15

EN

1. Place the high spacers on the mounting

bracket, according to picture.

2. Separate the upper plate (M6 nut) from

the lower, to be able to reach the outer rear

hole. Use the countersunk M8 screw.

3. Use the front set of holes in the lower plate of Turnout

and x Turnout with 4 pcs M8x50 screws through the spa-

cers and the mounting bracket.

1. Pull the lower part of the spacers backwards and remove the

screws placed in the front part of the rail attachment in Turnout.

Then pull the lower part of the rail maximum forward.

2. Place the Turnout, with the protecting proles under the rails,

on the spacers. Move the rail to the side (Fig.1) to be able to

screw an M8x30 screw through the front hole of the lower part

of the rail, the protecting prole, the spacers and the mounting

bracket. Repeat on the opposite side.

3. Pull Turnout forward on the rails and screw Turnout back

into the front part of the rails again.

4. Screw M8x30 screws through the rear holes of the rails,

the protecting proles, the spacers and the mounting

bracket. (Fig.2)

Fig. 1

Fig. 2

• For Turnout 4E and 4:

• Change of movement for Turnout 4 and 4E:

Low type slewing

bracket attachment

When using an open slewing bracket, the Turnout swivels

slightly outwards before moving forward and then swivel-

ling out. This provides extra space for a person sitting in

driver position where the space by steering wheel is snug.

The distance to the B-pillar can be reduced by 4 cm with

an open slewing bracket, compared to using the standard

slewing bracket.

The bracket is mounted with the oblong hole to the up-

per plate of Turnout and the circular hole to the slewing

bracket attachment on the lower plate.

For Turnout 4 E, use a low type slewing bracket attach-

ment and the spacer (included in the package). The spa-

cer is mounted between the oblong hole of the slewing

bracket and the attachment in the upper plate of Turnout.

Openslewing bracket

Standard slewing bracket

IMPORTANT!

When reuniting the plates, tighten the M6 nut using 50 Nm.

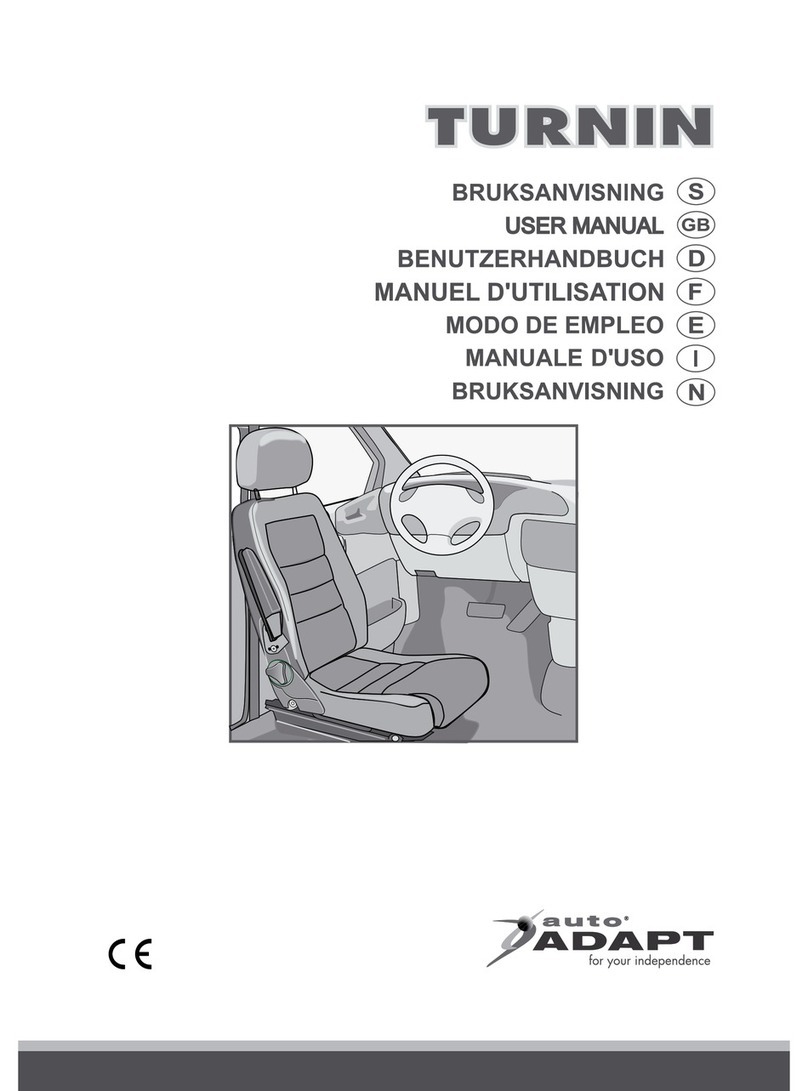

• For Turnout 2E and 2:

Spacer, high

TURNOUT 2E

TURNOUT 2

The open slewing bracket

mounted on Turnout.

Turnout 4: # 101685

Turnout 4E: # 102242