Autojack TJ250 Installation manual

SAFETY AND OPERATING MANUAL

TROLLEY JACK

TJ250

TJ250

ORIGINAL INSTRUCTIONS

Made in China

160120 Version 1

TJ250

TABLE OFCONTENTS

Safety Precautions .01

MachineDetails ..03

Operation .04

Maintenance ....06

Troubleshooting ..07

DeclarationofConformity 09

Parts list ..10

Parts Diagram 11

TJ250

01

SAFETYPRECAUTIONS

Important: Read these instructions carefully. Note THE SAFE

OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS.

USE THIS JACK CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. Failure to do so may

cause damage or personal injury. Retain THESE INSTRUCTIONS

for future use.

-Ensure the jack is in sound condition and good working order. Take

action for immediate repair or replacement of damaged parts.

-Use genuine parts only. The use of improper parts may be

dangerous.

-Locate the jack in a suitable, well-lit working area. Keep working

area clean and tidy and free from unrelated materials.

-Use the jack on level and solid ground, preferably concrete. Avoid

tarmacadam as jack may sink in.

-Place wedges under the wheels of vehicle, but ensure the jack

wheels are free to move and that there are no obstructions.

-Ensure the vehicle handbrake is engaged, engine is switched off

and transmission is in gear (or “PARK” if automatic).

-Ensure minimum distance of 0.5m between vehicle and static

objects such as doors, walls, etc., to allow for vehicle tilting.

-Ensure there are no passengers in the vehicle and that all non-

essential persons keep a safe distance whilst the jack is in use.

-Place jack under lifting points recommended by vehicle

manufacturer (see vehicle hand book). Ensure lifting point is stable

and centred on Saddle.

-NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF

THIS PRODUCT.

TJ250

02

SAFETY PRECAUTIONS

DANGER: Use the jack for lifting only, NOT for supporting the lifted

load.

-Use suitable capacity

axle stands under the vehicle before

proceeding with any task.

-Ensure there are no persons or obstructions beneath the vehicle

before lowering.

-DO NOT operate the jack if damaged.

-DO NOT work under the vehicle until axle stands have been

correctly positioned.

-DO NOT exceed the rated capacity of the jack (3.0tonne).

When lifting a load of maximum capacity or close to it, it is

recommended that the effort be reduced by the use of

assistance during this operation.

-DO NOT adjust the safety overload valve.

-DO NOT jack vehicle if there is a risk of spillage of fuel,

battery acid, or other dangerous substances.

-DO NOT allow the vehicle to move while supported by the

jack, or use the jack to move the vehicle.

-DO NOT top up the hydraulic system with brake fluid. Use

hydraulic jack oil only and use a qualified person to maintain

jack hydraulic system.

-DO NOT allow untrained persons to operate the jack and DO

NOT use the jack for purposes other than which it is designed.

-DO NOT allow persons to ride on the jack.

-When not in use store the jack, fully lowered, in a safe, dry,

childproof area.

TJ250

03

MACHINE DETAILS

Specifica ons

Capacity - 2.5 Tonne

Min. Saddle height - 80mm

Max. Saddle height - 515mm

Length - 722mm

Weight - 34.1KG

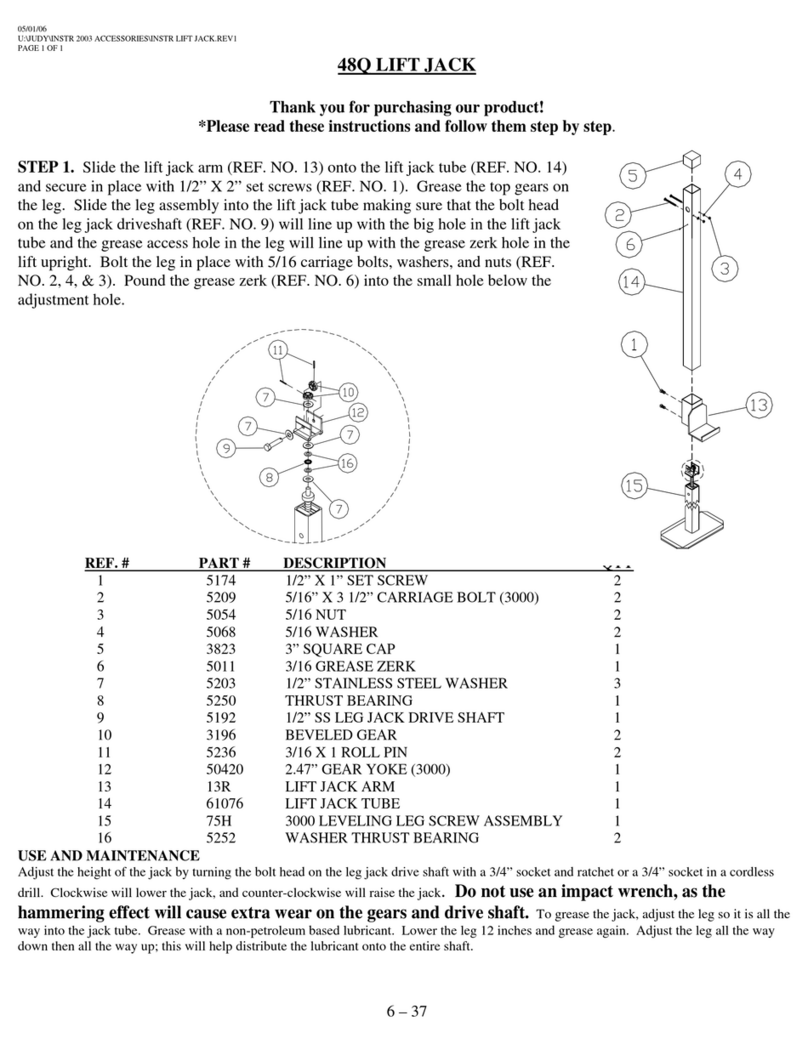

Product Features

8

9

7

6

5

4

3

2

1

load:360-515mm

1. Bottom floor jack pump

handle

2. Pump handle socket

3. Floor Jack frame

4. Pump handle hex bolt

5. Pump system

6. Castor wheel

7. Fixed wheel

8. Saddle

9. Lifting arm

TJ250

04

Operation

The owner and/ or operator shall

have an understanding of the

product, its operating characteristics

and safety operating instructions

before operating this device.

Safety information shall be

emphasized and understood. If the

operator is not fluent in English, the

product and safety instructions shall

be read to and discussed with the

operator in the operator’s native

language by the purchaser/owner or

his designee, making sure that the

operator comprehends their contents.

Inspection

a. Visual inspection shall be made

before each use of the jack by

checking for abnormal

conditions, such as cracked

welds, leaks, and damaged,

loose, or missing parts.

b. Other inspections shall be made

as per product operating

instructions.

c. This jack should be inspected

immediately if the jack is

believed to have been subject to

an abnormal load or shock. It is

recommended that this

inspection be made by a

manufacturer’s or supplier’s

authorised repair facility.

d. Owners and/or operators should be

made aware that the repair of this

equipment may require specialised

knowledge and facilities. It is

recommended that an annual

inspection of the product be made

by a manufacturer’s or supplier’s

authorised repair facility and that

any defective parts, safety labels or

signs be replaced with

manufacturers or supplier’s specified

parts.

Damaged Equipment

Any jack that appears to be damaged

in any way, is found to be worn, or

operates abnormally must be

removed from service until repaired.

It is recommended that necessary

repairs are to be made by a

manufacturer’s or supplier’s authorised

repair facility, if repairs are permitted by

the manufacturer or supplier.

Alterations

Due to the potential hazards

associated with this type of equipment,

no alterations shall be made to the

product.

Attachments & Adapters.

Only attachments and/or adapters

supplied by the manufacturer shall be

used.

TJ250

05

Before use

a. Before using jack for the first

time, purge the hydraulic unit in

order to eliminate any air in the

system. Place handle onto the

release valve and open valve by

turning the handle anti-

clockwise, place handle back

into the jacking point and pump

for 30 to 40 seconds. When

complete, close the release

valve by turning the valve

clockwise. When lifting a load of

maximum capacity or close to it,

it is recommended that the effort

be reduced by the use of

assistance during this operation.

b. Prior to each use, visual

inspection shall be made to the

jack by checking for abnormal

conditions, such as cracked

welds, leaks, and damaged,

loose, or missing parts.

c. Consult the vehicle owner’s

manual to determine the location

of the jack points.

d. Be sure to set the vehicle in park

with the emergency brake on

and wheels secured and

checked.

e. Be sure that the vehicle and the

jack are on a hard, level surface.

To Lift

1. Turn the release valve clockwise

to the closed position. Do not

over tighten.

2. Position the jack under the

specified lift point.

3. Begin lifting by pumping the

handle up and down.

4. Immediately after lifting, support

the vehicle with appropriate

rated jack stands.

5. Turn the release valve slowly

counter clockwise to lower the

vehicle onto the jack stands.

To Lower

1. Turn the release valve clockwise

to the closed position. Do not

over tighten.

2. Pump the handle up and down

to lift the vehicle off the jack

stands.

3. Remove the jack stands. Do not

get under or let anyone under

the vehicle while lowering.

4. Turn the release valve slowly

counter clockwise to lower the

vehicle onto the ground.

TJ250

06

MAINTENANCE

NOTICE: Useonly agood grade of hydraulic

oil.Neverusebrake fluid,motoroil,

transmission fluid,turbine oil oranyother

fluids.

ISO-VG22 equivalent hydraulicoil is

recommended.

IMPORTANT: NO RESPONSIBILITY IS

ACCEPTEDFOR INCORRECT USEOFTHIS

PRODUCT.

Check and Refill Oil

1. Removehydraulicunit cover, ifcoveris

provided.

2. With jackinthefullyloweredandlevel

position,removetheoilfillerplug.

3. Recommendedoil levelshouldbejust

coveringinnercylinderasseenfromtheoil

fillerplughole.

4. Donotoverfill.Alwaysfillwith new,clean

hydraulicjackoil as recommendedabove.

5. Replaceoilfillerplug.Then replacetheunit

cover.

Lubricationandcleaning

Periodically clean and lubricate all moving

partsand pivotpoints.

AirVentingProcedures

1. With the jackin the fully lowered

position and releasevalve open,

remove the oil fillerplug.

2. Inserthandle intothehandle sleeve

and pump rapidly several times.

Replaceoil fillerplug.

3. Turn the releasevalve clockwisetothe

closeposition.

4. Pump the handle until the liftarm

reachesthe maximum heightand

continue topumpseveral timesto

remove the trapped air in the system.

5. Turn the releasevalve counter

clockwiseone full turn andlowerthe

liftarm tothe lowestposition,using

forceon saddle the if necessary.

6. Carefully and slowly pinch the oil filler

plug toreleasepressurised air.

7. Repeat above stepsuntil trapped air is

completely vented.

T250

07

Problem Possible Cause Remedy

Jack will

not lift the load. 1) Overloaded.

2) Oil level low.

3) Release valve not

correctly closed.

4) Air in system.

5) Piston rod not

functioning.

6) Packing worn or

defective.

1) Be sure to use jack the with

adequate capacity.

2) Top up oil level.

3) Check and close release

valve.

4) Open release valve and

pump the handle a few times.

Close valve and re-try.

5) Clean and replace oil.

6) Replace packing.

Jack doe

s not lift high

enough or feels “Spongy”.

1) Oil level too high or

too low.

2) Worn seals.

3) Air in system.

4) Release valve not

closed.

1) Fill or remove excess oil.

2) Return jack to local service

agent.

3) Open release valve and

pump the handle a few times.

Close valve and re-try.

4) Check and close release

valve.

Jack lifts

poorly 1) Pump packing or

valves malfunctioning.

2) Oil is dirty.

3) Air in the system.

1) Replace packing and/or

clean valves.

2) Replace oil.

3) Open release valve and

pump the handle a few times.

TROUBLESHOOTING

TJ250

08

Problem Possible Cause Remedy

Jack lifts but will not hol

d load. 1) Release valve partially

open.

2) Dirt on valve seats.

3) Air in system.

4) Faulty seals.

5) Packing worn or

defective.

1) Check and close release

valve.

2) Lower jack, close release

valve. Place foot on front wheel

and pull up lifting arm to its full

height by hand. Open the

release valve to lower arm.

3) Open release valve and pump

the handle a few times. Close

valve and re-try.

4) Replace packing or contact

local service agent.

5) Replace packing.

Jack will not lower completely. 1) Unit requires lubrication

2) Piston rod bent or damaged

3) Jack frame/link system

distorted due to

overloading/poor positioning

4) Air in system

5) Release valve partially closed

6) Jack spring damaged or

unhooked.

1) Oil all external moving parts.

2) Replace rod or contact local

service agent.

3) Replace damaged parts or

contact local service agent.

4) Open release valve and pump

the handle a few times. Close

valve and re-try.

5) Check and fully open release

valve.

6) Replace spring or contact

local service agent.

Jack does not lower at all. 1) Release valve closed.1) Check and fully open

release valve.

TROUBLESHOOTING

TJ250

09

EP82

-

3

09

TJ250

10

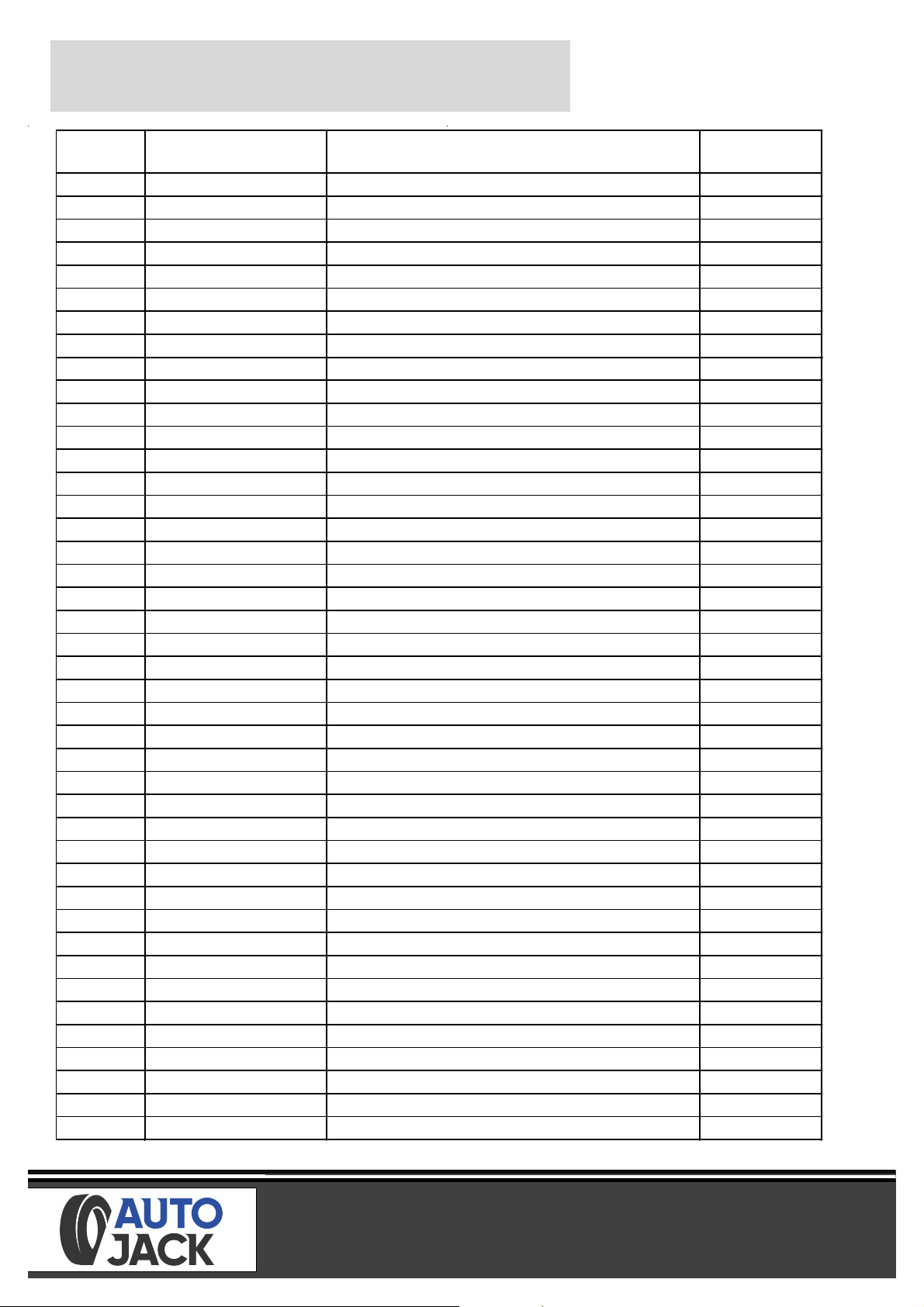

PARTS LIST

REF# PART# DESCRIPTION QTY

1 TZ830026-GS.3 Power unit assembly 1

2 T830023.4.1(asm) Universal joint assembly 1

3 GB308-6 Steel ball bearing Ø6mm 1

4 TF1201C-29 Oil plug 1

5 Return spring 2

6 Cotter pin Ø4X45mm 1

7 Coupling connector 1

8 GB894.1-25 C-clip Ø25mm 4

9 Supporting shaft 1

10 Lifting arm assembly 1

11 T830003L-16 Pin for saddle 1

12 T825011L-3 Saddle 1

13 GB894.1-16 C-clip Ø16mm 2

14 Connecting rod pintle 2

15 Frame assembly 1

16 T830018-1 Front wheel 2

17 GB894.1-18 C-clip Ø18mm 2

18 Washer M16 2

19 GB859-16 Spring washer M16 4

20 GB6170-M16 Nut M16 4

21 T83508.6(ASM) Rear caster assembly 2

22 Spring washer M12 4

23 Socket head cap screw M12X25mm 2

24 Back shaft 1

25 Nut M12 2

26 Handle Socket 1

27 QLZ2C-1a Handle socket screw M10X19mm 1

28 GB894.1-12

C-clip Ø12

mm

1

29 T825011CL.2-3 Contact roller 1

30 T825011CL.2-2 Pin for contact roller 1

31 Washer M18 2

32 Spring washer M18 2

33 Shoulder bolt M18x54mm 2

34 T825011BCL-2 Cover plate 1

35 GB845 Socket head cap screw 4

36 Position shaft 1

37 T84004-7 Rubber sleeve 2

38 GB859-8 Spring washer M8 2

39 GB823- M8X16

Pan head combination drive machine screw M8X16mm 2

40 T830018Z.2a Handle assembly 1

41 T83508.5-4 Handle lock pin 1

42 T830026.MF Seal kit 1

EP82

-

3

09

TJ250

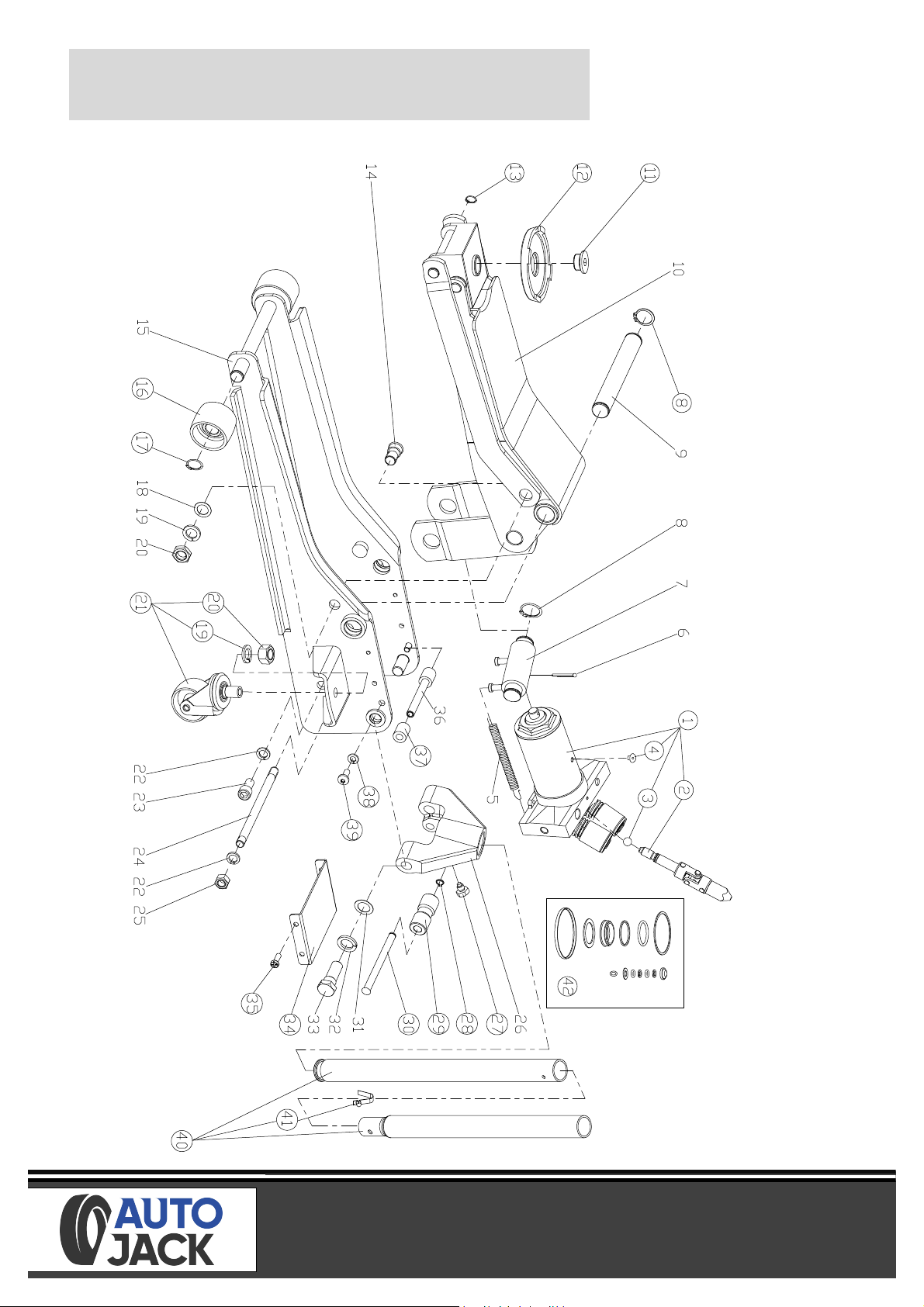

11

PARTS DIAGRAM

Table of contents

Other Autojack Jack manuals

Popular Jack manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED KH 3046 operating instructions

Clarke

Clarke STRONG-ARM VPJ300 Installation and maintenance instructions

Cornwell Tools

Cornwell Tools CTJTRJ22T operating manual

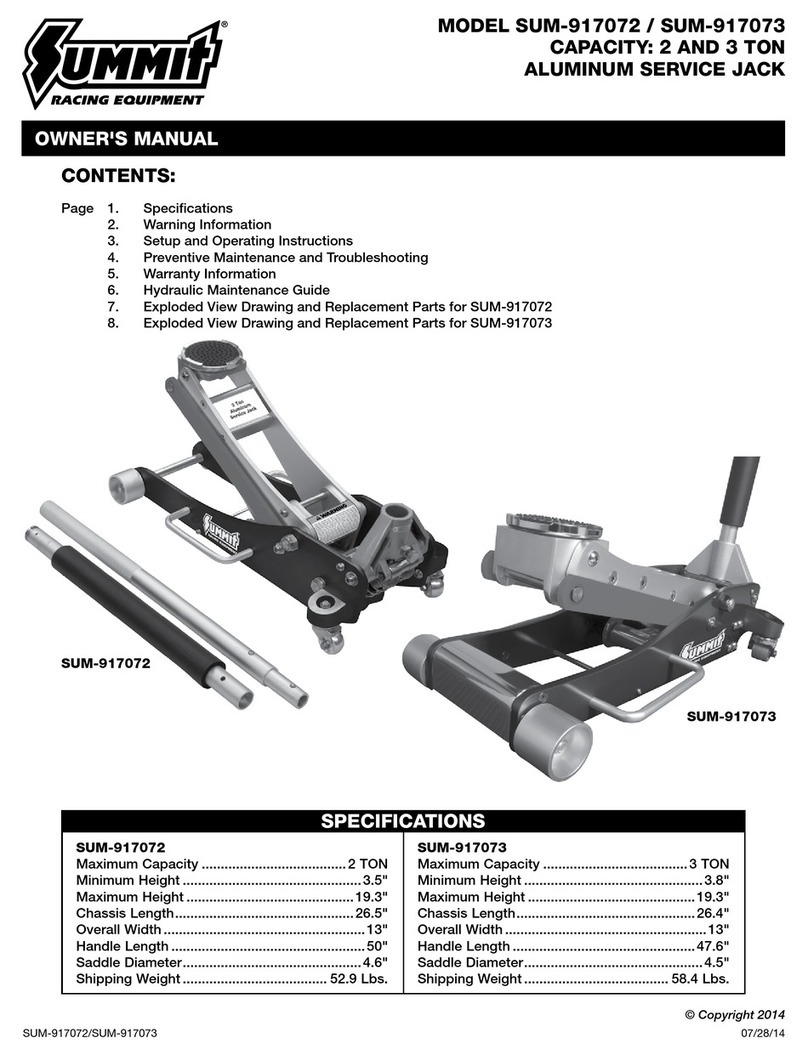

Summit

Summit SUM-917072 owner's manual

MARTINS Industries

MARTINS Industries MFJ-PL2T manual

Evercraft

Evercraft 776-2007 manual

Torin

Torin T92007AT Operator's instruction manual

Sealey

Sealey 1025HL.V2 instructions

Hi-Force

Hi-Force JCS Series Operating instructions manual

Challenger Lifts

Challenger Lifts RJ4.5 Installation, operation & maintenance manual

Weaver

Weaver WA-72B OPERATION & SERVICE INSTRUCTIONS

Michelin

Michelin Ratchet Locking Jack Stands user guide