontal windlasses.

The sensor may be tted inside the windlass or you may need a sensor

holder (Part #9070). See Fig 6 below. Often the sensor and magnet can only

be tted by the windlass manufacturer.

Sensor Holder

Sensor

Magnet

Sensor Position: The AutoAnchor sensor may be tted using a sensor holder xed to the

deck to sit under the chainwheel (See Fig 6). The AutoAnchor sensor holder (#9070) is not

included in the standard kit. Check with your supplier if you need this. The AA black sensor

and the reed switch sensor must be tted directly in line with the magnet in the chainwheel.

The AA grey sensor may be tted up to 20mm out of alignment. The gap between the

sensor and magnet must be as per the table below.

12

Before starting check with the AutoAnchor manufacturer, or supplier, that it is

possible to t the sensor and magnet to your horizontal windlass.

For an accurate rope count the rode must run between the sensor and magnet. On a

horizontal windlass the magnet and sensor must be tted by the windlass manufacturer.

If it is not possible to have the sensor and magnet tted to achieve this you can use the

chain only horizontal windlass installation above. This provides an accurate count of rode

deployed but during retrieval the display may be incorrect because it cannot allow for

the stretch in the rope.

2.1.10 INSTALLATION ON A HORIZONTAL WINDLASS - ROPE & CHAIN

2.1.11 INSTALLATION ON DRUM WINCHES

For Drum Winch Set Up and Operation Refer to Page 29.

Gap Between the Sensor and Magnet:

Minimum 5mm and maximum 40mm

The magnet and sensor must be tted so that the gap remains consistent as the

winch turns

Magnet Installation:

Size: 10mm x 8mm magnet (#9061)

The magnet can be mounted on the main shaft or on the side of the drum. See Figs 8 and

9. If mounted on the side of the drum, position it close to the inside to reduce the

peripheral speed of the magnet. Fix the magnet into position with epoxy ensuring it is

completely sealed to prevent corrosion.

Sensor Installation

The Grey 3 wire AA sensor (#9067) is recommended but a proximity sensor may be used.

Every installation is different so this manual can provide guidelines only. The AA sensor

holder #9070, or a customised sensor holder will be required to ensure the sensor remains

in position and the gap is consistent between the sensor and magnet during operation.

Fig 8

Sensor

Sensor Connection: The AutoAnchor plug and play sensor extension cable must be

used to connect the sensor to the AA702 base station. Ensure the connectors are rmly

screwed together.

Loose cable should be tied in place with cable ties and kept clear of chain.

Magnet on

side of drum Magnet

on shaft

Sensor

Fig 9

Magnet

Sensor

Fig 7

OD

ID

13

AA702

Terminal

Default Function

Assignment

Alternative Function Assignment

BATT (-) Ground

BATT (+) Positive

OUT 1 (+) 1 Windlass

Down

OUT 2 (+) 1 Windlass

Up

OUT 3 (+) 2

Port

Windlass

Option A

OUT 4 (+) 2

Starboard

Windlass

Option B

OUT 5

White

(+) 2

Port

Power Enable 3Rope/Chain

Motor Load Wires

OUT 6

Brown

(+) Thruster B (Stern)

Starboard

Dual Speed 3Rope/Chain

Motor Load Wires

2.4.1 BASE STATION INTERNAL CONNECTIONS

Notes:

Unused outputs are automatically assigned as auxiliary outputs.

All outputs are active high (+).

1Only one windlass can be connected to a base station. 2 windlasses require 2 base

stations. The windlass outputs OUT1 and OUT2 are xed, however, the

control buttons for up and down can be swapped in the set up menu as can the

location of the windlass (bow or stern).

2Stern and bow thruster output locations stated are the default locations. These can

be swapped in the set up menu. The port and starboard directions for each output

cannot be changed.

3Only required for rope/chain counting

OUT 5 = White Motor Load Wire

OUT 6 = Brown Motor Load Wire

The kit has one master base station and one remote console.

Each base station has 6 outputs. Up to 2 slave stations can be attached to the master

station to provide extra

2.4 REMOTE CONSOLE AND BASE STATION INSTALLATION

AA570

outputs.

*THRUSTER AND AUXILARY CONTROLS ONLY FUNCTION WITH AA710

HAND HELD REMOTE (AA9408 / AA9400)

*Thruster A (Bow)

*Thruster A (Bow)

*Thruster B (Stern)

2*

FOR USE ONLY WITH AA710 REMOTE.

14

2.4.2 CONSOLE INSTALLATION

The console is supplied with mounting kit and

a cover. One remote console can operate multiple

base stations.

The unit should be mounted on a flat surface

at least 3ft (1m) away from any equipment

transmitting or cables carrying radio signals

eg VHF radios, cables and antennas or radar

antenna and at least 6ft (2m) away from any

SSB equipment.

The remote console is sealed to IP67.

Up to 4 remote consoles can be connected to a system.

To maintain the IP67 waterproof seal through the

cable gland a tinned, marine grade multi core

cable must be used and the base station must be

mounted so that the cables extend below the unit

when xed to the wall.

•the lid can be removed easily during operation.

• the LED indicators can be seen during operation.

•the best reception is available (see Fig 10).

• the cables extend below the unit when xed to the wall

to avoid condensation entering through the cable gland.

LED Indicators

2.4.3 BASE STATION

Wireless Communication

Best reception for the wireless signal is on the top or sides

of the base station as per the diagram. Alloy, steel or

carbon bre will restrict the wireless communication. An

antenna may need to be tted if wireless communication is

impeded. AA727 Antenna Part # AA9403

Up to 3 base stations can be connected to a system.

When operating a windlass, the base station should be

mounted close to the windlass, in a position where:

Fig 10

B

e

s

t

r

e

c

e

p

t

i

o

n

t

o

p

o

r

s

i

d

e

s

15

12V or 24V DC power supply is required to the AA702 base station.

Check battery polarity before connecting power and ensure output terminals will not short.

Refer to the manufacturer’s specications for fuse/breaker, isolator and main power

cable specifications, for the equipment being controlled by the AA570.

Ensure any fuse/breaker on the control circuit has a rating applicable to the current loads

connected to the outputs. (AA702 Output maximum is 3.5 Amps). An additional isolating

switch should be installed for controls if the main breaker or isolator is not readily acessible

from the helm.

Multiple battery bank negative terminals must be permanently connected together to

become the common negative return (ground).

2.5.1 WINDLASS INSTALLATIONS

Power supply to the AA702 base station must be from the windlass control circuit, along

with all other windlass controls eg. toggle switch, remote switches, deck switches, other

AutoAnchor devices. Power supply must not be from the motor positive near the

windlass.

2.5.2 MULTIPLE BASE STATION INSTALLATIONS

The master base station must be powered up when using a slave base station application.

Separate base stations may be powered from separate supplies, however, if 2 products

are connected to the same base station they must be powered by the same supply,

or relays must be used as a means of isolation. To maintain power to the windlass it is

recommended that the windlass be attached to the master base station.

THE POWER SUPPLY MUST BE DISCONNECTED WHEN INSTALLING,

CONNECTING OR CHANGING THE WIRING

2.5 POWER SUPPLY

2.6 VOLTAGE LEVELS

Neither the windlass nor the AutoAnchor will operate with insufcient power. (See minimum

voltages below). Batteries must be properly maintained and charged and all connections

and wires must be of good quality and the correct gauge to prevent voltage drop.

Minimum Voltage Required 12V DC System 24V DC System

Minimum voltage required to start windlass 10V DC 20V DC

If the windlass is already operating, this is the

minimum voltage required to continue operating.

6V DC 12V DC

16

CABLE SPECIFICATIONS

An appropriate multi-core cable must be used to maintain the cable gland

seal into the base station.

Total Length Cable Size

Cable from AA702 Base Station to the Power Supply

Less than 8m (26ft) 1.5mm2(AWG16)

8m (26ft) - 11m (36ft) 2.0mm2 (AWG14)

11m (36ft) - 17m (56ft) 2.5mm2(AWG12)

Cable from AA702 Base Station to Outputs

Less than 10m (33ft) 1.5mm2(AWG16)

10m (33ft) and 20 m (66ft) 2.0mm2 (AWG14)

20m (66ft) and 40m (132ft) 2.5mm2(AWG12)

Cable from Motor Load Wires

Up to 30.5m (100ft) 1.0mm2(AWG18)

2.7 WIRING

2.7.1 MOTOR LOAD WIRES (BROWN AND WHITE) OUTPUTS 5 & 6

Rope & Chain Counting: The brown and white wires must be connected direct to the

windlass motor terminals for rope & chain counting. A 1000 Ohm resister must be tted

near the motor terminal for short circuit protection. The motor load terminators supplied

in the kit have motor terminal connectors with a 1000 Ohm resistor pretted.

If the AA710 is tted to an all-chain windlass, a thruster or auxiliary equipment. Outputs

5 and 6 can be used for other options.

Interlock protection is included in the system. Do not t diodes or interlock devices to

outputs as these will prevent the system from operating correctly.

All battery and motor cables must be ring type, insulated to prevent short circuits and

installed no closer than 1ft (300mm) away from the sensor head.

To reduce the potential for interference all cables must be located at least 1.5ft (500mm)

away from any equipment transmitting or cables carrying radio signals eg VHF or SSB

radios, cables and antennas or radar antennas.

Do not leave cables hanging loose, they must be tied in place with cable ties.

2.7.2 MULTIPLE AUTOANCHOR INSTALLATIONS

It is important when wiring multiple AutoAnchor products that potential differences do not

occur along the ground connection. This can cause incorrect counting. Ensure AA560

and AA150 consoles and AA702 base stations are star grounded, and that there are no

other high current paths between consoles. All wiring for multiple installations is run in

parallel. Refer to wiring diagrams for further details.

17

2.7.4 PLUG & PLAy SENSOR CONNECTIONS

The AA701 Base Station and the sensor are pretted with connector plugs. The 2m sensor

cable plugs direct into the base station. Extension cables are available. See page 8for

plug and play sensor cable information.

2.7.6 WIRING dIAGRAMS FOR AA702 BASE STATION

Wiring diagrams are included in the kit. Please refer to them for wiring detail.

These diagrams and installation help are also available on www.autoanchor.co.nz

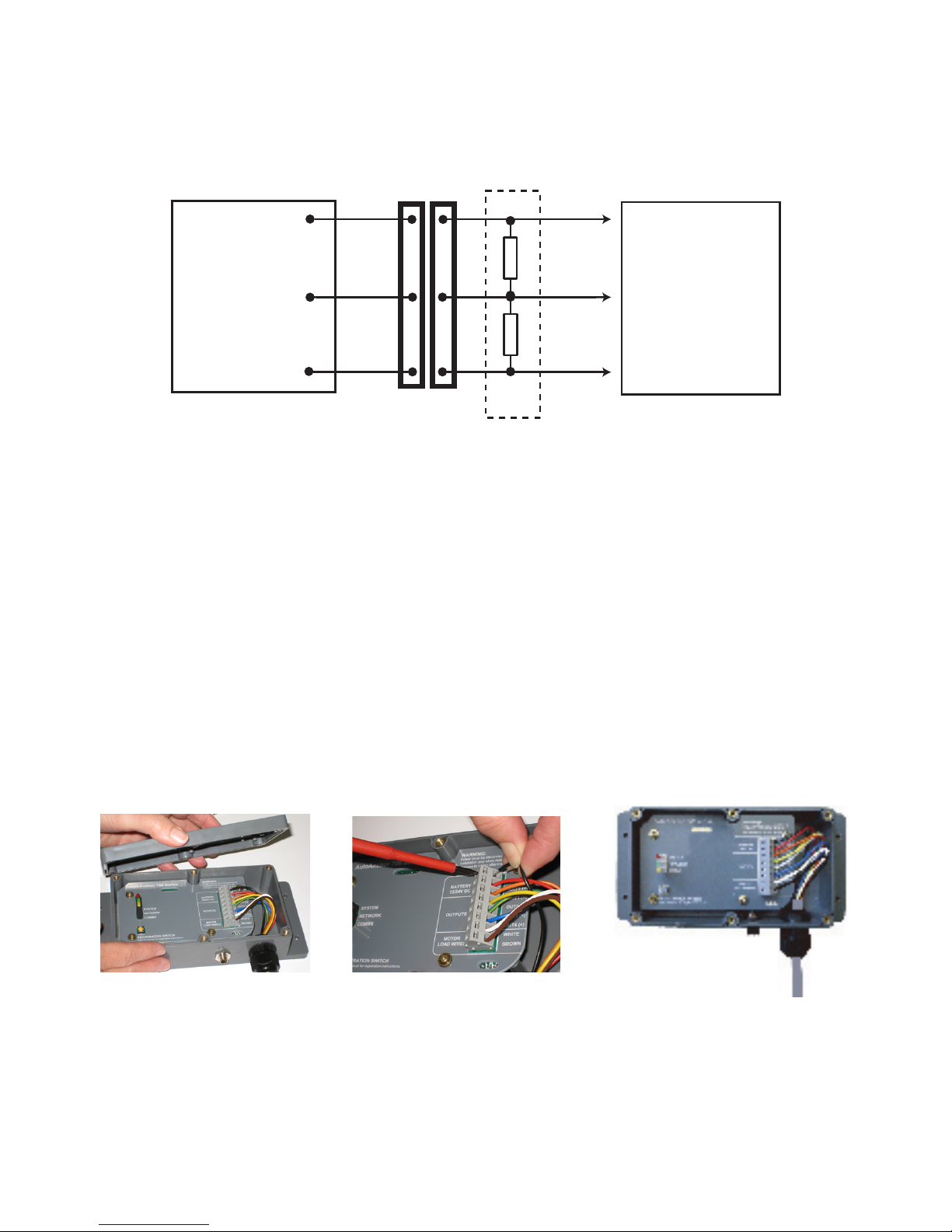

2.7.5 CONNECTING THE CABLES INTO THE BASE STATION

Remove the lid from the AA702 base station.

Feed the multi-core cable through the waterproof gland.

Connect the cables to the terminal block, using a screwdriver to press down and open

each terminal as required. (See the photograph below).

Tighten the cable gland.

Replace the lid.

2.7.3 CONNECTION TO LOW CURRENT dRIVES

When connecting to equipment with solid state switching or other low current drives, eg

PLC or AC variable frequency, a dummy resistor load (Part # 9515) may be required to

provide sufcient loading and to meet EMC and safety considerations. The resistor pack

should be installed close to the equipment control not on the AA702 base station.

Up

Up

Down

Down

BATT (-)

-

1

2

3

1000R

1000R

1

2

3

Low current

windlass drive

Part No

9515

AutoAnchor Product

AA150

AA560

AA601

AA710

AA730

18

3.1 USING THE AUTOANCHOR BUTTONS

Scroll: Menu/Numbers/Up/Down.

Mode/Select/Enter/Save.

On/Off/Escape or Back.

Hold together to access the Set up menu.

Hold for 2 seconds to disable the lock.

Hold for 2 seconds to return the AutoAnchor to the idle state.

PART 3 SET UP

downUp

3.2.1 SYSTEM OVERVIEW

The AA570 kit is supplied with 1 x AA570 remote console and 1 x AA702 master base

station. Each console and base station has a unique ID and the units must be registered

to each other to operate the system. If extra outputs are required up to 2 additional base

stations, known as slave stations, may be added into the system. Up to 4 consoles can be

registered to operate a system. Follow the instructions to register the consoles and base

stations.

3.2 WIRELESS INTERFACE SET UP

3.2.2 REGISTRATION SWITCH

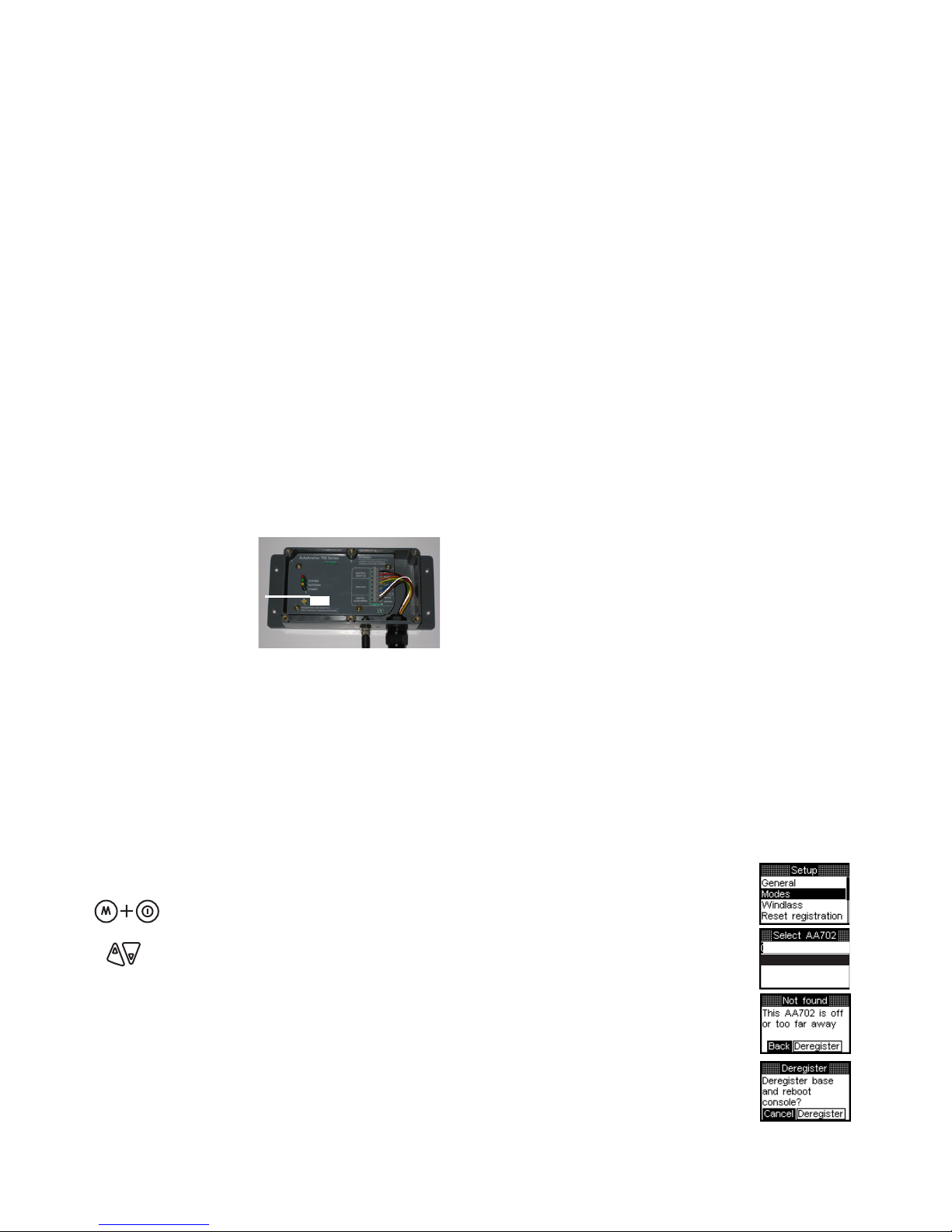

Located inside the base station. Use to register the

base station to the console and to register a slave

to the master base station. See the instructions over.

3.2.3 LED INDICATORS

System (Red)

Steady red indicates power is on. Flashing continuously indicates registration

state is active. Times out after 5 minutes. Flashing a slow pulse indicates sensor

is connected when the windlass is turning.

Network (Green)

Steady green indicates the base station is a master station. Off indicates the base

station is a slave (See instructions to connect a slave station below).

Comms (Yellow)

Flashing indicates data is received.

Registration

Switch

19

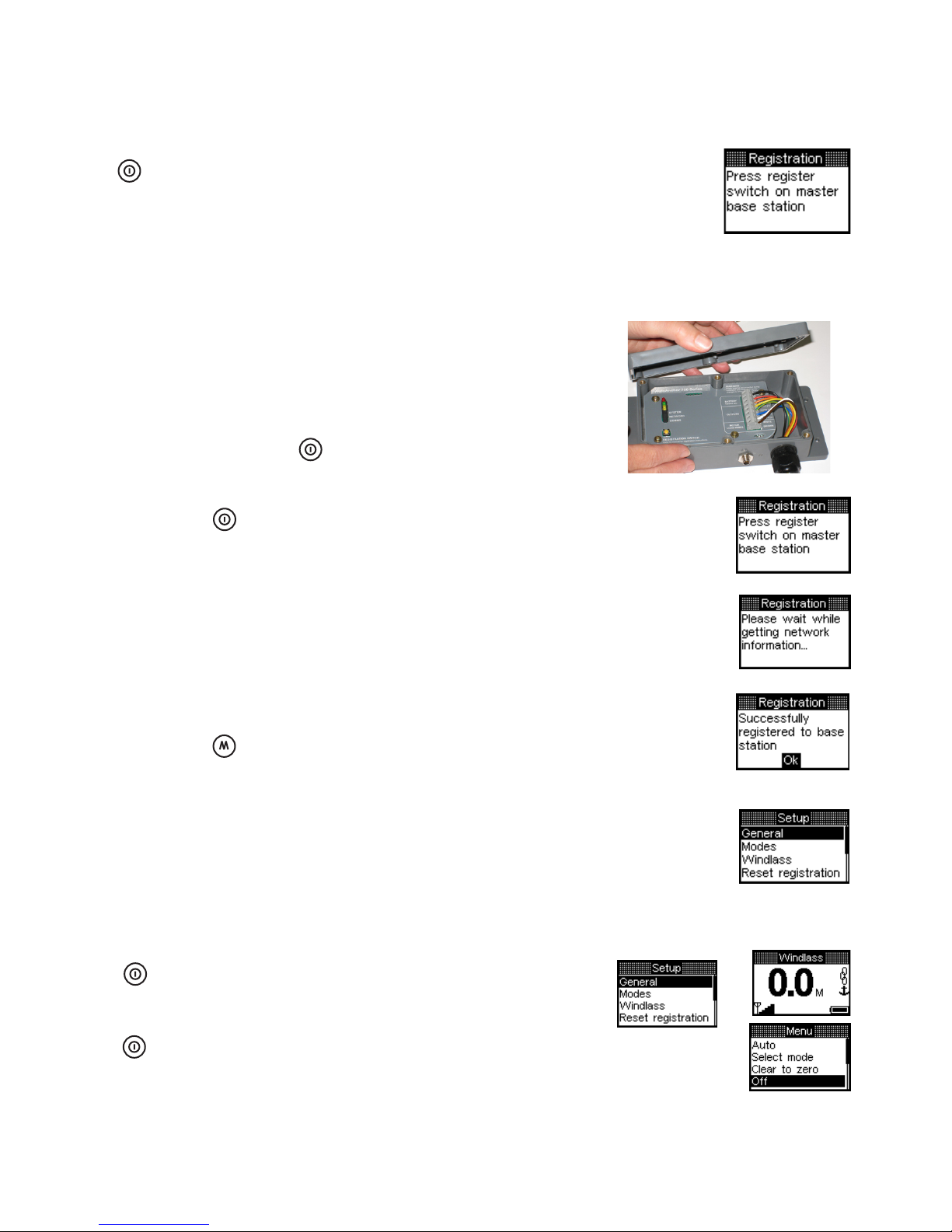

3.2.5 REGISTER REMOTE CONSOLES TO THE BASE STATIONS

Each console must be registered separately.

1. Turn off all consoles.

3. Unscrew and remove the cover from the master base station.

4. Press the Power button to turn on the remote console.

The screen will tell you to “Press the register switch on the

master base station”. NB. On first use AA570 will be on already.

5. Press and release the registration button. The green LED

will stay on. The red LED will ash to indicate the connection

is registering.

6. Registration is automatic. The screen will show that

the system is getting the network information and then

that the console has been successfully registered to the

base station. This could take up to 30 seconds.

7. Press the Mode button to select OK. The console

will return to the set up screen ready to set up the

system functions.

8. If you have more than 1 console to register to the

base station repeat the steps above ensuring the

rst console is turned off before you start.

9. When nished replace the lid on the base station.

3.2.6 TO TURN THE AA570 REMOTE CONSOLE OFF AFTER REGISTRATION

Press the to escape from Setup to

the default start up screen.

3.2.4 TURN THE AA710 SYSTEM ON FOR THE FIRST TIME

Ensure the AA702 base station is powered up.

Press the Power button on the AA570

console to turn it on. Because the system

is not yet set up, the screen will tell you to press

the registration switch on the master base station.

See instructions below to register the console to

to the base station.

Power

Press and hold the Power button for 2 seconds

to switch off.

2. Connect the power to all base stations.

20

3.2.7 Add EXTRA BASE STATIONS (S )

Slave base stations are added to supply the outputs for additional functions. All base

stations are supplied as masters and they must be reset to operate as a slave. Decide

which base station is to remain the master and then follow the directions below to register

the slave stations. Tomaintain power to the windlass it is recommended that it be attached

to the master base station.

1. Ensure all remote consoles are turned off.

2. Unscrew and remove the lid from both base stations.

3. Turn on the power to both base stations. The green LED will light up on both stations.

4. Slave: Hold down the registration button, on the slave station, for 6 seconds until the

green LED turns off. Then release the button. The red LED will ash to indicate the unit

is in registration mode.

5. Master: Press and release the registration button. The green LED will stay on. The red

LED will ash to indicate the connection is registering. Registration is complete when

the red LED stops ashing on both base stations.

6. Repeat the process to add further slave stations as required.

7. Before replacing the lids on the base stations you need to record the unique ID number

for each base station. The ID is on the white label next to the registration switch.

This number is the same as the last 4 digits on the bar code label on the outside of the

base station.

Master Base Station ID ______________

Slave Station 1 ID ______________

Slave Station 2 ID ______________

Note: The console will automatically update and register the additional slave

station when it is next turned on.

801D

Base Station ID

3.2.8 dEREGISTERING A BASE STATION

If a base station is removed or replaced it must be deregistered from the system. To do

this:

Turn the power off to the affected base station and disconnect it. Record the ID number.

Power up the master base station. Turn off the AA

Hold together to display the Set Up Menu. It may take up to

20 seconds for the network information to be updated.

Select Modes.

Scroll to the base station ID.

Select the base station. The screen will show Not Found.

Select Deregister.

Select Deregister again. This will remove the registration

and restart the system.

If you have deregisterered a slave station no further action is required.

If you have deregistered a master base station the system must be set up again as if it is a

new system.

815A

803D

AA570

LAVES )FOR TWINWINdLASS

This manual suits for next models

1

Table of contents

Other Auto Anchor Marine Equipment manuals