Auto Crane 5005H SERIES User manual

5005H

OWNERS MANUAL

Manual No. 360706000

Rev. 07/26/2004

Serial No. __________________

Mailing Address:

P.O. Box 580697

Tulsa, OK 74158-0697

Physical Address: Phone (918) 836-0463

4707 N. Mingo Rd. Fax (918) 834-5979

Tulsa, OK 74117-5904 http://www.autocrane.com

To: Fax:

From: Date:

Re: Pages:

Name: Phone:

Address:

City: State: Zip:

Contact:

Name:

Address:

City: State: Zip:

Contact:

VIN #

ONE REGISTRATION FORM PER UNIT (CRANE OR BODY)

Registration form must be mailed or faxed within 15 days of customer installation.

Mail to:

Warranty Department

Auto Crane Company

P.O. Box 581510

Tulsa, OK 74158-0697

Date Product Delivered: Date Processed:*

* For Auto Crane use only

Product Information: (Required for Warranty Activation)

Model No.: Serial No.:

E-mail Address:

Distributor Information: (Required for Warranty Activation)

Product Registration

E-mail Address:

(Required for Warranty Activation)

Auto Crane Warranty Registration

(918) 834-5979Warranty Department

End User Information:

Fax Transmission

Warranty Registration Rev. 072403

5005H SERIES

OWNER’S MANUAL – REVISION RECORD

i

Revision

Date

Section(s)

Or

Page(s)

Description of Change

09/02/03 Last page New 2-year warranty policy to replace 1-year warranty

policy

12/30/03 Mounting & Instl.

(p. 3-2.0.0)

Lub. & Maintenance

(p.4-1.0.0)

Revised torque specs for mounting hardware for crane,

rotation bearing and rotation gear box.

4/23/04 Pages 3-2.0.0, 5-1.0.0

& 8-9.0.0

Updated receiver & transmitter to 2nd generation

07/26/04 Pages 10-1.0.0, 10-3.0.0,

10-5.0.0, 10-6.0.0, 10-

9.0.0 & 10.10.0.0

Added voltage relay circuit

WARNINGS

READ THIS PAGE

Warnings 12/2002

WARNING! Federal law (49 cfr part 571) requires that the Final Stage Manufacturer of a vehicle

certify that the vehicle complies with all applicable federal regulations. Any modifications performed

on the vehicle prior to the final state are also considered intermediate stage manufacturing and must

be certified as to compliance. The installer of this crane and body is considered on of the

manufacturers of the vehicle. As such a manufacturer, the installer is responsible for compliance

with all applicable federal and state regulations, and is required to certify that the vehicle is in

compliance.

WARNING! It is the further responsibility of the installer to comply with the OSHA Truck Crane

Stability Requirements as specified by 29 CFR part 1910.180 (C) (1).

WARNING! NEVER OPERATE THE CRANE NEAR ELECTRICAL POWER LINES!

Death or serious injury will result from boom, line, or load contacting electric lines. Do not use crane

within 10 feet (3.05m) of electric power lines carrying up to 50,000 volts. One foot additional

clearance is required for every additional 30,000 volts or less. SEE DANGER DECAL (P/N 040529)

in this Owner's Manual.

WARNING! NEVER.........................................

♦ EXCEED load chart capacities (centerline of rotation to hoist hook).

♦ Un-reel last 5 wraps of cable from drum!

♦ Wrap cable around load!

♦ Attempt to lift or drag a load from the side! The boom can fail far below its rated capacity.

♦ Weld, modify, or use unauthorized components on any Auto Crane unit! This will void any

warranty or liability. Also failure of the crane may result.

♦ Place a chain link on the tip of the hook and try to lift a load!

♦ Use a sling bar or anything larger than the hook throat that could prevent the hook latch from

closing, thus negating the safety feature!

♦ Hold on any pendant Select Switch that will cause unsafe operating conditions!

WARNING! In using a hook with latch, ALWAYS make sure that the hook throat is closed before

lifting a load! Proper attention and common sense applied to the use of the hoist hook and various

slings will prevent possible damage to material being hoisted and may prevent injury to personnel.

WARNING! Failure to correctly plumb and wire crane can cause inadvertent operation and damage

to crane and/or personnel!

WARNING! Auto Crane Company remote controlled cranes are not designed or intended to be

used for any applications involving the lifting or moving of personnel.

WARNING! ALWAYS operate the crane in compliance with the load capacity chart. DO NOT USE

the overload shutdown device to determine maximum rated loads, if the crane is equipped with this

type of device.

TABLE OF CONTENTS

5005H SERIES

6/04/2003

INTRODUCTION 1-1.0.0

OPERATING PRACTICES & WARNINGS 2-2.0.0

OPERATION OF UNIT / OUTRIGGERS 2-3.0.0

CONTROLLER OPERATION 2-4.0.0

QUALIFCATIONS FOR OPERATORS 2-6.0.0

INSPECTION, TESTING, & MAINTENCE 2-9.0.0

DECAL SECTION 2-14.0.0

GENERAL DIMENSIONS 3-1.0.0

MOUNTING AND INSTALLATION 3-2.0.0

LUBRICATION AND MAINTENANCE SCHEDULE 4-1.0.0

PEDESTAL ASSEMBLY 5-1.0.0

BOOM ASSEMBLY 5-4.0.0

ROTATION GEAR BOX 5-6.0.0

HOIST ASSEMBLY 5-8.0.0

GENERAL ASSEMBLY 5-11.0.0

ELECTRICAL SCHEMATIC 6-1.0.0

WIRE HARNESS ASSEMBLY 6-2.0.0

HYDRAULIC SECTION 7-1.0.0

DIAGNOSTICS 8-1.0.0

LOAD CHART 9-1.0.0

HARD WIRED SERIES, SUPPLIMENTAL INFORMATION 10-1-0.0

WARRANTY LAST PAGE

NOTES

INTRODUCTION

5005H SERIES

1-1.0.0

12/2002

Auto Crane products are designed to provide

many years of safe, trouble-free, dependable

service when properly used and maintained.

To assist you in obtaining the best service

from your crane and to avoid untimely crane

and/or vehicle failure, this manual provides the

following operating and service instructions. It is

specifically recommended that all operating and

service personnel consider this manual as

mandatory material for reading and study before

operating or servicing Auto Crane products. It is

highly recommended that crane owners,

equipment managers and supervisors also read

this manual.

Auto Crane has incorporated several safety

features in the 5005H crane for your protection.

For your convenience the overall dimensions

of the 5005H crane are included on the General

Dimension Drawing. Rotation and turning radius

are also listed on that drawing.

Remember, the crane adds weight to the

vehicle. Adding weight may change the driving

and riding characteristics of the vehicle unless

the appropriate overload spring(s) are installed

on the truck. The payload of the vehicle is

reduced by the weight of the crane. The operator

should exercise care when loading the vehicle.

Distributing the payload on the vehicle evenly

will greatly improve the driving and riding

characteristics of the vehicle.

Auto Crane Company issues a

limited warranty certificate with each

unit sold. See last page for warranty

The 5005H cranes are attached directly to

your 12 volt truck electrical system. The power

cable is included with the crane. The 5005H is

another highly efficient Auto Crane product.

The use of a maintenance-free battery is not

recommended for use on any Auto Crane

product. The recommended alternator and

battery that will give the longest life with the

most useful duty cycle is a 75 amp alternator

with a 500 cold cranking amp battery. These

specifications should be considered minimum.

It has always been Auto Crane Company

policy to handle all warranty claims we receive

as promptly as possible. If a warranty claim

involves discrepant material or workmanship,

Auto Crane will take immediate corrective

action. It is understandable that Auto Crane

Company cannot assume responsibility of

liability when it is obvious that our products

have been abused, misused, overloaded or

otherwise damaged by inexperienced persons

trying to operate the equipment without reading

the manual.

Auto Crane will not assume

responsibility or liability for any

modifications or changes made to unit,

or installation of component parts done

without authorization.

Auto Crane maintains a strong

distributor network and a knowledgeable

Customer Service Department. In most cases, an

equipment problem is solved via phone

conversation with our customer service

department. The customer service department

also has the ability to bring a local distributor, a

regional sales manager, or a factory serviceman

into the solution of an equipment problem. If,

through no fault of Auto Crane Company, it is

necessary to send an experienced factory

serviceman on a field service call, the rates stated

in the Auto Crane Distributor's Flat Rate Manual

will apply.

Auto Crane Company's extensive

Research and Development Program allow our

customers to use the best equipment on the

market. Our Engineering Staff and our

knowledgeable sales people, are always available

to our customers in solving crane and winch-type

application problems. When in doubt, call the

Auto Crane factory.

DISTRIBUTOR ASSISTANCE:

Should you require any assistance not given

in this manual, we recommend that you consult

your nearest Auto Crane Distributor. Our

distributors sell authorized parts and have service

departments that can solve almost any needed

repair.

NOTE: THIS MANUAL SHOULD REMAIN

WITH THE CRANE AT ALL TIMES.

This manual does not cover all maintenance,

operating, or repair instructions pertinent to all

possible situations. If you require additional

information, please contact the Auto Crane

Company at the following telephone number:

(918) 836-0463. The information contained in

the manual is in effect at the time of this

printing. Auto Crane Company reserves the right

to update this material without notice or

obligation.

--- IMPORTANT ---

SAFETY TIPS AND PRECAUTIONS

1. No unqualified or unauthorized person shall be

allowed to operate the crane.

2. WARNING: Never weld, modify, or use

unauthorized components / parts on any Auto Crane

unit. This will void any warranty or liability. Also,

failure of the crane may result.

3. Make certain the vehicle meets minimum chassis

requirements. (These requirements do not guarantee

unit stability.)

4. Make certain the crane is installed per factory

specifications. Contact your local distributor or the

Auto Crane factory if any questions arise.

5. Visual inspections and tests should be conducted at

the beginning of each shift each day to ensure that the

crane and all its operating systems are in good

condition and working order before it is used.

6. Inspect hydraulic hoses frequently for signs of

deterioration, and replace them as required.

7. If a hydraulic break occurs, leave the area of the

break and do not attempt to stop the break by hand as

the hydraulic oil may be hot and under high pressure

which can cause serious injury. Shut the system

down as soon as possible.

8. Check the hook at least every thirty days for

distortions or cracks and replace it as required.

9. Oil gears as required.

10. Stop all operations when cleaning, adjusting or

lubricating the machine.

11. Keep dirt and grit out of moving parts by keeping a

crane clean. Make sure machine is free of excess oil,

grease, mud and rubbish, thus reducing accidents and

fire hazards.

12. When a new cable is installed, operate first with a

light load to let the cable adjust itself.

13. Locate the vehicle at the work site for the best

stability possible.

14. Keep the vehicle in a level position while loading or

unloading.

15. Observe operating area for obstructions and/or power

lines that might be a hazard

16. WARNING: NEVER OPERATE THE CRANE

NEAR ELECTRICAL POWER LINES. Auto Crane

Company recommends that the crane never be any

closer to a power line (including telephone lines) than

10 feet at any point.

17. Allow the vehicle engine to warm up before

operating crane.

18. Know the weight of your rigging and load to avoid

overloading the crane.

19. Deduct the weight of the load handling equipment

from the load rating to determine how much weight

can be lifted.

20. All load ratings are based on crane capacity, NOT the

vehicle stability.

Remember in lifting a heavy load, the weight can

create enough tipping moment to overturn the vehicle

21. Always comply with load chart capacities, (centerline

of rotation to hook).

22. Secure all loads before lifting.

23. Always set the emergency brake before beginning

operation.

24. Keep objects and personnel clear of crane path during

operation.

25. Operate control levers slowly and smoothly in order

to meter oil flow for safe operation.

26. Always use outriggers from vehicle to the ground

during crane operation. Ensure that they are firmly

positioned on solid footings. Stand clear of

outriggers while they are being extended.

27. If any outrigger, when extended, rests on a curb or

other object that prevents it from extending to its

maximum distance, shorten bearing or fulcrum point

and reduce the maximum load accordingly.

28. When an outrigger will not reach the ground due to

holes or grades, it shall be blocked up to provide

level and firm support for the truck.

29. When working in soft earth, use wide pads under

outrigger feet to prevent sinking.

30. Always store outriggers before transportation.

WARNING!

Auto Crane Company cranes are not designed or intended for use in lifting or moving persons. Any such use

shall be considered to be improper and the seller shall not be responsible for any claims arising there from.

This sale is made with the express understanding that there is no warranty that the goods shall be fit for the

purpose of lifting or moving persons or other improper use and there is no implied warranty or responsibility

for such purposes.

2-1.0.0

12/2002

--- IMPORTANT ---

SAFETY TIPS AND PRECAUTIONS

31. Always store the crane in its stowed position for

transportation.

32. Remember the overall height of the entire unit for

garage door clearance or when moving under

objects with low overhead clearance

33. Disengage power takeoff (PTO) before moving

the vehicle.

34. Always walk around the vehicle before moving.

35. Never drive with a load suspended from crane.

36. Do not take your eyes off a moving load. Look

in the direction you are moving.

37. Never swing a load over people.

38. Do not stop the load sharply in midair so that it

swings like a pendulum. Meter the control levers

to avoid this situation.

39. Crane boom length should be kept as short as

possible for maximum lifting capacity and greater

safety. Longer booms require additional care in

accelerating and decelerating the swing motion,

and thus slow down the working cycle and reduce

productivity.

40. Keep the load directly and vertically under the

boom point at all times. Crane booms are

designed primarily to handle vertical loads, not

side lifts.

WARNING: Never attempt to lift, drag, tow or

pull a load from the side. The boom can fail far

below its rated capacity.

41. Do not push down on anything with boom

extensions, lift or outer boom function.

42. Do not lift personnel with any wire rope

attachment or hook. There is no implied

warranty or responsibility for such purposes.

43. WARNING: In using a safety hook, ALWAYS

close the hook throat before lifting a load. Proper

attention and common sense applied to the use of

the hook and various slings will prevent possible

damage to material being hoisted and may

prevent injury to personnel.

44. WARNING: Never place a chain link on the tip

of the hook and try to lift a load with the hoist.

45. WARNING: Never use a sling bar or anything

larger than the hook throat which could prevent

the safety latch from closing, thus negating the

safety feature.

46. If the crane is equipped with an optional winch:

do NOT allow personnel to ride on

loadline, hook, load, or any other device

attached to winch line.

do NOT extend boom without reeling off

line at the same time when using winch.

do pull load-block up against the boom tip.

47. Do not wrap the wire rope around sharp objects

when using winch.

48. WARNING: Never unreel last 5 wraps of cable

from drum.

2-1.1.0

12/2002

--- IMPORTANT ---

OPERATING PRACTICES AND WARNINGS

1. Make certain the vehicle meets minimum chassis

requirements. (These requirements do not guarantee unit

stability)

2. Make certain the crane is installed per factory

specifications. Contact your local Distributor or the

Auto Crane factory if any questions arise.

3. Keep the vehicle in as level a position as possible while

loading or unloading.

4. ALWAYS set the vehicle emergency brake before

beginning crane operations.

5. ALWAYS use outriggers from vehicle to the ground

during crane operation. Make sure they are firmly

positioned on solid footings.

6. All load ratings are based on crane capacity, NOT

truck/crane stability.

7. Keep objects and personnel clear of crane path during

operation.

8. Keep hoist cable pulled tight at all times.

9. REMEMBER, in lifting a heavy load, the weight can

create enough tipping momentum to overturn the

vehicle.

10. ALWAYS keep load as close to ground as possible.

11. Hydraulic hoses need to be inspected frequently for signs

of deterioration, and be replaced as required.

12. The hoist hook is an important item that an operator

should consider and use properly. It should be checked

on a daily basis for distortion or cracks.

13. ALWAYS store outriggers before road travel.

14. WARNING! NEVER OPERATE THE CRANE

NEAR ELECTRICAL POWER LINES! Death or

serious injury will result from boom, line, or load

contacting electric lines. Do not use crane within 10

feet (3.05m) of electric power lines carrying up to

50,000 volts. One foot additional clearance is required

for every additional 30,000 volts or less.

15. WARNING! NEVER EXCEED load chart

capacities (centerline of rotation to hoist hook).

16. WARNING! NEVER un-reel last 5 wraps of cable

from drum!

17. WARNING! NEVER wrap cable around load!

18. WARNING! NEVER attempt to lift or drag a load

from the side! The boom can fail far below its rated

capacity.

19. WARNING! NEVER weld, modify, or use

unauthorized components on any Auto Crane unit!

This will void any warranty or liability. Also failure

of the crane may result.

20. WARNING! NEVER place a chain link on the tip of

the hook and try to lift a load!

21. WARNING! NEVER use a sling bar or anything

larger than the hook throat that could prevent the hook

latch from closing, thus negating the safety feature!

22. WARNING! In using a hook with latch, ALWAYS

insure that the hook throat is closed before lifting a

load! Proper attention and common sense applied to

the use of the hoist hook and various slings will

prevent possible damage to material being hoisted and

may prevent injury to personnel. Switch on that will

cause unsafe operating conditions!

WARNING! NEVER hold any Control Select

Switch on that will cause unsafe operating conditions!

WARNING!

Auto Crane Company remote controlled, stiff boom

cranes are not designed or intended to be used for any

applications involving the lifting or moving of personnel.

2-2.0.0

12/2002

--- IMPORTANT ---

OPERATION OF UNIT

1. Make sure this manual has been thoroughly read by

all crane operating personnel and supervisors.

2. A routine inspection of the crane should be

mandatory before each operating day. Any defects

should be corrected immediately.

3. At a job site the vehicle should be positioned so that

the crane can adequately reach the load within the

rated capacity (centerline of rotation to hoist hook).

4. Keep the vehicle as level as possible during

operation.

5. For electric cranes, engage emergency brake and

leave ignition on with transmission in neutral (or in

park for automatic transmissions). Activate any

crane power switches. For Auto Crane units

requiring battery and hydraulic operation, engage

emergency brake, place gear selector in neutral,

press clutch, activate PTO, release clutch and after

hydraulic fluid is warm, set throttle control to proper

engine speed.

6. Always use outriggers from the truck to the ground.

Be sure these are firm and adequately positioned.

When rotating, keep load as low to the ground as

possible.

7. Remove the transmitter from cab or storage area.

Power transmitter on. Detach hook from dead man.

Crane is now ready for operation.

8. Always boom up before rotating so the boom will

clear the required boom support.

9. When extending the boom, always maintain clearance

between the boom crown and the traveling block or

hoist hook.

10. Always observe safe and practical operation to avoid

possible accidents. Refer to Safety Tips and

Precautions.

11. After completing lifting operations, return the boom to

stowed position on the boom support. Avoid

unneeded pressure on the boom support.

12. Store transmitter in proper location (in cab or storage

area).

13. Return outriggers to stowed position. Make sure they

are pinned in place or jacklegs are returned to

compartment.

14. Check work area for any tools or equipment not

stored.

15. Release throttle control, depress clutch and disengage

PTO. Deactivate any crane power switches.

16. Report any unusual occurrence during crane operation

that may indicate required maintenance or repair.

17. NEVER use two cranes to support a load too large for

either crane.

OPERATION OF

OUTRIGGERS

For hydraulic outriggers:

1. Shift crane/outrigger control valve to

"outrigger" position.

2. Operate the outrigger control valves (located

on the outrigger cylinders) to position the

outriggers.

3. After outriggers are positioned, return

crane/outrigger selector to "crane" position.

4. Crane is now ready to operate.

For manual outriggers:

1. Pull lock pins to release jack leg or drop down

outrigger and move to outermost lock position.

2. Make sure lock pins are reinstalled properly.

3. Lower outrigger pad to firm ground and adjust

foot to take out slack.

4. Crane is now ready to operate.

2-3.0.0

12/2002

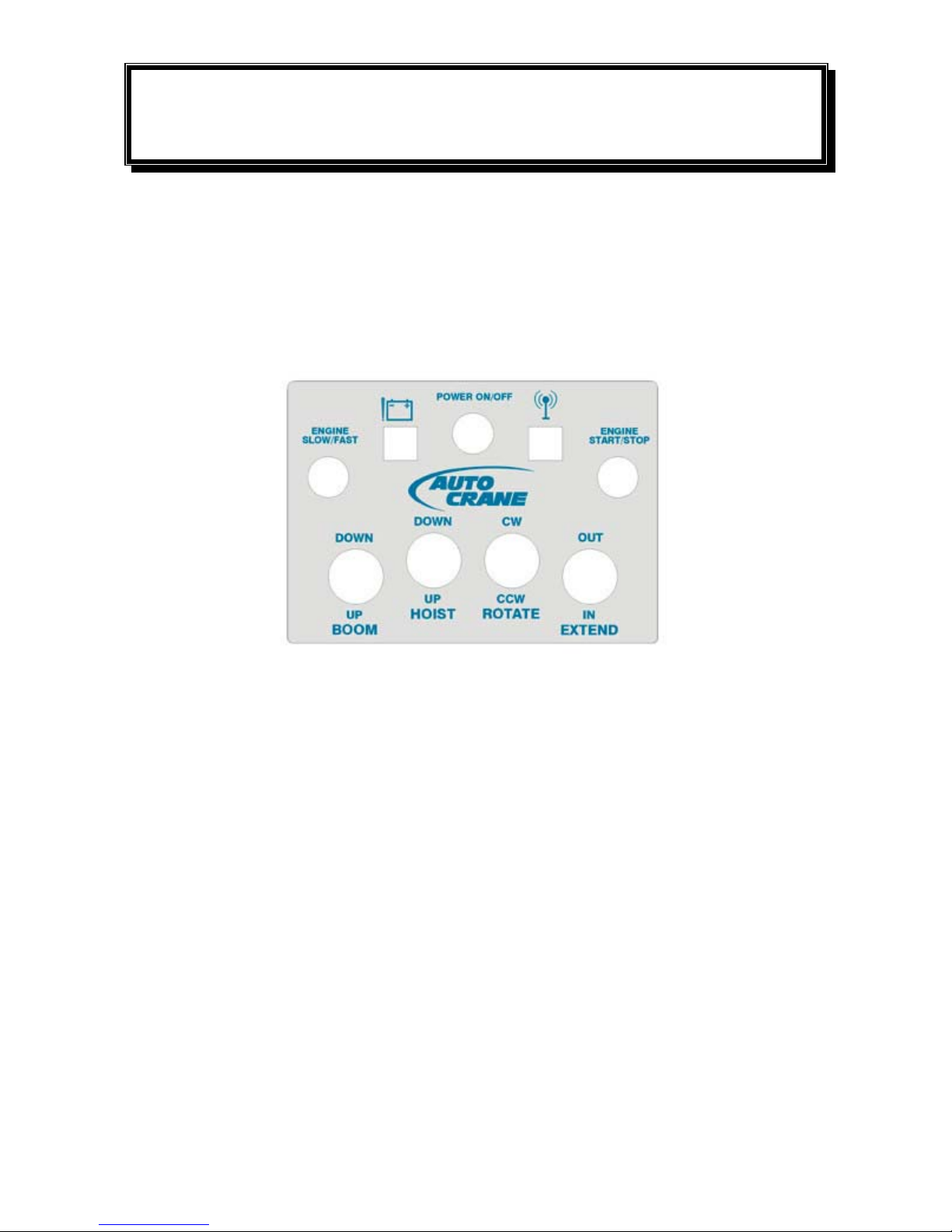

CONTROLLER OPERATIONS

Transmitter Layout: The red light to the left of the Power On/Off button indicates low

transmitter battery. As the battery runs down, the light will begin to flash. It will flash increasingly

faster as the battery power decreases. (see “Charging the Transmitter”)

The green light to the right of the Power On/Off button indicates that the unit is

transmitting. This light will flash when a function is activated.

In addition to the two lights mentioned above there are four function toggle switches.

These functions from left to right are used to raise and lower the boom, raise and lower the hoist

cable, rotate the crane and extend and retract the boom. There are also buttons for auxiliary

functions such as Engine Start/Stop and Engine Fast Idle.

Power On/Off (E-Stop) Button: To turn the transmitter on, press and hold the Power On/Off

button, release once the transmit light becomes solid. To turn the unit off, press and hold the

power button, release once the transmit light stops flashing. When this button is pressed both the

red battery low and the green transmit light will flash alternately and stop flashing once the unit is

either on or off.

IMPORTANT – THE POWER ON/OFF BUTTON ALSO OPERATES AS AN E-STOP.

PRESS THE BUTTON MOMENTARILY TO DISABLE CRANE FUNCTIONS. THE E-

STOP WILL NOT STOP THE TRUCK ENGINE.

Function Switches: To operate a function, toggle one of the function switches with either the

thumb of the hand holding the unit or the thumb or fingers of the opposite hand. Using the

forefinger of the hand holding the unit, slowly pull the trigger back to start the function. The speed

of the function increases as the trigger is pulled. More than one function can be activated at one

time.

NOTE: A FUNCTION SWITCH MUST BE ACTIVATED BEFORE THE TRIGGER IS

PULLED OR THE CRANE WILL NOT OPERATE.

2-4.0.0

12/2002

CONTROLLER OPERATIONS

Auxiliary Buttons:

Functions described in this paragraph will not worked if not properly connected to the

vehicle at the time of installation. Press the Engine Fast/Slow button to provide a maintained

voltage to a throttle control. To stop the engine, press the Engine Start/Stop button. To start the

engine, press the Engine Start/Stop button a second time within five (5) seconds of releasing it.

To activate the auxiliary function, press the Engine Fast/Slow and the Engine Start/Stop buttons

simultaneously.

Safety Features:

For safety reasons the speed of all functions, excluding the hoist, is reduced when the lift

cylinder pressure exceeds a set pressure. This will occur under load or under boom down

operation. To limit slow operation of an unloaded crane, activate boom up momentarily after

booming down to relieve cylinder pressure created by the counterbalance valve.

The crane is also equipped with an anti-bridging feature. The logic in the receiver will not

allow the operator to rest the boom of the crane on a load supporting structure and lift a load.

Doing so is dangerous and could damage the crane. When the crane is bridged, the receiver will

display ‘RSBM’ which requires the boom to be raised. This feature is disabled when the crane is

in the ‘HOME’ position to allow for stowing. When in the ‘HOME’ position, the hoist is also slowed

to prevent inadvertent damage to the crane or boom support.

Operation Failure:

If the crane does not operate as expected, observe the readout through the window on

the receiver and refer to the front panel for explanation. The codes are further explained in the

Diagnostics section of this manual. Please note that ‘NRML’ is displayed when the crane is

operating normally, ‘HOME’ is displayed when the crane is forward and in a position to be stowed

and ‘SLOW’ is displayed when functions are slowed due to load.

Charging the Transmitter:

The transmitter can be charged using one of three methods. It can be charged with the

cigarette lighter charger, the pendant cable or the optional AC adapter (P/N 366505000). To

charge the transmitter with the pendant cable, the crane must have electrical power. The crane

can be operated by pendant or by FM remote therefore the battery can be charged without

suspending operation of the crane.

The transmitter should be fully charged after approximately 6 to 8 hours of charging. It is

not recommended to leave the transmitter charging for extended periods of time (3 or 4 days).

Doing so will eventually degrade the battery and it will not keep a good charge.

2-5.0.0

12/2002

QUALIFICATIONS FOR AND CONDUCT OF OPERATORS

AND OPERATING PRACTICES

OPERATORS

1. Crane operation shall be limited to personnel with

the following minimum qualifications:

A. Designated persons.

B. Trainees under the direct supervision of a

designated person.

C. Maintenance and test personnel (when it is

necessary in the performance of their duties).

D. Inspectors (crane).

2. No one other than the personnel specified above

shall enter the operating area of a crane with the

exception of persons such as oilers, supervisors,

and those specified persons authorized by

supervisors whose duties require them to do so and

then only in the performance of their duties and

with the knowledge of the operator or other

persons.

QUALIFICATIONS FOR OPERATORS

3. Operators shall be required by the employer to

pass a practical operating examination.

Qualifications shall be limited to the specific type of

equipment for which examined.

4. Operators and operator trainees shall meet the

following physical qualifications:

A. Vision of at least 20/30 Snellen in one eye and

20/50 in the other, with or without corrective

lenses.

B. Ability to distinguish colors, regardless of position,

if colors differentiation is required for operation.

C. Adequate hearing with or without hearing aid for

the specific operation.

5. Evidence of physical defects or emotional

instability which render a hazard to operator or

others, which in the opinion of the examiner could

interfere with the operator's performance may be

sufficient cause for disqualification. In such cases,

specialized clinical or medical judgment and tests

may be required.

6. Evidence that the operator is subject to seizures or

loss of physical control shall be sufficient reason for

disqualification. Specialized medical tests may be

required to determine these conditions.

7. Operators and operator trainees should have

normal depth perception, coordination, and no

tendencies to dizziness or similar undesirable

characteristics.

8. In addition to the above listed requirements, the

operator shall:

A. Demonstrate the ability to comprehend and

interpret all labels, operator's manuals, safety

codes and other information pertinent to correct

crane operations.

B. Possess knowledge of emergency procedures and

implementation of same.

C. Demonstrate to the employer the ability to operate

the specific type of equipment.

D. Be familiar with the applicable safety regulations.

E. Understand responsibility for maintenance

requirements of crane.

F. Be thoroughly familiar with the crane and its

control functions.

G. Understand the operating procedures as outlined

by the manufacturer.

CONDUCT OF OPERATORS

9. The operator shall not engage in any practice,

which will divert his attention while actually

operating the crane.

10. Each operator shall be responsible for those

operations under the operator's direct control.

Whenever there is any doubt as to safety, the

operator shall consult with the supervisor before

handling the loads.

11. The operator should not leave a suspended load

unattended unless specific precautions have been

instituted and are in place.

12. If there is a warning sign on the switch or engine

starting controls, the operator shall not close the

switch or start the engine until the warning sign

has been removed by the appointed person.

13. Before closing the switch or starting the engine,

the operator shall see that all controls are in the

"OFF" or neutral position and all personnel are

in the clear.

14. If power fails during operation, the operator shall:

A. move power controls to the "OFF" or neutral

position.

B. land the suspended load and boom, if practical.

2-6.0.0

12/2002

QUALIFICATIONS FOR AND CONDUCT OF OPERATORS

AND OPERATING PRACTICES

15. The operator shall be familiar with the equipment

and its proper care. If adjustments or repairs are

necessary, the operator shall report the same

promptly to the appointed person, and shall also

notify the next operator.

16. All controls shall be tested by the operator at the

start of each shift. If any controls do not operate

properly, they shall be adjusted or repaired

before operations are begun

17. Stabilizers shall be visible to the operator while

extending or setting unless operator is assisted by

a signal person.

OPERATING PRACTICES

HANDLING THE LOAD

18. Size of load

A. No crane shall be loaded beyond the rated load

except for test purposes.

B. The load to be lifted is to be within the rated load

of the crane and its existing configuration.

C. When loads which are not accurately known are

to be lifted, the person responsible for the job

shall ascertain that the weight of the load does not

exceed the crane rated load at the radius at which

the load is to be lifted.

19. Attaching the load

A. The load shall be attached to the hook by means

of slings or other devices of sufficient capacity.

B. Hoist rope shall not be wrapped around the load.

20. Moving the load

A. The operator shall determine that:

B. The crane is level and, where necessary, the

vehicle/carrier is blocked properly.

C. The load is well secured and balanced in the

sling or lifting device before it is lifted more

than a few inches.

D. Means are provided to hold the vehicle

stationary while operating the crane.

E. Before starting to lift, the hook shall brought

over the load in such a manner as to minimize

swinging.

F. During lifting care shall be taken that:

1. There is no sudden acceleration or

deceleration of the moving load.

2. Load, boom or other parts of the crane do

not contact any obstruction.

G. Cranes shall not be used for dragging loads

sideways.

H. This standard recognizes that articulating boom

cranes are designed and intended for handling

materials. They do not meet personnel lift or

elevator requirements. Therefore, no lifting,

lowering, swinging or traveling shall be done

while a person is on the hook or load. Hook

attached suspended work platforms (baskets)

shall not be used with cranes covered by this

standard. Work platforms attached to the boom

must be approved by crane manufacturer.

I. The operator should avoid carrying loads over

people.

J. When the crane is so equipped, the stabilizers

shall be fully extended and set. Blocking under

stabilizers shall meet the requirements as

follows:

1. Strong enough to prevent crushing.

2. Of such thickness, width and length as to

completely support the stabilizer pad.

K. Firm footing under all tires, or individual

stabilizer pads should be level. Where such a

footing is not otherwise supplied, it should be

provided by timbers, cribbing, or other structural

members to distribute the load so as to not

exceed allowable bearing capacity or the

underlying material.

L. In transit, the boom shall be carried in stowed

position.

M. When rotating the crane, sudden starts and stops

shall be avoided. rotational speed shall be such

that the load does not swing out beyond the

radius at which it can be controlled.

N. The crane shall not be transported with a load on

the hook unless recommended by the

manufacturer.

O. No person should be permitted to stand or pass

under a suspended load.

21. Stowing procedure. Follow the manufacturer's

procedure and sequence when stowing and un-

stowing the crane

2-7.0.0

12/2002

QUALIFICATIONS FOR AND CONDUCT OF OPERATORS

AND OPERATING PRACTICES

MISCELLANEOUS

OPERATING NEAR ELECTRICAL POWER

LINES

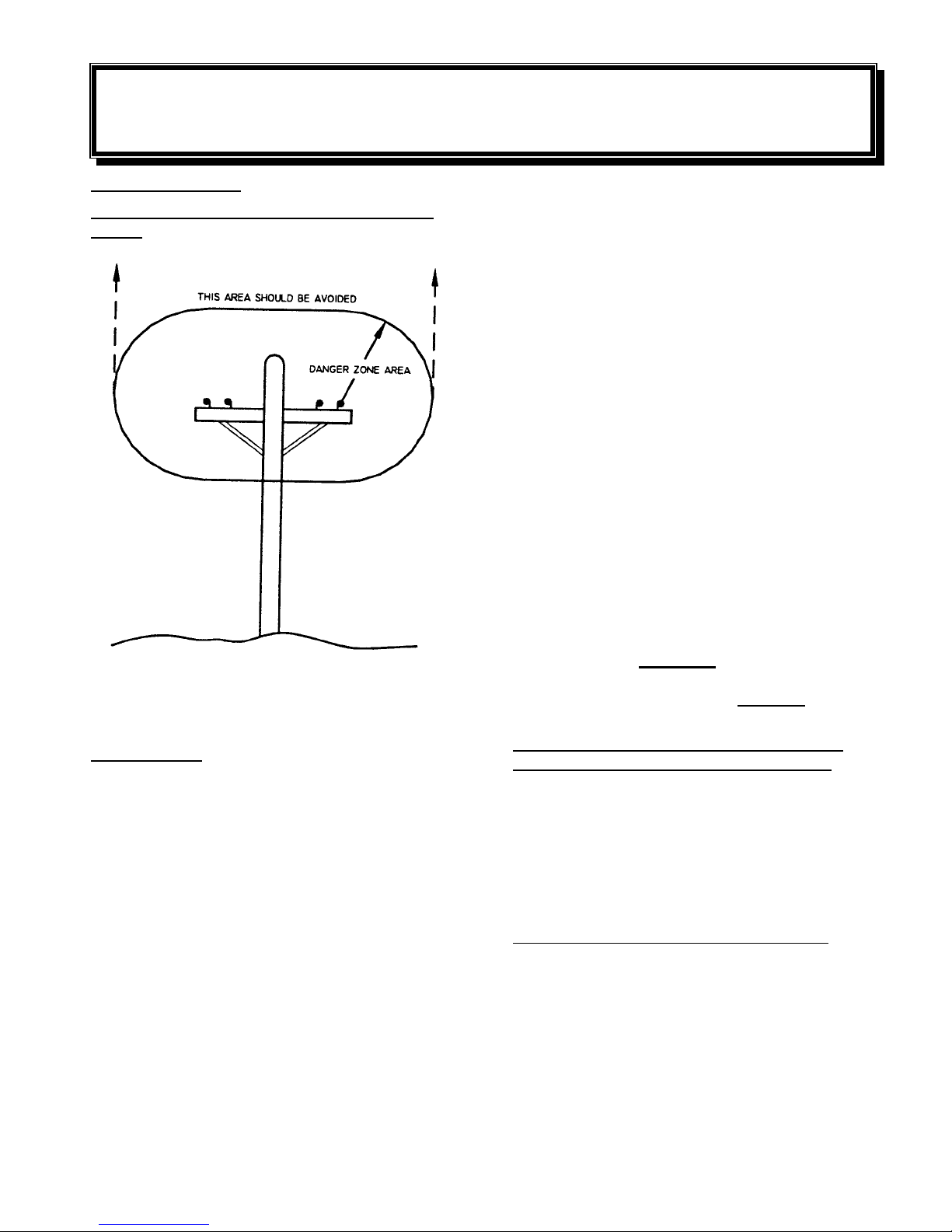

22. Cranes shall be operated so that no part of the

crane or load enters into the danger zone shown

above.

EXCEPTIONS

A. The danger zone may be entered after confirmation

by an appointed person that the electrical distribution

and transmission lines have been de-energized and

visibly grounded at the point of work; or

B. The danger zone may be entered if insulating

barriers (not a part of nor an attachment to the crane)

have been erected to prevent physical contact with

the lines.

23. For lines rated 50 kV or below, minimum

clearance between the lines and any part of the

crane or load (including handling appendages)

shall be 10-ft. (3m). For higher voltages, see

Table1.

24. Caution shall be exercised when working near

overhead lines, because they can move

horizontally or vertically due to wind, moving the

danger zone to new positions.

25. In transit with no load and boom lowered the

clearance shall be specified in Table 1.

26. A qualified signalperson shall be assigned to

observe the clearance and give warning before

approaching the above limits.

A. Any overhead wire shall be considered to be an

energized line unless and until the person

owning such line or the electrical utility

authorities verify that it is not an energized line.

B. Exceptions to this procedure, if approved by the

administrative or regulatory authority if the

alternate procedure provides equivalent

protection and set forth in writing.

C. Durable signs shall be installed at the operator's

station and on the outside of the crane, warning

that electrocution or serious bodily injury may

occur unless a minimum clearance of 10 ft.

(3.0m) between the crane or the load being

handled and energized power lines. Greater

clearances are required because of higher

voltage as stated above. These signs shall be

revised but not removed when local jurisdiction

requires greater clearances.

normal voltage, kV

(phase to phase) ft (m)

over to 50 10 (3.50)

over 50 to 200 15 (4.6)

over 200 to 350 20 (6.1)

over 350 to 500 25 (7.62)

over 500 to 750 35 (10.67)

over 750 to 1000 45 (13.72)

over to 0.75 4 (1.22)

over 0.75 to 50 6 (1.83)

over 50 to 345 10 (3.83)

over 345 to 750 16 (4.87)

over 750 to 1000 20 (6.1)

while in transit with no load and boom lowered

TABLE 1

minimum required

____clearance____

when operatin

g

near hi

g

h volta

g

e poower lines

2-8.0.0

12/2002

Other manuals for 5005H SERIES

1

Table of contents

Other Auto Crane Lifting System manuals

Popular Lifting System manuals by other brands

POP UP

POP UP PUSH 8 ECO Operator's Safety and Maintenance Handbook

HydroHoist

HydroHoist HarborHoist Triton owner's manual

Challenger Lifts

Challenger Lifts CL16 Series Installation, operation and maintenance manual

K Tool International

K Tool International XD KTI-63414A owner's manual

morse

morse 82H-124 Operator's manual

Kleton

Kleton MJ521 instruction manual